Passing type steel pipe hardening and tempering production line and application method thereof

A production line and steel pipe technology, applied in the field of pass-through steel pipe quenching and tempering production line, can solve the problems of backflow to the quenching furnace and quenching water splash, and achieve the effect of protecting personnel safety, ensuring quenching quality, and good working environment for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

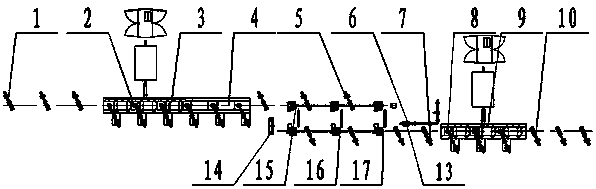

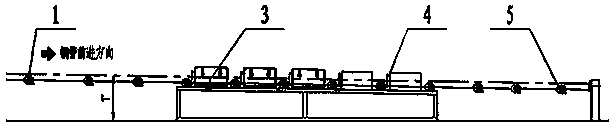

[0026] This embodiment provides a figure 1 , figure 2 and image 3 The through-type steel pipe quenching and tempering production line shown includes a quenching furnace 3 and a tempering furnace 9. The quenching furnace 3 is laid along a straight line from the entrance to the exit. 5. A pass-through annular quenching device 4 is installed on the quenching roller table 2, and a water blowing device 6 is installed at the 5 place of the quenching furnace exit roller table; Fire roller table 8, tempering furnace discharge roller table 10.

[0027] The working process of the through-type steel pipe quenching and tempering production line is as follows:

[0028] The steel pipe is transported to the quenching furnace 3 through the quenching furnace entering roller table 1, transported by the quenching roller table 2 to the quenching furnace 3 for heating, and quenched by the ring quenching device 4, and then the steel pipe is output from the quenching furnace by the roller table...

Embodiment 2

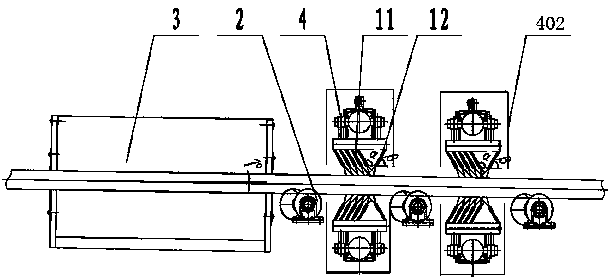

[0030] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, the through-type annular quenching device 4 includes a water spray ring 401, a frame 404 and a conveying roller table 403 driven by a motor. The water spray ring 401 is vertically installed on the frame 404, and the conveying roller table 403 is perpendicular to the spraying roller The central axis of the water ring 401 is placed on the ground, and the conveying roller table 403 is located below the central axis of the water spray ring 401. The water spray ring 401 includes a water supply pipe 4011, which is an annular steel pipe, and several The branch pipe 4010 communicated with the annular steel pipe, the branch pipe 4010 is vertically connected to the swing arm 409, one end of the swing arm is driven by the power unit 4012, and the other end is connected to the nozzle main pipe 408, and several nozzles 407 are installed at the end of the nozzle main pipe 408.

[0031] The working process of passin...

Embodiment 3

[0035] On the basis of Embodiment 2, the through-type annular quenching device 4 also includes a machine cover 402 that is covered on the water spray ring 401 to prevent the quenching water from splashing everywhere, and the frame 404 and the machine cover 402 cover the water spray ring together to prevent The quenching water is splashed everywhere; the lower surface of the frame 404 is perforated and the deflector 4014 is welded to guide the quenching water. A water tank 406 is arranged below the deflector 4014, and the quenching water is introduced into the water tank 406. The bottom of the frame 404 is installed with a lifting guide device 405 that drives its lifting. It should be noted that the lifting guide device 405 is an existing structure. As a preference, the present embodiment selects an oil cylinder or an electric push rod, and the lifting guide device 405 drives Frame 404 is integrally lifted, so that the water spray ring, the machine cover and the frame are lifted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com