High-temperature solid smelting furnace heat-treatment quenching machine

A technology for quenching machines and furnaces, applied in the field of quenching machines, which can solve problems affecting quenching quality, difficulty in debugging, unstable operation of quenching trolleys, etc., and achieve the effect of ensuring quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

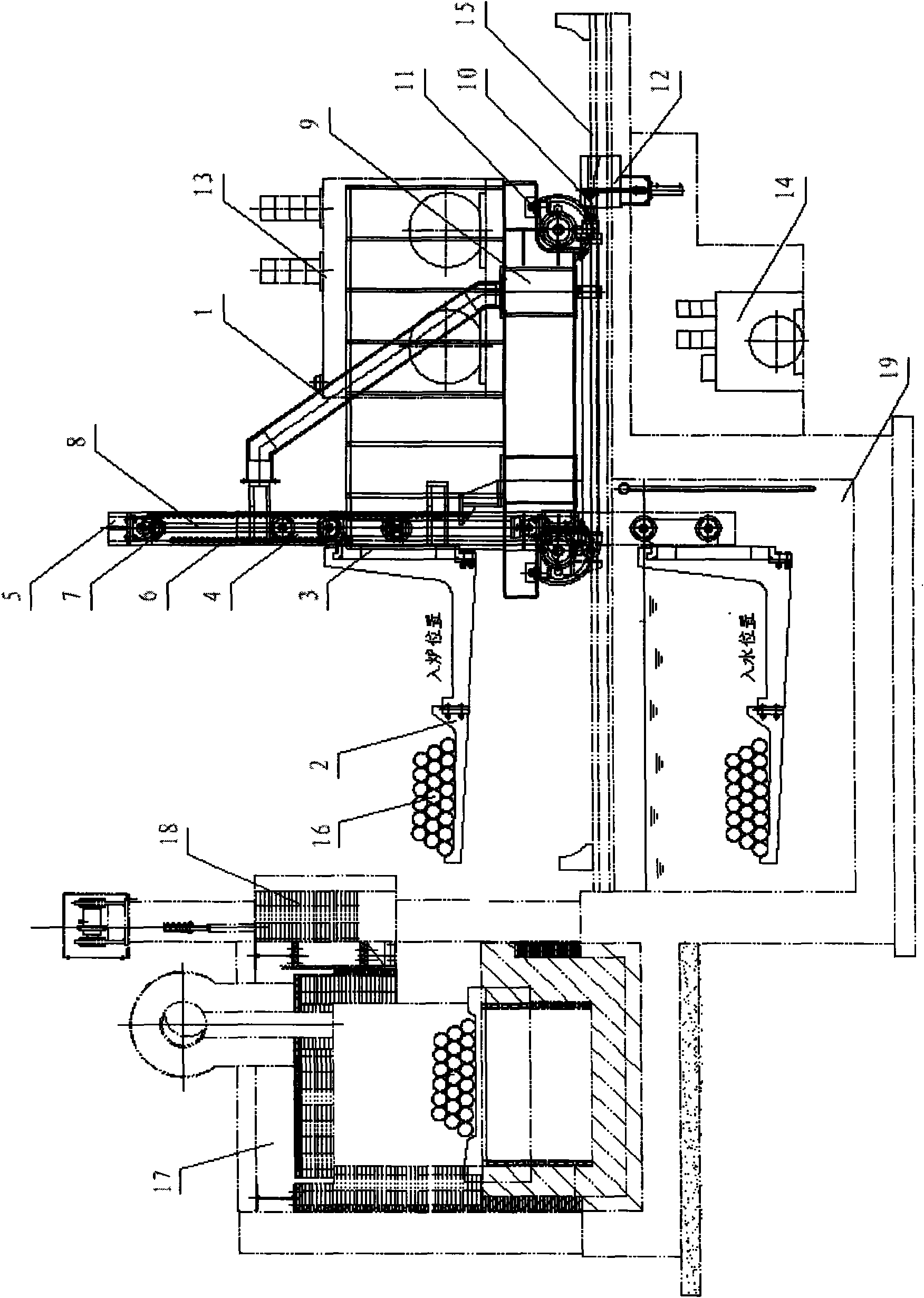

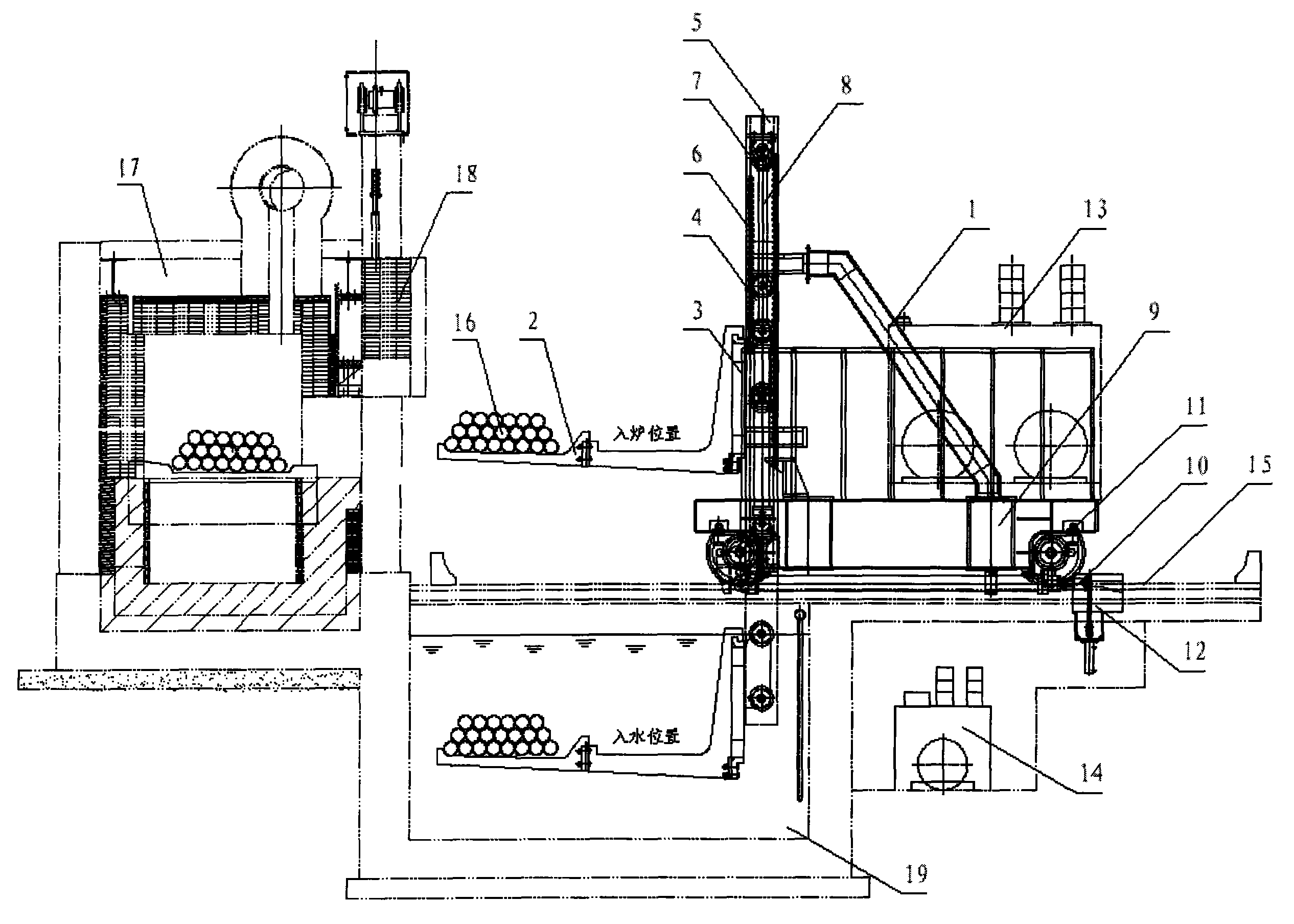

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0010] As shown in the figure: the quenching machine includes shovel teeth (2), shovel tooth frame (3), lifting guide rail inner frame (4), fixed guide rail frame (5), shovel tooth lifting chain (6), shovel tooth lifting sprocket (7), shovel tooth lifting cylinder (8), car body (9), trolley in and out furnace cylinder (10), trolley hydraulic motor (11), trolley in and out of furnace solid baffle (12), trolley main hydraulic system (13 ), auxiliary hydraulic system (14); the fixed guide rail frame (5) is installed on the front end of the car body (9), and the four strokes are 1200mm shovel tooth lifting oil cylinders (8). Installed on the inner frame (4) of the lifting guide rail, the inner frame (4) of the lifting guide rail is driven by the shovel tooth lifting cylinder (8) to move up and down in the fixed guide rail frame (5) through the rollers, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com