Die press quenching device for fully quenching steel ferrules

A molded quenching and steel sleeve technology, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of inapplicable products of various sizes, high rework and scrap rate, uncontrollable quenching process, etc., to achieve quenching technology and control The effect of technology improvement, short quenching time and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

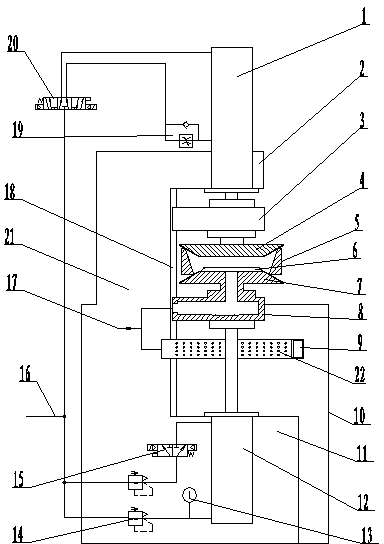

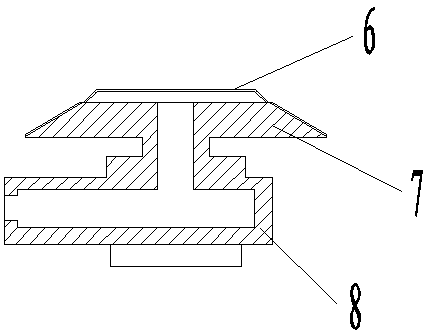

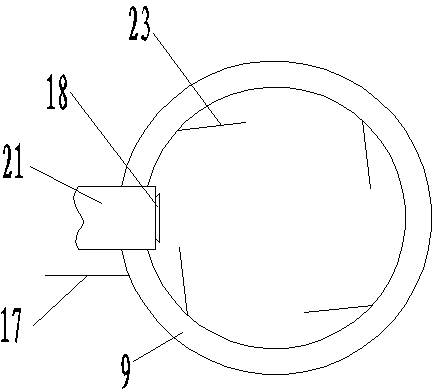

[0015] In the figure, 1-upper mold cylinder, 2-beam, 3-upper slider, 4-upper mold, 5-workpiece to be quenched, 6-shroud, 7-lower mold, 8-lower slider, 9-spray Oil ring, 10—oil pool, 11—base, 12—lower mold cylinder, 13—precision pressure gauge, 14—pressure regulating valve, 15—reversing valve II, 16—high pressure pipeline, 17—cooling oil pipe, 18 —Guide rail, 19—one-way speed control valve, 20—reversing valve 1, 21—column, 22—the fuel injection port on the injection ring, 23—baffle plate.

[0016] like figure 1 , 2 , 3, the bed of this device is made up of a base 11, a column 21 installed on the left side of the base and a beam 2 installed on the upper end of the column, the base is installed in the oil pool 10, and a vertical Guide rail 18, upper slider 3 and lower slider 8 are respectively installed on the guide rail, upper mold cylinder 1, lower mold cylinder 12 are respectively fixed on the beam and the base, and the axes of upper and lower mold cylinders coincide, upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com