Oil quenching heat treating process for low chrome multielement alloy cast balls

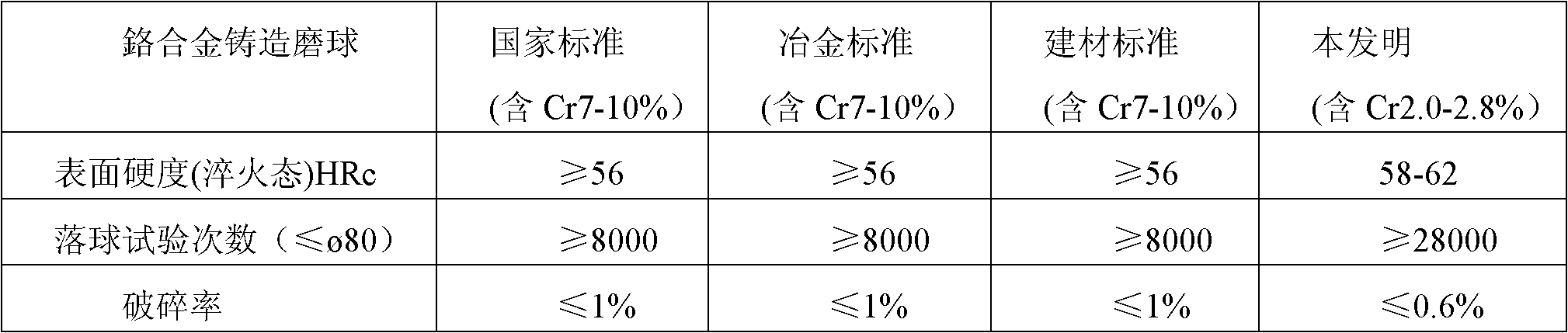

A multi-element alloy and casting ball technology, which is applied in heat treatment furnaces, heat treatment equipment, quenching agents, etc., can solve the problem of unsatisfactory comprehensive mechanical properties such as hardness, toughness, and wear resistance, as-cast structure cannot be changed, and product performance is unstable And other problems, to achieve good thermal oxidation stability, low broken ball rate, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A low-chromium multi-element alloy cast ball oil quenching heat treatment process, characterized in that: the weight percentage of the components contained in the low-chromium multi-element alloy cast ball is: C: 1.5-2.0, Mn: 0.3-1.0, Cr: 2.0- 2.8, S: ≤0.02, P: ≤0.03, the matrix is iron; the low-chromium multi-element alloy cast ball adopts oil quenching heat treatment process, and its specific process steps include:

[0029] a. Put the as-cast low-chromium multi-element alloy casting ball just taken out of the mold into the special quenching frame quantitatively, and then put it in the quenching furnace for heating. After heating to 950-1000°C, keep it warm for 2-3 hours;

[0030] b. Pour the low-chromium multi-element alloy casting balls after heating and heat preservation into the quenching shaker, and then sink into the quenching oil with the quenching shaker, and make the cast balls and casting segments roll freely with the up and down movement and shaking of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com