Engine cooling water pipe and preparing process thereof

A technology of engine cooling and preparation process, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve the problem of alloy steel tensile strength, yield strength, corrosion resistance, product performance such as strength and hardness Insufficient, numerous procedures and other problems, to achieve the effect of mature preparation method, easy microstructure, and reduce processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

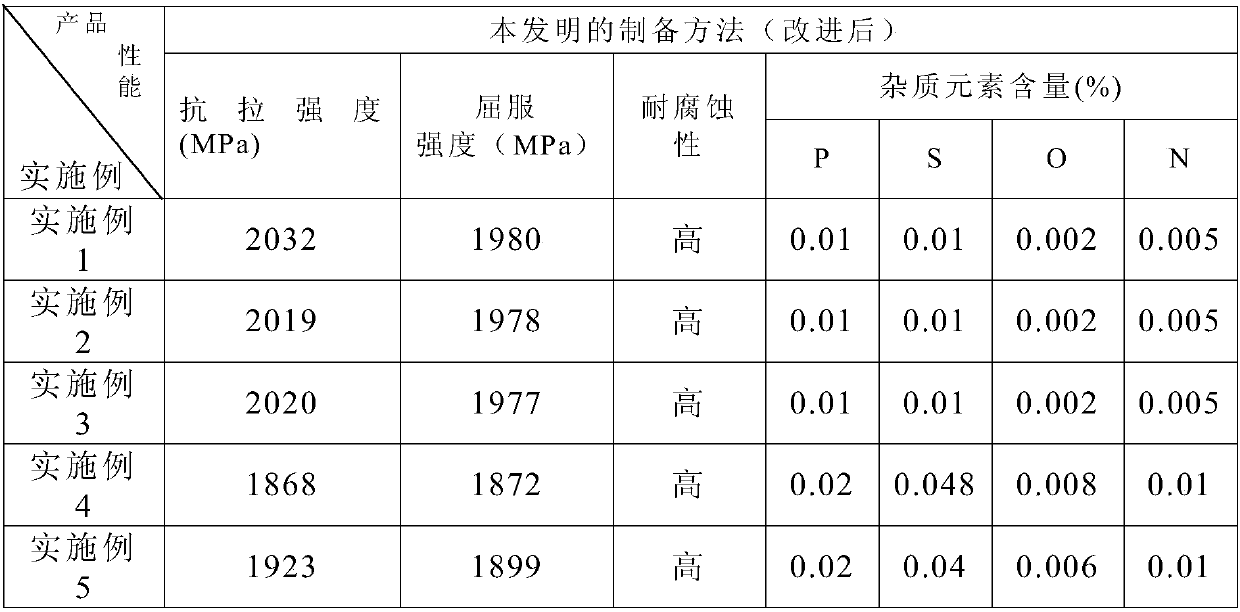

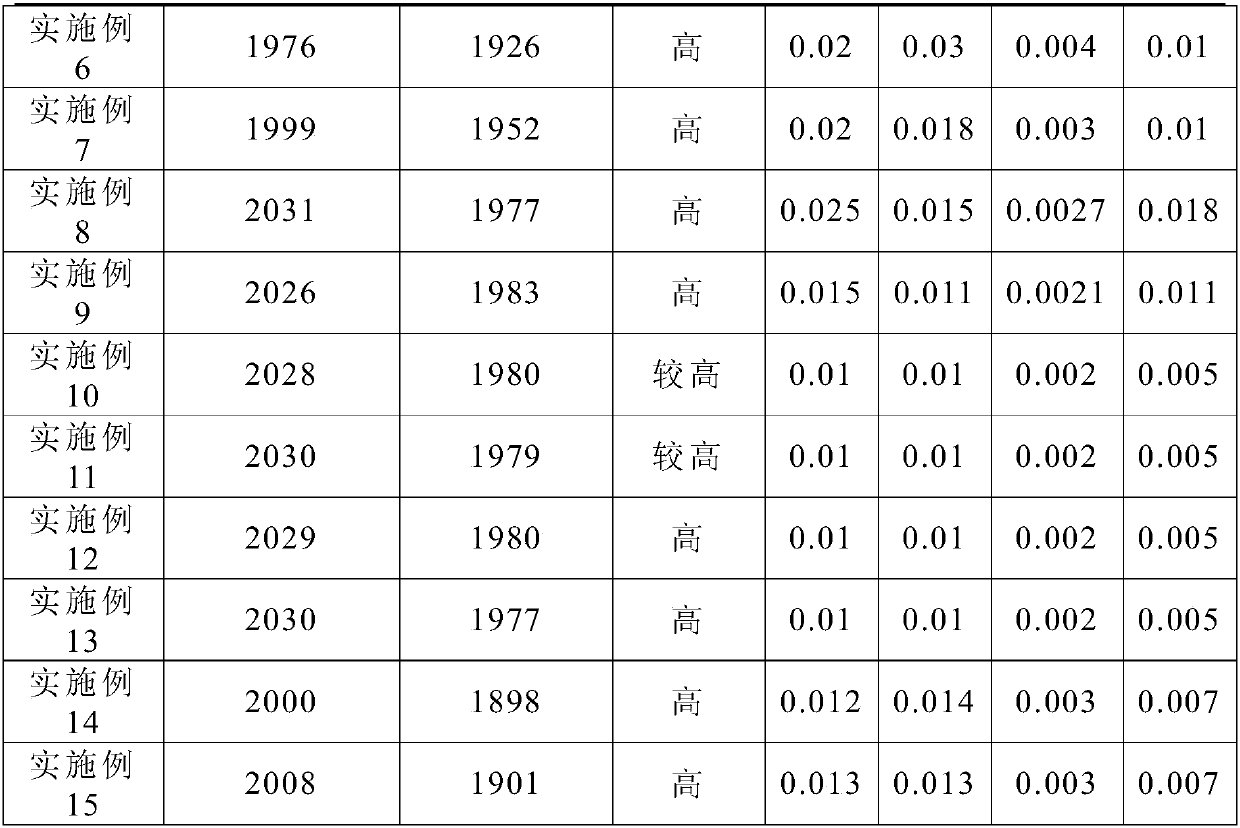

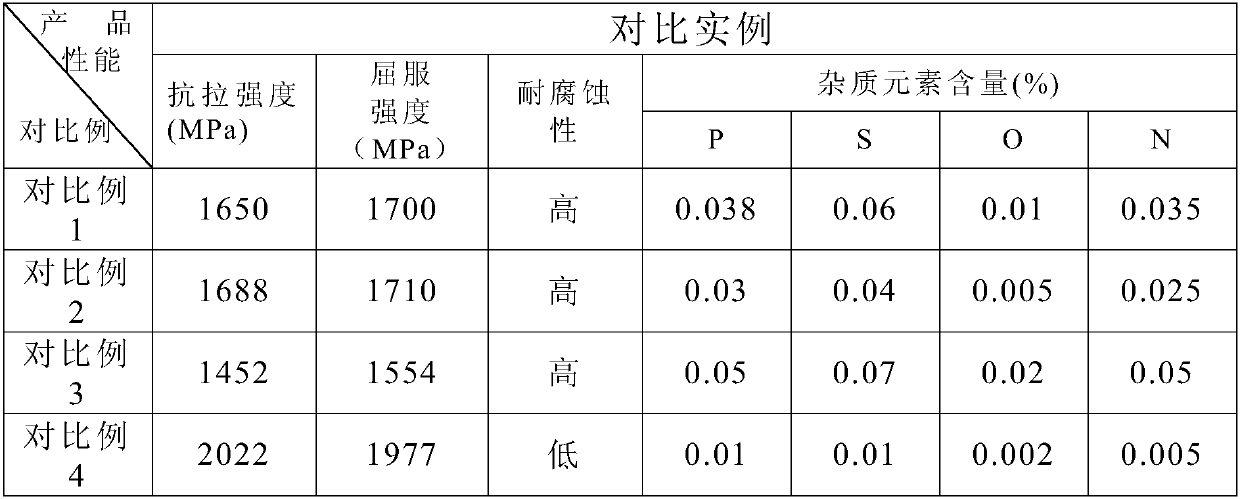

Examples

Embodiment 1

[0034] Milling: Weigh the raw materials according to the engine cooling water pipe composition and mass percentage in claim 1 or 2, containing Be: 2%, Zr: 0.6%, C: 0.05%, Si: 0.5%, Cr: 0.7%, Ni: 4%, the balance is Fe and impurities, and Ni is weighed in proportion to NiCl 2 ·6H 2 O. will remove NiCl 2 ·6H 2 Various raw materials other than O were processed into powders with a particle size of 3 μm by jet milling.

[0035] Coating powder: NiCl·6H 2 O and H 3 BO 3 Mix according to 10:1, add distilled water until completely dissolved, then slowly add iron powder into the solution and stir, while adding hydrochloric acid to induce displacement reaction, nickel will form a coating layer on the surface of iron powder. The pH of the solution was controlled to be 4, and the temperature was maintained at 75°C. After the reaction coating was completed, the solution was poured out and filtered, and the obtained powder was dried and reduced at 450° C. for 15 minutes under a hydrog...

Embodiment 2-3

[0040] The only difference from Example 1 is that the particle diameters of the raw materials in Examples 2-3 are 4 μm and 5 μm, respectively.

Embodiment 4-7

[0042] The only difference from Example 1 is that the contents of Be in the raw materials of Examples 4-7 are 0.2%, 0.5%, 1%, and 1.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com