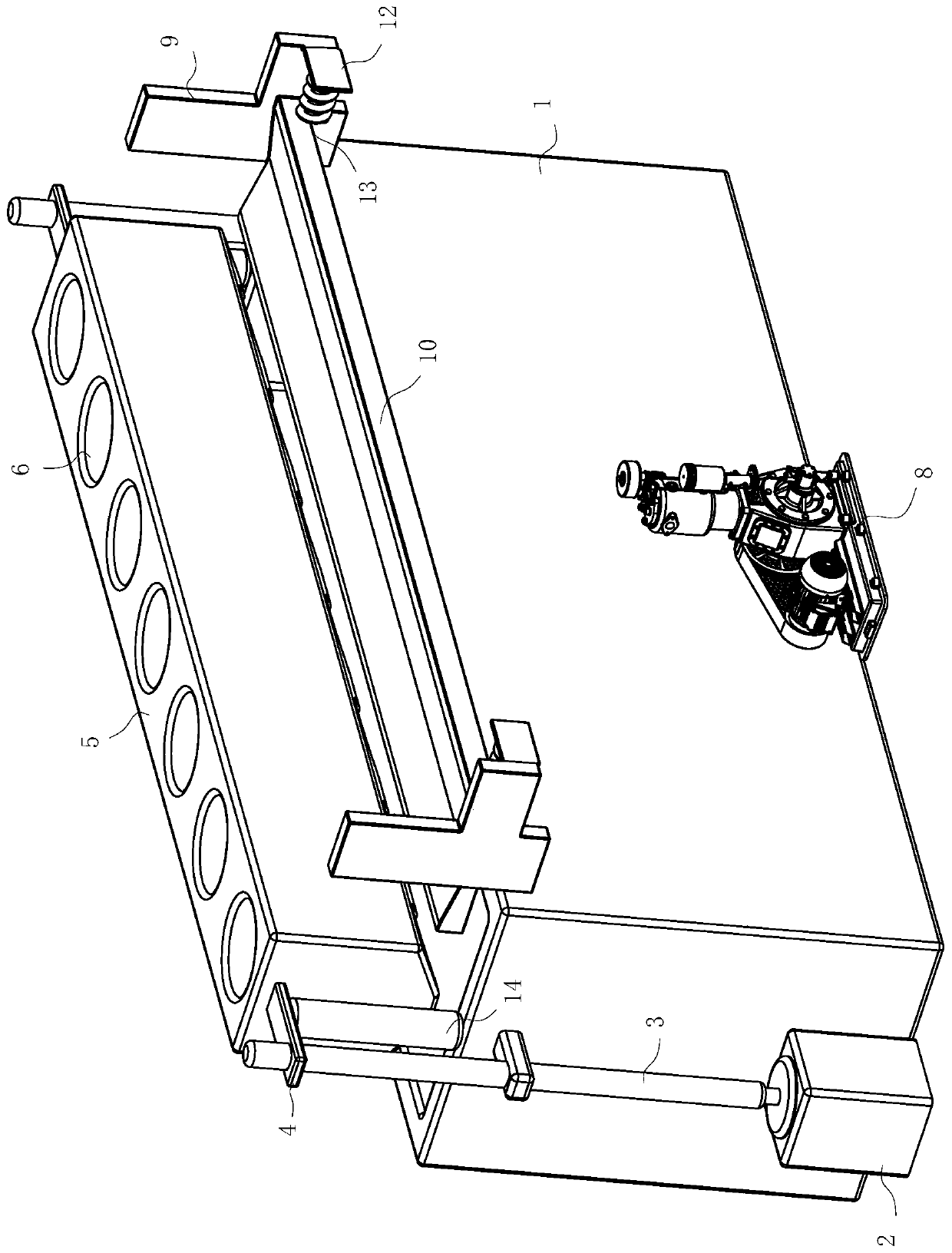

Nodular cast iron grinding ball quenching device

A quenching device and ductile iron technology, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of large surface area, uneven surface hardness of grinding balls, uneven surface cooling of grinding balls, etc., to ensure quenching efficiency and improve performance. , to avoid the effect of uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

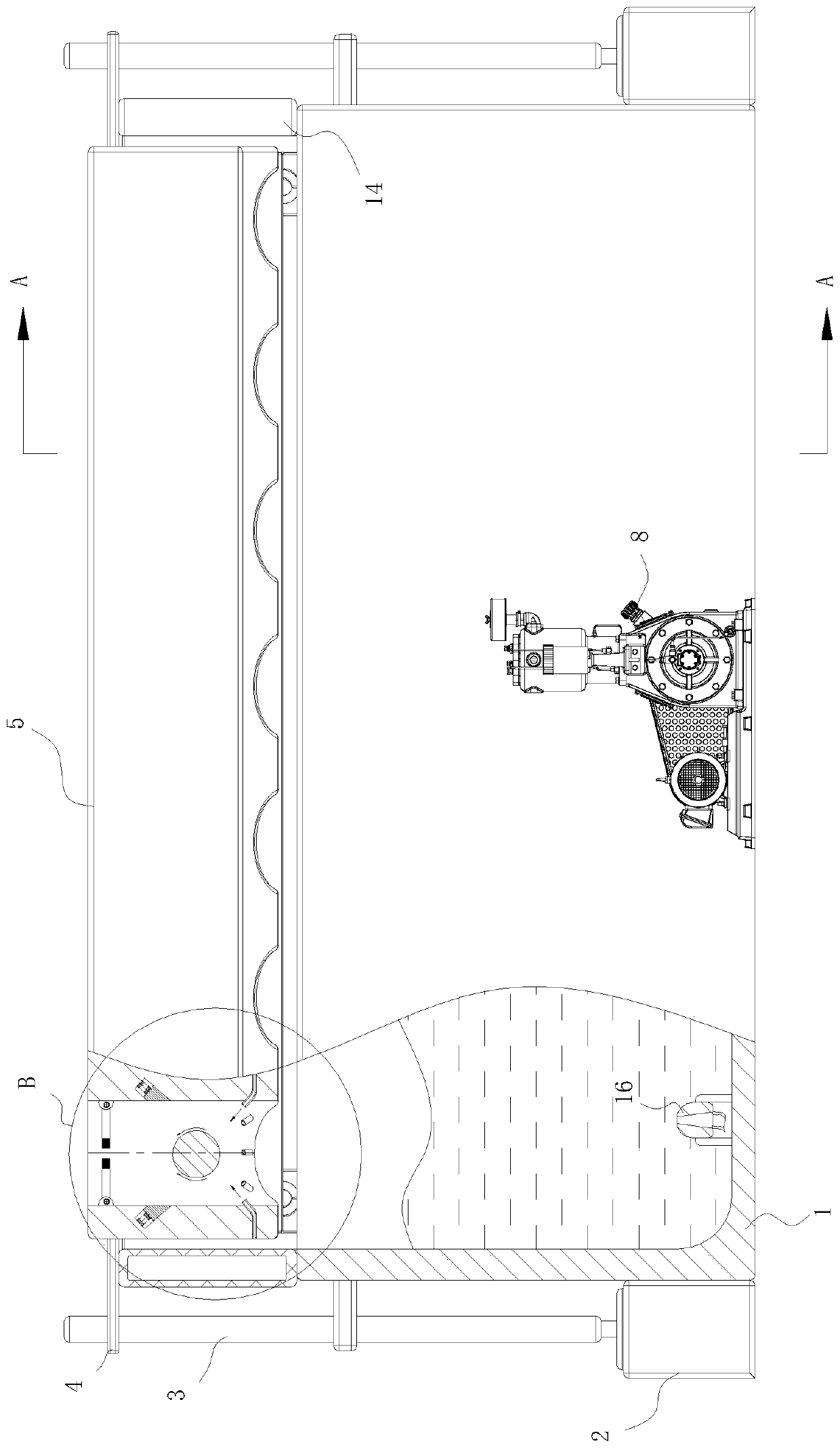

Method used

Image

Examples

Embodiment approach

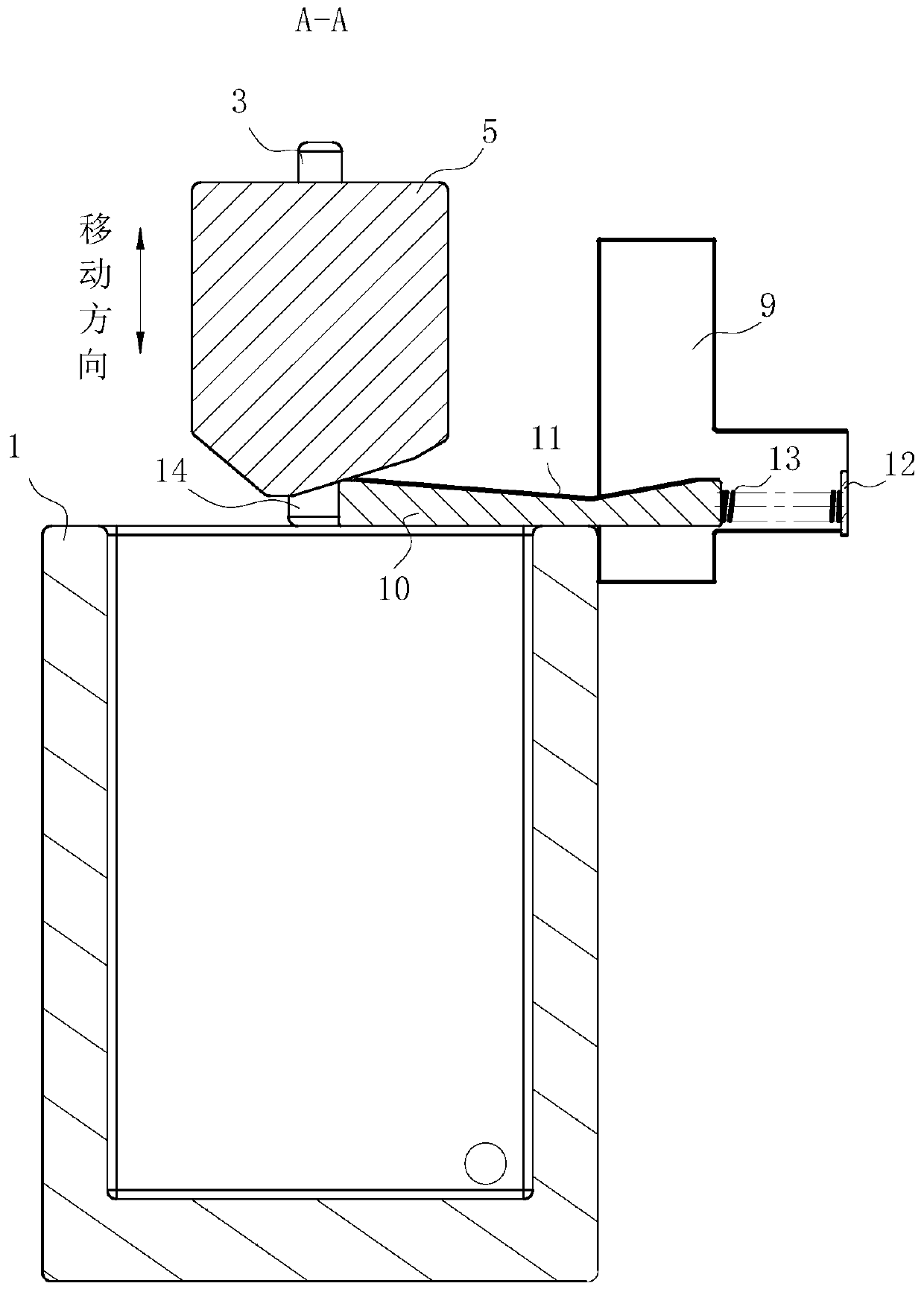

[0033] As a specific embodiment of the present invention, the output end of the second nozzle 15 is inclined in a direction away from the water tank 1, and the included angle between the axis of the second nozzle 15 and the axis of the through hole 6 is 70°~80°, during operation, if the output end of the second nozzle 15 is facing the grinding ball, it will easily cause the gas thrust to be too large, which will cause the position of the grinding ball to shift greatly, which will cause the floatation of the grinding ball to fail; The deflection angle of the No. 2 nozzle 15 is set to 70°~80° so that the gas ejected from the No. 2 nozzle 15 is tangent to the edge of the grinding ball, so that the grinding ball will not shift while rotating, ensuring that The normal floating of the grinding ball.

[0034] As a specific embodiment of the present invention, the bottom end of the inner cavity of the water tank 1 is arranged with more than two nozzles 16 along its length. The nozzles 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com