Automatic shaft quenching device

A quenching device and automatic technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of low production efficiency, complex structure, large volume, etc., and achieve the effect of easy manufacture and realization, favorable for popularization and application, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

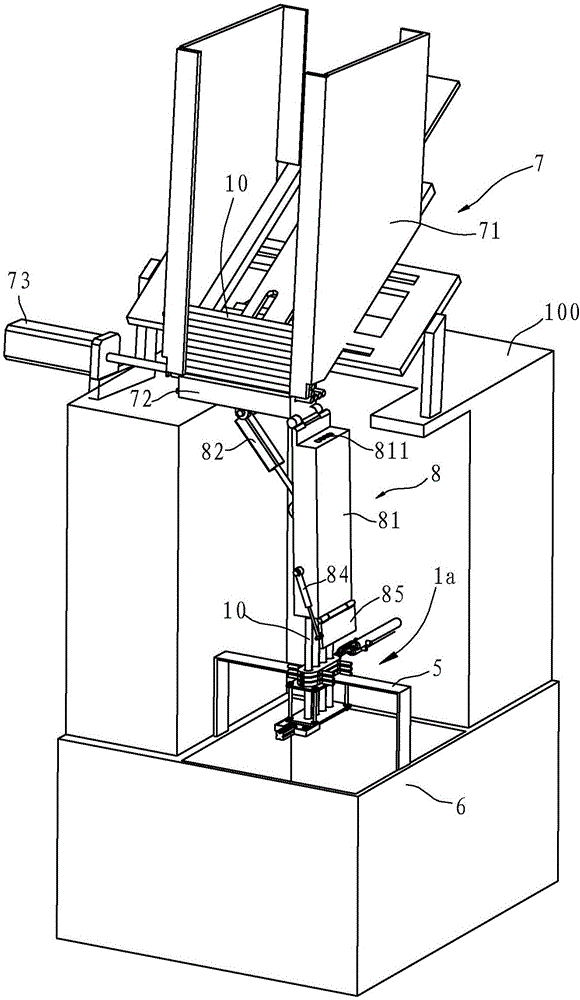

[0036] Example 1, such as figure 1 As shown, the shaft automatic quenching device in this embodiment includes a working table 100, a feeding mechanism 7, a collecting box 6, a support frame 5, a quenching mechanism 1a, and a high-frequency induction heating machine 2a (see Figure 9 ), steering assembly 8 and controller 101, feeding mechanism 7 is located on the work surface 100, and can output the workpiece horizontally and horizontally; the collection box 6 is located below the work surface 100 and has an upper port, and the support frame 5 is located on on the upper port of box 6.

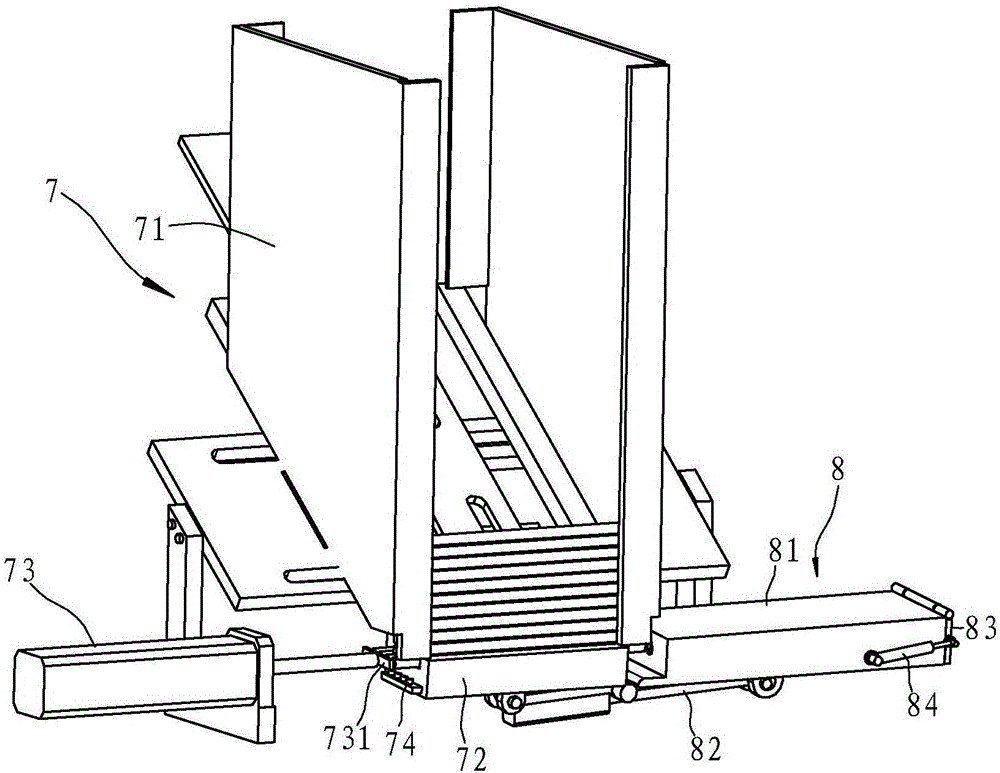

[0037] Such as figure 2 and Figure 4 As shown, the feeding mechanism 7 includes a feeding box 71, a feeding chute 72, a feeding cylinder 73 and a material limiting cylinder 75. The bottom surface of the feeding box 71 is an inclined surface inclined from top to bottom, and the feeding chute 72 is located on the feeding box 71. On the discharge port at the bottom, the feeding cylinder 73 is ...

Embodiment 2

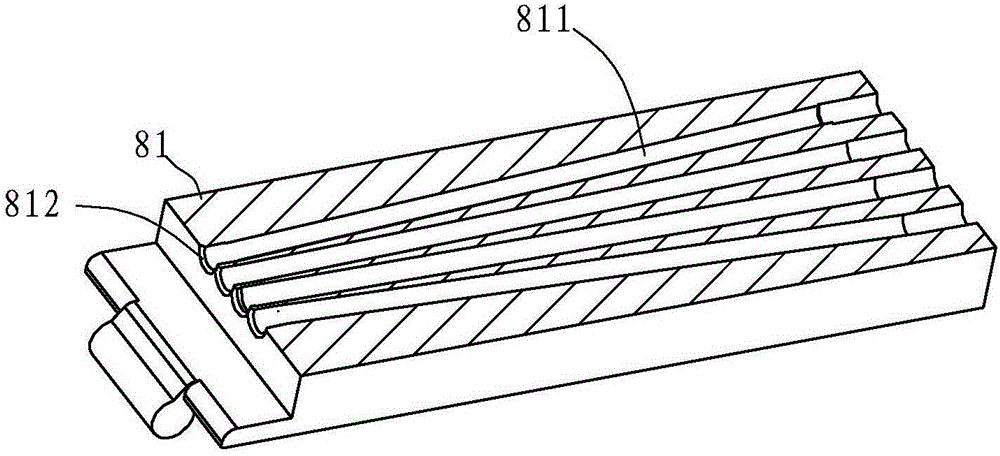

[0046] Example 2, such as Figure 10 and Figure 11 As shown, the bottom of the feeding trough 72 in this embodiment is provided with an insertion hole, and the work surface 100 is provided with a guide assembly 9, which includes a guide cylinder 91 and an insert plate 92, and the insert plate 92 is located on the guide cylinder 91. At the power output end, the front end of the insertion plate 92 has a plurality of guide teeth 93 that are arranged at intervals and can increase the gap between the workpieces. The guide cylinder 91 can drive the insertion plate 92 to move close to the feeding groove 72, so that the guide teeth 93 pass through the insertion hole 721 And protrude upwards from the bottom of feeding chute 72, as Figure 12 As shown, the channels in the steering block 81 are arranged in parallel. Before being sent into the steering block 81 , the gap between the workpieces is enlarged in advance through the function of the guide assembly 9 , so as to facilitate sub...

Embodiment 3

[0047] Example 3, such as Figure 13 As shown, the front end of the feed chute 72 in this embodiment is extended with a guide portion 72a, so that the length of the feed chute 72 is greater than the length of the workpiece 10, and the upper end surface of the guide portion 72a has a plurality of intervals and can be arranged between the workpieces 10. Guide block 72b with increased clearance. The passages 811 in the steering block 81 are arranged in parallel. Before being sent into the steering block 81, the gap between the workpieces is enlarged in advance through the action of the guide block 72b on the guide part 72a, so as to facilitate subsequent entry into the inductor 2 for quenching. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com