Gear induction quenching equipment and technology

An induction hardening equipment and induction hardening technology are applied in the field of metal surface hardening, which can solve the problems of low production efficiency, poor profiling effect of gear induction hardening technology, and high cost of induction dual-frequency hardening equipment, so as to reduce equipment cost and equipment purchase Cost, the effect of optimizing the hardened layer distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

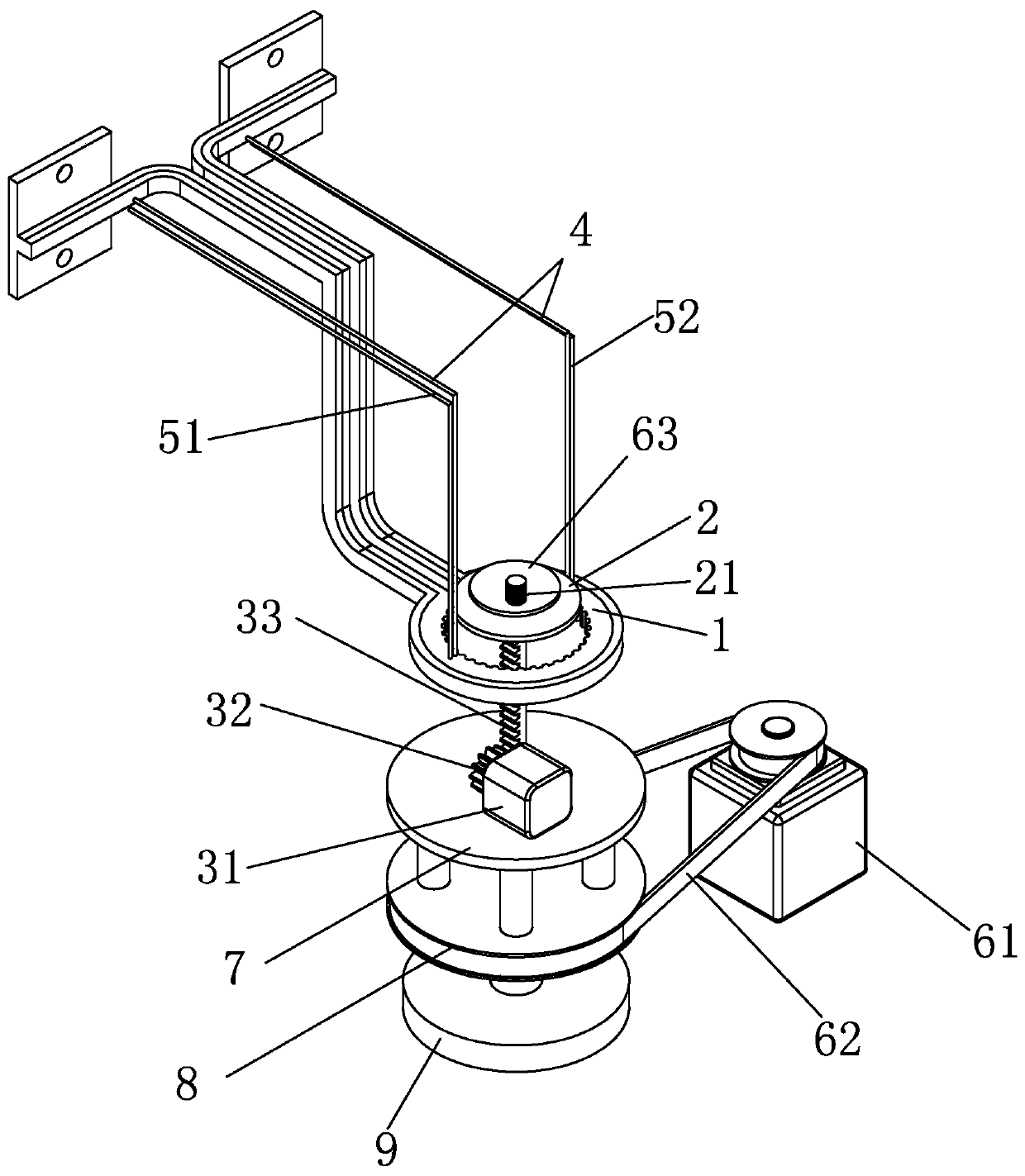

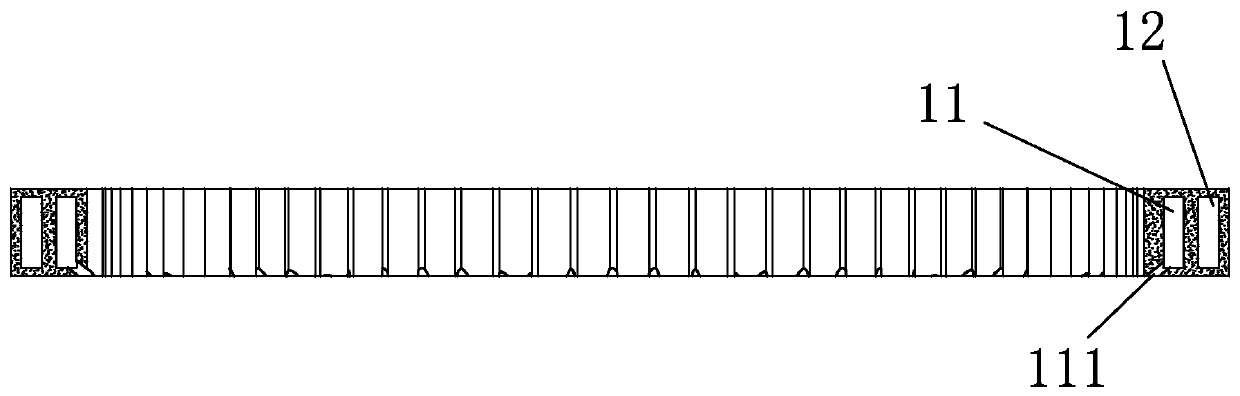

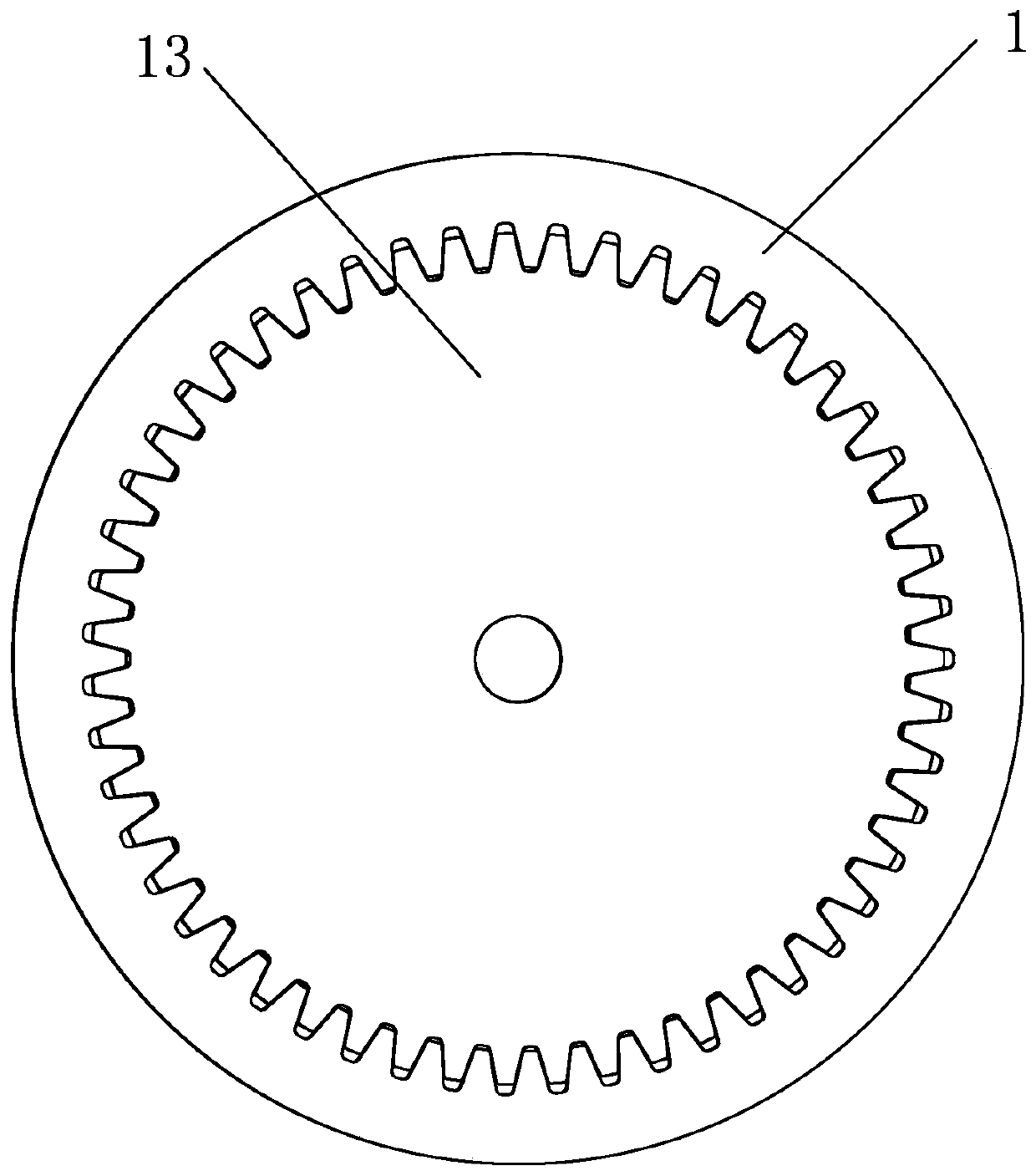

[0041] Such as Figure 1-3 As shown, a gear induction hardening equipment, which includes a profiling induction coil 1, a first support plate 2 for supporting the gear and a driving device, the profiling induction coil 1 has a contour of a full ring gear structure to match the The gear 13 is meshed, and the profiling induction coil 1 imitates the outer contour of the gear. The driving device drives the profiling induction coil 1 or the first support plate 2 to move up and down, so as to realize the relative movement between the profiling induction coil 1 and the gear in the up and down direction.

[0042] In this way, the main innovation of this case is to add a driving device for the profiling induction coil to realize the scanning quenching of the gears in the up and down direction through the profiling indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com