Small roller and roller sleeve quenching treatment device and heat treatment method

A treatment device and roller sleeve technology, applied in the direction of quenching device, heat treatment furnace, heat treatment equipment, etc., can solve the problems of unable to install fixed quenching facilities, no heat treatment area, narrow working space, etc., to prevent deformation or uneven ground, Good promotion prospects and low capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

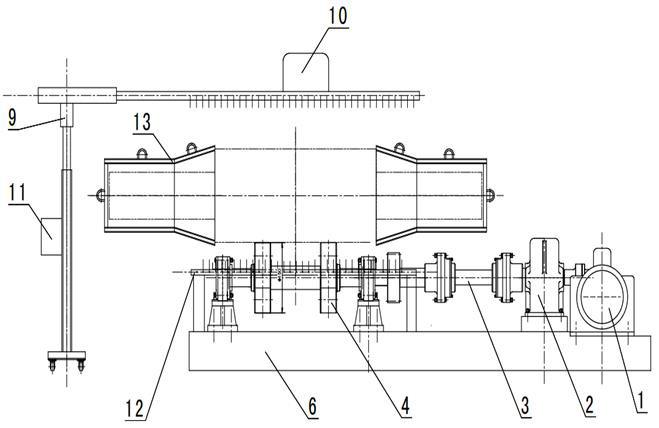

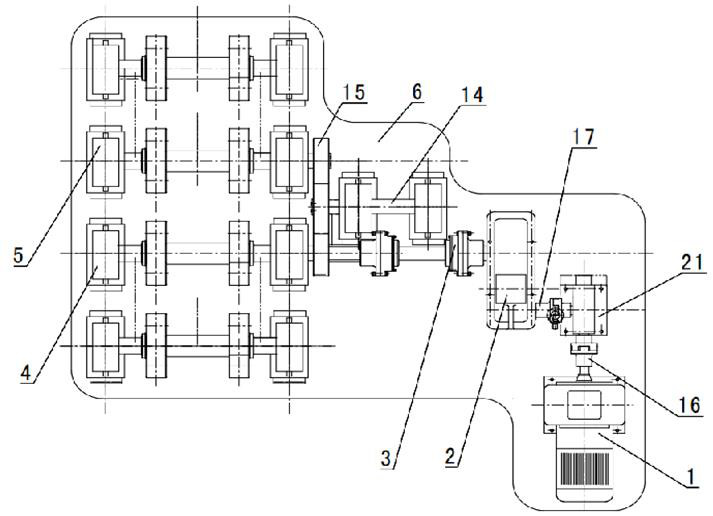

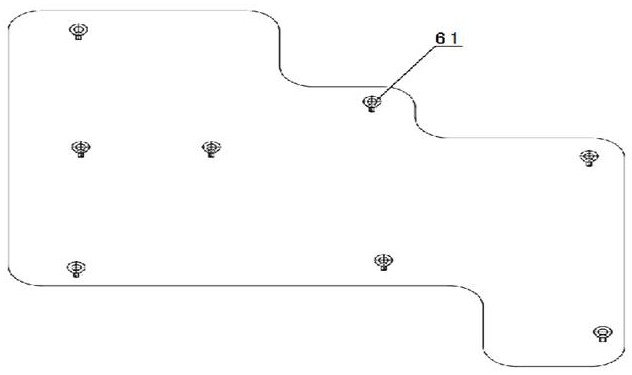

[0058] A quenching treatment device for small rolls and roll sleeves, including motor 1, reducer 2, shaft adapter 3, driving roll pair combination 4, passive roll pair combination 5, bottom plate 6, clamp I7, clamp II8, upper spray Shower device 9, lower spray device 12, temperature control sensor 10, flow control valve 11 and intermediate wheel combination 14, gear guard 15;

[0059] The reducer 2 is connected to the shaft handle 3 through the driving roller pair combination 4, the shaft connecting handle 3 includes the long axis 33 and the half handle I 31 and the half handle II 32 at both ends of the long shaft 33; the driving roller pair combination 4 includes the driving gear 41, the driving roller 42 and driving shaft 43, the driving roller 42 that sleeves on the driving shaft 43 has bearings at both ends of the driving roller 42, the bearings are installed on the driving roller bearing seat 44, and the driving roller bearing seat 44 is installed on the driving roller bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com