Wheel body quenching device and method

A technology of quenching device and wheel body, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of prolonging water spraying time, reducing production efficiency, excess quality, etc., and achieving the effect of ensuring uniformity and quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

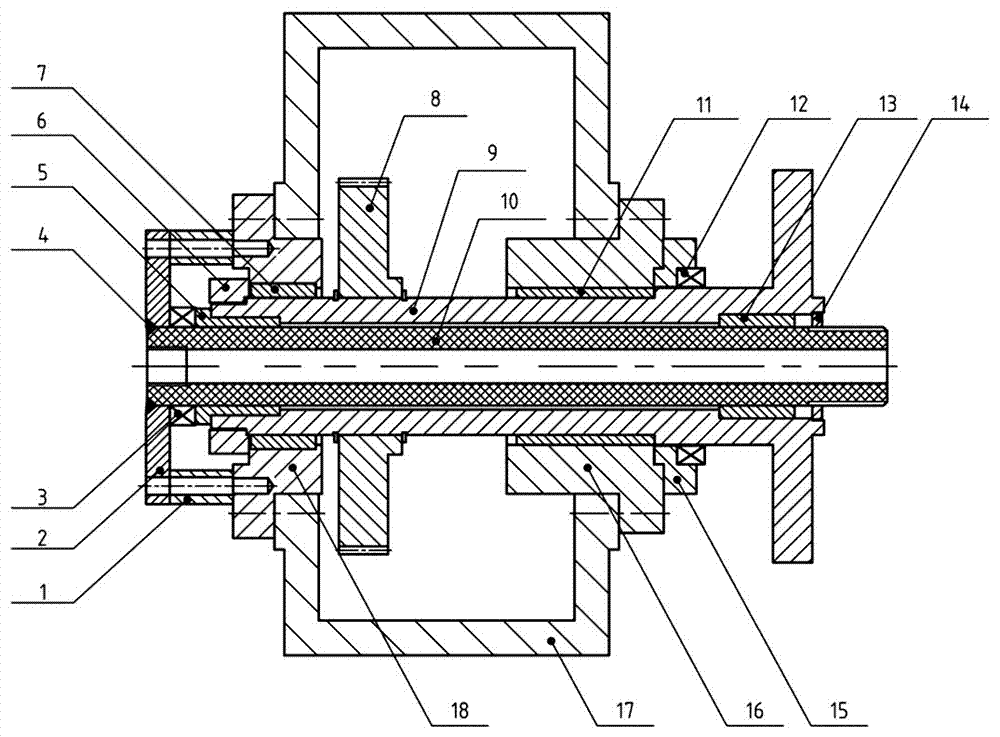

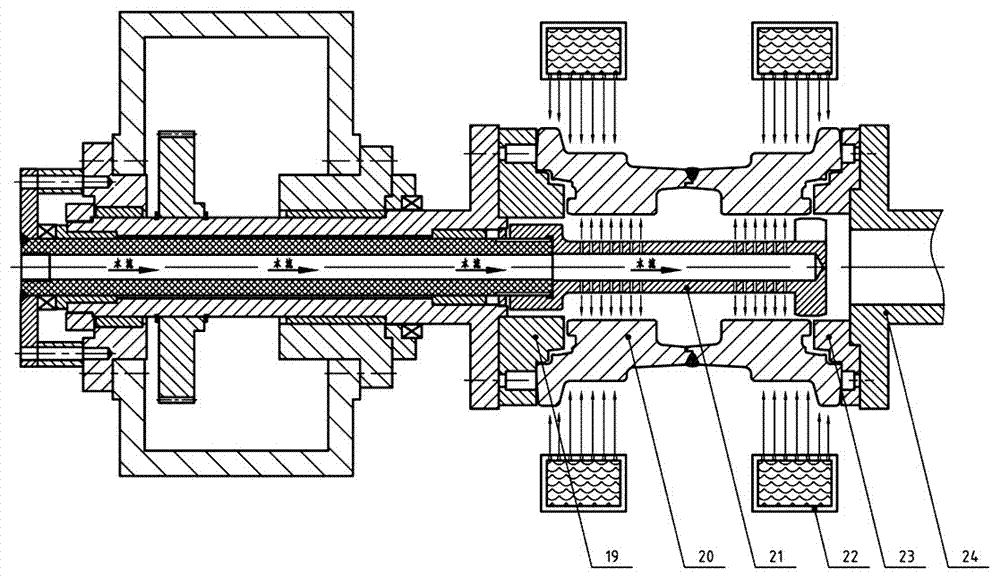

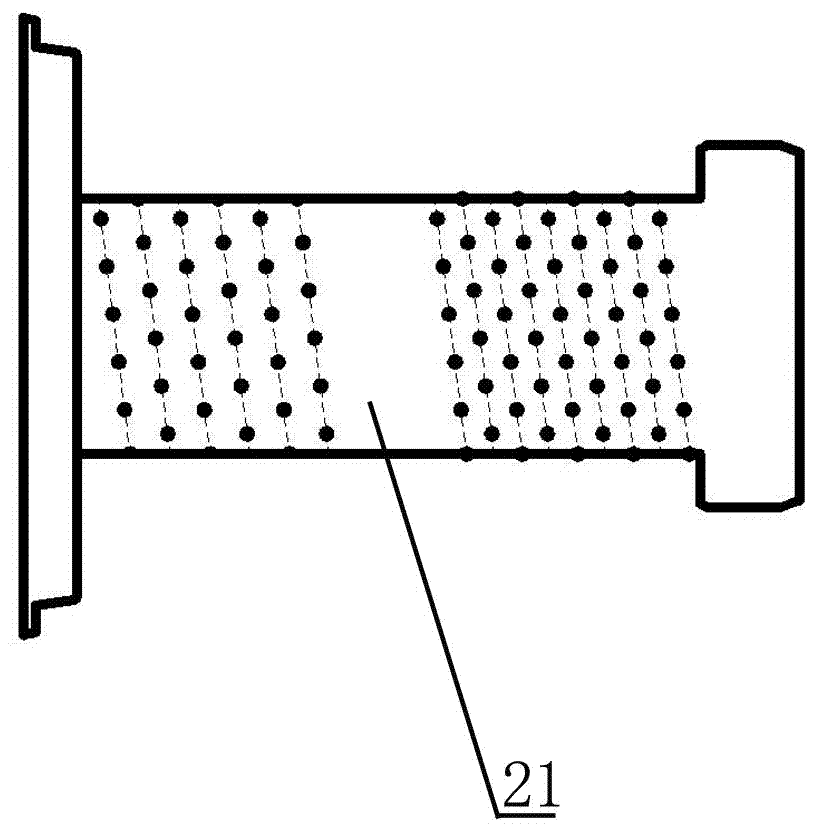

[0026] Such as figure 1 , figure 2 As shown, the wheel body 20 quenching device of the present invention includes a machine tool and a motor; the machine tool is equipped with a cylinder and a manipulator; it also includes a fixed shaft 10, a moving shaft 9, a bearing, a bearing seat, a water spray ring and a gear 8; Bearings include sliding bearings and one-way flat-bottomed thrust ball bearings 3; the fixed shaft 10 is a hollow tube; the moving shaft 9 is a hollow tube, and the moving shaft 9 is sleeved on the fixed shaft 10; A sliding bearing is arranged between the inner wall of the moving shaft 9 and the outer wall of the fixed shaft 10; the moving shaft 9 is sleeved in the bearing seat, and a sliding bearing is arranged between the outer wall of the moving shaft 9 and the bearing seat; the bearing seat passes through the box The body 17 is fixed on the machine tool; the gear 8 is sleeved on the outer wall of the moving shaft 9 and electrically connected to the motor; t...

Embodiment 2

[0035] On the basis of Example 1, this implementation takes VOLVO supporting wheel EC210 (medium carbon alloy steel, 45# supporting wheel) as an example, parameter setting: heating temperature and heat preservation in the quenching furnace (roller hearth quenching furnace) Time, quenching temperature 840±10℃; holding time 2h±10min; feeding cycle 5min; water spray pressure 0.5~0.8Mpa; flow rate: outer surface 20~25m 3 / h; inner diameter surface 0.8~1.2m 3 / h; pre-cooling and quenching pre-cooling time on the inner diameter surface: 15-17S; water spraying time on the outer diameter surface: 65-70S; water spraying time on the inner diameter surface: 25-30S. Since the water spray on the outer diameter surface and the inner diameter surface can be controlled separately, the quenching of the medium carbon steel (poor hardenability) wheel body 20 not only meets the requirements for the hardness of the outer diameter surface (HRC48~62) and the depth of the hardened layer, but also req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com