Waste heat hardening and tempering process of motorcycle crank forged piece

A technology for forging waste heat and motorcycles, which is applied in the direction of manufacturing tools, heat treatment equipment, and other manufacturing equipment/tools. It can solve the problems of difficult control of workpiece quenching cracking, coarse grains, and unstable product quality. Quenching cracking phenomenon, uniform temperature, excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

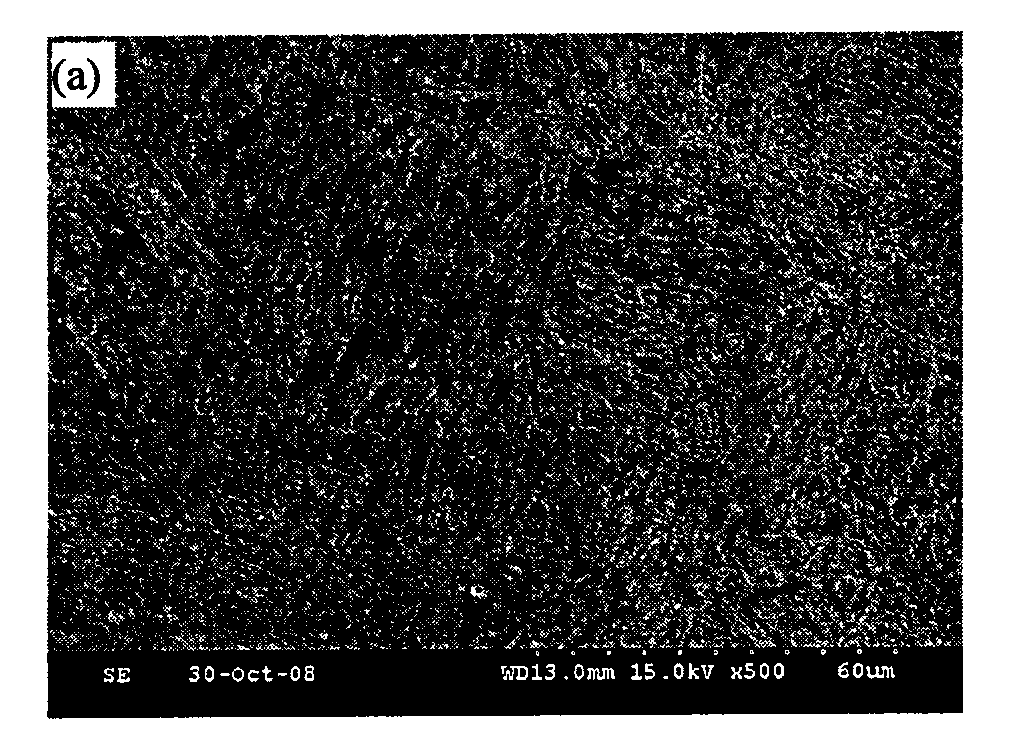

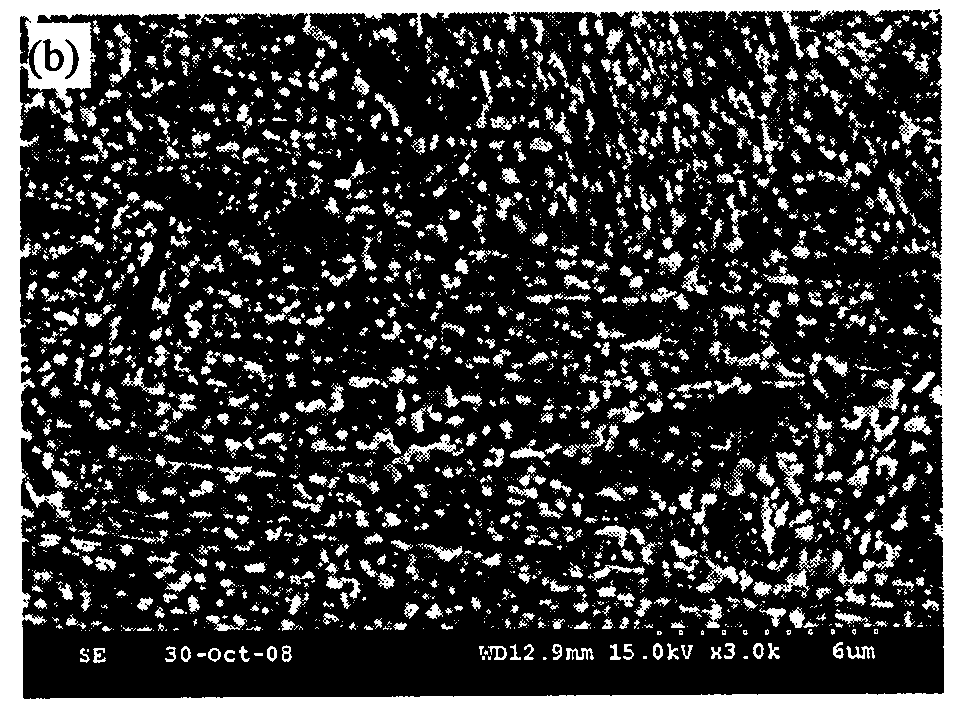

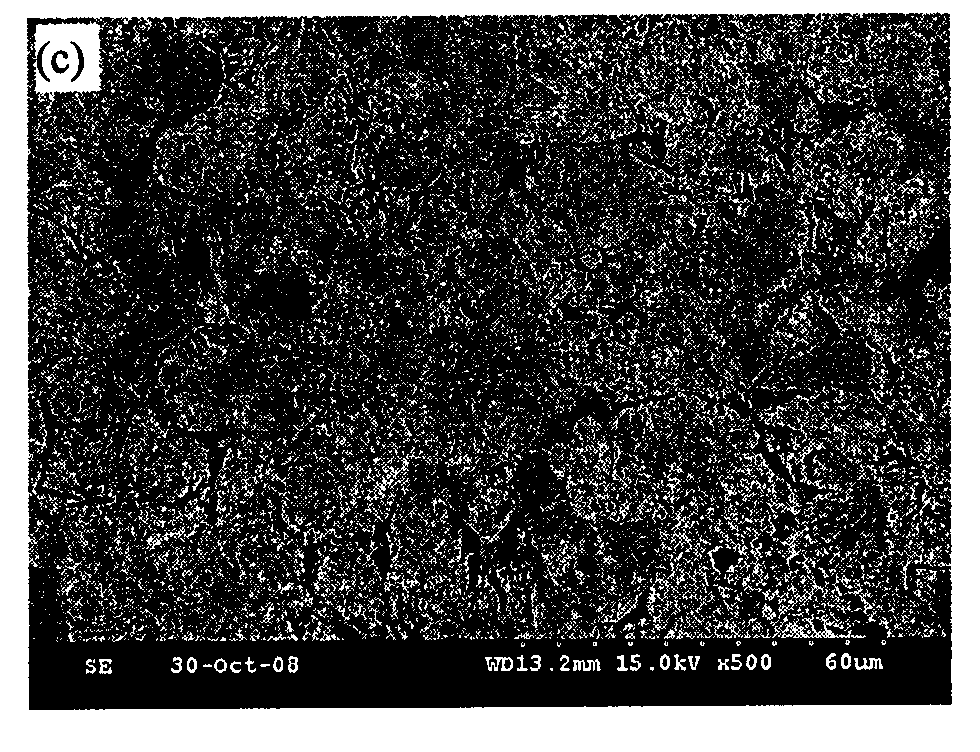

Image

Examples

Embodiment 1

[0030] Embodiment 1, the waste heat quenching and tempering process of motorcycle C100 type crank forging comprises the following steps:

[0031] a. Put the 45# round steel bars into a 250KW intermediate frequency furnace, heat the intermediate frequency to 1050°C, and use an infrared thermometer to control the temperature;

[0032] b. At 950°C, a 150T air hammer is used to draw out the heated bar to produce a crank blank;

[0033] c. Carry out rough die forging on the crank blank through a 630T friction press, and control the temperature at 920°C to form the handle and rod of the crank;

[0034] d. Precise die forging is carried out with a 300T friction press at 880°C to remove the oxide layer on the surface of the crank, so that the specific size of the crank matches the design size;

[0035] e. Put the crank into the mesh belt constant temperature furnace, and treat it at a constant temperature of 850°C for 220 seconds, so that the temperature on the surface of the crank i...

Embodiment 2

[0038] Embodiment 2, the waste heat quenching and tempering process of motorcycle C125 type crank forging comprises the following steps:

[0039] a. Put the 40Cr round steel bar into a 250KW intermediate frequency furnace, heat it to 1150°C with intermediate frequency, and use an infrared thermometer to control the temperature;

[0040] b. At 1000°C, a 150T air hammer is used to draw out the heated bar to produce a crank blank;

[0041] c. Carry out rough die forging on the crank blank through a 630T friction press, and control the temperature at 935°C to form the handle and rod of the crank;

[0042] d. Precise die forging is carried out with a 300T friction press at 900°C to remove the oxide layer on the surface of the crank, so that the specific size of the crank matches the design size;

[0043] e. Put the crank into the constant temperature mesh belt furnace, and treat it at a constant temperature of 855°C for 240 seconds, so that the temperature of the crank surface is ...

Embodiment 3

[0046] Embodiment 3, the waste heat quenching and tempering process of motorcycle C250 type crank forging comprises the following steps:

[0047] a. Put the 40Cr round steel bar into a 250KW intermediate frequency furnace, heat it to 1200°C with intermediate frequency, and use an infrared thermometer to control the temperature;

[0048] b. At 1100°C, a 150T air hammer is used to draw out the heated bar to produce a crank blank;

[0049] c. Carry out rough die forging on the crank blank through a 630T friction press, and control the temperature at 950°C to form the handle and rod of the crank;

[0050] d. Precise die forging is carried out with a 300T friction press at 920°C to remove the oxide layer on the surface of the crank, so that the specific size of the crank matches the design size;

[0051] e. Put the crank into the constant temperature mesh belt furnace, and treat it at 860°C for 260 seconds, so that the temperature on the surface of the crank is basically the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com