Large-size mandril structure property control method

A control method and large-scale technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., to achieve the effects of inhibiting the growth of grains, ensuring the quality of quenching, and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: In this example, the composition and weight percentage of the alloy material that adopts are as follows:

[0020] C 0.39%, Si 0.83%, Mn 0.3%, Cr 5.06%, Mo 1.31%, V 1.01%, P 0.01%, S0.01%, Fe balance.

[0021] The main process steps of the microstructure control technology adopted by this alloy material are as follows:

[0022] 1) Melting is carried out according to the traditional conventional process, that is, arc smelting-ladle refining-electroslag remelting secondary refining. After refining, the electroslag ingot poured out of the smelting is placed in the electroslag remelting device for electroslag remelting .

[0023] 2) Put the steel ingot into a heat treatment furnace within the temperature range of 1250°C for uniform microstructure treatment. Keep warm for 20 hours, melt the eutectic carbide into the material matrix, homogenize the structure, and then bury the sand for cooling.

[0024] 3) Heating the above steel ingot to 1150°C for forging proc...

PUM

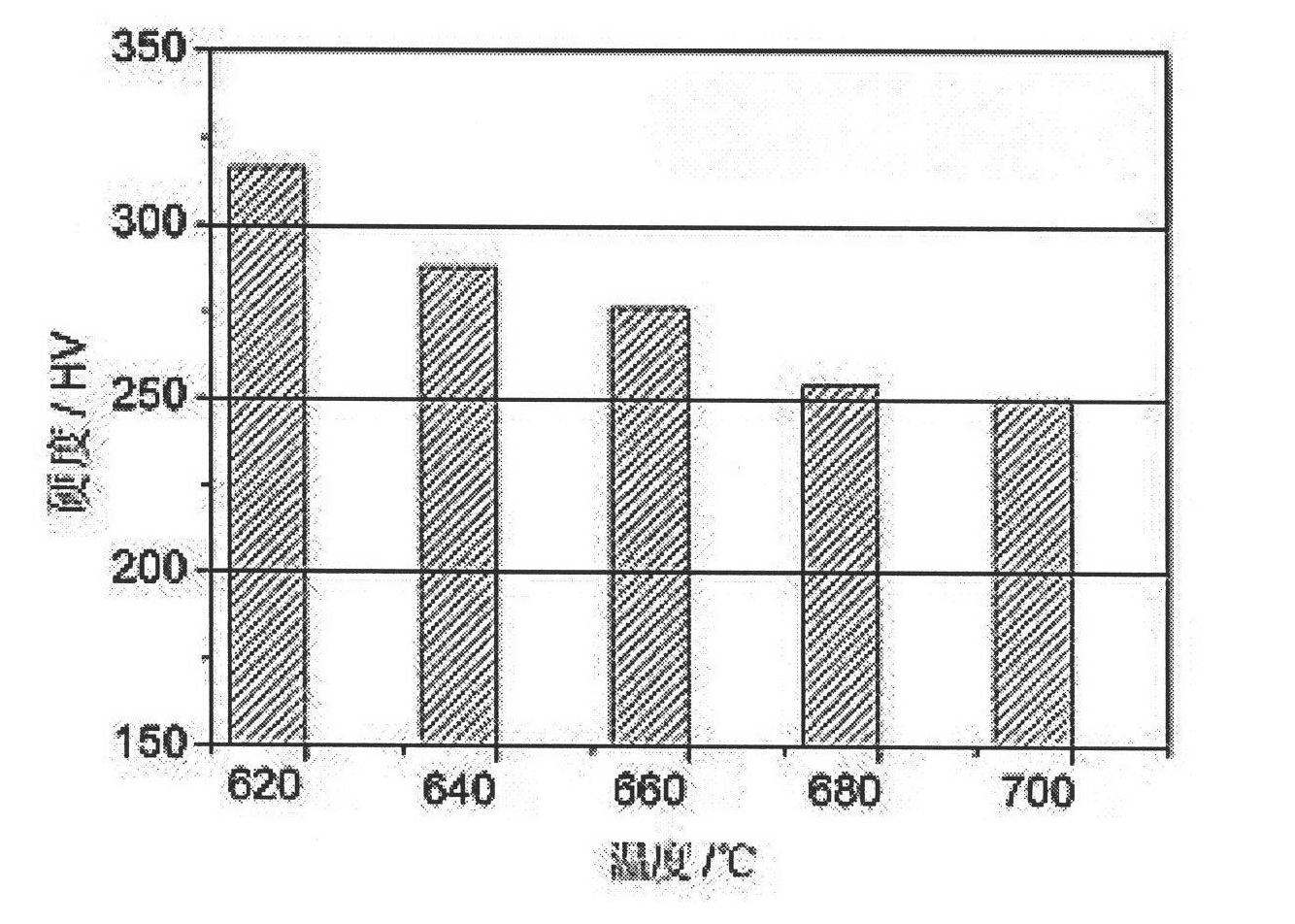

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com