Shaft materials quenching method and device therefor

A technology of equipment and quenching box, applied in the field of quenching, which can solve the problems of increased temperature of shaft material, uneven cooling, difficult to produce products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment: The quenching method of the present invention is as follows: the shaft material is heated in an induction device connected with an intermediate frequency power supply first, and the heated shaft material is quenched in a quenching medium. According to the size of the outer diameter of the shaft material, the heating time is controlled. The heating time of the shaft material with an outer diameter of 15-30mm is 1-3 minutes, and the heating time of the shaft material with an outer diameter of 31-50mm can be 4-5 minutes. The heating time of 80mm shaft material can be 6-8 minutes.

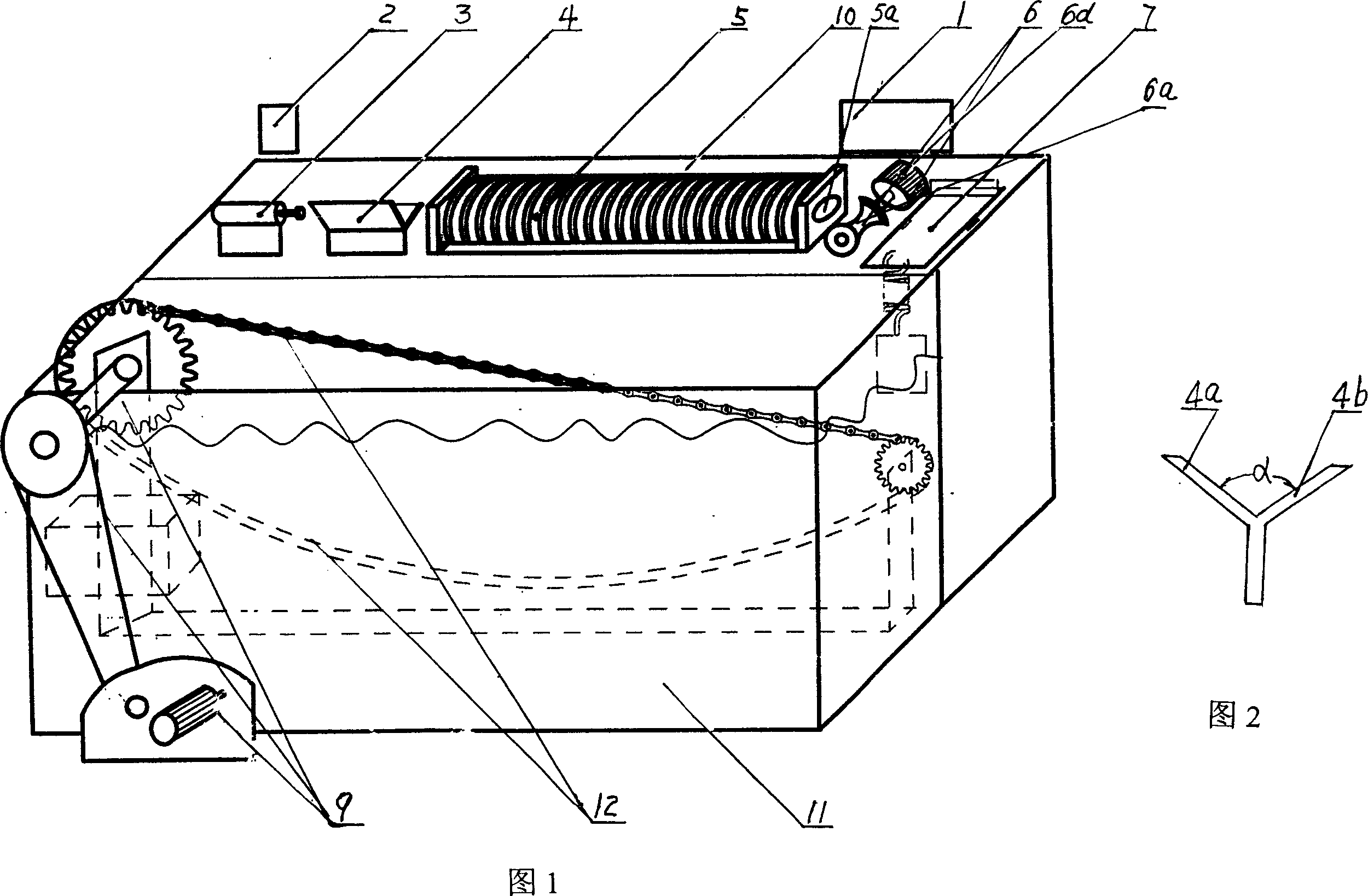

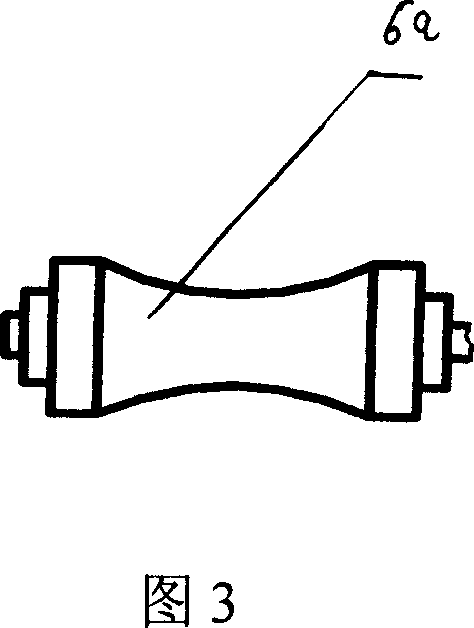

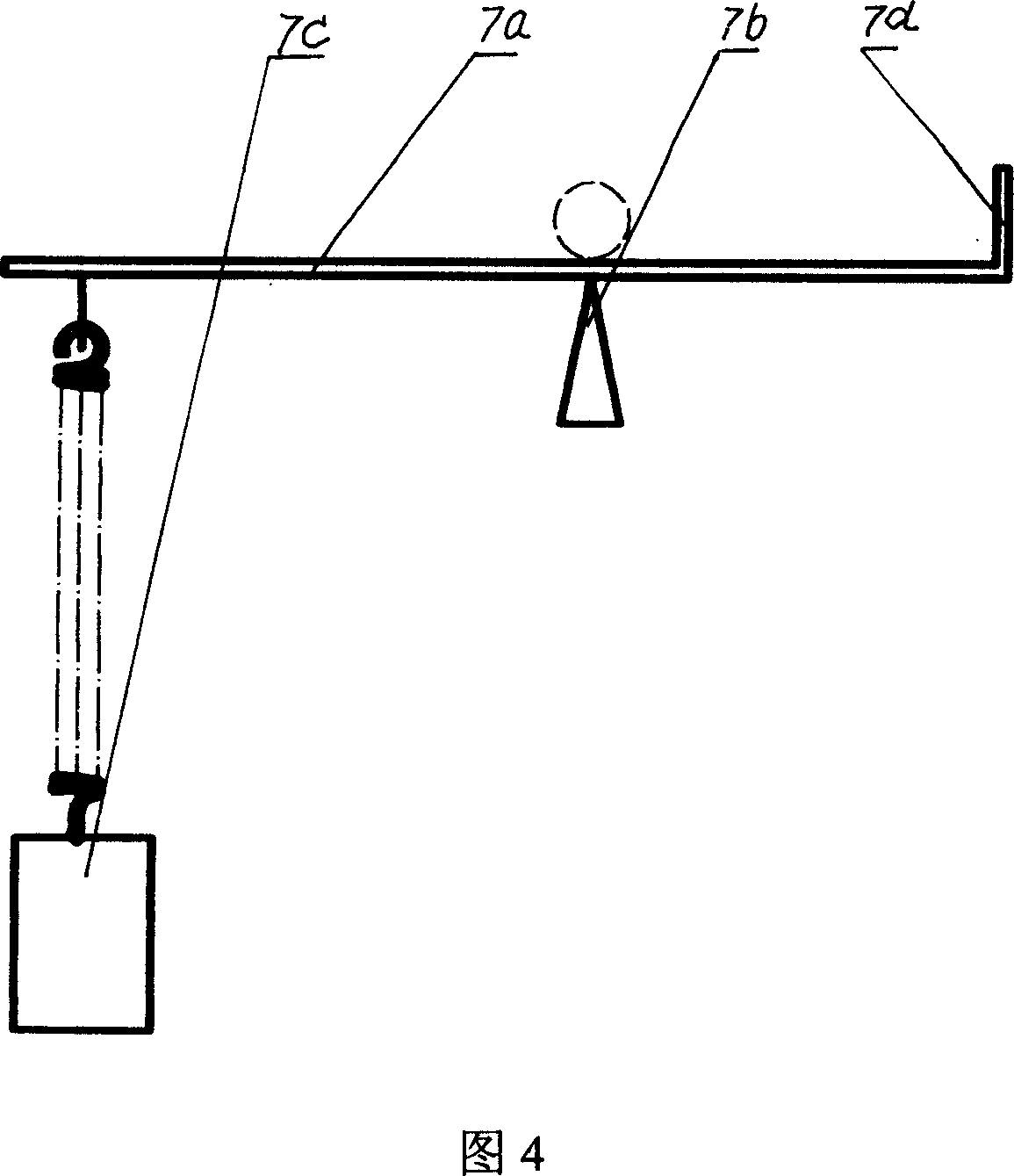

[0019] Using this method to quench the shaft material should use special equipment, this equipment includes intermediate frequency power supply 1, automatic control system 2, transmission system 9 and workbench 10, on the workbench 10 is equipped with pusher device 3, discharge material in sequence Table 4, induction device 5, discharge device 6 and material turning device 7, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com