Anti-clogging rod of furnace cover air outlet pipe of tiltable drum-type resistor rotary furnace

An anti-blocking and gas outlet pipe technology, which is applied to rotary drum furnaces, furnaces, furnace components, etc., can solve problems such as blockage of gas outlet pipes of furnace cover, failure to reach quenching temperature, and affecting quenching quality of quenched parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

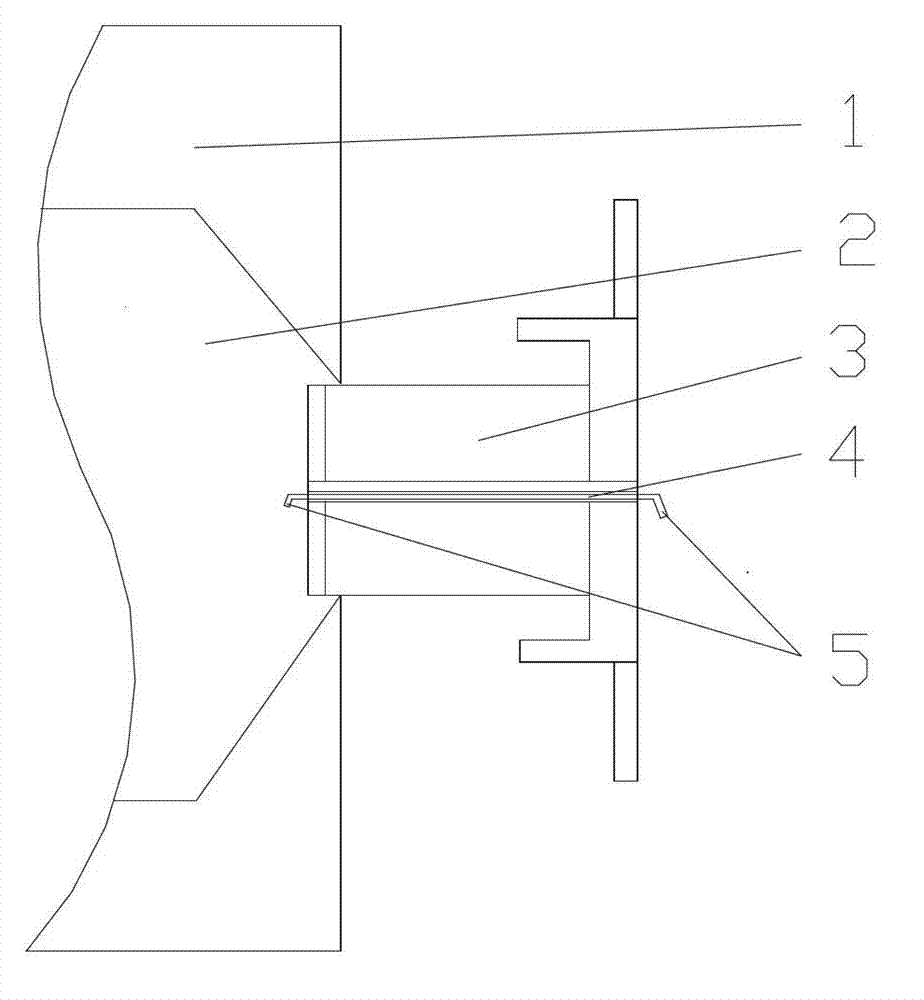

[0012] Such as figure 1 The shown embodiment is as follows: a kind of anti-blocking rod of the gas outlet pipe of the furnace cover of the tilting drum type electric resistance rotary furnace. The tilting drum resistance rotary furnace includes a furnace body 1 . The liner 2 that is contained in the middle of body of heater 1. A cylindrical furnace cover 3 connected with the inner tank 2. A cylindrical furnace cover gas outlet pipe 4 is designed in the middle of the cylindrical furnace cover 3 . It is characterized in that an anti-blocking rod 5 is movably worn in the middle of the furnace cover outlet pipe 4 . This anti-clogging rod 5 two ends all stretch out outside the port at two ends of the furnace cover air outlet pipe 4. Anti-clogging rod 5 stretches out the two ends anti-clogging rods outside the port of furnace cover gas outlet pipe 4 two ends and bends out the curved rod 6 that has certain angle and makes anti-clogging rod 5 can not slide out from furnace lid gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com