Patents

Literature

78results about How to "Guarantee the quality of quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-size mandril structure property control method

ActiveCN101787420AImprove purityImprove impact toughnessFurnace typesHeat treatment furnacesThighThermal fatigue

The invention relates to a large-size steel mandril structure thinning control method for improving the performance of a base body, belonging to the field of steel material manufacturing technique control technology. The method mainly comprises structure thinning treatment for mandril billet in the production process of a mandril by a thigh channel as well as quenching treatment-thinned and hardened structure of finished products of the mandril, namely, all performances of the mandril can be improved by technical way of double thinning structure. The large-size steel mandril manufactured by the method has higher impact toughness, better heat stability and higher thermal fatigue resistance.

Owner:SHANGHAI UNIV

Heat treatment process of preparing bearing roller by using G20CrNi2MoA steel instead of G20Cr2Ni4A steel

InactiveCN101660165ACarburizing process is easy to controlShorten the high temperature tempering timeSolid state diffusion coatingFurnace typesQuenchingOperational performance

The invention relates to a heat treatment process of preparing bearing rollers by using G20CrNi2MoA steel instead of G20Cr2Ni4A steel, belonging to the technical field of bearing production. The method comprises the following steps: using 10-110mm of G20CrNi2MoA steel to prepare carburizing steel rollers, separately adopting quenching mediums--quenching oil, polyving alcohol water solution and alkaline solution to cool the steel rollers according to different diameter of steel rollers and performing high temperature tempering at 600 DEG C for 5h after carburization. The big size carburizing bearing rollers prepared by replacing G20Cr2Ni4A steel and G15CrNi4MoA steel with G20CrNi2MoA steel can not only meet the demands of the operational performance, but also increase the technological properties, shorten the processing cycle, lower the processing cost, save a large number of noble alloying elements--Cr and Ni, reduce the material cost and have higher economic benefit and popularizationand application value.

Owner:LUOYANG LYC BEARING

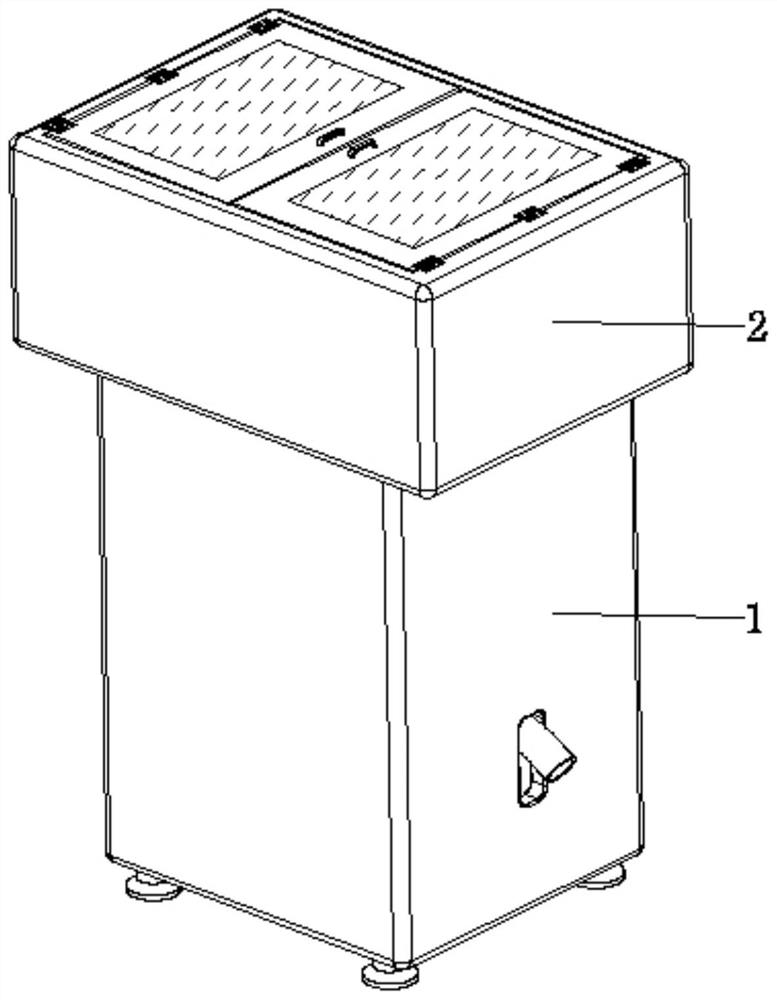

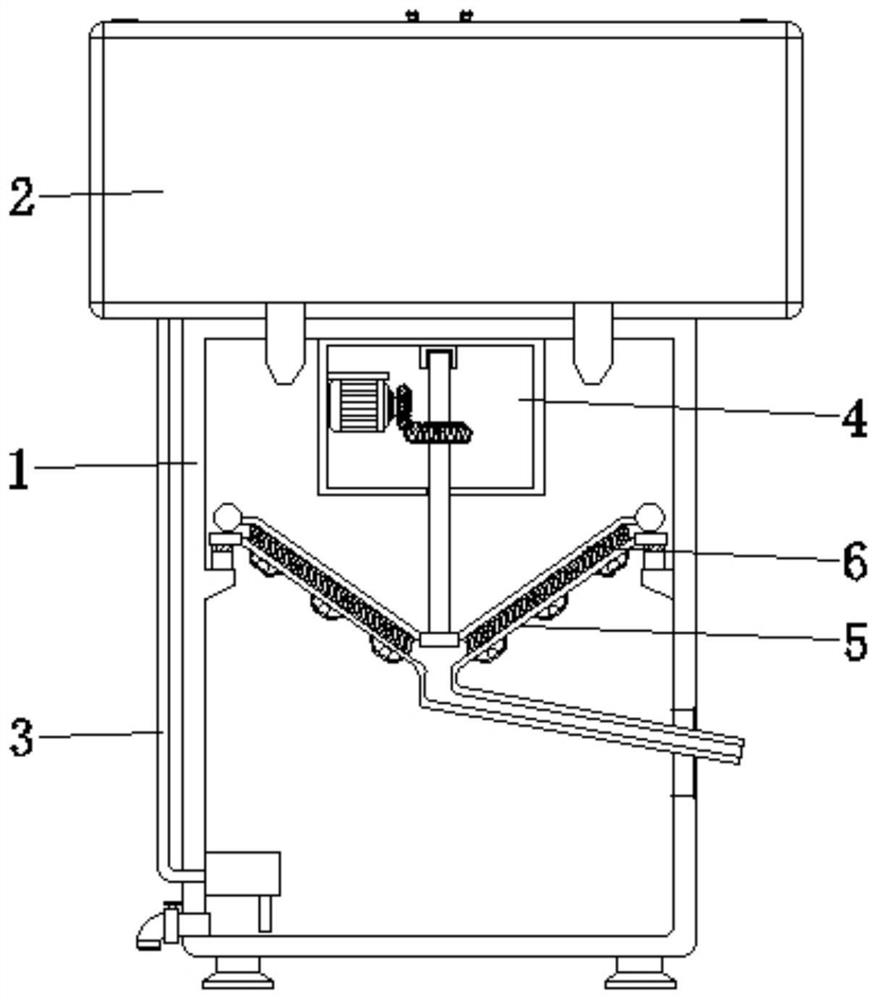

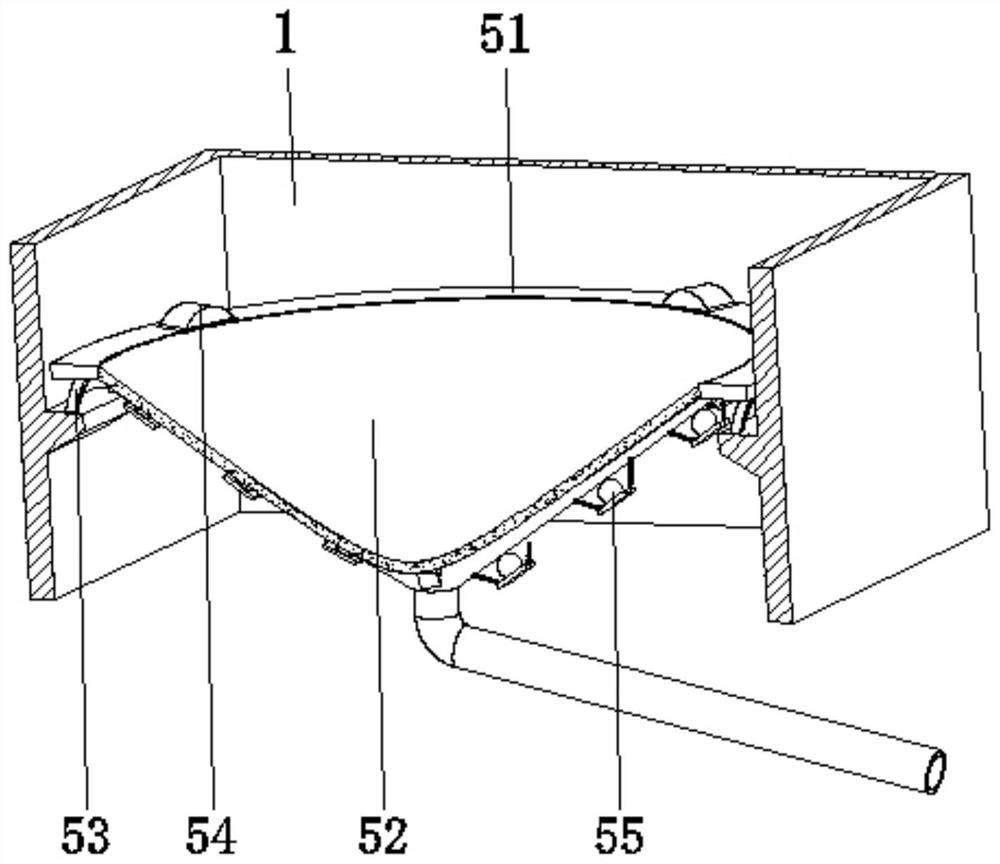

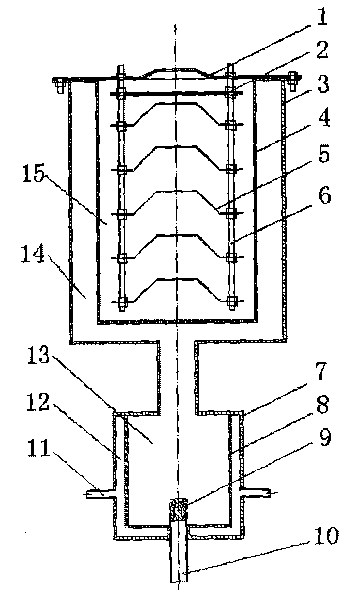

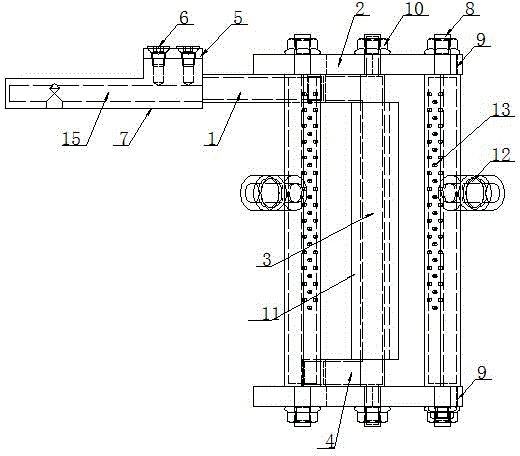

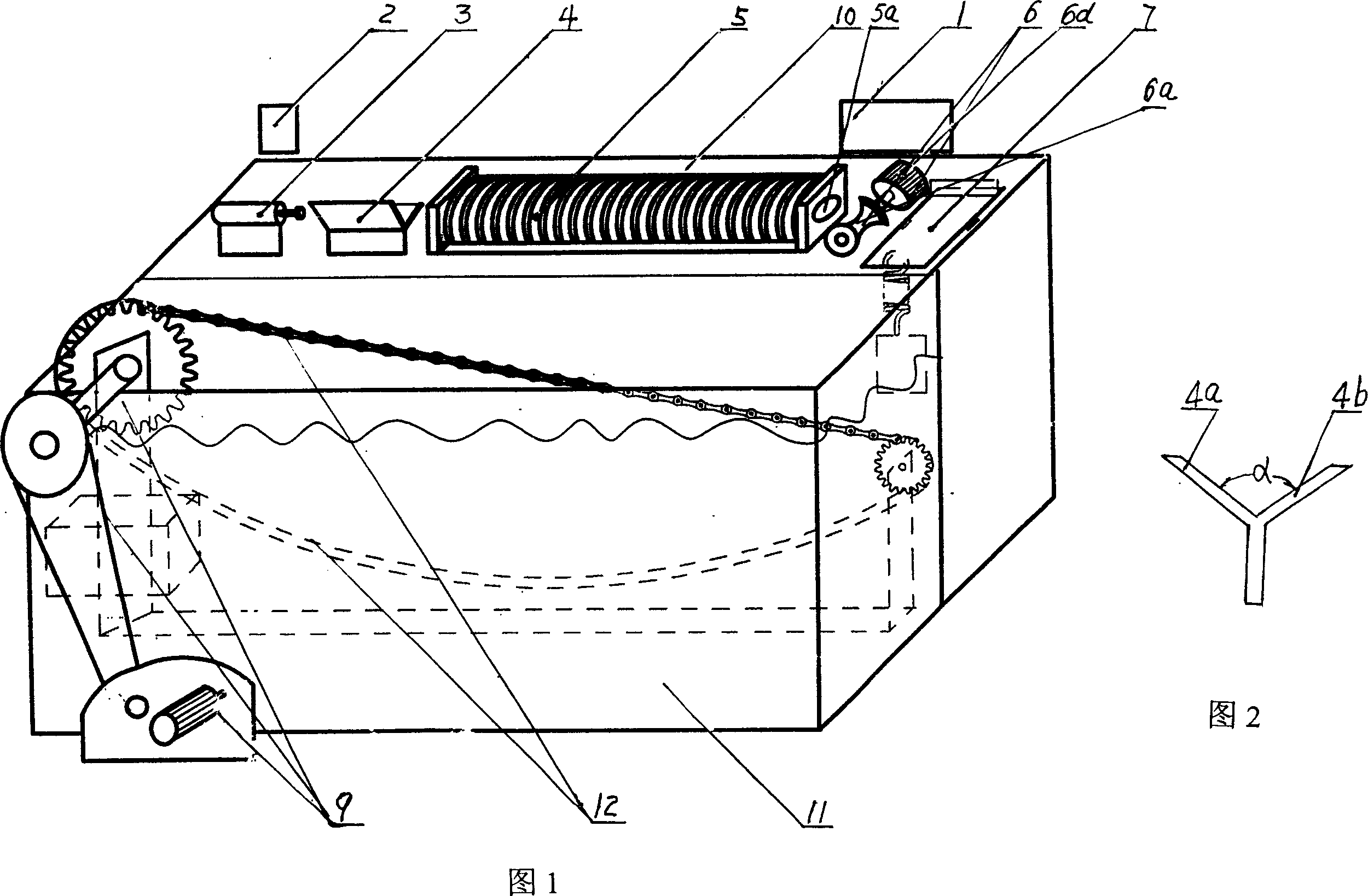

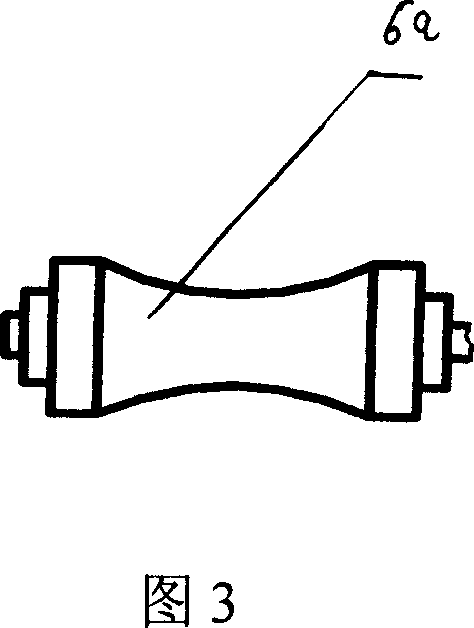

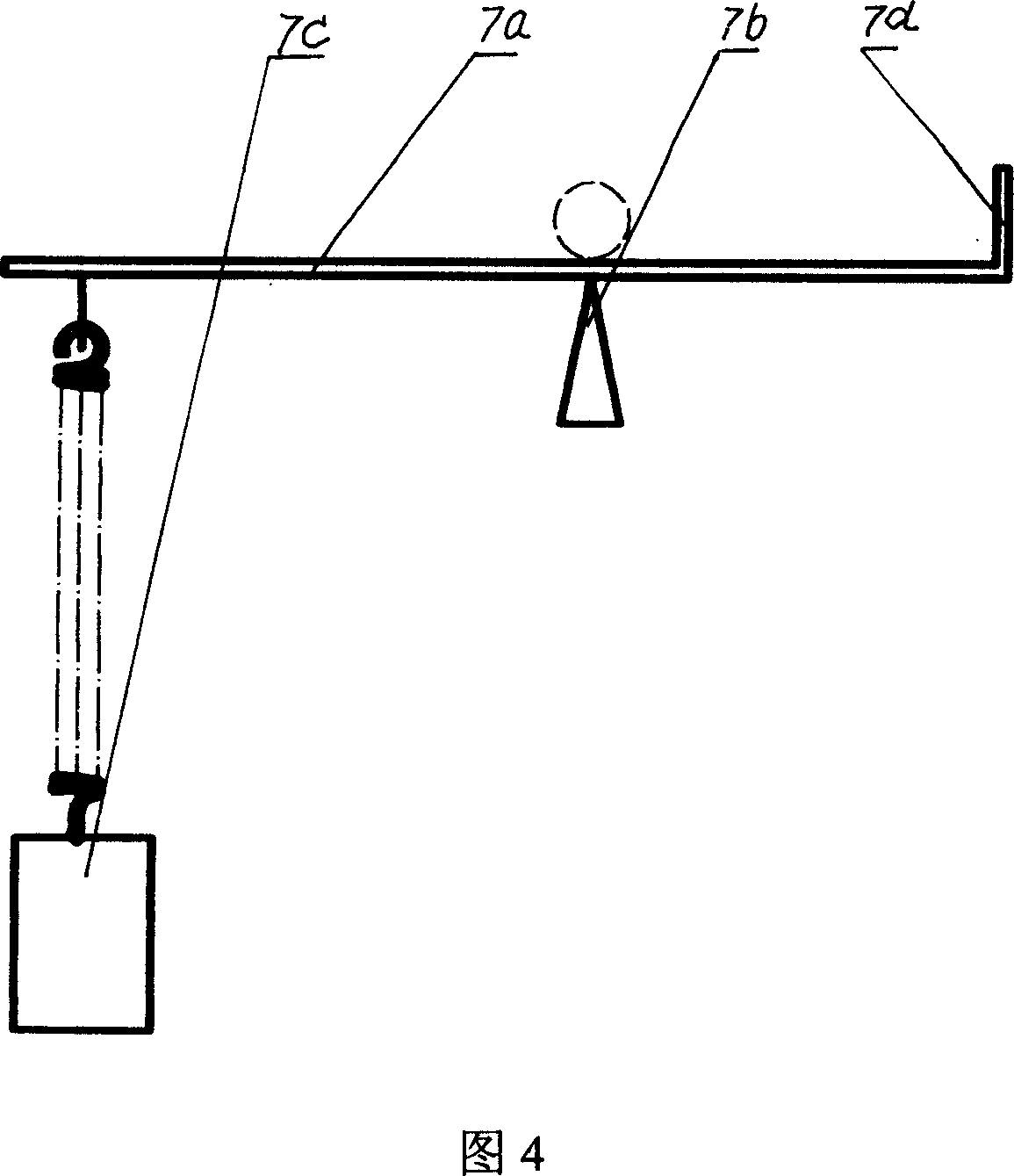

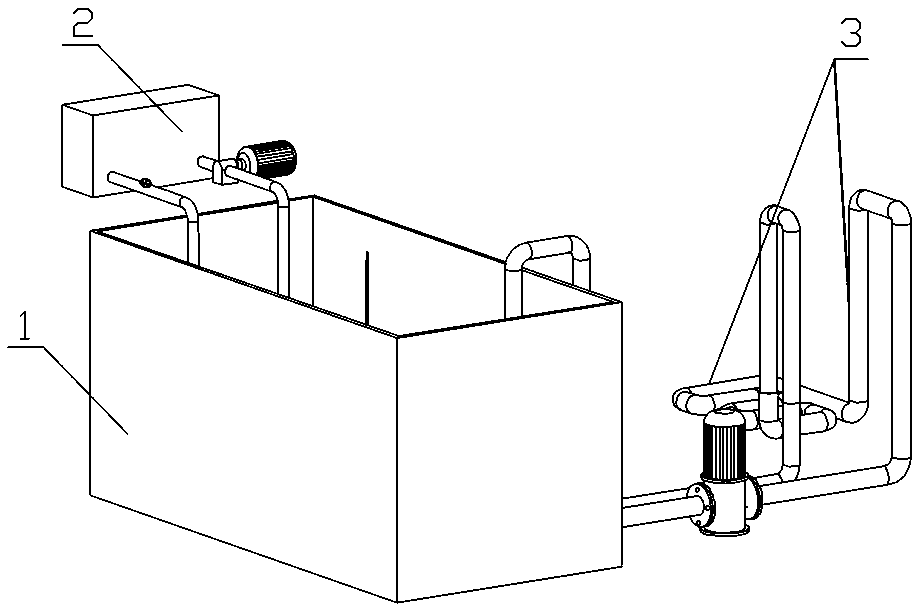

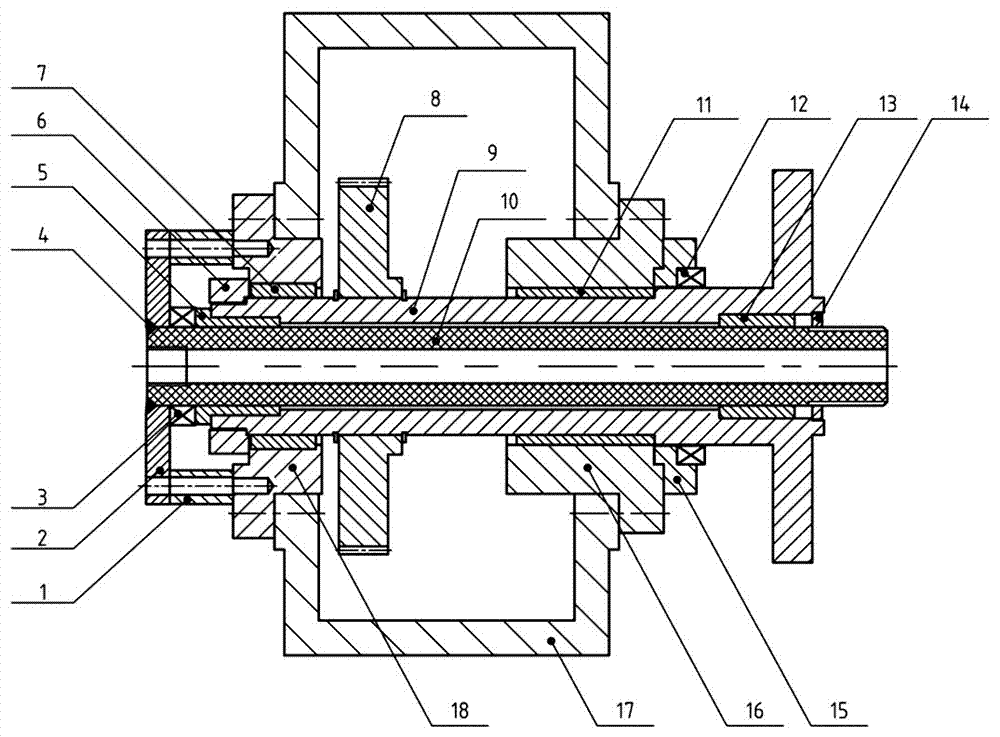

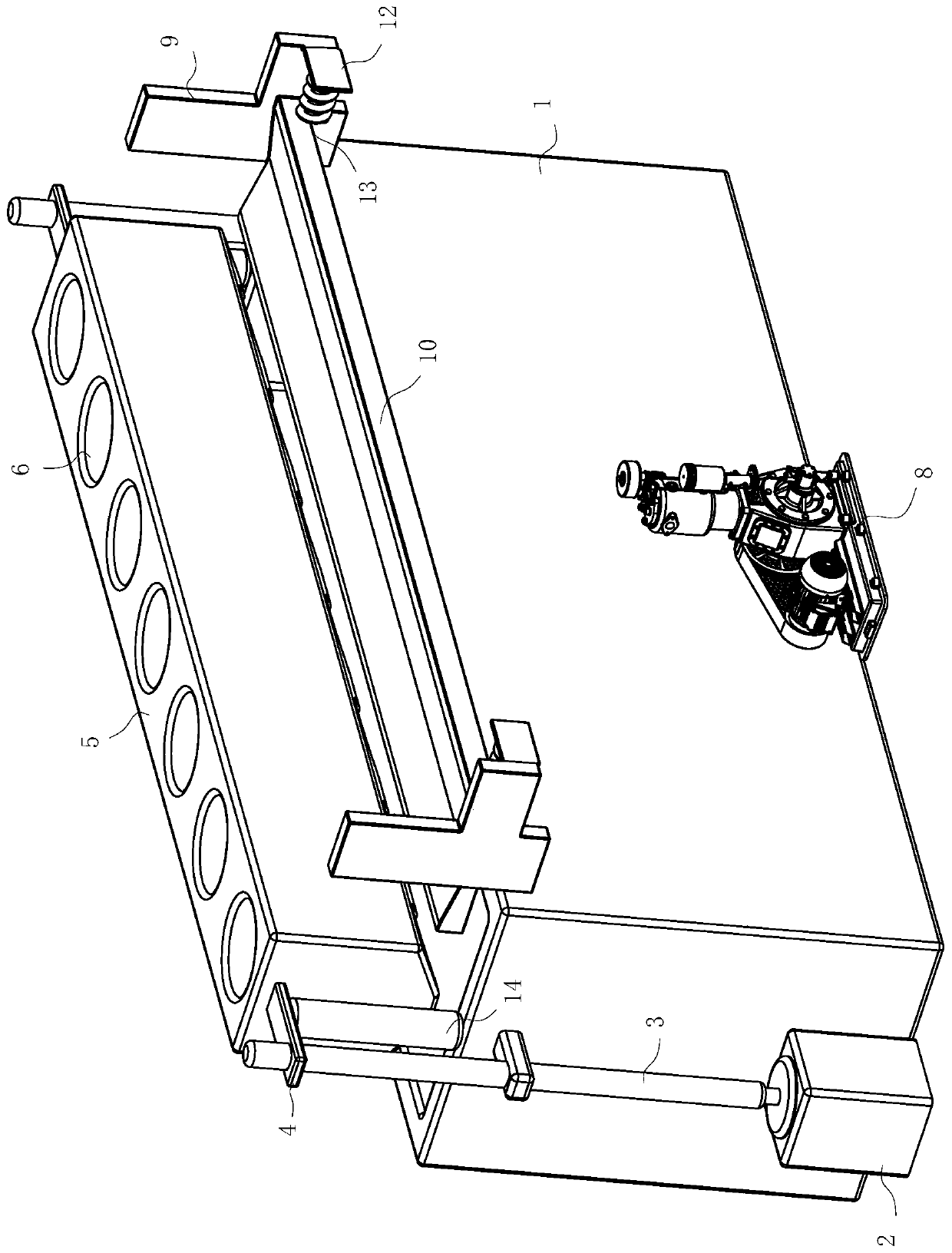

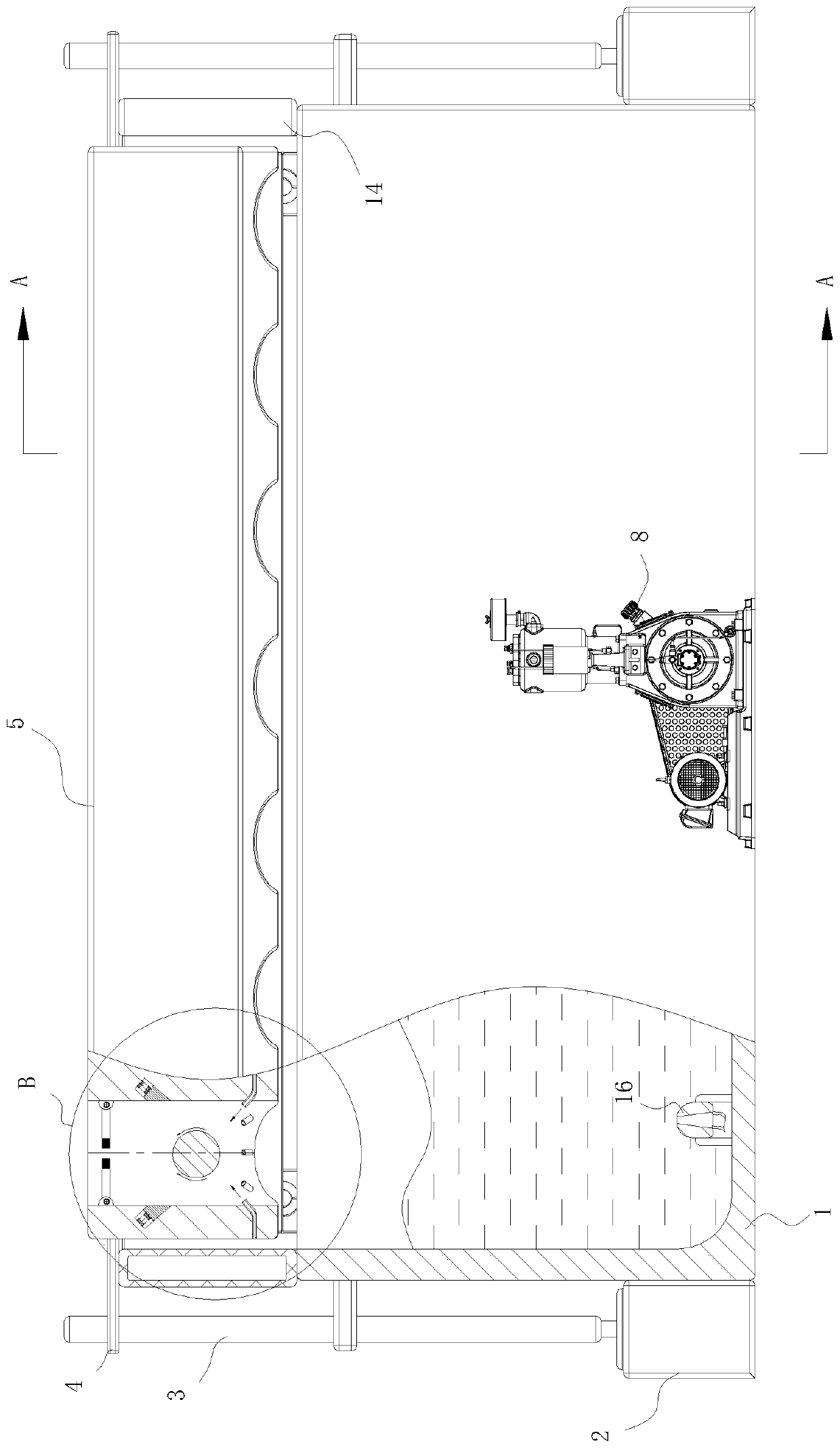

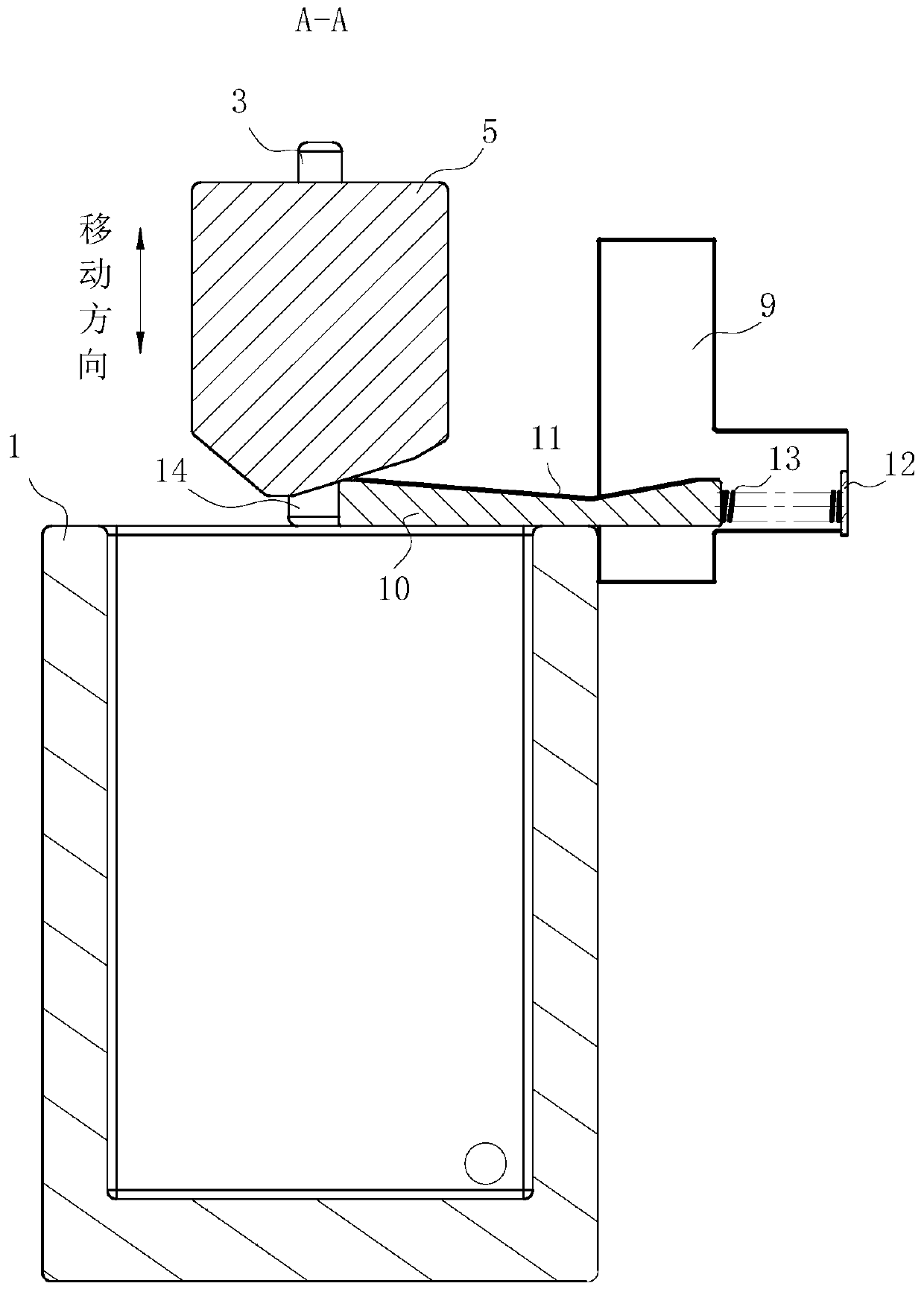

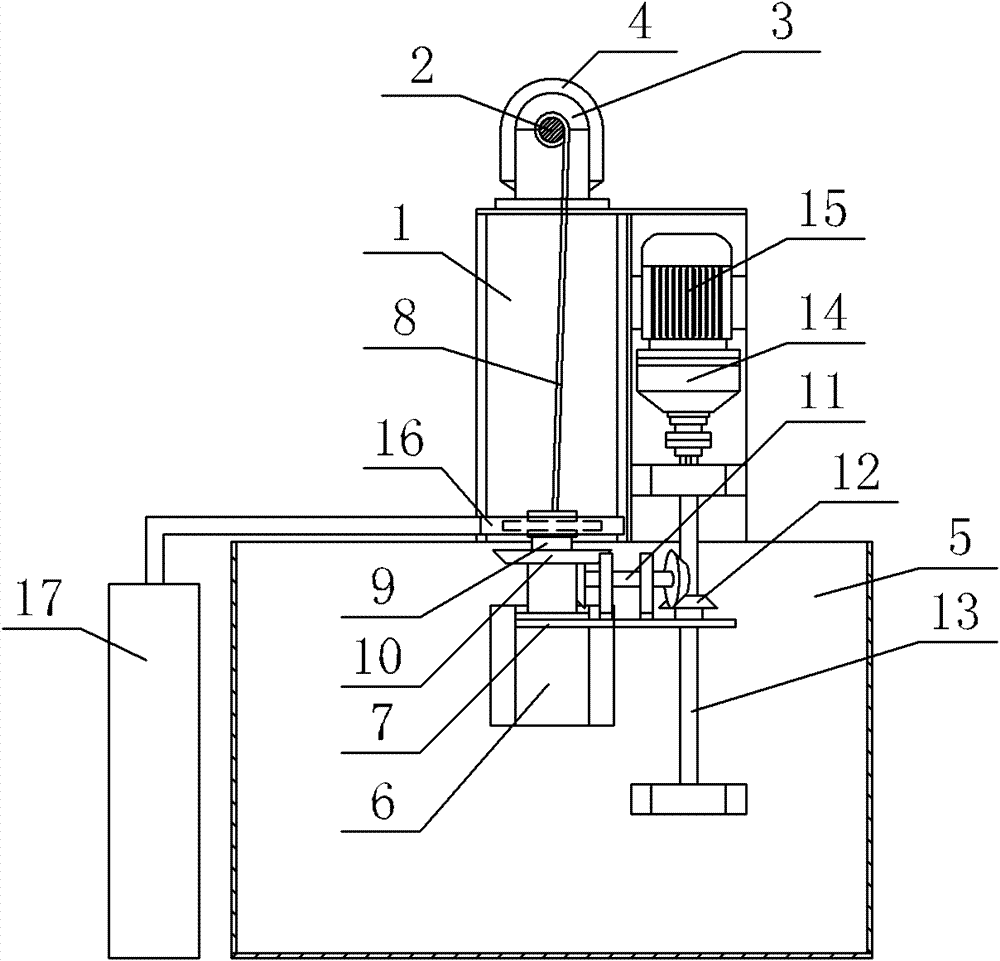

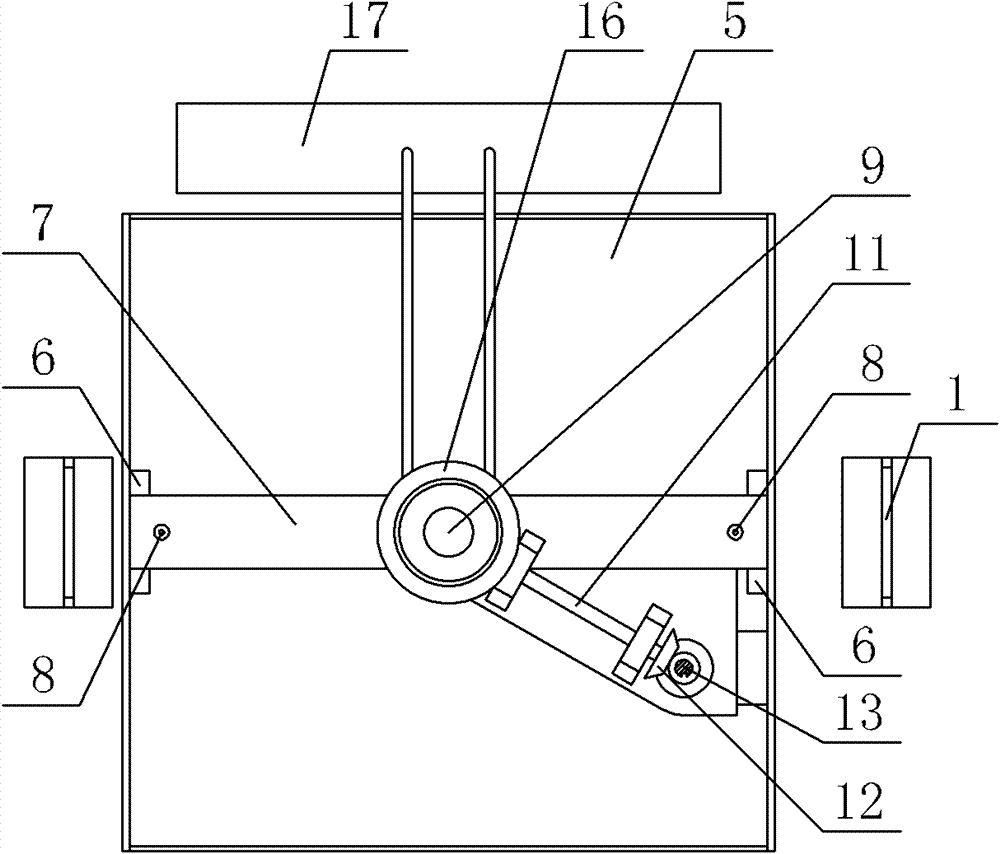

Large-size carburizing steel double-row self-aligning roller bearing outer ring quenching mold

InactiveCN113975865AEfficient removalReduce the impactFurnace typesStationary filtering element filtersEngineeringStructural engineering

The invention discloses a large-size carburizing steel double-row self-aligning roller bearing outer ring quenching mold which comprises a box body, a quenching mechanism and a spraying connecting pipe, the quenching mechanism is arranged at the top of the box body, and the spraying connecting pipe is arranged on one side of the surface of the box body and is connected with the quenching mechanism in a matched mode; a driving mechanism, an impurity removing device and a cleaning device are arranged in the box body, the driving mechanism is arranged in the center of the top of the inner wall of the box body, the impurity removing device is arranged on the inner wall of the box body and located in the center, and the cleaning device is connected to the bottom of the driving mechanism in a matched mode; the bottom of the cleaning device is connected with the impurity removing device in a matched mode. The large-size carburizing steel double-row self-aligning roller bearing outer ring quenching mold achieves the purpose of filtering and deslagging, can filter water in time, reduces the influence of impurities, ensures the quenching quality, can perform anti-blocking, and improves the use performance.

Owner:吕磊

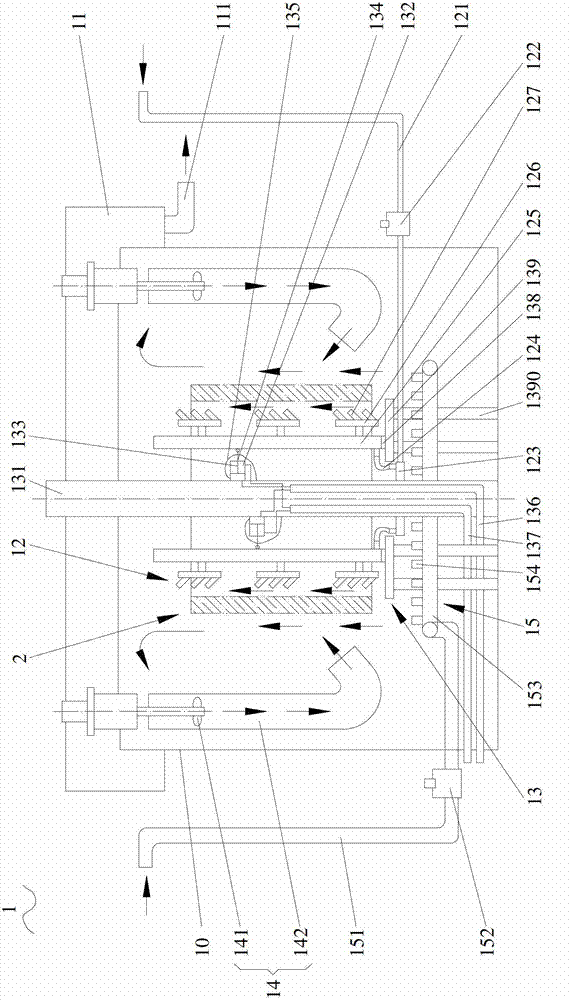

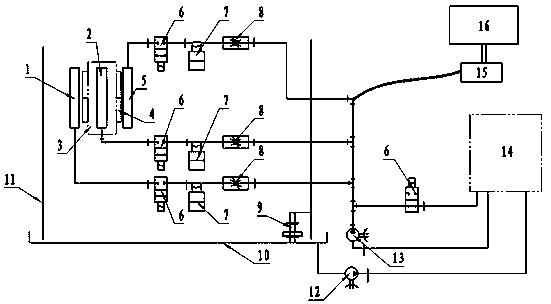

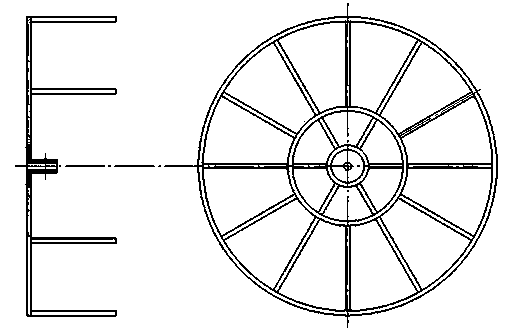

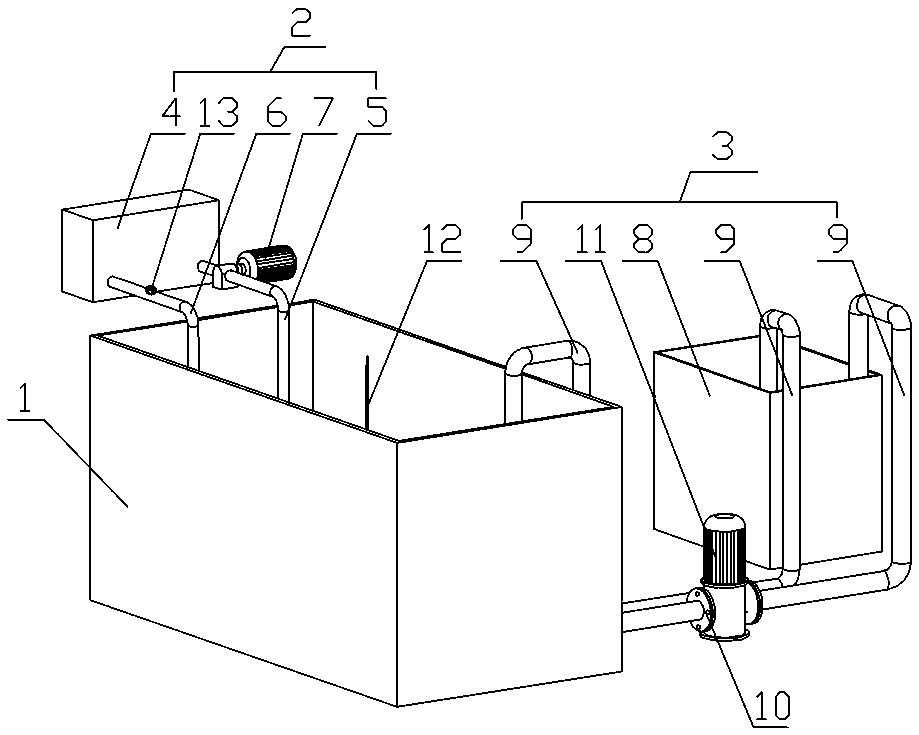

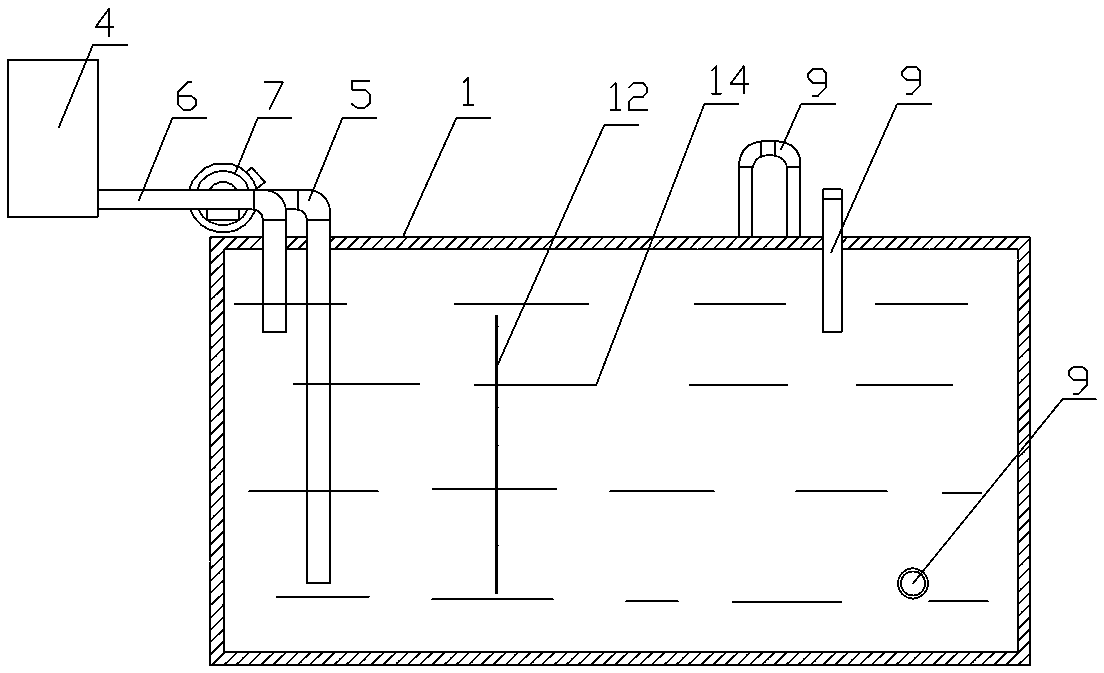

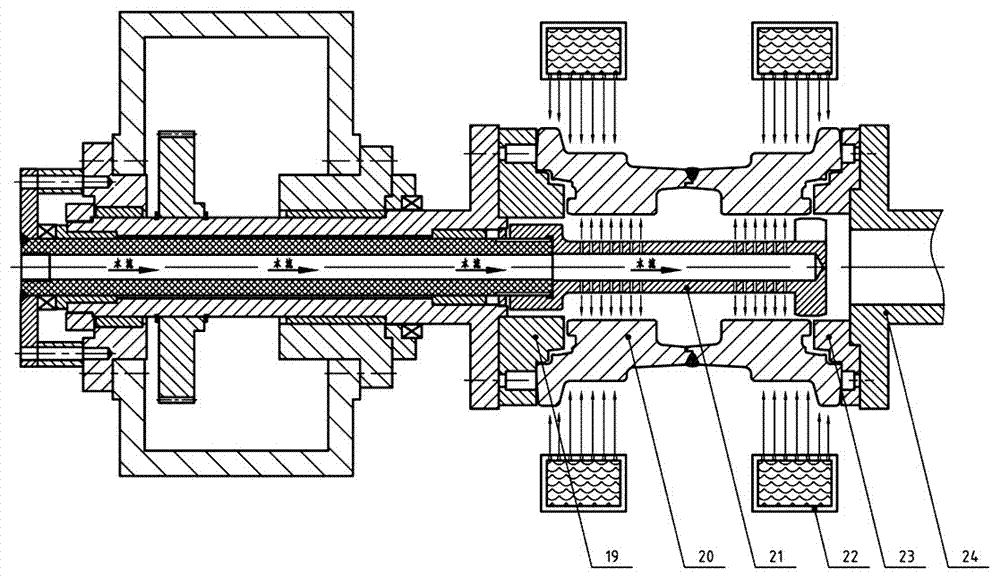

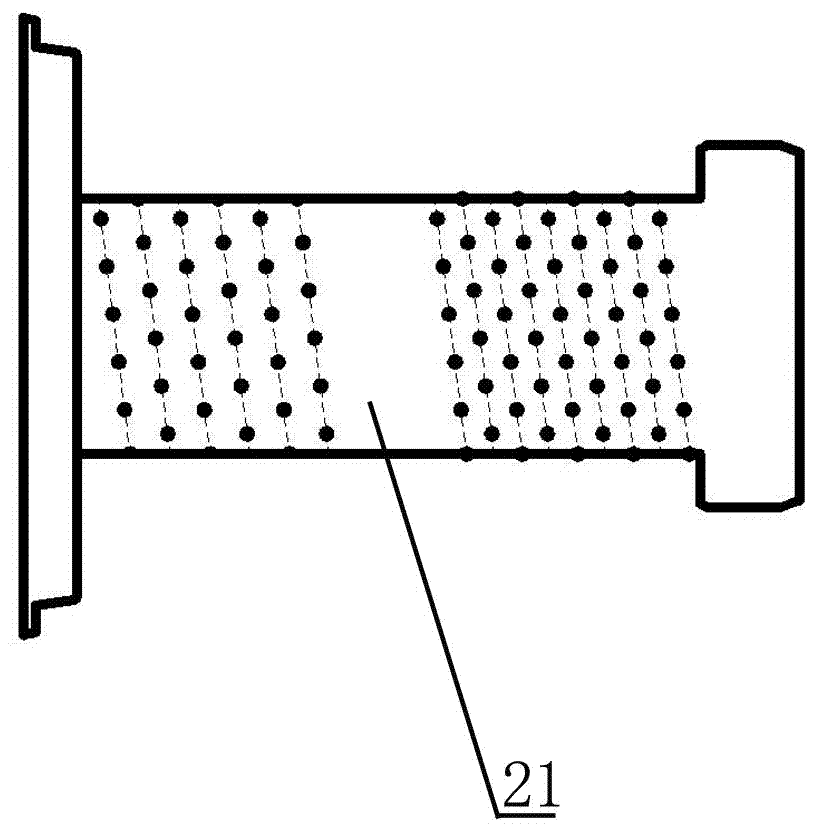

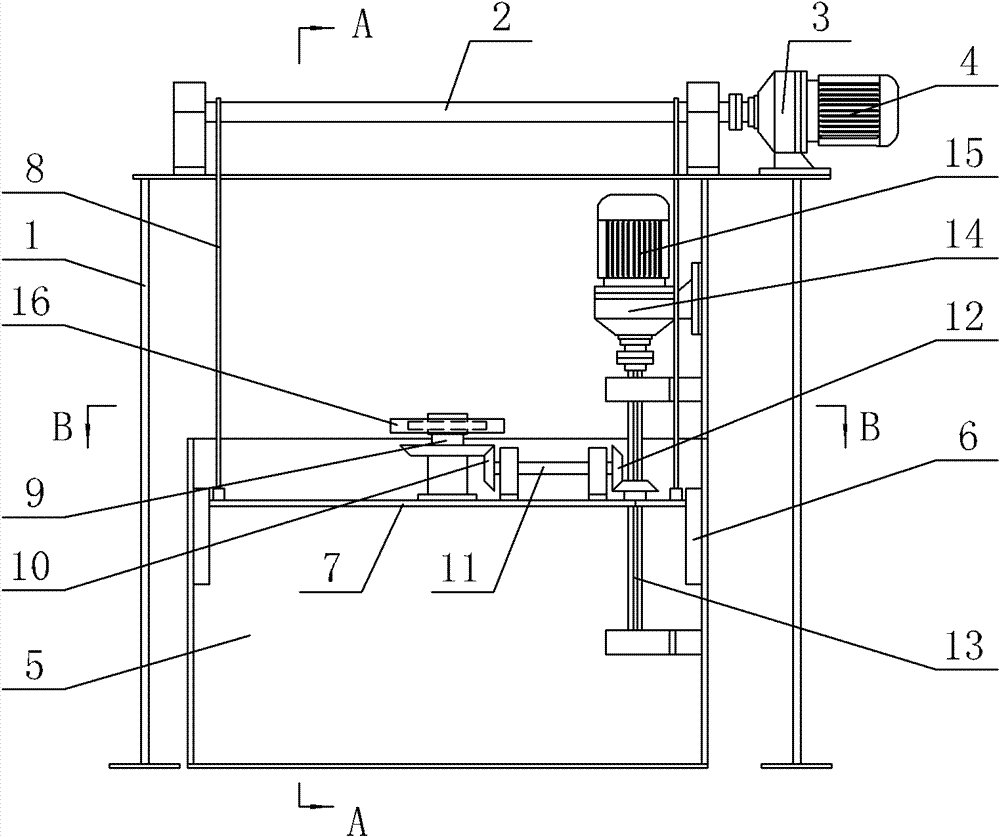

Method for controlling flow fields in quenching water tank of large cylindrical workpiece

InactiveCN102925641AControl of flow field structureUniform flow rateFurnace typesHeat treatment furnacesControl flowPropeller

The invention provides a method for controlling flow fields in a quenching water tank of a large cylindrical workpiece. The method comprises the step of simultaneously forming an inlet communicated with quenching liquid outside the water tank and an inner spraying nozzle jet flow field performing spraying towards the inner lateral wall of the workpiece in an inclined and upward mode, an inlet communicated with the quenching liquid outside the water tank and an outer spraying nozzle jet flow field performing spraying to the outer side of the workpiece from bottom to top, and an inlet communicated with the top of the water tank and a propeller stirring jet flow field performing spraying towards the outer lateral wall of the workpiece in an inclined and upward mode. The workpiece quenching process is adjusted by adjusting the inner spraying nozzle jet flow field, the outer spraying nozzle jet flow field and the propeller stirring jet flow field. By means of the method, the structures of the flow fields in the quenching water tank can be controlled according to the size and the quenching requirements of the workpiece, so that quenching media around the cylindrical workpiece have equal and appropriate flow velocity and can circulate in the quenching water tank well, and quenching quality of the large cylindrical workpiece is ensured effectively.

Owner:SHANGHAI DIANJI UNIV

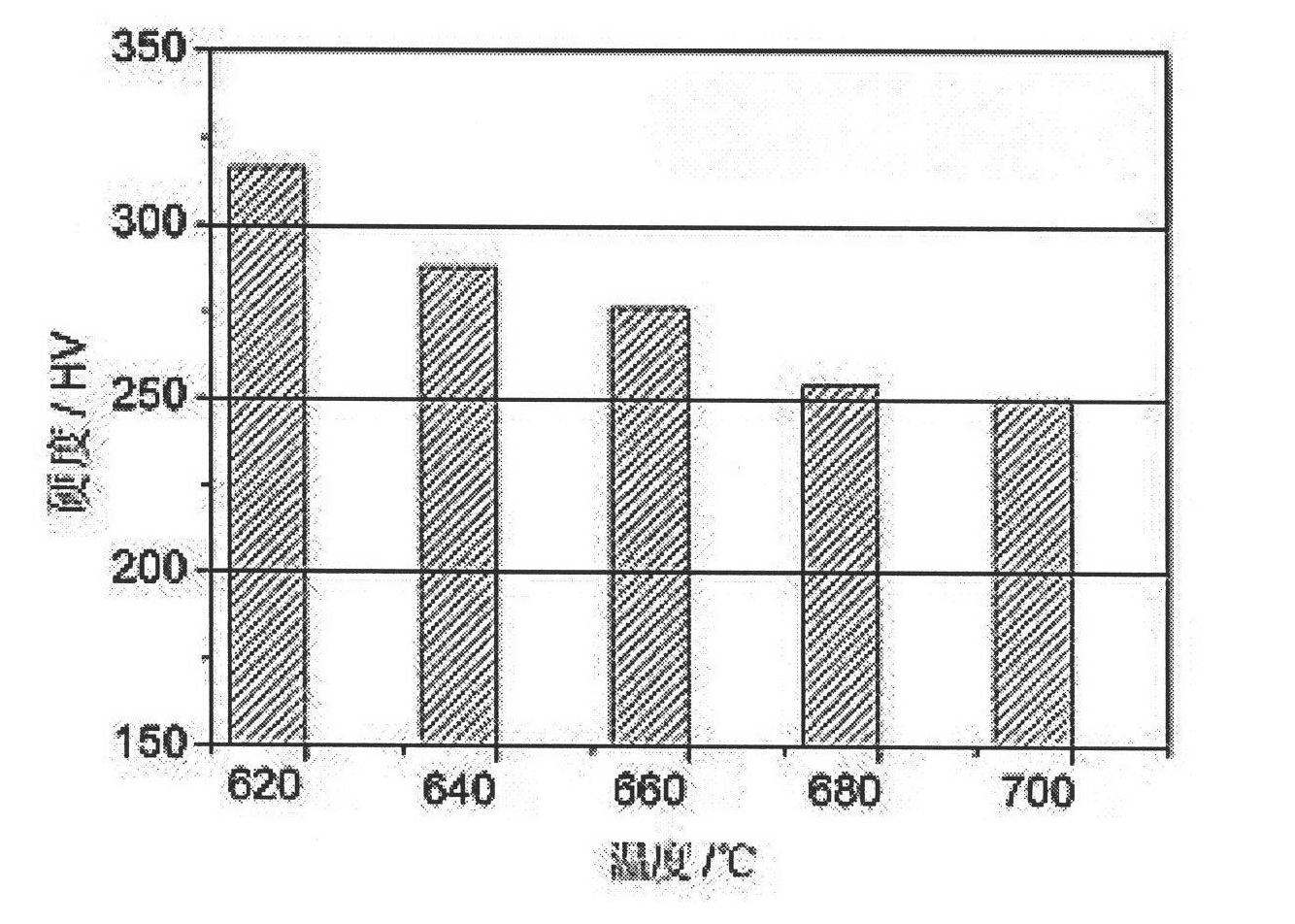

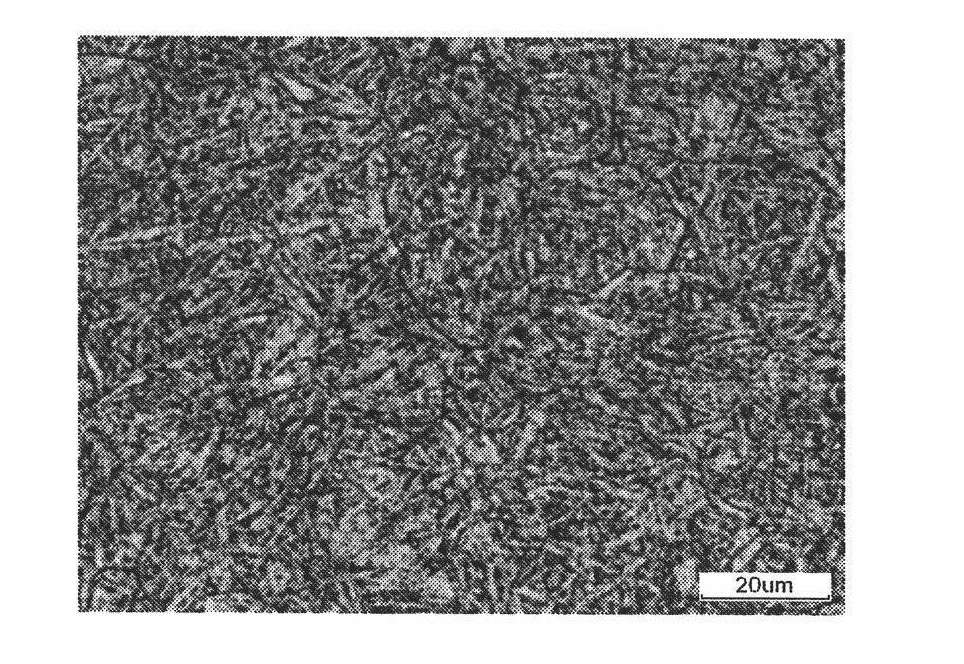

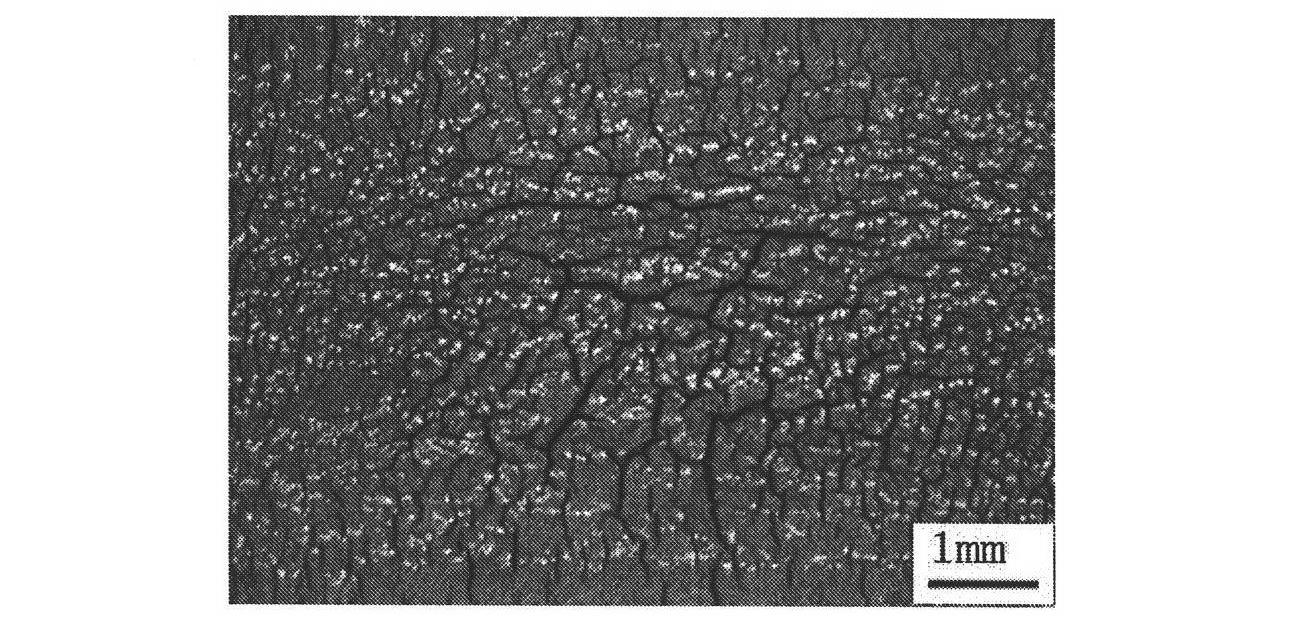

Heat treatment method of M2 high-speed steel work roller

InactiveCN109457102AImprove quenching stress stateGuarantee the quality of quenchingFurnace typesHeat treatment furnacesWater basedRoom temperature

The invention relates to a heat treatment method of an M2 high-speed steel work roller, and belongs to the technical field of roller heat treatment. The method comprises the following process steps of(1) primary preheating, wherein the roller is heated by a heat treatment furnace at the speed ranging from 50 DEG C / h to 200 DEG C / h till the temperature ranges from 500 DEG C to 600 DEG C, and heatpreservation is carried out; (2) secondary preheating, wherein the roller continues to be heated at the speed ranging from 50 DEG C / h to 200 DEG C / h till the temperature ranges from 800 DEG C to 900 DEG C, and heat preservation is carried out; (3) high-temperature heating, wherein the roller is heated at the speed ranging from 50 DEG C / h to 100 DEG C / h till the temperature ranges from 1140 DEG C to 1210 DEG C, and heat preservation is carried out; (4) cooling, wherein the roller subjected to high-temperature heating and heat preservation is cooled by a water-based quench bath, the roller is vertically placed into the water-based quench bath to be cooled till the temperature ranges from 300 DEG C to 400 DEG C; and (5) tempering treatment, wherein the cooled roller is heated till the temperature ranges from 540 DEG C to 560 DEG C, after heat preservation is carried out for 3 h to 10 h, air cooling is carried out to room temperature, and tempering treatment is carried out several times. By means of the heat treatment method, the quenching stress state can be improved, and the quenching quality can be guaranteed.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

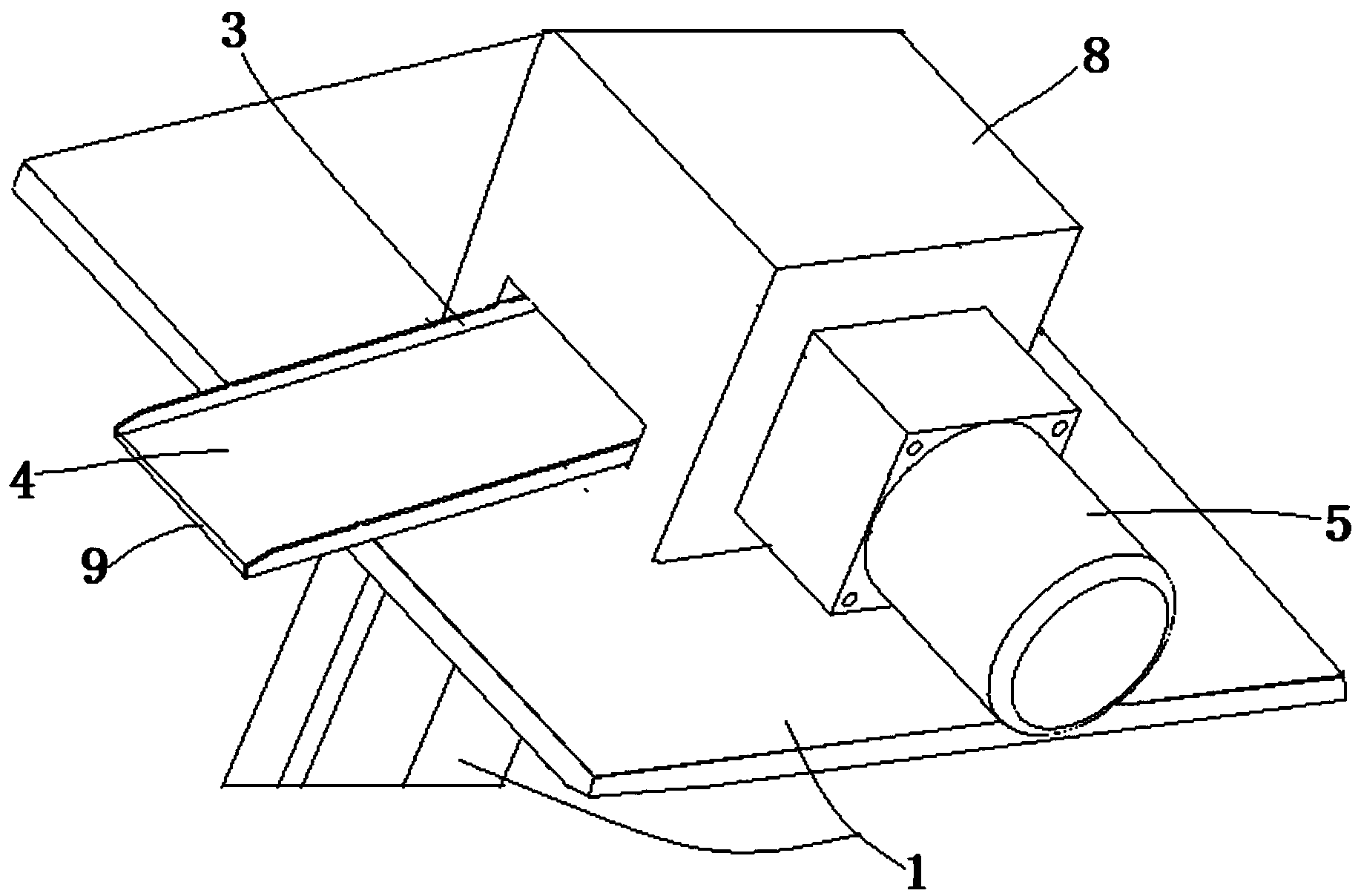

Premixed spray quenching system for steel rail

ActiveCN102899464AGuarantee the quality of quenchingReduce energy consumptionFurnace typesRailway track constructionLow noiseSpray nozzle

The invention relates to the field of metal heat treatment, and provides a premixed spray quenching system for steel rail, aiming at online waste heat quenching and offline full-length quenching treatment of steel rail. The system is the improvement on wind spray quenching equipment, and has the following characteristics: several groups of atomizing and humidifying nozzles are arranged on an air inlet pipe of the wind spray quenching equipment; the atomizing and humidifying nozzles are connected to the air inlet pipe through a bolt and a flange and are sealed; atomized mist is sprayed into the air inlet pipe by the atomizing and humidifying nozzles, and mixed with the compressed air in the air inlet pipe; and the compressed air containing mist is sprayed onto the steel rail by an wind spray nozzle of the air inlet pipeline. The premixed spray quenching system for steel rail has advantages of wind spray quenching and mist spray quenching of steel rail and overcomes their disadvantages, and can ensure the quenching quality of steel rail; besides, the system has low noise, low energy consumption and low processing cost, and can be used for off-line quenching of steel rail, especially for online slack quenching of steel rail.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO +1

Quenching equipment used for large complex thin-wall aluminum alloy castings and application method thereof

ActiveCN103468893AHigh degree of automationSimple and fast operationHeat treatment process controlQuenching devicesEquipment useThin walled

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

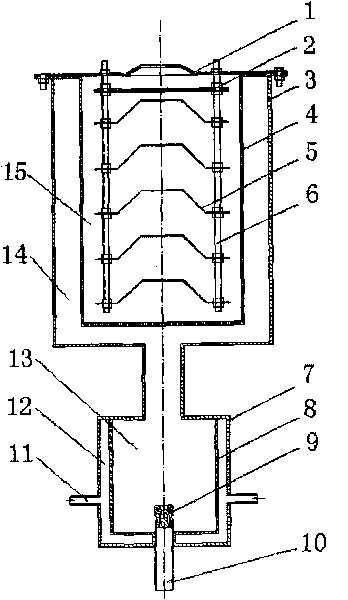

Atomization gas quenching device

InactiveCN101709360AReduce defectsUniform compositionQuenching agentsQuenching devicesLiquid mediumProduct gas

The invention provides an atomization gas quenching device, comprising a quenching box body which is provided with a cover at the top and is internally provided with an internal cylinder with holes, current collectors and carrier netting pieces are fixed in the internal cylinder at interval by supporting rods; the atomization gas quenching device is characterized in that: the atomization gas quenching device comprises an atomization box which is connected with the quenching box, the atomization box comprises an outer box body which is provided with a gas inlet and a liquid outlet, and an inner cylinder which is arranged in the outer box body and is provided with holes on the wall and is internally provided with a cavity, the liquid inlet on the box body is extended in the inner cylinder, and a nozzle is arranged on the inner end opening; the liquid medium for quenching is atomized in the atomization box through the nozzle and then is mixed with the gas, and then the atomized gas and the liquid mixed medium are provided to the quenching box, so as to improve the quenching efficiency, ensure the quenching quality and eliminate the defects on the surface of the parts; the structure is simple, the usage is convenient, the atomization effect is good, the ingredients are uniform, and the water and gas feeding can be controlled respectively, and the content ratio of the atomization composition ca be easily adjusted, so as to meet the atomization requirements of different workpieces.

Owner:KUNMING UNIV OF SCI & TECH

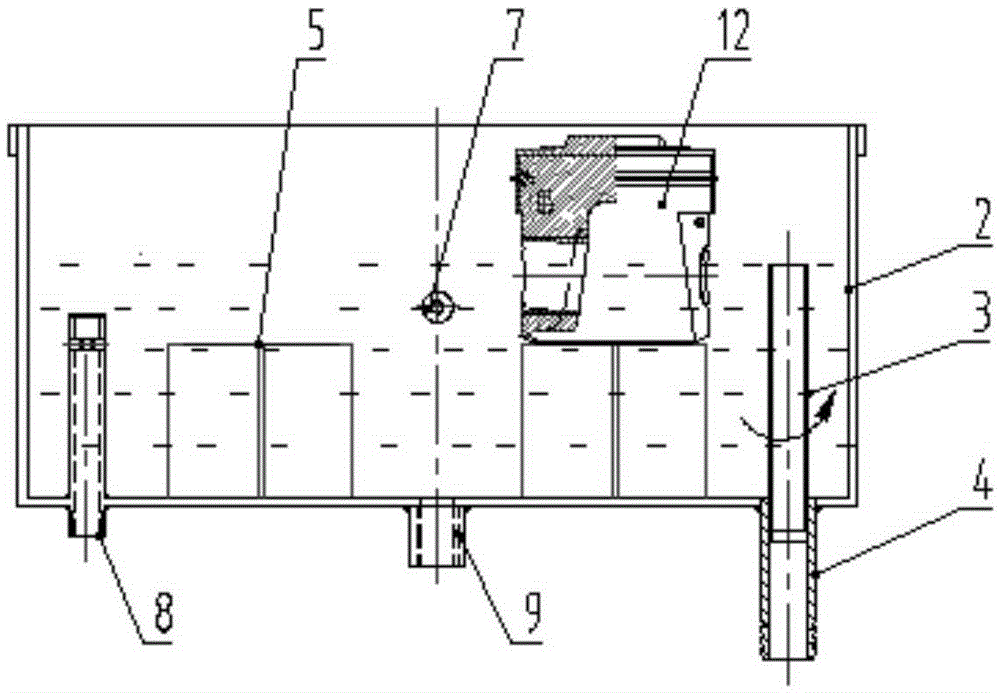

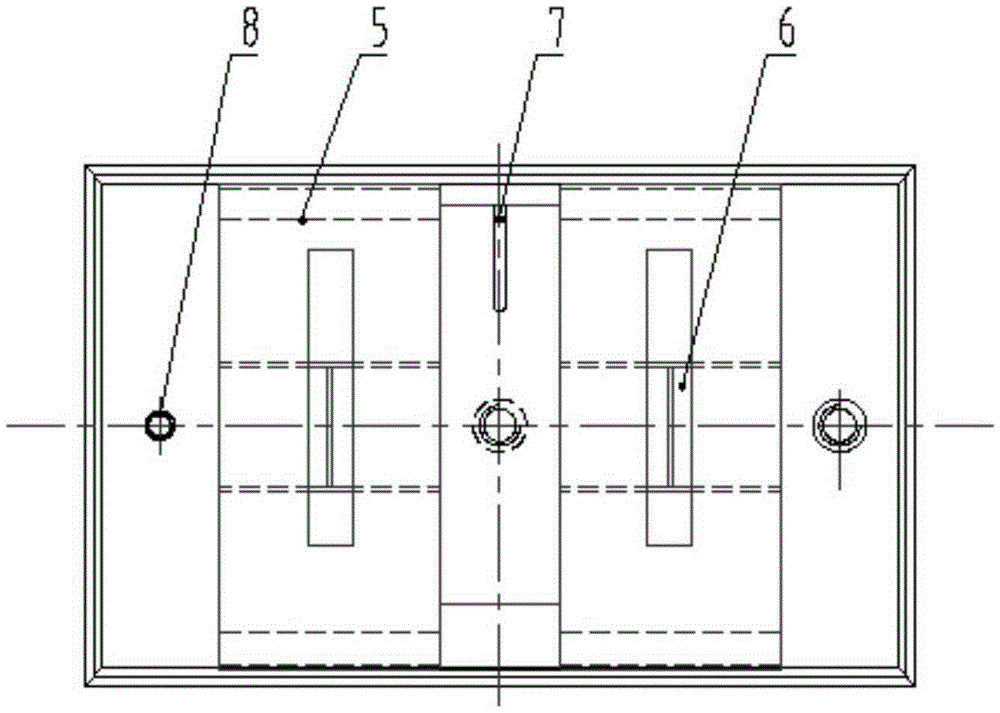

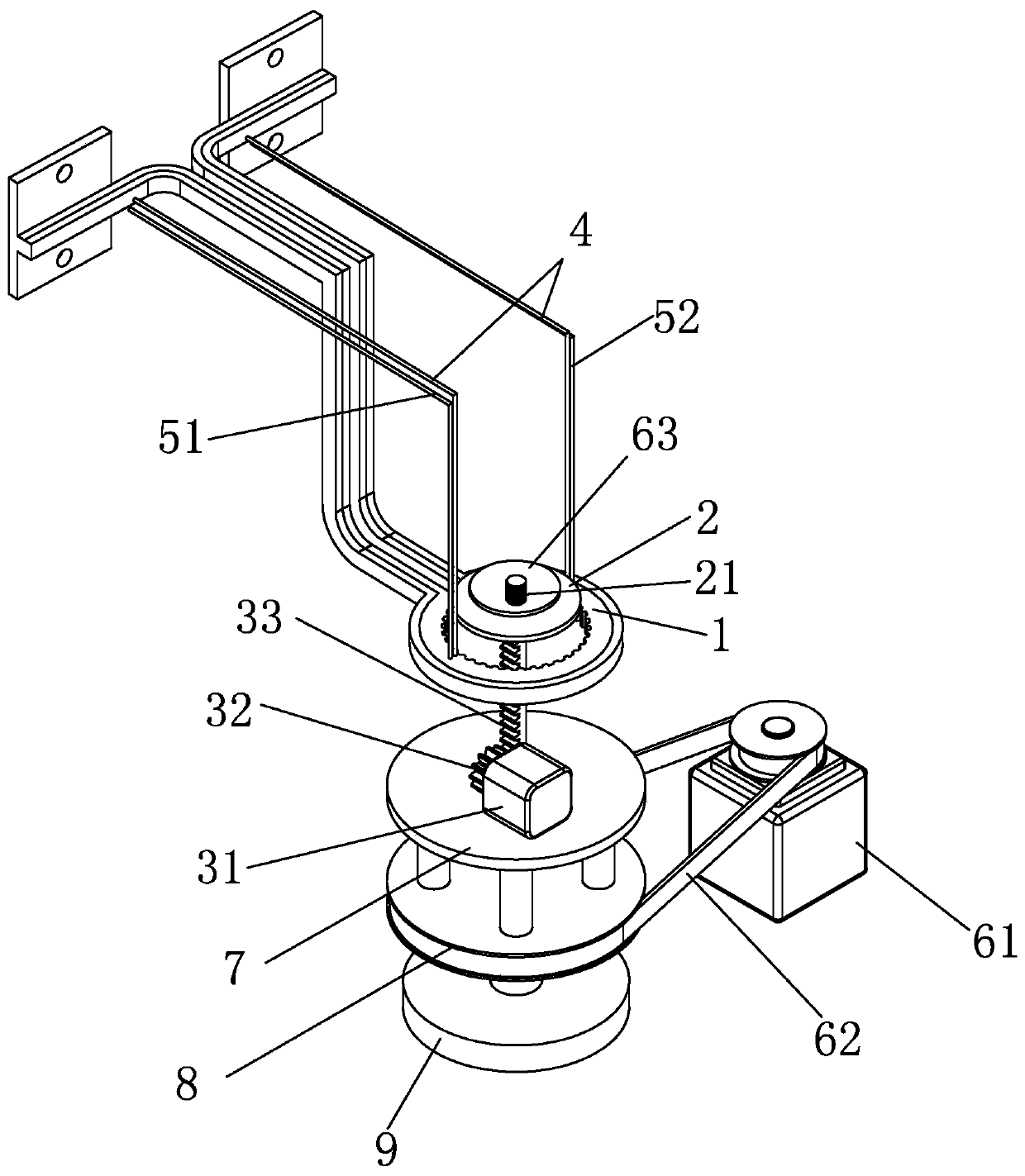

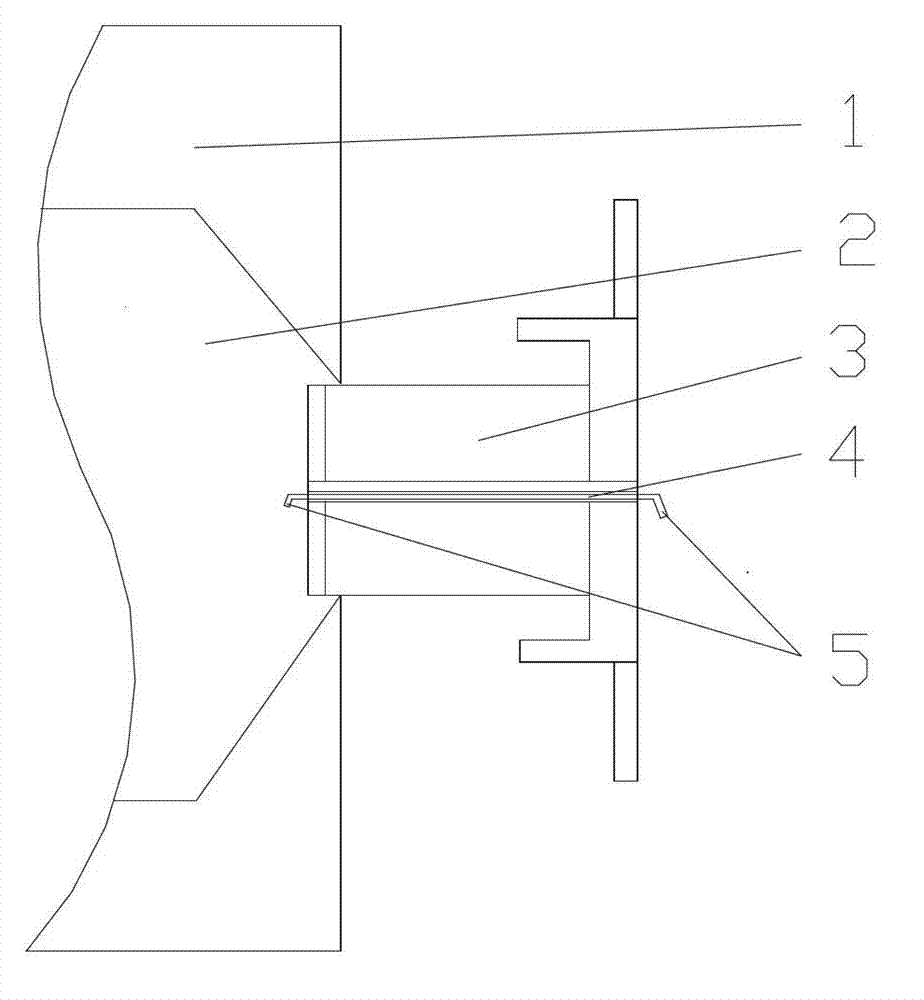

Quenching device

ActiveCN105256113ARealize regulationEasy to controlQuenching devicesBiochemical engineeringQuenching

The invention discloses a quenching device which comprises a support (1) and a quenching tank (2) arranged on the support (1) and used for containing liquid and blanks (12) and further comprises a liquid discharging pipe (3) connected with the quenching tank (2) in a sealed manner. One end of the liquid discharging pipe (3) is communicated with the outer side and the horizontal height of the liquid discharging pipe is lower than the horizontal height of the other end of the liquid discharging pipe. The other end of the liquid discharging pipe (3) is located in the quenching tank (2) and the horizontal height can be adjusted. According to the quenching device, the liquid level of liquid in the quenching device can be adjusted according to the different blanks (12), the application range of the quenching device is broadened, and the quenching quality of the blanks is guaranteed.

Owner:湖南江滨机器(集团)有限责任公司

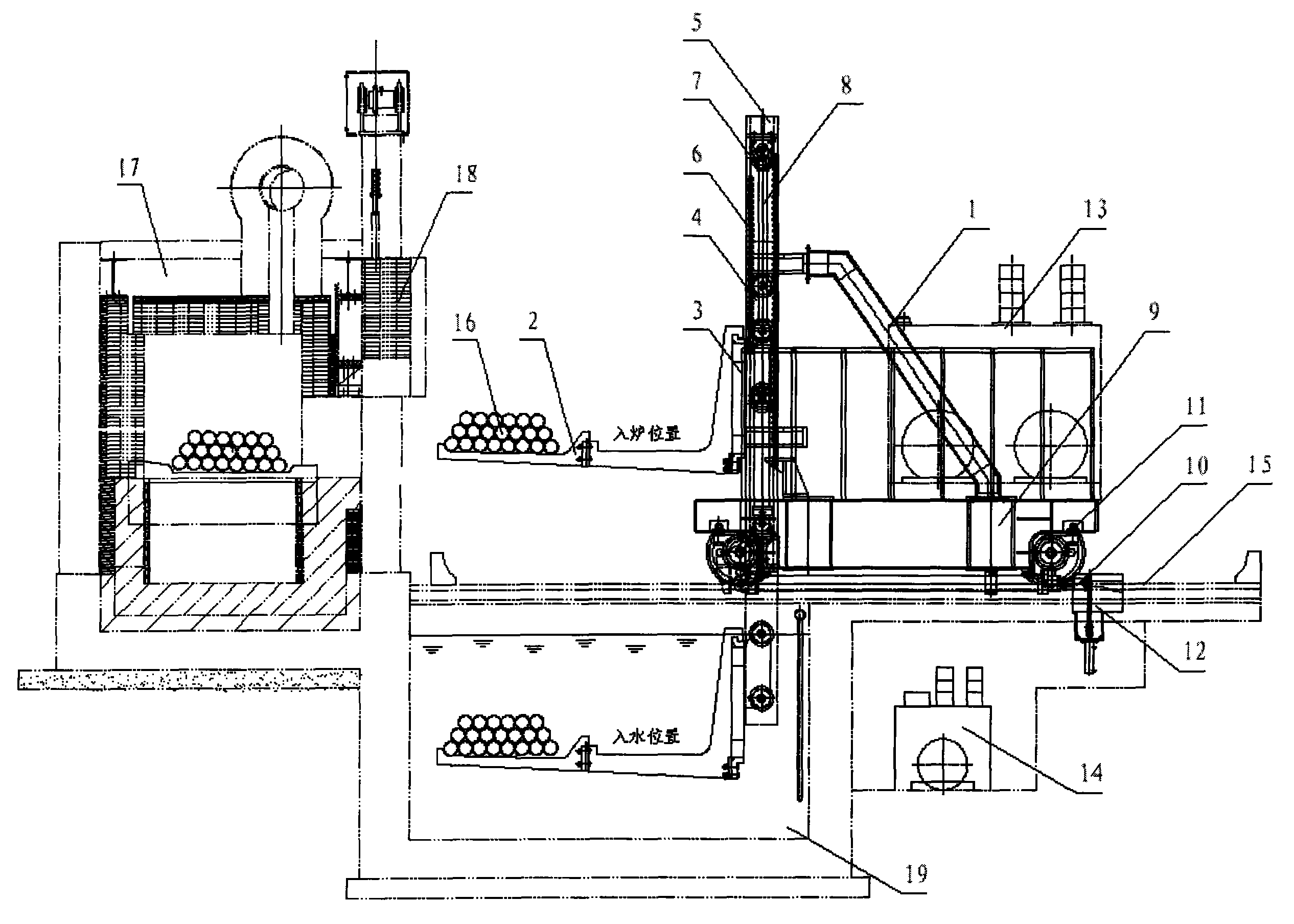

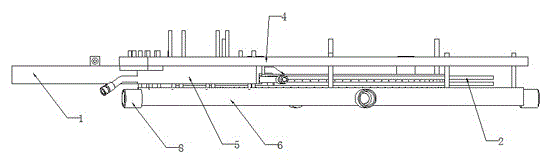

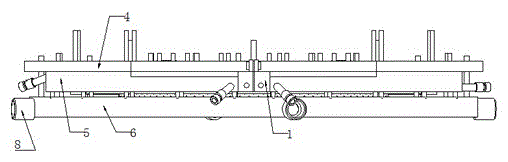

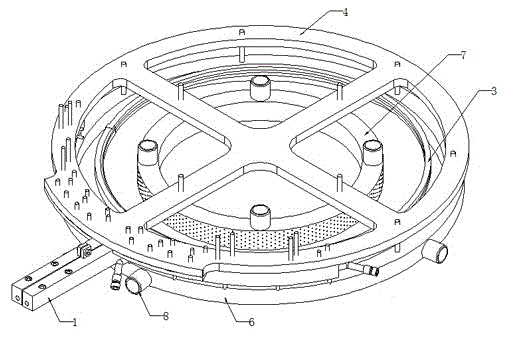

High-temperature solid smelting furnace heat-treatment quenching machine

The invention discloses a high-temperature solid smelting furnace quenching machine with accurate control, high safety and reliability and smooth operation. The quenching machine comprises a form-relieved tooth, a form-relieved tooth carrier, a lifting guide rail internal bracket, a fixed guide rail bracket, a form-relieved tooth lifting chain and chain wheel assembly, a form-relieved tooth hoist cylinder, a truck body, a truck entry and exit furnace fuel cylinder, a truck advancing hydraulic motor, a truck entry and exit furnace earth-fixed baffle, a truck main hydraulic system and an auxiliary hydraulic system, wherein the form-relieved tooth is installed on the form-relieved tooth carrier, the form-relieved tooth carrier can move up and down in the lifting guide rail internal bracket through roller wheels, and the lifting guide rail internal bracket can move up and down in the fixed guide rail bracket through the hoist cylinder; the truck is driven by a rear wheel hydraulic motor before entering the furnace, and furnace entrance and exit are completed by the truck entry and exit furnace fuel cylinder. The truck is provided with the hydraulic systems which provide power for the advance, the exit and the lifting of the truck. The quenching machine is mainly applicable to the quenching of various blanks in steel mills.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

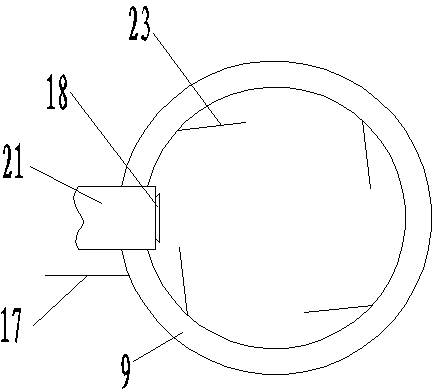

Special quenching inductor for rotary support rail

InactiveCN106480275AShorten induction hardening timeGuarantee the quality of quenchingFurnace typesIncreasing energy efficiencyInductorEngineering

The invention discloses a special quenching inductor for a rotary support rail. The special quenching inductor comprises a pair of conductive connection plates, wherein one ends of the pair of conductive connection plates are connected with an annular effective heating ring, the pair of conductive connection plates forms a closed current circuit with the effective heating ring, cooling liquid channels are arranged in the pair of conductive connection plates and the effective heating ring, the effective heating ring and the pair of conductive connection plates form a circulating cooling liquid channel, and a clamped magnetizer is arranged on the effective heating ring; an installation-fixation plate is arranged above the effective heating ring, and one side of the installation-fixation plate is fixed on the pair of conductive connection plates through a pair of fixed support seats; and a first annular water sprayer is arranged below the effective heating ring, the installation-fixation plate is connected with the first water sprayer, the effective heating ring and the first water sprayer are correspondingly arranged in a manner of vertical concentricity, and water spray holes are distributed in an end surface corresponding to a workpiece, of the first water sprayer. The device increases the efficiency by 6-10 times and saves energy compared with an existing local scanning manner.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

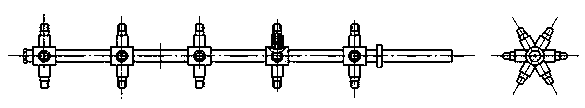

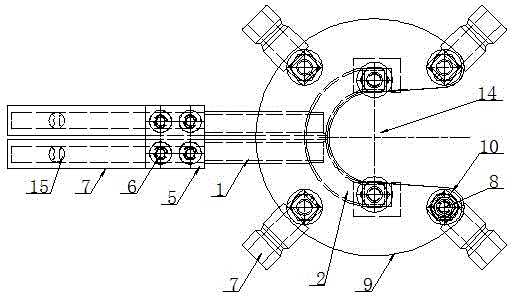

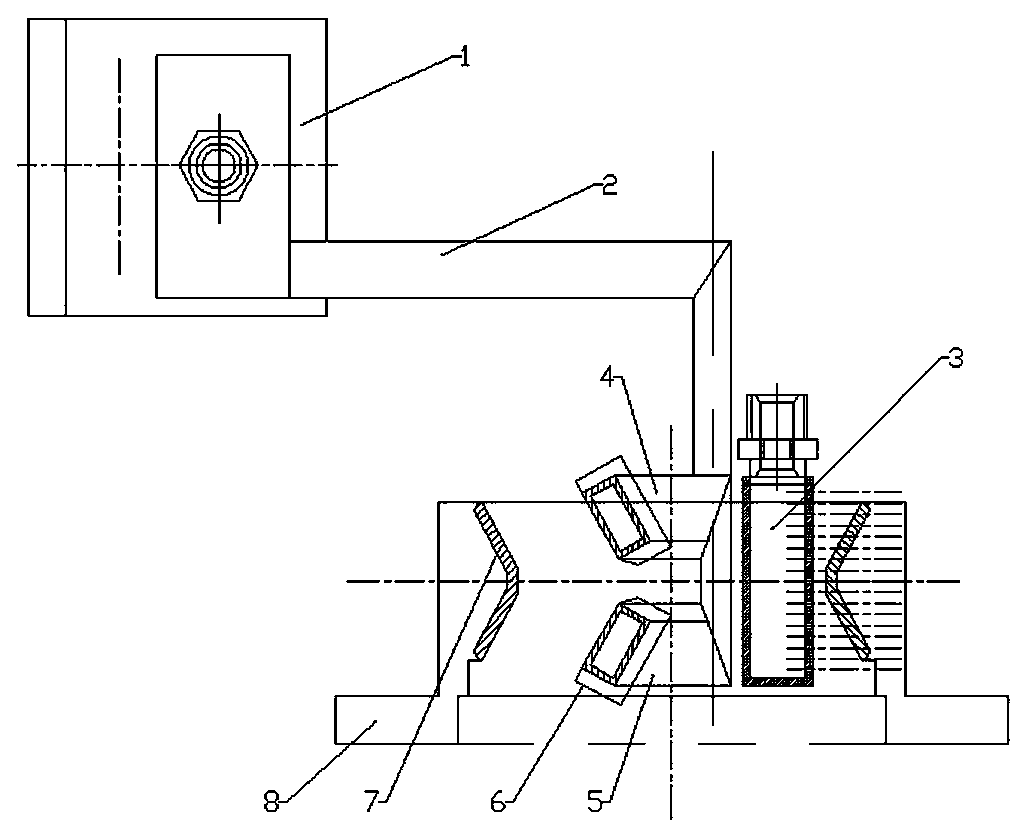

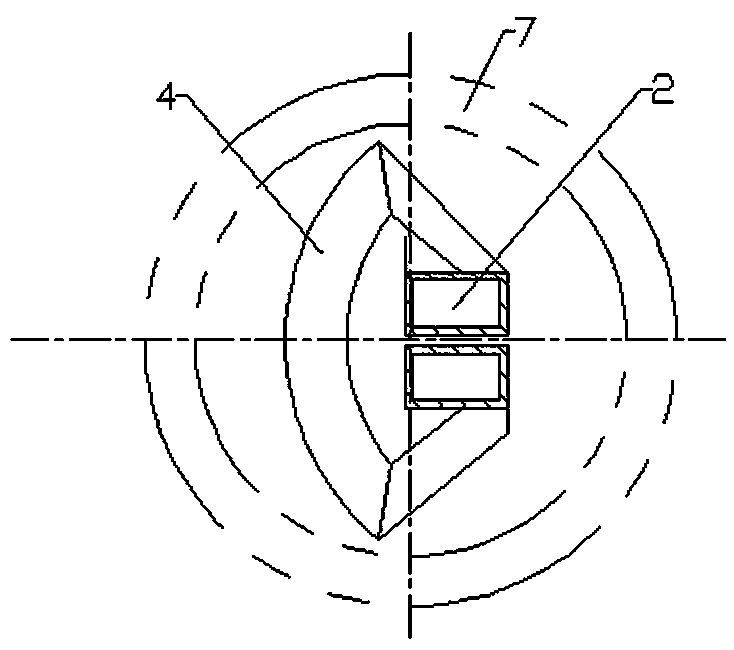

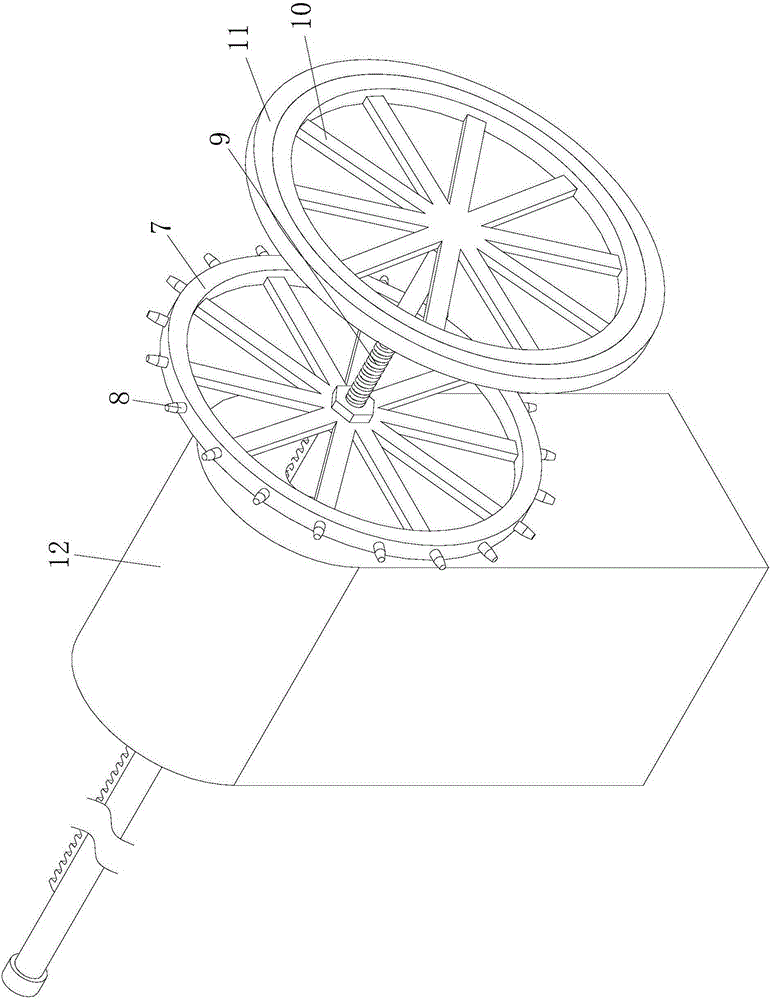

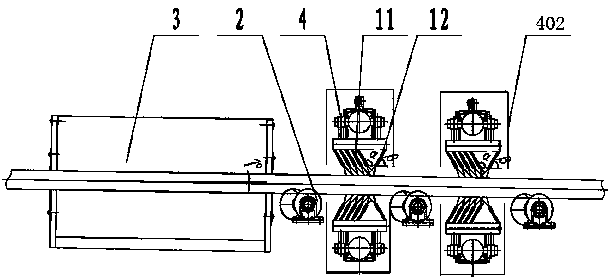

Quenching inductor for threaded surface of shaft disc type parts

ActiveCN105624373AUniform and stable coolingGuarantee the quality of quenchingIncreasing energy efficiencyFurnace typesQuenchingInductor

The invention provides a quenching inductor for the threaded surfaces of shaft disc type parts. The quenching inductor is mainly composed of an induction coil, a sprinkler, magnetizers and sprinkler fixing plates. The induction coil is a loop induction coil composed of first connecting pipes, a first connecting ring, effective coils and a second connecting ring. A second connecting pipe communicates with an inner hole of the induction coil to form a loop coolant channel. The effective coils are symmetrically distributed along the two sides of the axis of the threaded surface of a workpiece and fixed between the symmetrically arranged sprinkler fixing plates through studs and nuts, and the studs and the nuts are arranged on the end faces of the effective coils. Each magnetizer is fixed to the corresponding effective coil in a clamped mode. The sprinkler is composed of sprinkler heads and quickly-changed water nozzles. The sprinkler heads are fixed between the symmetrically arranged sprinkler fixing plates through studs and nuts, and the studs and the nuts are arranged on the end faces of the sprinkler heads. Sprinkler holes are distributed in the face, corresponding to the induction coil, of each sprinkler head. Each sprinkler fixing plate is provided with a workpiece guide opening. According to the quenching inductor for the threaded surfaces of the shaft disc type parts, the structure is simple and reasonable, all the components are connected with one another to form a whole, installing and replacing are convenient and fast, and rapid induction quenching of the kind of workpieces is achieved.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

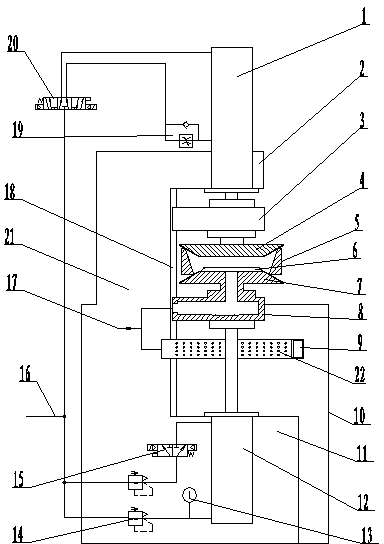

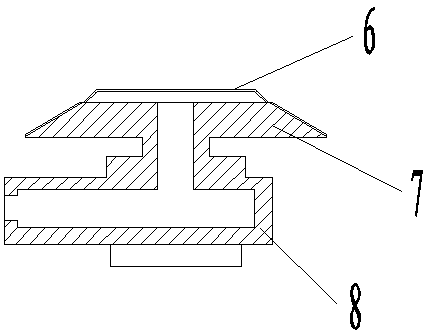

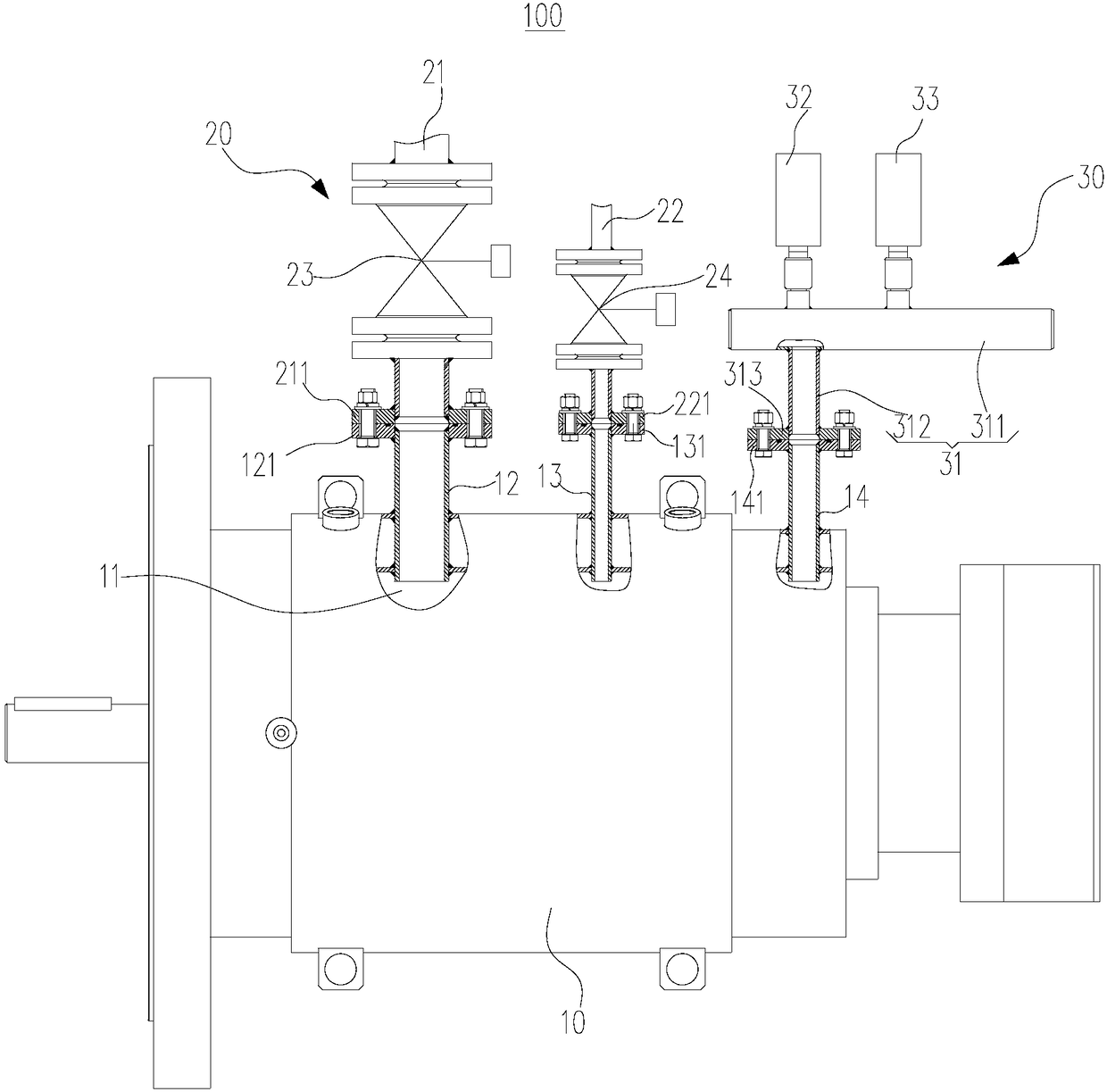

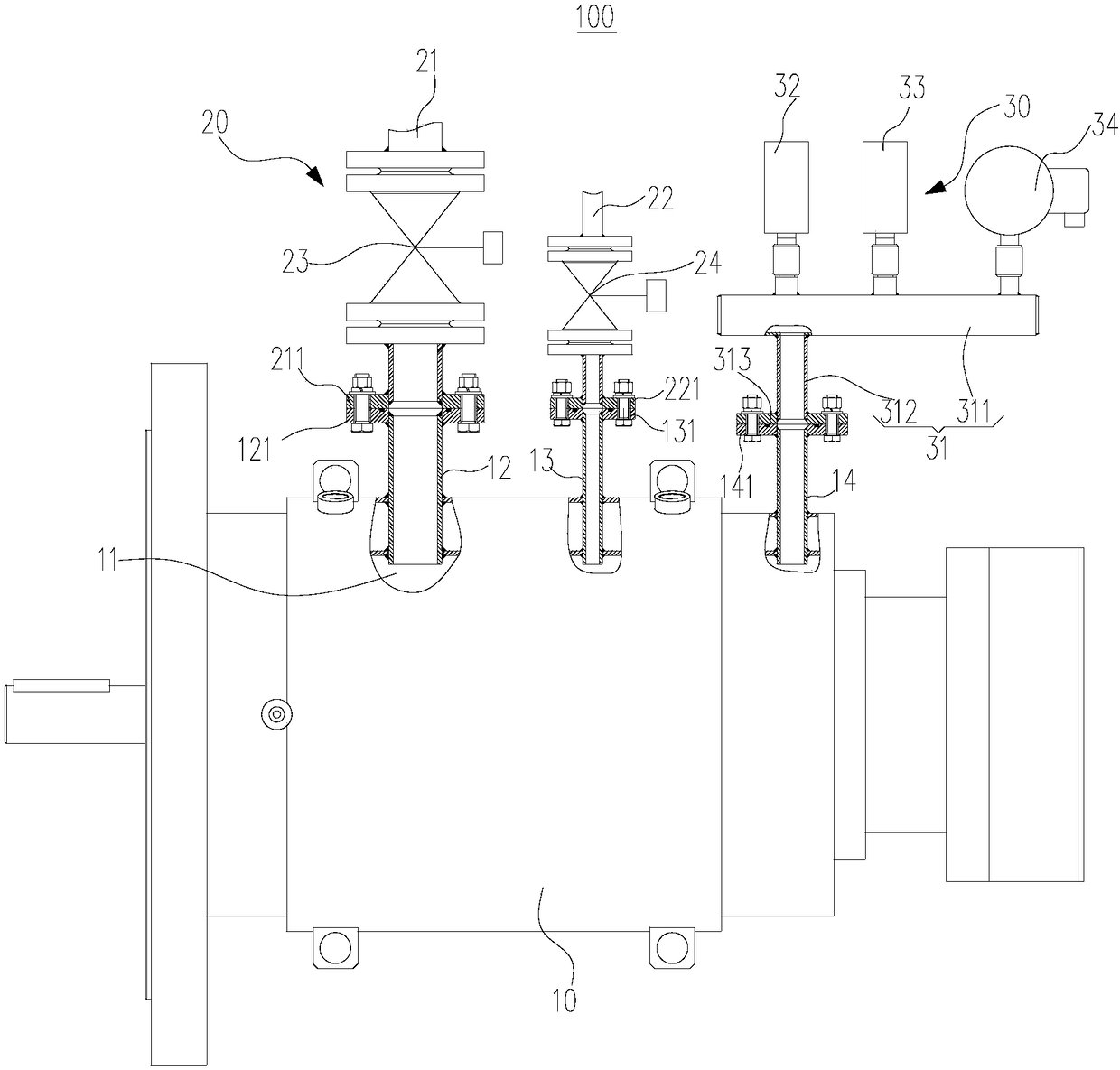

Die press quenching device for fully quenching steel ferrules

ActiveCN103451406AIncrease manufacturing costReduce manufacturing costsFurnace typesHeat treatment process controlHigh pressureQuenching

The invention relates to a heat treatment quenching device, in particular to a die press quenching device for fully quenching steel ferrules. The die press quenching device comprises a base, a stand column at one side of the base and a cross beam at the upper end of the stand column, wherein an upper sliding block and a lower sliding block are respectively arranged on a guiding rail of the stand column, and piston rods of an upper die cylinder and a lower die cylinder are respectively connected with the upper sliding block and the lower sliding block. The die press quenching device is characterized in that a high-pressure pipeline is connected with the upper die cylinder and the lower die cylinder respectively, a one-way speed regulating valve and a reversing valve I, which are used for controlling the speed and the direction of the upper die cylinder, are respectively arranged on a high pressure pipeline connected with the upper die cylinder, a pressure regulating valve and a reversing valve II, which are used for controlling the pressure and the direction of the lower die cylinder, are respectively arranged on a high pressure pipeline connected with the lower die cylinder, and cooling oil for quenching is connected with an oil outlet and an oil spraying ring on the lower die. According to the device, the press quenching force and the press quenching speed can be precisely regulated, the quenching time is short, the deformation of quenched workpieces is small, the quenching quality is effectively ensured, and existing quenching and controlling technologies are greatly improved.

Owner:NINGXIA MACHINERY RES INST

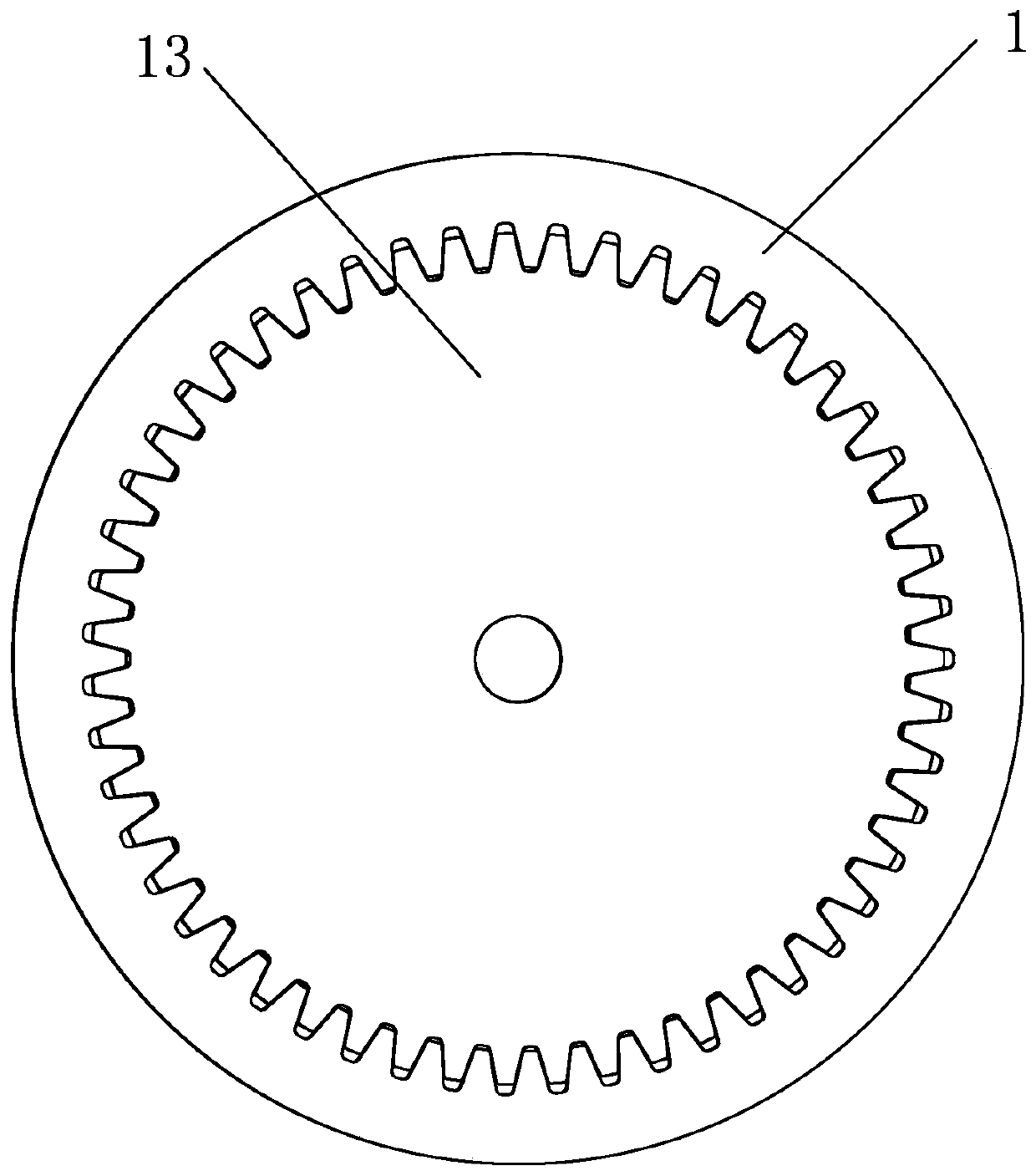

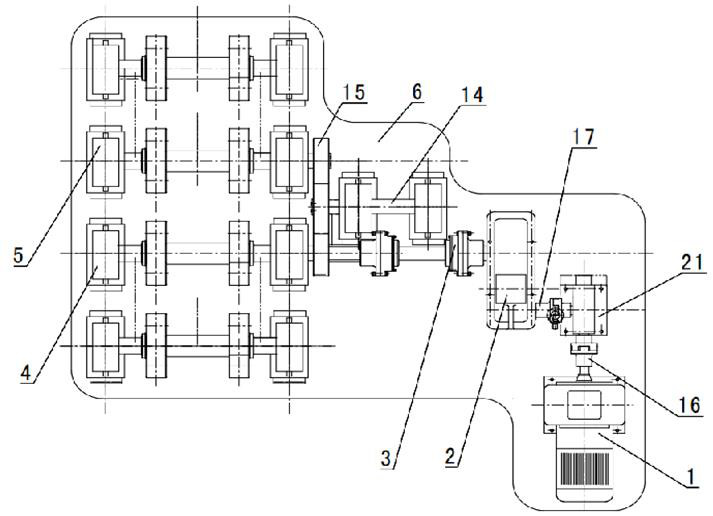

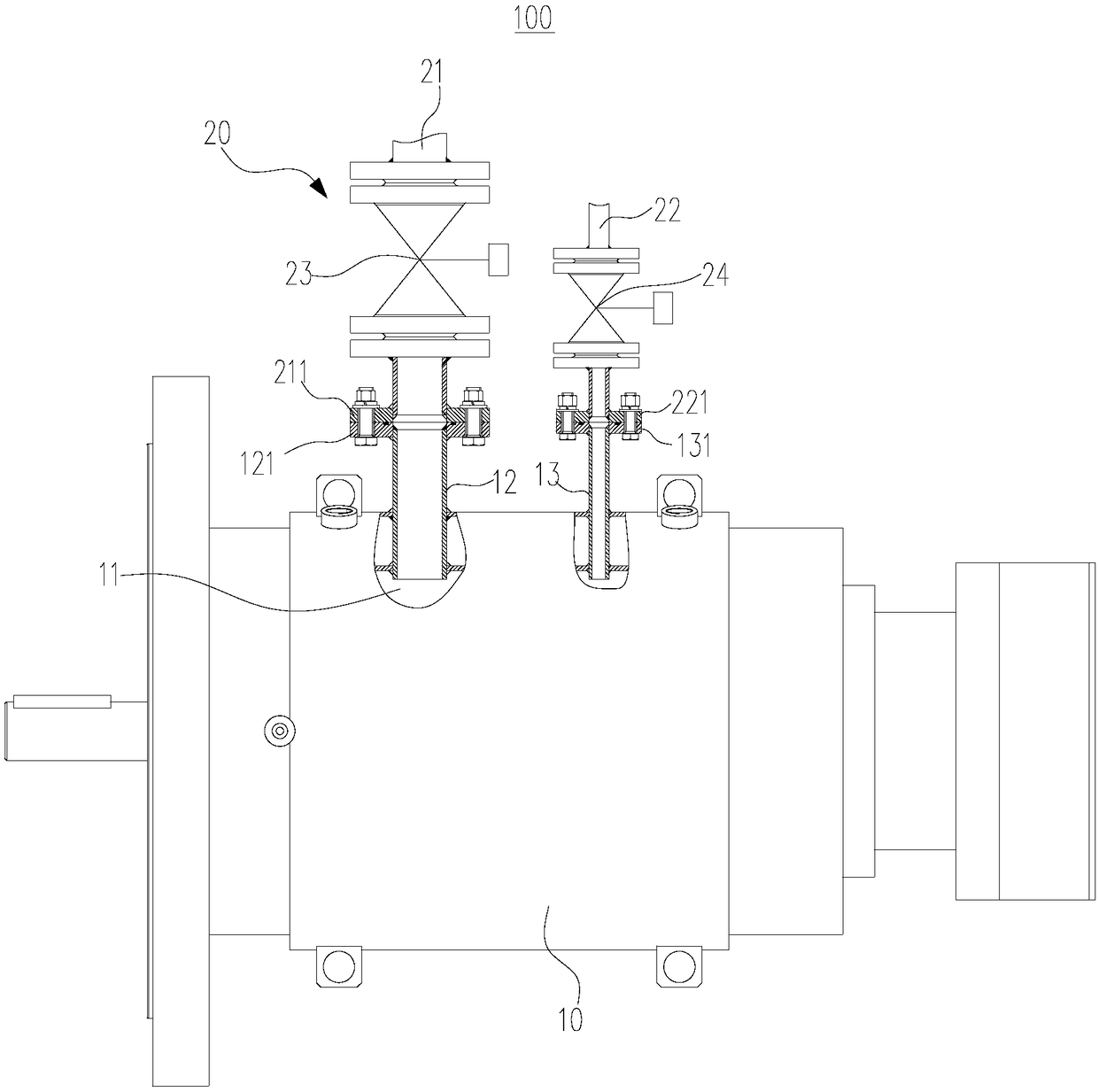

Gear induction quenching equipment and technology

PendingCN110592359AGuarantee the quality of quenchingImprove distributionFurnace typesIncreasing energy efficiencyEngineeringDouble frequency

The invention discloses gear induction quenching equipment and technology. The equipment comprises a profiling induction ring, a first supporting disc used for supporting a gear and a driving device,wherein the profiling induction ring is provided with a profile of a whole gear ring structure so as to mesh with the gear, and the driving device drives the profiling induction ring or the first supporting disc to do up-and-down lifting motion. The equipment solves the problems of poor profiling effect, low production efficiency and high manufacturing cost of induction double-frequency quenchingequipment in the prior gear induction quenching technology.

Owner:泉州职业技术大学

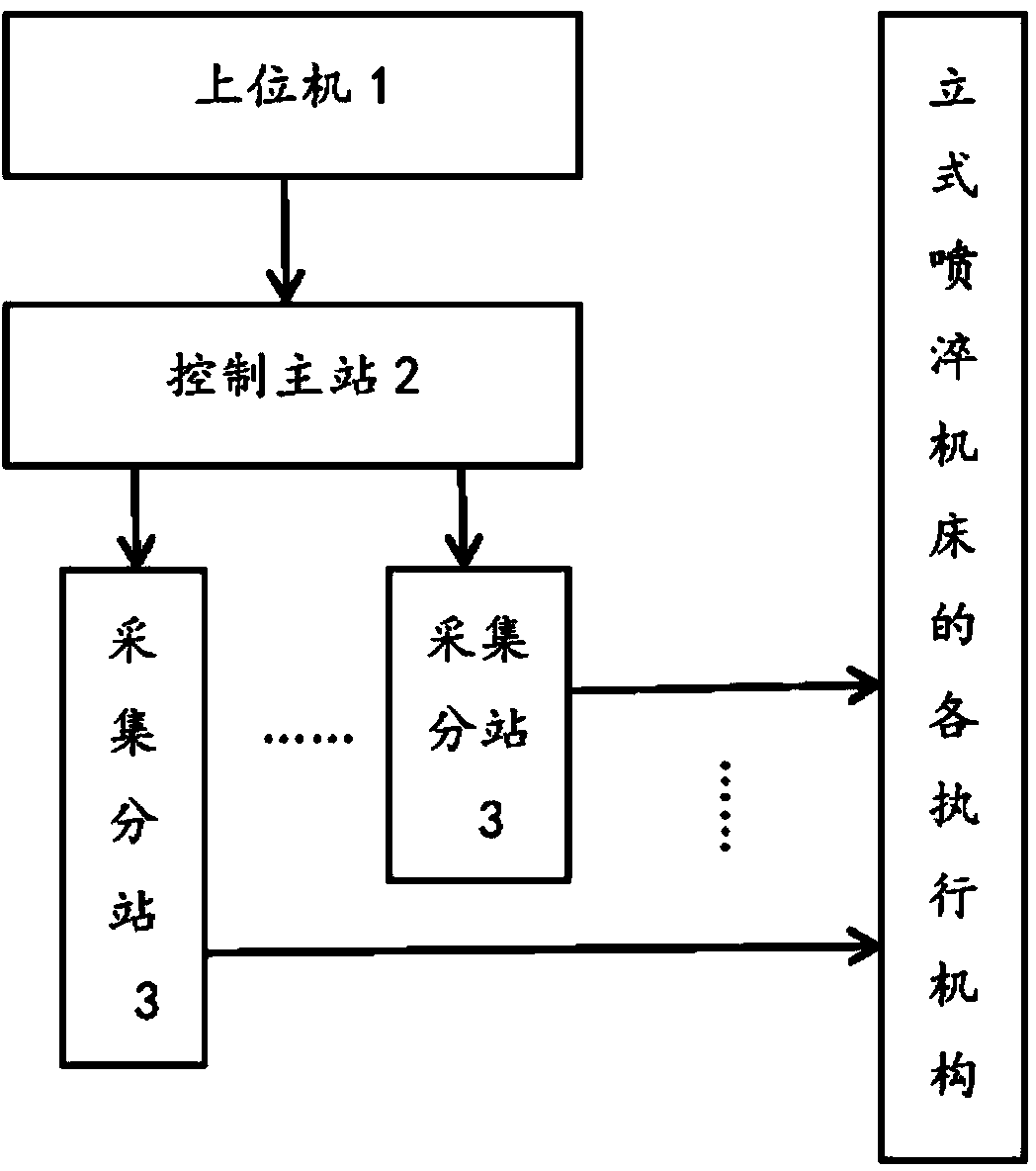

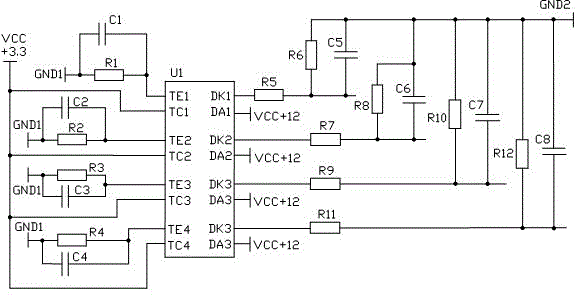

Electrical control device of vertical jet quenching machine tool

InactiveCN104216374AGuarantee the quality of quenchingTotal factory controlProgramme total factory controlMaster stationElectrical control

The invention relates to an electrical control device of a vertical jet quenching machine tool. The electrical control device comprises an upper computer, a control master station and multiple collection substations, wherein the upper computer is connected with the control master station, and the control master station is connected with each collection substation; the upper computer comprises a setting unit, the collection substations are distributed around the vertical jet quenching machine tool and connected with actuators of the vertical jet quenching machine tool respectively, and each actuator of the vertical jet quenching machine tool comprises a coder and a displacement sensor. By the aid of the electrical control device, water jet reducing and spray reducing can be controlled accurately, and quenching quality of heat treatment workpieces is guaranteed.

Owner:LUOYANG XINSILU ELECTRIC

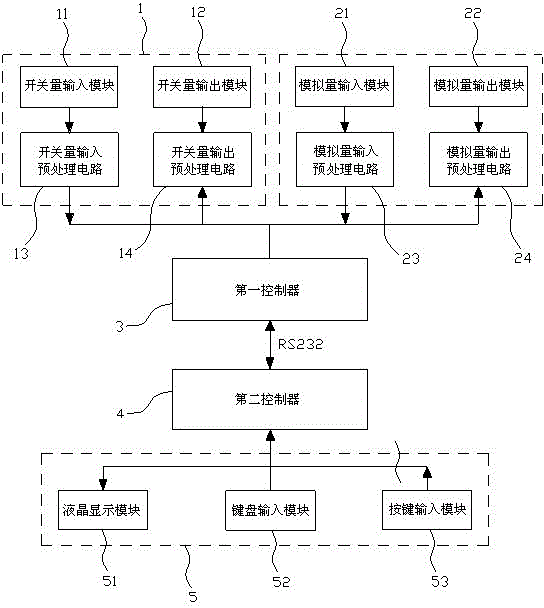

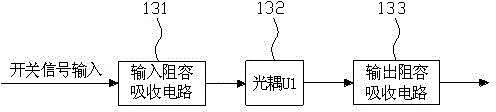

Superaudio large-power quenching numerical control machine tool energy parameter and technological parameter management device

InactiveCN104834268AReasonable structural designGuaranteed stabilityNumerical controlElectricityNumerical control

The invention relates to a superaudio large-power quenching numerical control machine tool energy parameter and technological parameter management device, comprising a switching value preprocessing unit, an analog quantity preprocessing unit, a first controller, a second controller, and an input / output unit. The switching value preprocessing unit is electrically connected with the first controller, and the switching value preprocessing unit comprises a switching value input module and a switching value output module. The analog quantity preprocessing unit is electrically connected with the first controller, and the analog quantity preprocessing unit comprises an analog quantity input module and an analog quantity output module. The first controller is connected with the second controller through an RS232 interface, so as to realize startup, stop, remote control, close control, data input, and data storage. The input / output unit comprises an LCD module, a keyboard input module, and a key input module. The device is reasonable in structure and design, good in anti-interference capability, and ensures technological parameter and stability of energy parameters, and improves energy efficiency, operation intelligence, and reliability of part quenching numerical control integrated equipment.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

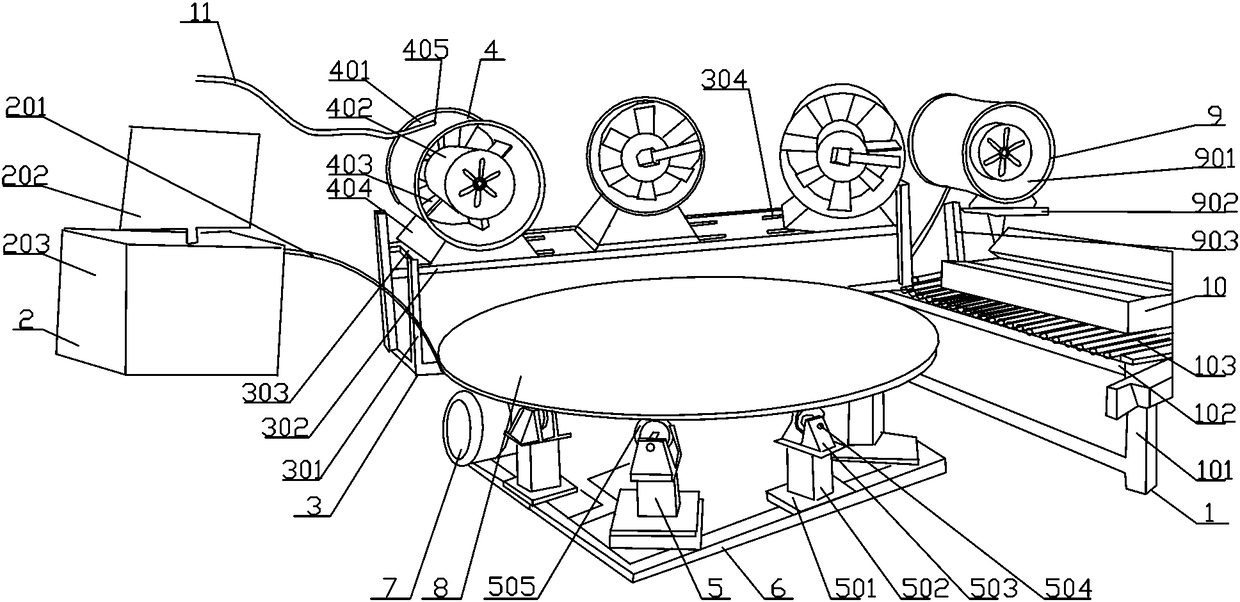

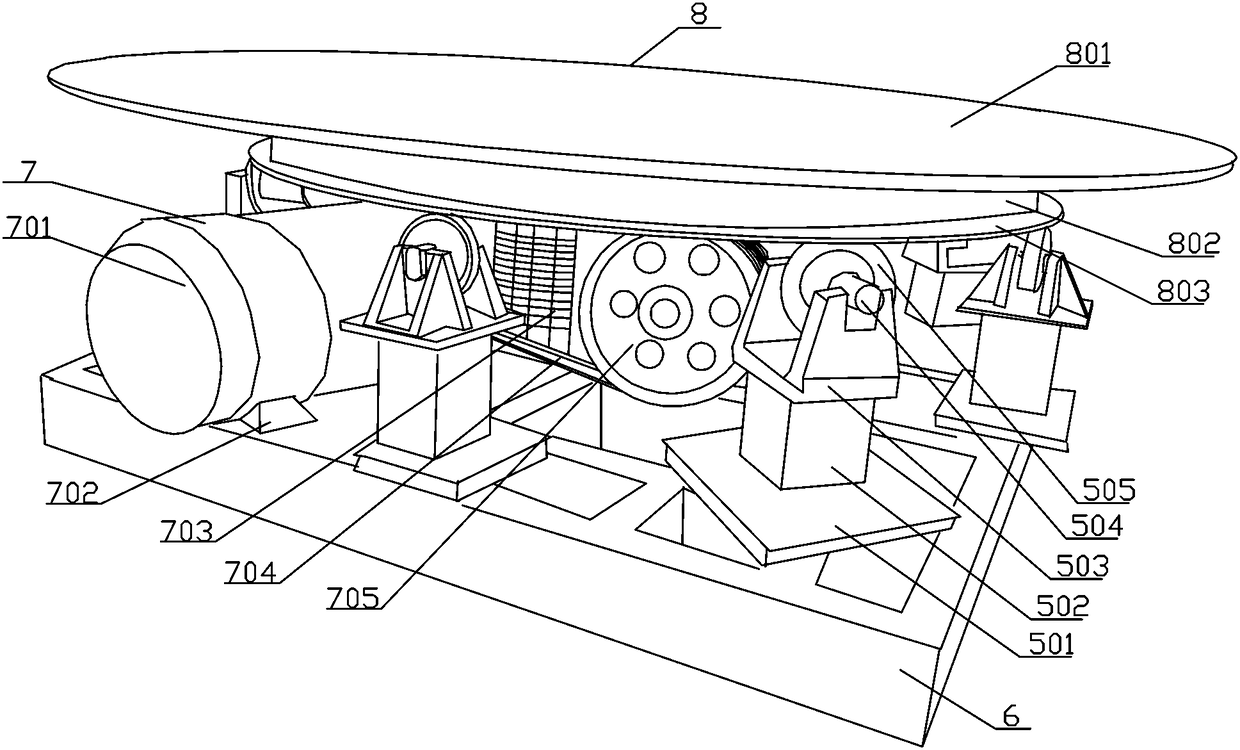

Rotary spraying quenching device and rotary spraying quenching method for high-chromium wear-resistant iron castings

PendingCN108396122AImprove quenching efficiencyGuarantee the quality of quenchingHeat treatment process controlQuenching devicesWear resistancePower apparatus

The invention provides a rotary spraying quenching device and a rotary spraying quenching method for high-chromium wear-resistant iron castings. The rotary spraying quenching device comprises a base,wherein a plurality of rotary disc support assemblies are arranged at the top of the base in a manner of uniform distribution, a rotary disc device is supported at the top of each rotary disc supportassembly, and each rotary disc device is connected with a rotary power device at the bottom of the rotary disc device, and drives the rotary disc device to rotate; and a first support frame device isarranged on the side surface of each rotary disc device, a plurality of spraying devices used for spraying are adjustably installed at the top of each first support frame device, and are connected with a water source through a water supply pipe. The equipment is capable of realizing an integrated quenching technique process for the high-chromium castings, replaces the traditional manual quenchingcontrol manner, and then increases the working efficiency and optimizes the quenching technique process; and meanwhile, the quality of the castings is greatly improved, the rate of unqualified products is lowered, and the surface wear resistance of the high-chromium castings is greatly improved.

Owner:CHINA THREE GORGES UNIV

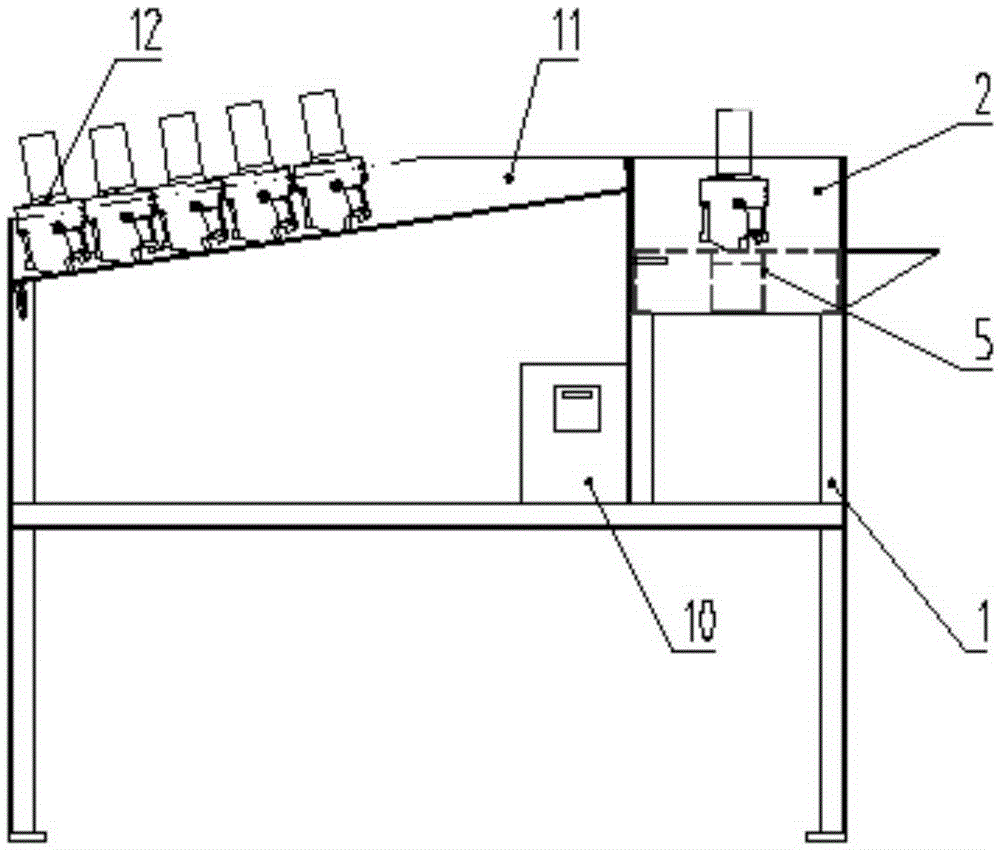

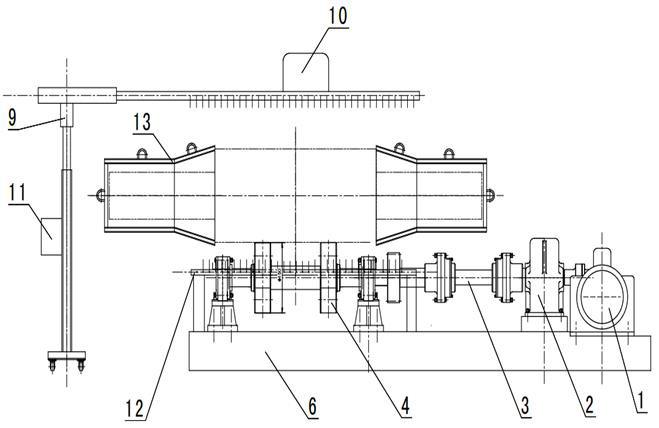

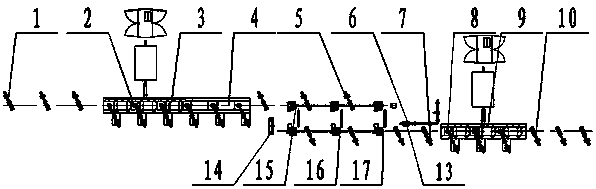

Shaft materials quenching method and device therefor

InactiveCN1966738AGuarantee the quality of quenchingReduce oxidation and decarburizationFurnace typesIncreasing energy efficiencyControl systemIntermediate frequency

The invention discloses a method for quenching shafts, which is induction-heated with intermediate frequency and quenched in quenchant. A material pushing device, a placing board, an outleting device and a turning device is fixed sequentially on the benchboard of the equipment for quenching. A quenching box is fixed under the benchboard. A transmission chain is close to one end of the turning device. The inferior part of the transmission chain is in the quenching box. The transmission chain is driven by the drive system. The responding device is connected with intermediate frequency power, pushing device, sensing device, reversing device,quenching box and drive system are connected with adaptive control system. The method is easy to operate and can guarantee product quality.

Owner:河南中轴集团有限公司

Automatic quenching oil cooling system

InactiveCN109207686AGuaranteed cooling effectGuarantee the quality of quenchingQuenching agentsQuenching devicesQuenchingFuel tank

The invention relates to the field of workpiece quenching processes, in particular to an automatic quenching oil cooling system which is provided with an oil storage tank with an opening in the upperend. The oil storage tank is connected with a cooling circulation device in the tank and a cooling circulation device outside the tank; the cooling circulation device in the tank is provided with a temporary oil storage tank; a pumping pipe A and a discharging pipe A communicate between the temporary oil storage tank and the oil storage tank; a pumping pump A is arranged on a pipe body of the pumping pipe A; the cooling circulation device outside the tank is provided with a cooling water tank and a pumping pipe B; a pipe body of the pumping pipe B is located on the outer part of the oil storage tank; a part of pipe body stretches into the cooling water tank; and a pumping pump B is arranged on the pumping pipe B. According to the automatic quenching oil cooling system provided by the invention, an active cooling mode is adopted, and heated quenching liquid is actively pumped into the cooling water tank, so that a cooling effect is ensured, the problem that a traditional cooling pipeline occupies the volume in the oil storage tank is avoided, and the automatic quenching oil cooling system has a favorable application prospect.

Owner:湖北博英精工科技股份有限公司

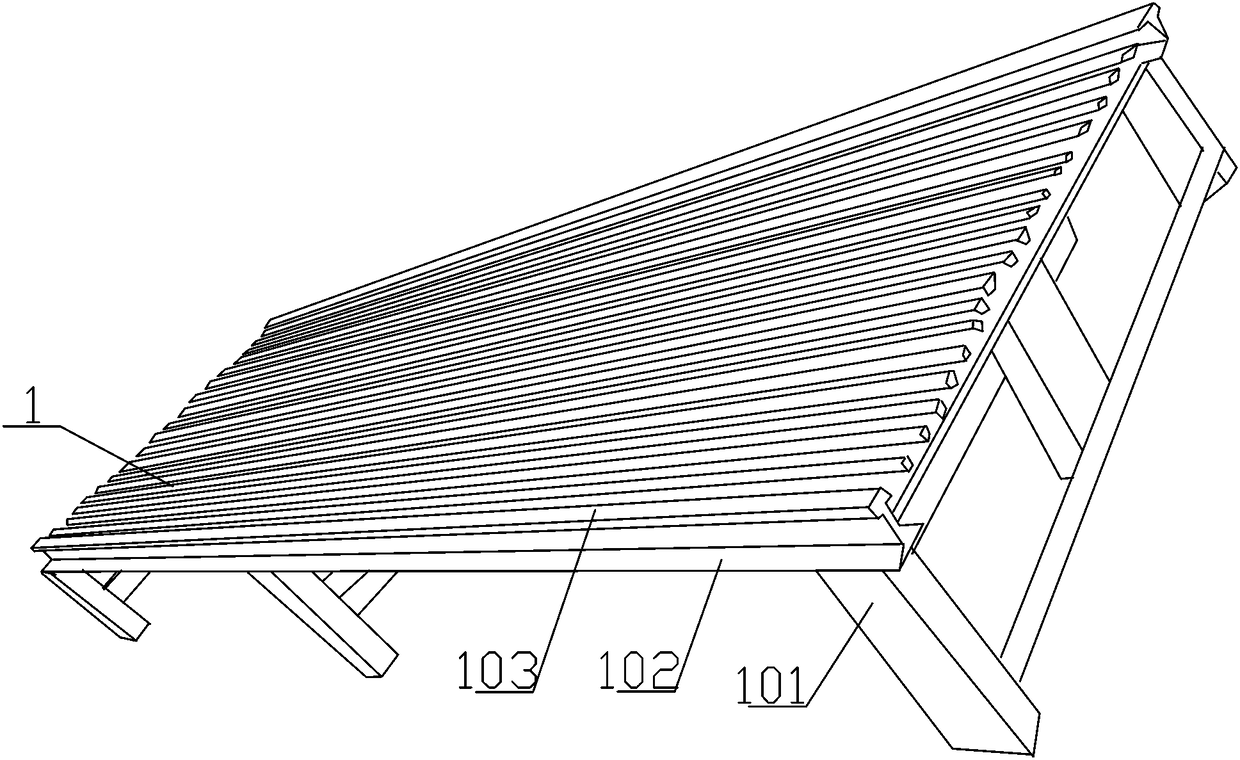

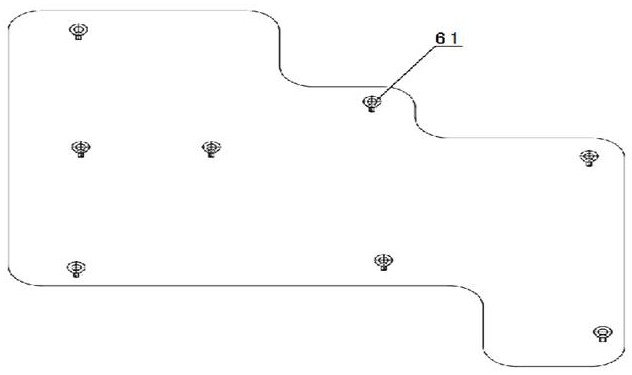

Small roller and roller sleeve quenching treatment device and heat treatment method

PendingCN112481475AReduce investmentSolve the small spaceFurnace typesHeat treatment process controlThermodynamicsOpen air

The invention relates to the technical field of machining and manufacturing of small rollers and roller sleeves, and relates to a portable small quenching device used for conducting spray quenching heat treatment outdoors or in a temporary field after the small rollers and the roller sleeves are roughly turned and formed, and a corresponding heat treatment method using the device. The quenching treatment device and the heat treatment method are complete in system, complete in function, convenient and reliable to operate, small in capital investment and quick in effect, and the problems that anexisting plant space is narrow and an existing place is endowed with multiple purposes can be solved; or the heat treatment operation is conducted in the open air and outdoors, under the condition that facilities, such as a quenching device and a quenching pool, are not fixed, all components can be combined on an irregular bottom plate, operation is achieved through a crown block or a crane withthe weight being 5 tons or above, only needed quenching liquid or gas needs to be prepared in advance, and through switching of the quenching device, the small rollers or the roller sleeves are rotated on the quenching device at a constant speed, and therefore any combined quenching mode integrating liquid, wind and air can be met, and the quenching quality of the small rollers or the roller sleeves is ensured.

Owner:甘肃酒钢集团西部重工股份有限公司

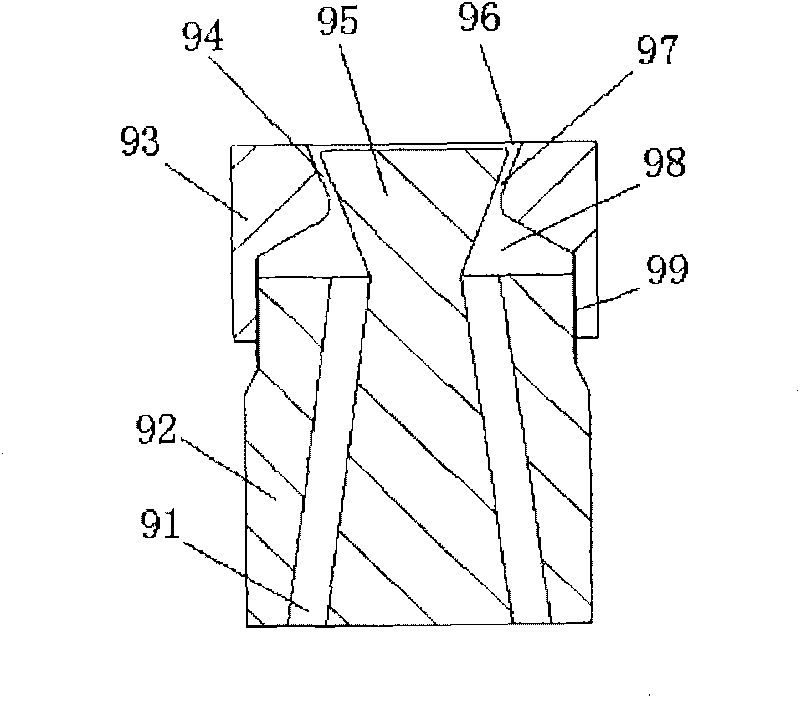

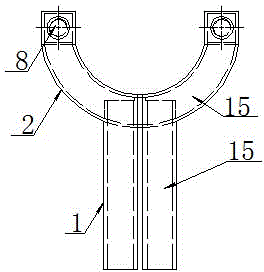

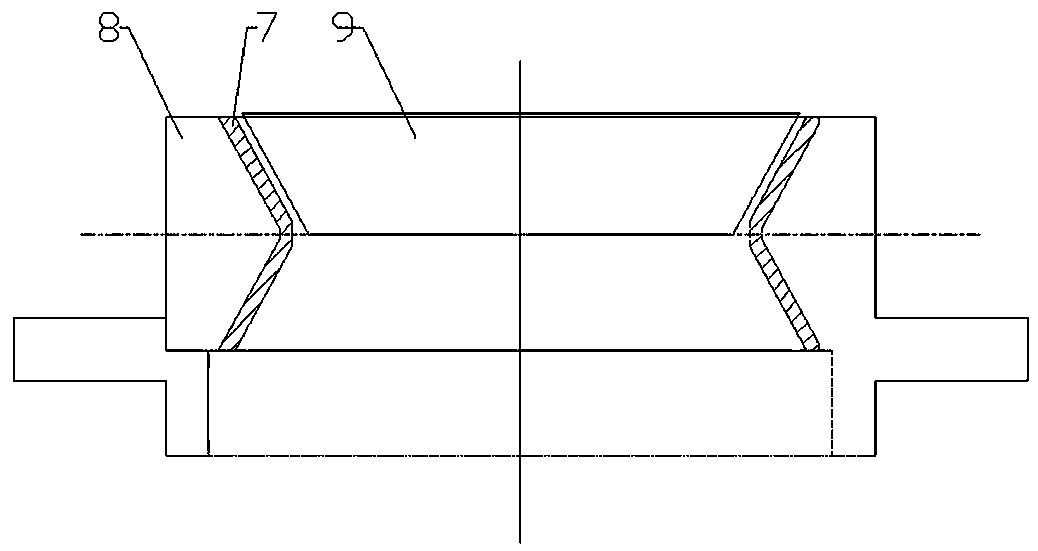

Inner hole quenching inductor for dual-conical-surface bearing sleeve ring

InactiveCN108796183ASimple processReduce manufacturing costIncreasing energy efficiencyFurnace typesTransformerInductor

The invention discloses an inner hole quenching inductor for a dual-conical-surface bearing sleeve ring. The inner hole quenching inductor comprises a quenching transformer, a bus bar and a water spray box, wherein the front end of the bus bar is connected with the quenching transformer; the water spray box is fixedly fixed at the tail end of the bus bar; an upper arc-shaped effective ring and a lower arc-shaped effective ring are arranged at the tail end of the bus bar; magnetizers are arranged on the upper arc-shaped effective ring and the lower arc-shaped effective ring; and the upper arc-shaped effective ring and the lower arc-shaped effective ring are separately used for heating upper and lower conical surfaces of the bearing inner ring. The inner hole quenching inductor adopts two fan-shaped inductors which are arranged up and down to complete quenching of upper and lower conical surfaces of the bearing inner ring once, so that the process is simplified, the production cost is reduced, and quenching quality is guaranteed.

Owner:刘斯年

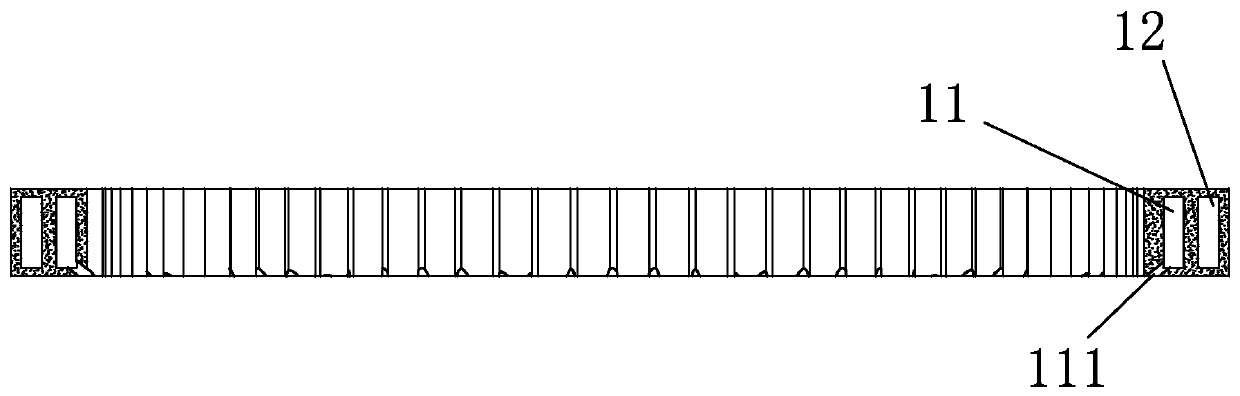

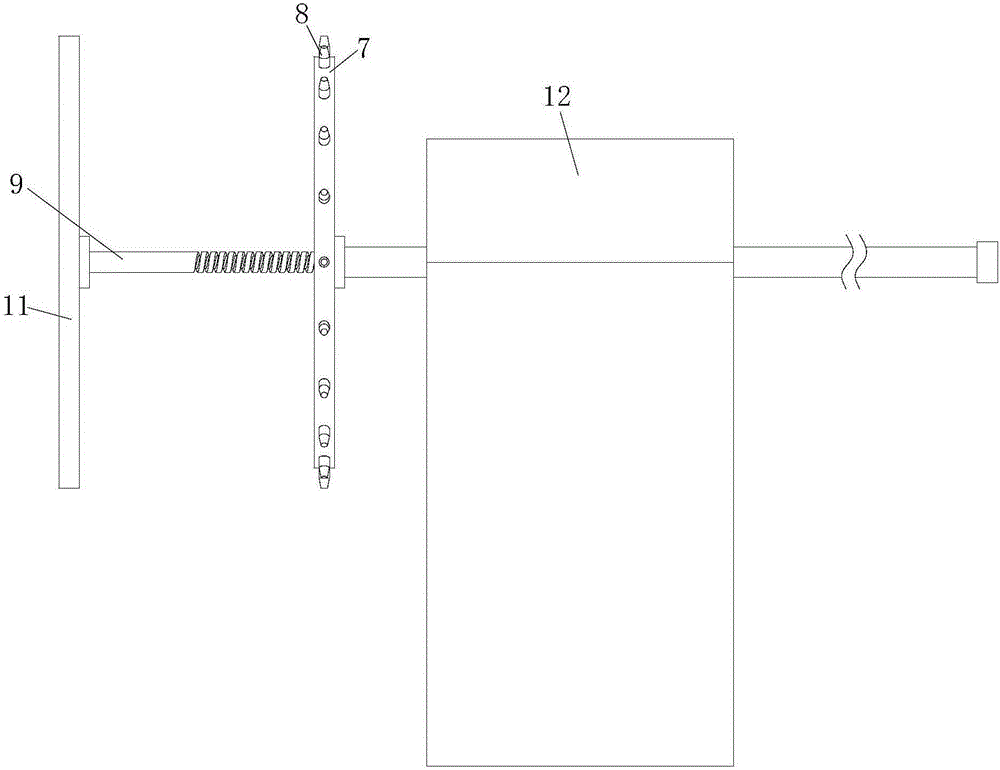

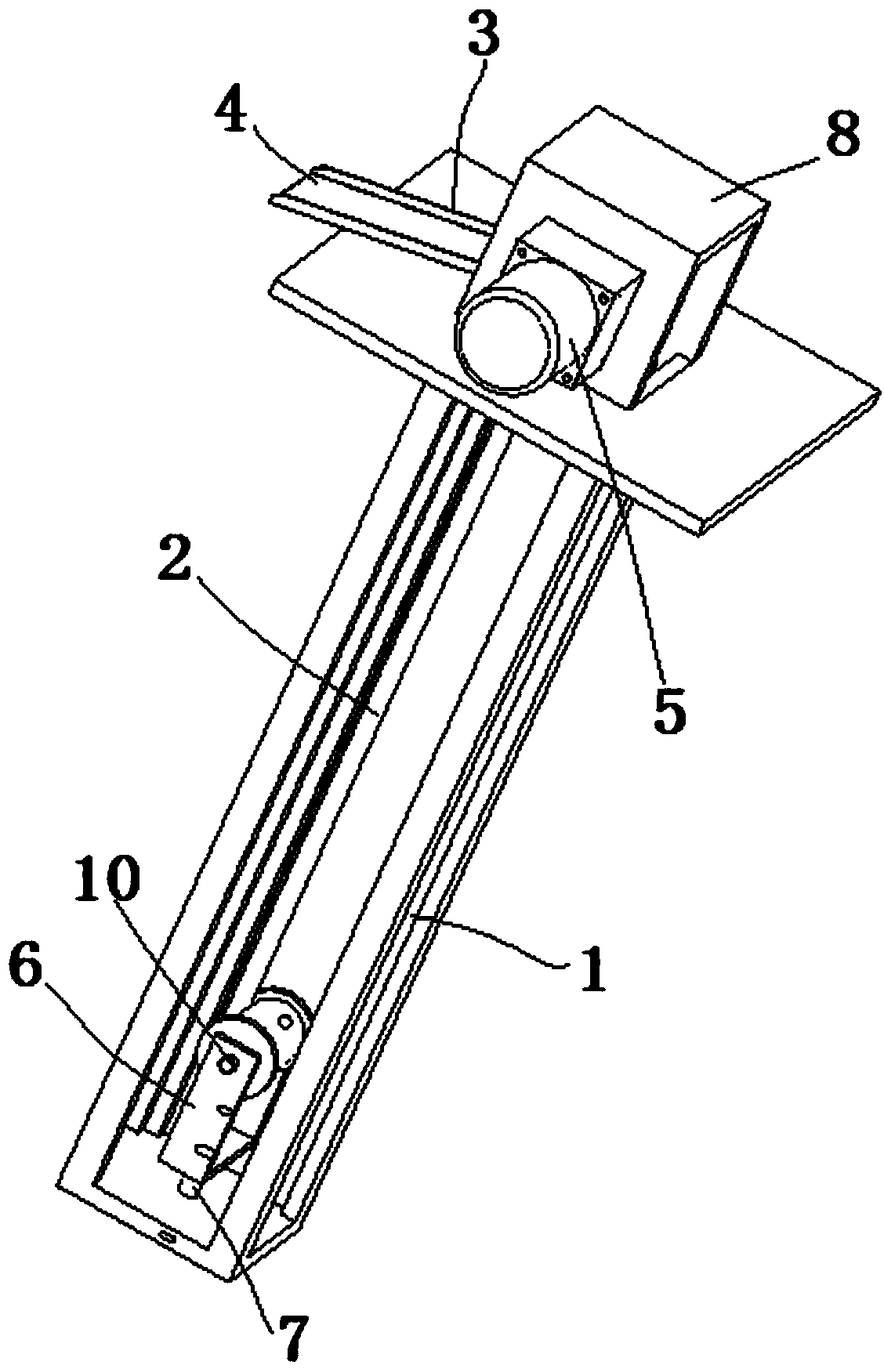

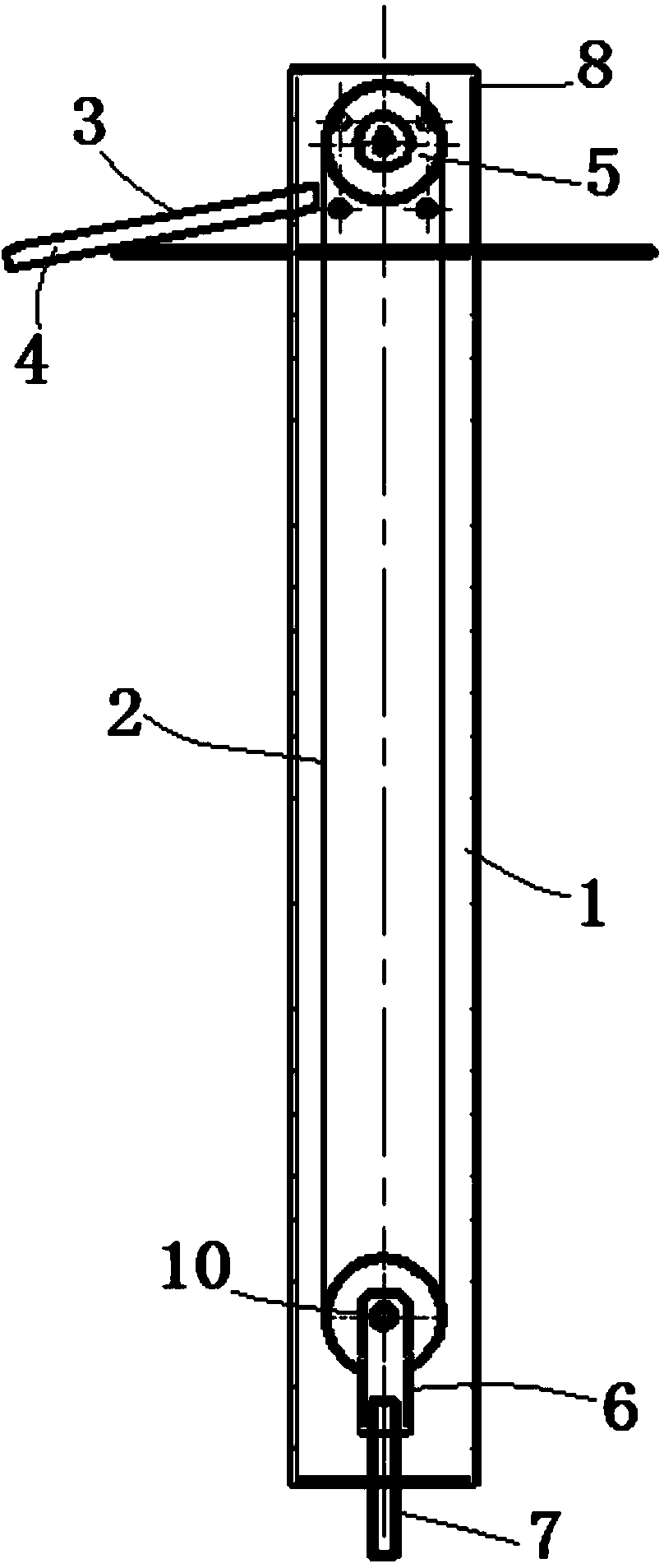

Long pipe inner wall quenching device

InactiveCN105177241ARealize quenchingGuarantee the quality of quenchingFurnace typesHeat treatment furnacesIntermediate frequencyArchitectural engineering

The invention discloses a long pipe inner wall quenching device which comprises a supporting frame. An installation plate is fixed to the upper end of the supporting frame and provided with a supporting base. A sliding rod is arranged in the supporting base. A first annular fixing frame is fixed to the outer wall at the left end of the sliding rod. Spray heads are evenly arranged on the outer ring of the first annular fixing frame. A threaded hole is formed in the left end of the sliding rod. A threaded rod is fixed in the threaded hole in a threaded connection manner. A second annular fixing frame is fixed to the left end of the threaded rod. An intermediate-frequency heater is fixed to the outer ring of the second annular fixing frame. The long pipe inner wall quenching device has the beneficial effects of being reasonable in structural design, low in production and manufacturing cost, convenient to use and the like, achieves quenching for the inner walls of pipes, and ensures the quenching quality of the inner walls of the pipes; and meanwhile the threaded rod design is adopted, and the distance between the intermediate-frequency heater and the spray heads can be adjusted according to technological requirements, so that the quenching efficiency of the device is improved, the production cost is saved, and production efficiency is improved.

Owner:安徽旭虹机械设备有限公司

Alloy steel bearing block machining method beneficial to reduction of heat treatment induced cracks

InactiveCN104195308AImprove toughnessImprove performanceFurnace typesHeat treatment furnacesMo elementQuenching

The invention discloses an alloy steel bearing block machining method beneficial to the reduction of heat treatment induced cracks and used for manufacturing alloy steel bearing blocks containing Cr, Ni and Mo elements. The machining method comprises the following steps of casting, heat treatment, reference plane machining, hole machining and connecting bolt hole making which are sequentially carried out, wherein the heat treatment process comprises the steps of quenching and tempering, a way of heating in stages is adopted in the quenching process, and the cooling step in the quenching process is realized in a way of air cooling after furnace cooling. The machining method is simple in process route and beneficial to quality improvement of the alloy steel bearing block and increment of machining efficiency.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Anti-clogging rod of furnace cover air outlet pipe of tiltable drum-type resistor rotary furnace

ActiveCN102829623AAvoid cloggingGuarantee the quality of quenchingFurnace componentsRotary drum furnacesKeroseneEngineering

The invention relates to an anti-clogging rod of a furnace cover air outlet pipe of a tiltable drum-type resistor rotary furnace. The tiltable drum-type resistor rotary furnace comprises a furnace body, an inner container mounted in the middle of the furnace body, a cylindrical furnace cover connected with the inner container, and the cylindrical furnace cover air outlet pipe designed in the middle of the cylindrical furnace cover, and the anti-clogging rod of the furnace cover air outlet pipe is characterized in that the anti-clogging rod is movably mounted in the middle of the furnace cover air outlet pipe in a penetrating manner; both ends of the anti-clogging rod extend to the outside of two ports at the two ends of the furnace cover air outlet pipe; at the two ends of the anti-clogging rod extending to the outside of the two ports at the two ends of the furnace cover air outlet pipe, the anti-clogging rod is bended to form bended bars with a certain angle, so that the anti-clogging rod can not slip out of the furnace cover air outlet pipe; the anti-clogging rod is made of high-temperature-resistant round steel; and the diameter of the anti-clogging rod is no more than one third the inner diameter of the furnace cover air outlet pipe. By adopting the anti-clogging rod provided by the invention, the furnace cover air outlet pipe can be prevented from being clogged, so that kerosene added to the tiltable drum-type resistor rotary furnace can normally and sufficiently burn, a quenching piece in the tiltable drum-type resistor rotary furnace can reach a set quenching temperature, and thus the quenching quality of the quenching piece can be ensured.

Owner:新浪爱拓设备(江苏)有限公司

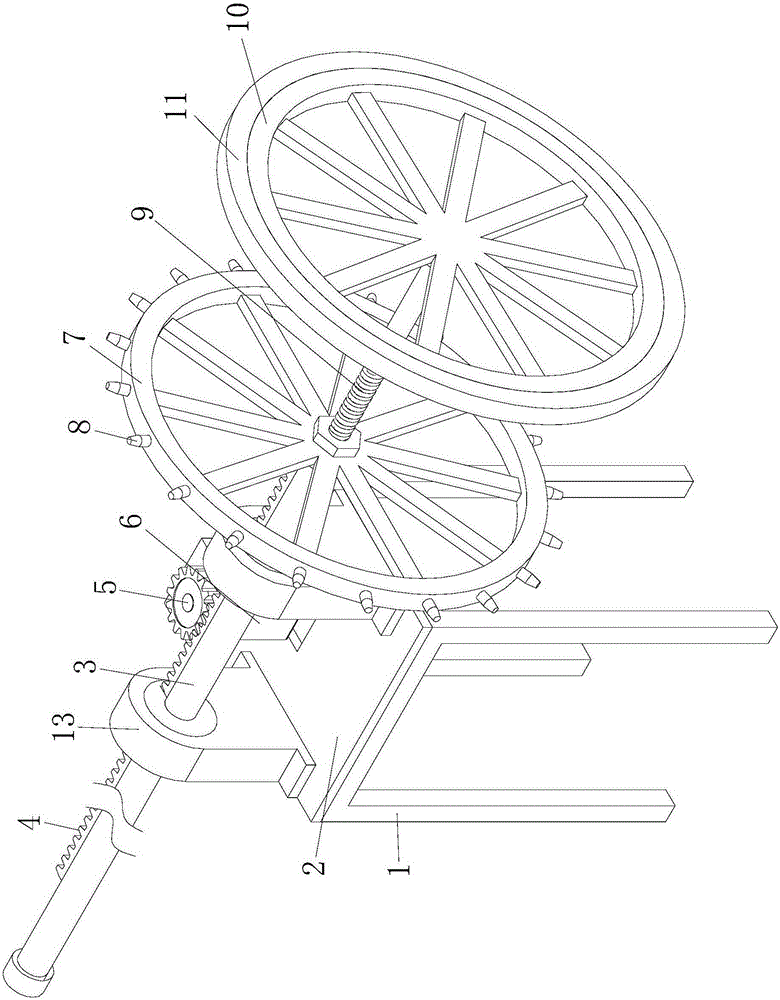

Wheel body quenching device and method

ActiveCN107385170AGuarantee the quality of quenchingHigh hardnessFurnace typesHeat treatment furnacesBall bearingEngineering

The invention discloses a wheel body quenching device and method and belongs to the field of wheel body machining. The wheel body quenching device comprises a machine tool and a motor and is characterized by further comprising a fixed shaft, a movable shaft, bearings, a bearing seat, water spraying rings and a gear; the bearings comprise the sliding bearing and the one-way flat bottom thrust ball bearing; the sliding bearing is arranged between the inner wall of the movable shaft and the outer wall of the fixed shaft; the bearing seat is fixed to the machine tool; the gear is connected to the outer wall of the movable shaft in a sleeving mode and connected with the motor; the outer wall of the fixed shaft is sleeved with the one-way flat bottom thrust ball bearing; a quenching tray is arranged at the front end of the movable shaft; the front end of the fixed shaft is sleeved with the inner water spring ring; and the outer water spring rings are arranged on the machine tool. The outer diameter and the inner diameter of a wheel body are quenched simultaneously. The hardness of the core part and the inner diameter face of alloy steel, especially carbon steel, is well enhanced, the hardness uniformity of the core part and the inner diameter face of the alloy steel, especially the carbon steel, is well improved, and a good effect is achieved. Through rotating of the wheel body, the outer water spraying rings and the inner water spraying ring keep static water spraying, relative movement between the outer diameter face of the wheel body and the water spraying rings as well as between the inner diameter face of the wheel body and the water spraying rings is achieved, and quenching uniformity is guaranteed.

Owner:陕西奥尔德机械有限公司

Motor vacuum startup system and motor vacuum startup method

PendingCN108282112AAvoid burningGuarantee the quality of quenchingStarter detailsVacuum furnaceThermal treatment

The invention provides a motor vacuum startup system and a motor vacuum startup method and belongs to the technical field of metal thermal treatment equipment. The motor vacuum startup system comprises a motor and a gas supply device; the motor has an inner cavity; the gas supply device is communicated with an inner cavity; the gas supply device is used for supplying gas to the inner cavity. The motor vacuum startup system may ensure quick startup for the motor such that forceful cooling gas in a vacuum furnace is subjected to heat exchanging. In addition, the startup failure of the motor dueto the influence that the inside of the vacuum furnace is vacuum is avoided, and therefore, quenching quality is effectively ensured for a workpiece in the vacuum furnace.

Owner:江苏石川岛丰东真空技术有限公司

Device and method for removing oil stain in high-frequency quenching liquid for steering gear

InactiveCN104313269AEasy to installIncrease profitLiquid separationQuenching devicesFixed framePulp and paper industry

The invention discloses a device and method for removing oil stain in high-frequency quenching liquid for a steering gear. The device comprises a fixed frame and a conveying belt which is immersed into the quenching liquid; a scraping plate for scraping oil stain on the conveying belt is arranged on the fixed frame; one end of the scraping plate for scraping the oil stain is positioned on the outer side of the conveying belt, and the other end of the scraping plate is an oil stain output end; a belt wheel at one end of the conveying belt is connected with a motor fixed on the fixed frame; a belt wheel at the other end of the conveying belt is connected with the fixed frame through a belt tightness adjusting mechanism; in the method for removing oil stain, the oil stain in the quenching liquid is removed by using the device for removing oil stain in high-frequency quenching liquid for the steering gear; through the adoption of the device and the method disclosed by the invention, the automatic removing of the oil stain in the quenching liquid is achieved, so that the labor cost is reduced and the utilization rate of the quenching liquid is increased; the purity of the quenching liquid and the quenching quality are both guaranteed.

Owner:WUHU STERLING STEERING SYST

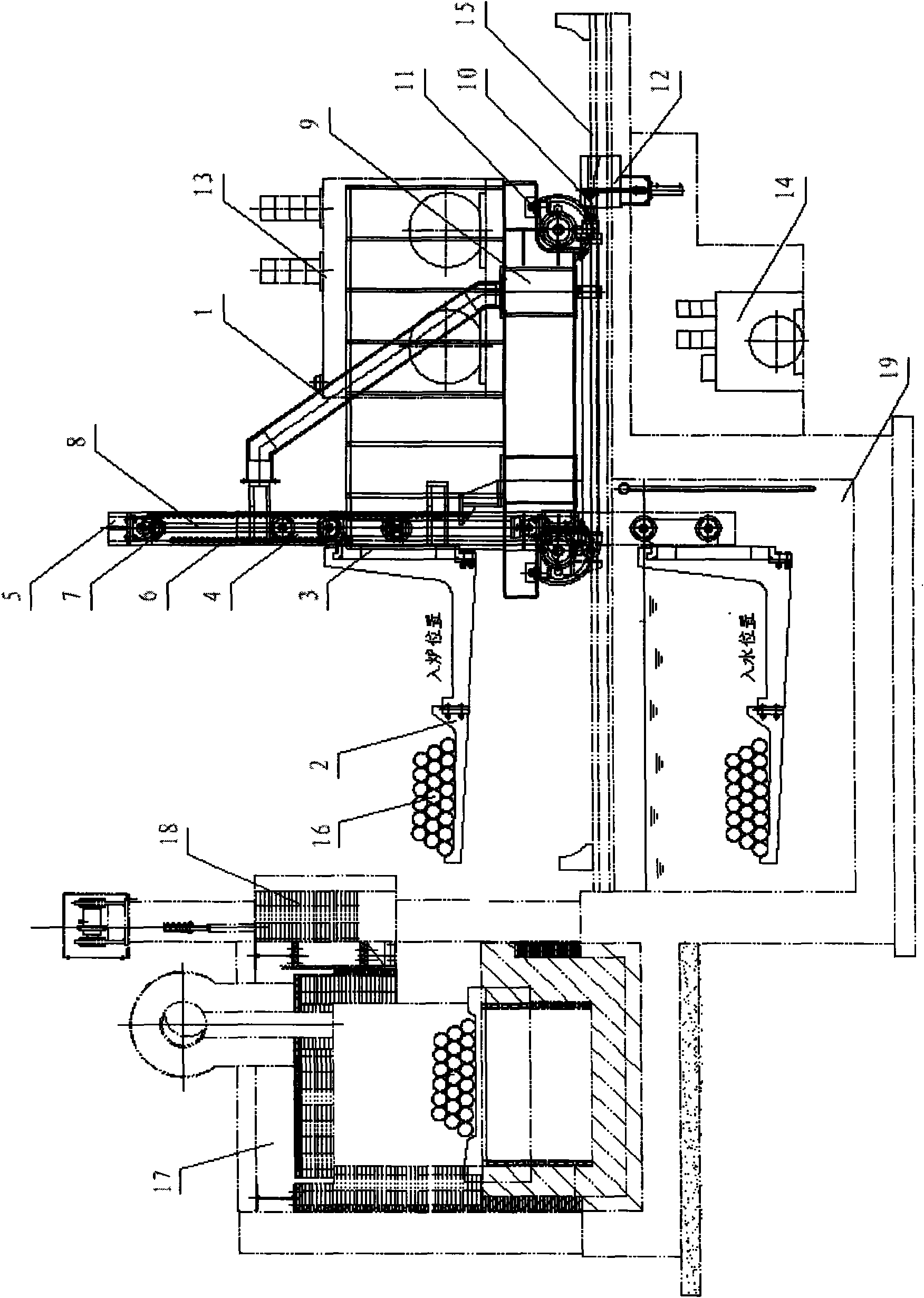

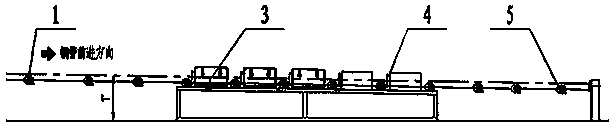

Passing type steel pipe hardening and tempering production line and application method thereof

PendingCN108048630AGuarantee the quality of quenchingImprove working environmentFurnace typesHeat treatment furnacesSputteringProduction line

The invention relates to a passing type steel pipe hardening and tempering production line and an application method thereof. The production line comprises a furnace entering roller way of a quenchingfurnace, a quenching roller way, the quenching furnace, an annular quenching device, a furnace discharging roller way of the quenching furnace, a water blowing device, a furnace entering roller way of a tempering furnace, a tempering roller way, the tempering furnace and a furnace discharging roller way of the tempering furnace, wherein a steel pipe is conveyed into the quenching furnace throughthe furnace entering roller way of the quenching furnace, and is heated in the quenching furnace; the annular quenching device performs quenching; then, the steel pipe is output from the furnace discharging roller way of the tempering furnace; the water blowing device dries the cooling water on the surface of the steel pipe through blowing and then performs tempering through being conveyed into the tempering furnace to be tempered from the furnace entering roller way of the quenching furnace and the tempering roller way; the steel pipe is then output from the furnace discharging roller way ofthe tempering furnace. The production line has the advantages that the structure is simple; the investment cost is low; the occupied area is small; the furnace entering roller way of the quenching furnace, the quenching roller way, the quenching furnace and the furnace discharging roller way of the quenching furnace are in inclined arrangement in a way of forming an angle being 1 degree; a spray nozzle of the annular quenching device and the steel pipe operation direction are respectively inclined for 5 degrees; quenching water sputtering and backflow into the quenching furnace can be prevented; the quenching furnace is protected; the steel pipe quenching quality is ensured.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Nodular cast iron grinding ball quenching device

InactiveCN111074057AGuarantee the quality of quenchingSo as not to damageFurnace typesHeat treatment furnacesEngineeringAir compressor

The invention belongs to the technical field of grinding ball heat treatment, and particularly relates to a nodular cast iron grinding ball quenching device. The nodular cast iron grinding ball quenching device comprises a water box, and the side wall of the water box is symmetrically and fixedly provided with servo motors; screws are fixed to the ends of output shafts of the servo motors, the surfaces of the screws are in threaded connection with slide blocks, and a rectangular block is fixed between the two slide blocks; and the top end of each rectangular block is provided with downward through holes at equal intervals in the length direction of the rectangular block, and the bottoms of the through holes are provided with first spray pipes at equal intervals in the circumferential direction of the through holes. According to the nodular cast iron grinding ball quenching device, by arranging an air compressor and the first spray pipes, high-speed gas is sprayed out from the first spray pipes, thus, grinding balls are in a suspension state under action of the high-speed gas, accordingly, the grinding balls are uniformly cooled in the process of making contact with air and water, the problem that heat transfer is uneven due to the fact that the grinding balls make contact with parts, and the quenching quality of the grinding balls is ensured.

Owner:汪彬彬

Quenching device for tooth surface of chain wheel

ActiveCN102251081BReduce labor intensitySimple structureFurnace typesIncreasing energy efficiencyMedial axisReduction drive

The invention relates to a quenching device for a tooth surface of a chain wheel, and the quenching device comprises a support, wherein a horizontal shaft is fixed on the top of the support through a bearing seat, and one end of the horizontal shaft is connected with an elevation motor through an elevation speed reducer; a cooling box with an opened top part is arranged below the support, two sliding chutes are symmetrically formed on both sides inside the cooling box, two ends of the a support plate are clamped in the two sliding chutes, the lower end of a steel rope wrapped around the horizontal shaft is fixedly connected with the support plate, a chain wheel shaft is vertically arranged on the supporting plate, the chain wheel shaft is connected with one end of an intermediate shaft through a first conical gear set, the other end of the intermediate shaft is connected with the vertical shaft of a key groove through a second conical gear set, and the upper end of the vertical shaft of the key groove is connected with a chain wheel rotation motor through a chain wheel rotation speed reducer; and a heating ring is arranged at the upper part, corresponding to the chain wheel shaft,of the cooling box, and the heating ring is connected with a heating device arranged at one side of the cooling box. The quenching device provided by the invention is convenient to use, has short production process, and can be used for reducing the labor intensity, saving time and labor, ensuring the quenching quality and increasing the production efficiency.

Owner:山东开泰工业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com