Air speed control device used in plastic cracking test of concrete

A cracking test, wind speed control technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of unstable wind speed, different wind speed, deviation of test results, etc., to improve the accuracy and repeatability, solve the problem of wind speed Effects of unstable and uneven problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

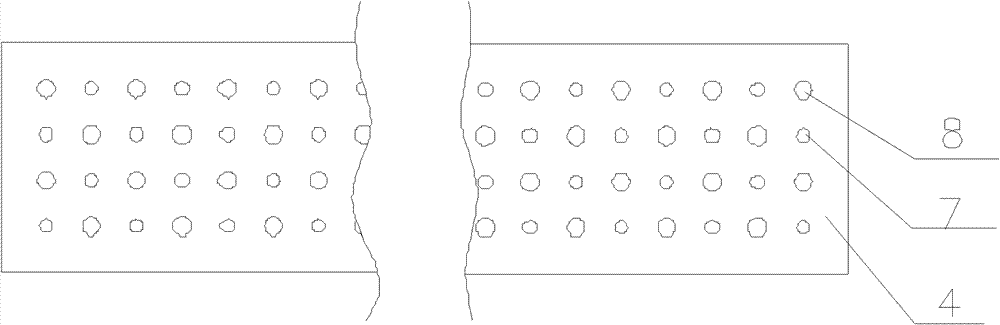

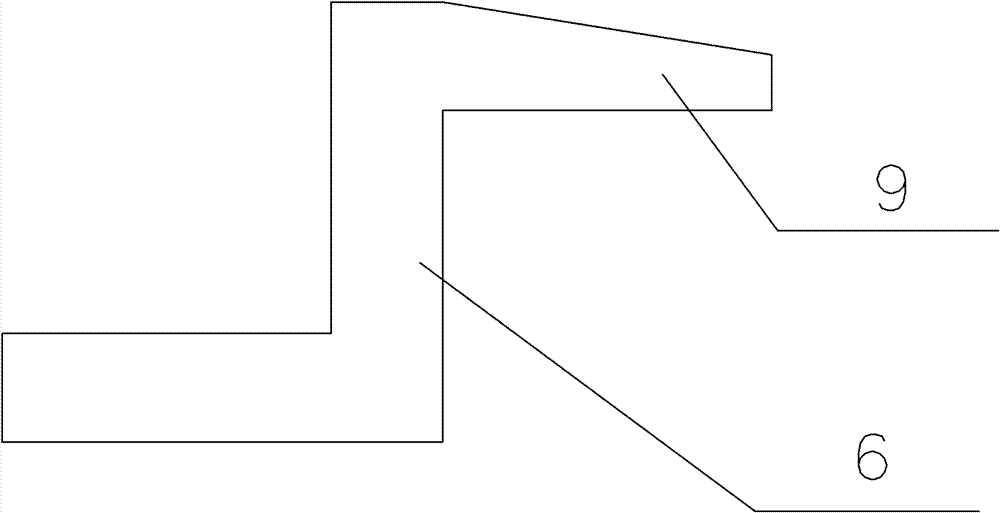

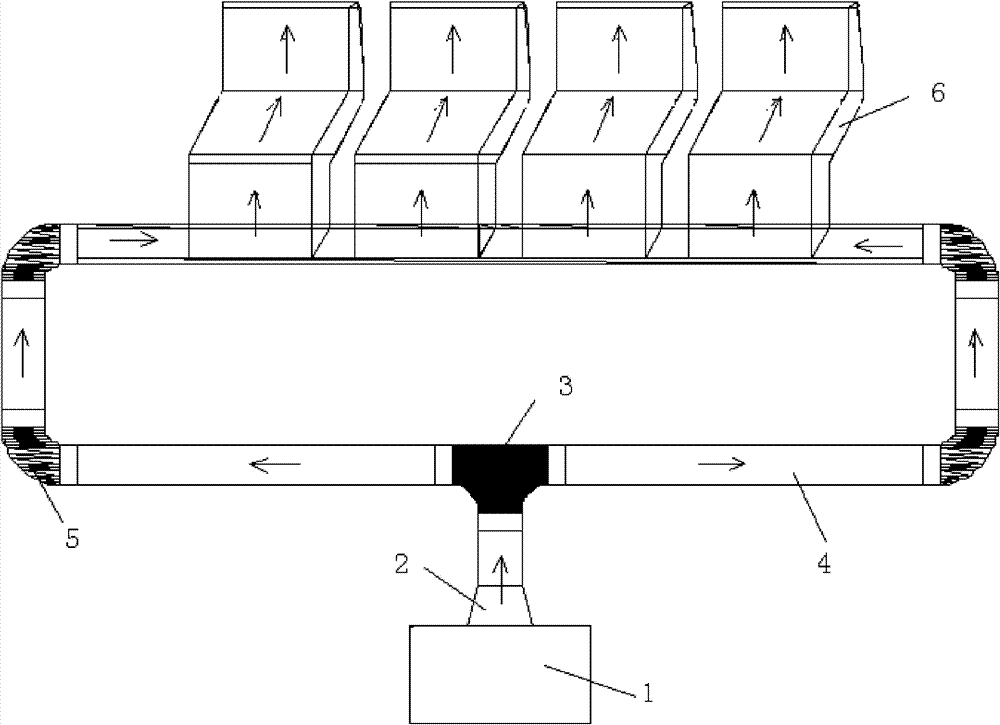

[0025] The wind speed control device of the present invention includes a wind source and a loop pipe connected with the wind source. The wind source is the centrifugal blower 1. The loop pipeline includes a pipeline, a tee 3 connected to the air source, and an elbow 5 connecting the pipeline into a circuit. The pipeline is a PVC pipe 4 with a nominal outer diameter of 100-150 mm. The sky round place connector 2 is connected. There is more than one loop pipeline air outlet on the loop pipeline, and there are several evenly arranged air outlet holes on the loop pipeline air outlet. There are 2 to 6 rows of air outlet holes, and each row has a diameter of 8 to 10mm. The number is There are 5-15 large air outlet holes 8 and 5-15 small air outlet holes 7 with a diameter of 4-6mm, and the large air outlet holes 8 and the small air outlet holes 7 are arranged at intervals. An air outlet pipe 6 is connected to the air outlet of the loop pipe. The shape of the air outlet pipe 6 is Z-...

Embodiment 2

[0032] The centrifugal blower 1 in Example 1 is changed, the model and main performance parameters of the centrifugal blower are shown in Table 3, and the rest of the configuration remains unchanged. At the same time, the wind speed tester is used to test the wind speed at the outlet 9 of the air duct. The wind speed test results of the wind speed control device are shown in Table 4.

[0033]

[0034] table 3

[0035]

[0036] Table 4

[0037] Through the comparison of the wind speed in the above two methods of Example 1 and Example 2, it is found that different types of blowers have a certain influence on the wind speed, and the influence of flow rate and total pressure is dominant, so in the actual application process, you can according to your own needs. , choose different types of blowers to get the required wind speed.

Embodiment 3

[0039] In Example 2, the angle between the upper surface of the air outlet 9 of the air outlet pipe and the horizontal plane is changed to 10.5°, and other configurations remain unchanged. At the same time, the wind speed tester is used to test the wind speed at the outlet 9 of the air duct. The wind speed test results of the wind speed control device are shown in Table 5.

[0040]

[0041] table 5

[0042] Through the comparison of the wind speed in the above two ways of embodiment 2 and embodiment 3, it is found that the change of the angle between the upper surface and the lower surface of the air outlet 9 can change the wind speed and obtain the required wind speed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com