Patents

Literature

80results about How to "Small quenching deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

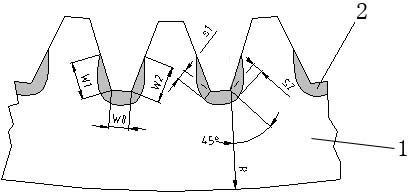

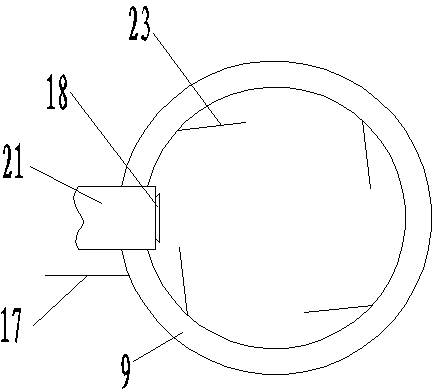

Process for quenching hard-tooth surface canine tooth loop intermediate-frequency edge roller seating space

InactiveCN101509063ALight structureSmall sizeFurnace typesHeat treatment furnacesLarge toothIntermediate frequency

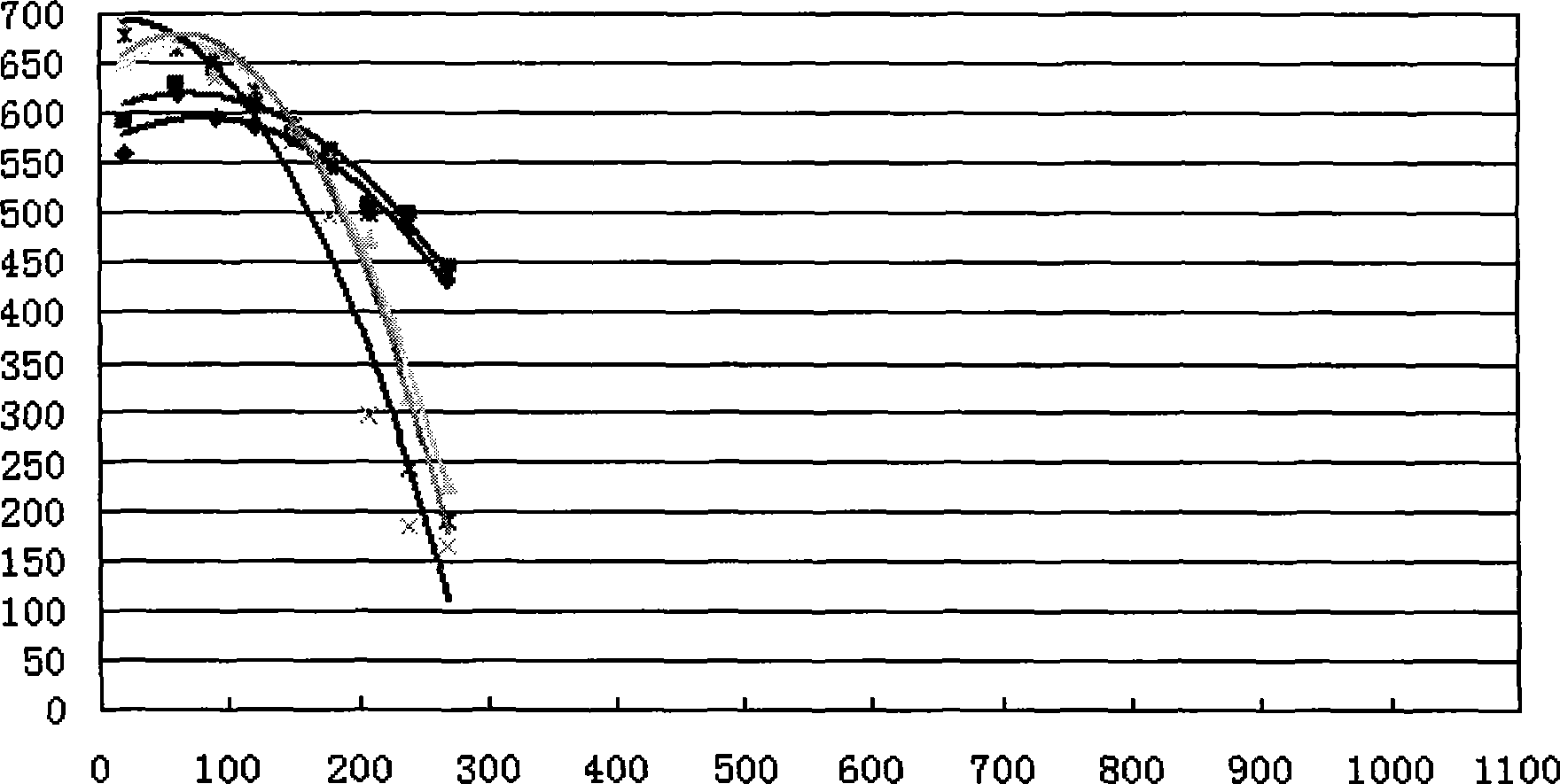

The invention provides a technique for quenching along the tooth space of a large tooth ring with hardened tooth surfaces on a medium-frequency basis, particularly for quenching and tempering the tooth surfaces along the tooth space on a medium-frequency induction basis. The technique comprises the following steps: 1), carrying out the tool preparation and on-site installation before quenching and tempering; 2), manufacturing medium-frequency copying inductors heating-quenching along the tooth space and taking the shape similar to the profile of the tooth space, and quenching and back-cooling the tooth surfaces in a synchronous manner; 3), quenching at intervals of 3 tooth spaces, wherein, one round of the rotation of the parts, that is, 54 teeth, constitutes a working cycle; 4) testing the hardness of a first quenching tooth surface every cycle; and 5), carrying out the tempering heat treatment in a half-tooth ring manner after the surface is quenched. The quenching level of the tooth surfaces of the large tooth ring with the hardened tooth surfaces reaches HRC40-45; the depth of effective hardening layers is larger than or equal to 4mm; the accuracy of the tooth wheel reaches the 988GE level; the tooth ring has the advantages of light and handy structure, large size and service life as long as two times of the ordinary tooth ring with the same specification; and the technique remarkably reduces the weight of the equipment, improves the reliability thereof, and improves the running efficiency thereof.

Owner:CITIC HEAVY INDUSTRIES CO LTD

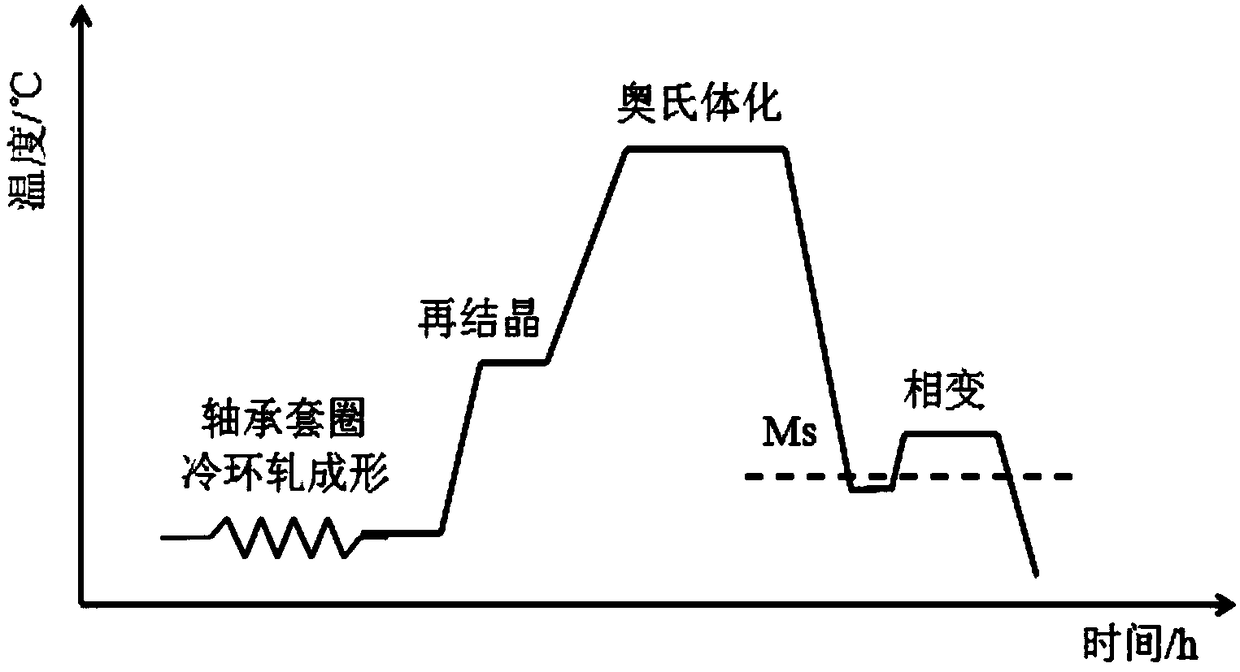

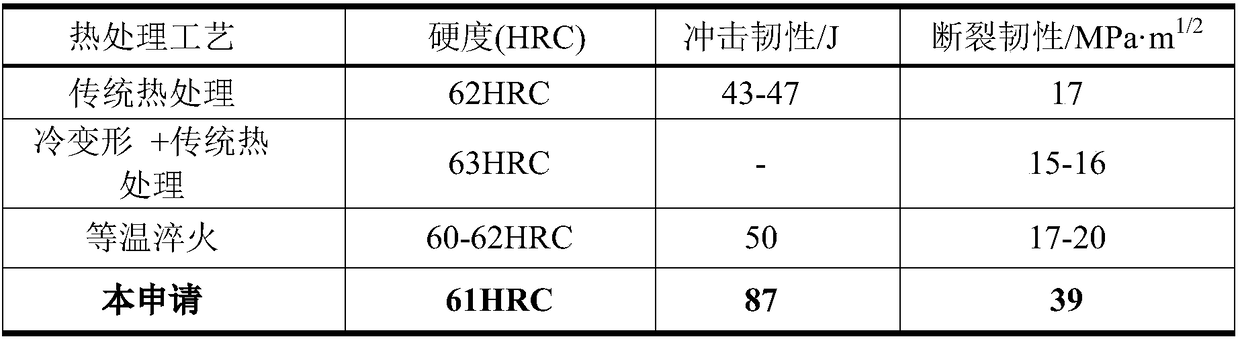

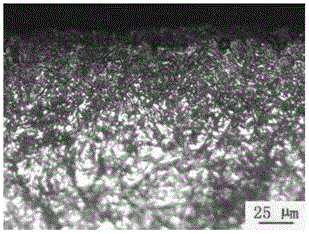

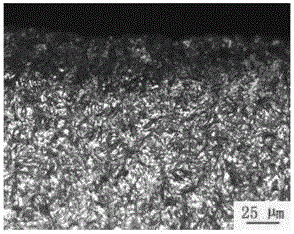

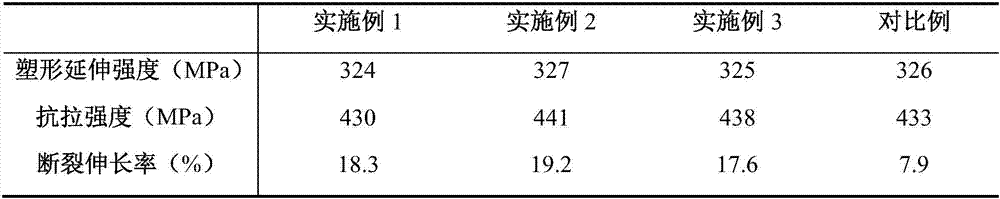

Manufacturing method capable of improving strength and toughness of cold-ring-rolled bearing ring and improving quenching deformation

InactiveCN108060291AImprove solubilityReduce heat treatment quenching deformationFurnace typesHeat treatment furnacesFerritic matrixCarbide

The invention discloses a manufacturing method capable of improving the strength and toughness of a cold-ring-rolled bearing ring and improving quenching deformation. The manufacturing method comprises the following steps: S1. cold-ring-rolling forming: carrying out rolling forming on a ring blank of the bearing ring through a cold-ring-rolling process; and S2. firstly, slowly heating the rolled-formed bearing ring to reach a certain temperature and carrying out recrystallization, and insulating heat for a period of time to eliminate the residual stress of cold-rolling; secondly, rapidly heating the bearing ring to reach a certain temperature and carrying out austenization; thirdly, carrying out pre-quenching treatment on the bearing ring and insulating heat, and forming lath martensites in partial low-carbon areas; fourthly, heating the bearing ring to reach a certain temperature and insulating heat, and carrying out bainite transformation; and finally, cooling the bearing ring to reach room temperature. According to the manufacturing method disclosed by the invention, the change of a ferrite matrix and spheroidized carbides is caused by virtue of cold-rolling plasticity, the pre-quenching process and the bainite phase-change heat treatment process are matched, and the microstructure of a material is controlled, so that the qualification rate of finished bearing rings is greatly increased, the strength and toughness of the material are greatly improved, and the fatigue life of the material is greatly prolonged.

Owner:WUHAN UNIV OF TECH

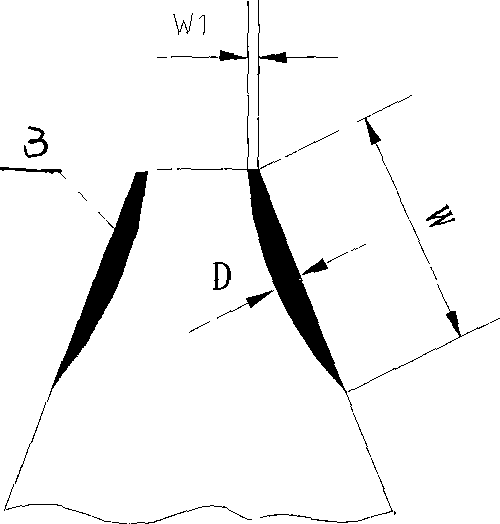

Double quenching technique for 9Cr2Mo leveler roll

InactiveCN101134996AAvoid decompositionGuaranteed hardnessFurnace typesHeat treatment process controlMartensite transformationDecomposition

The double liquid quenching process of 9Cr2Mo straightening roller includes the first quick cooling in water to avoid high temperature decomposition of overcooling austenite to the martensite transformation temperature, and the subsequent cooling in oil for martensite transformation to raise the hardness, reduce quenching deformation and avoid cracking. Before being loaded to furnace, the straightening roller has its end surfaces and central through hole covered with plates to reduce the quench cooling of these parts and ensure hardness of HRC 35-40.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Production process of ultrathin-wall aluminum alloy section for aviation

The invention discloses a production process of an ultrathin-wall aluminum alloy section for aviation. The production process comprises the following steps: 1) before extrusion, heating an aluminum alloy casting rod, an extrusion mold and an extrusion container; 2) extruding the section; 3) straightening; 4) carrying out sizing sawing on the straightened section; 5) heat treatment. According to the production process, the aluminum rod, the extrusion mold and the extrusion container are preheated before extrusion, so that the temperature of the section in the extrusion process can be kept stable, the mass defects of the section caused by an over-cold or over-heat condition are avoided, meanwhile, the end part of the section is completely wrapped and fixed by a clamp hole in the stretching and straightening processes, the contact area of the section and a clamp is large, the problem of rupture in the end part of the section in the stretching and straightening processes can be avoided, vertical quenching is carried out on the section by adopting quenching liquid of which the concentration is 8-10% and the temperature is 25-30 DEG C in the production process, the cooling speeds of various parts of the section are uniform, the quenching deformation can be greatly reduced, and the product quality is improved.

Owner:CHINA ZHONGWANG

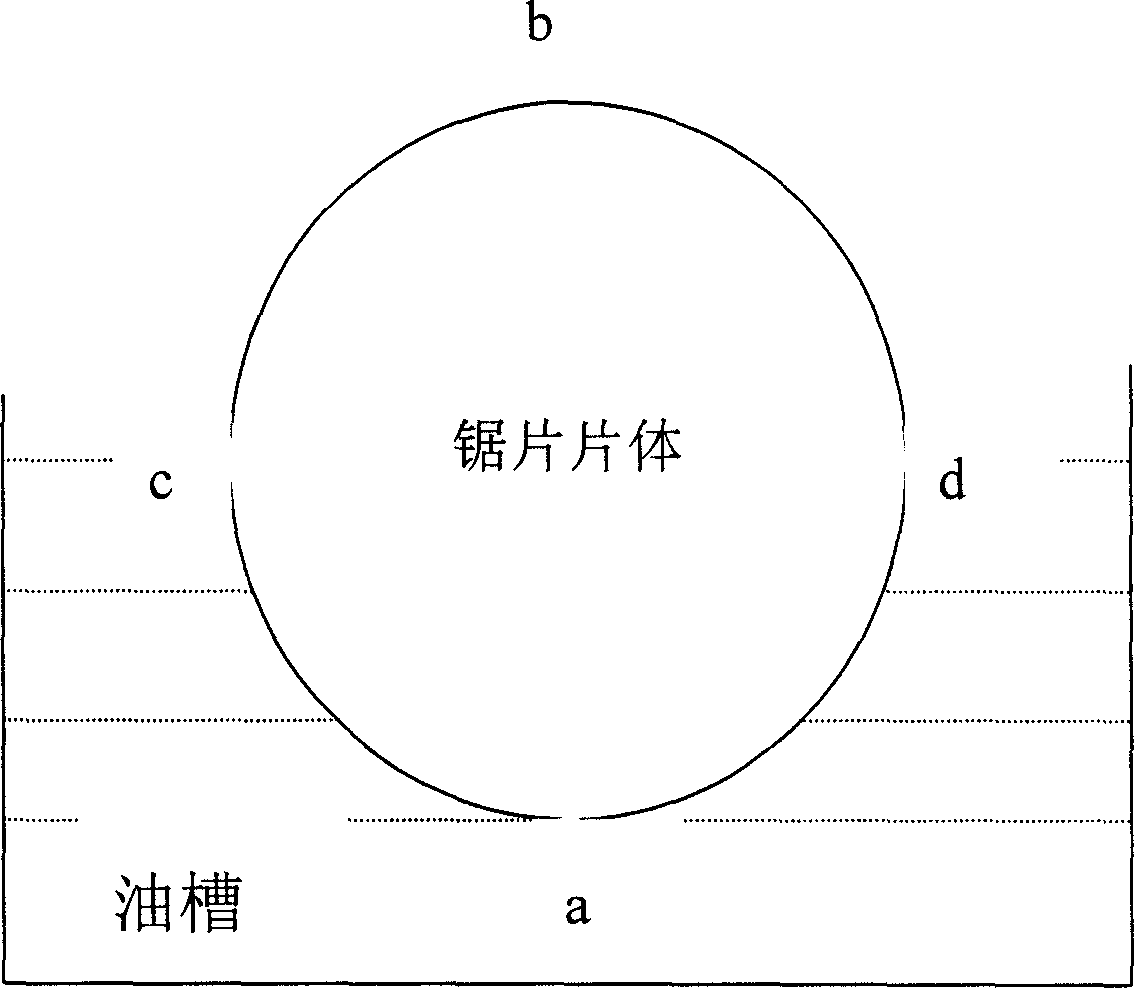

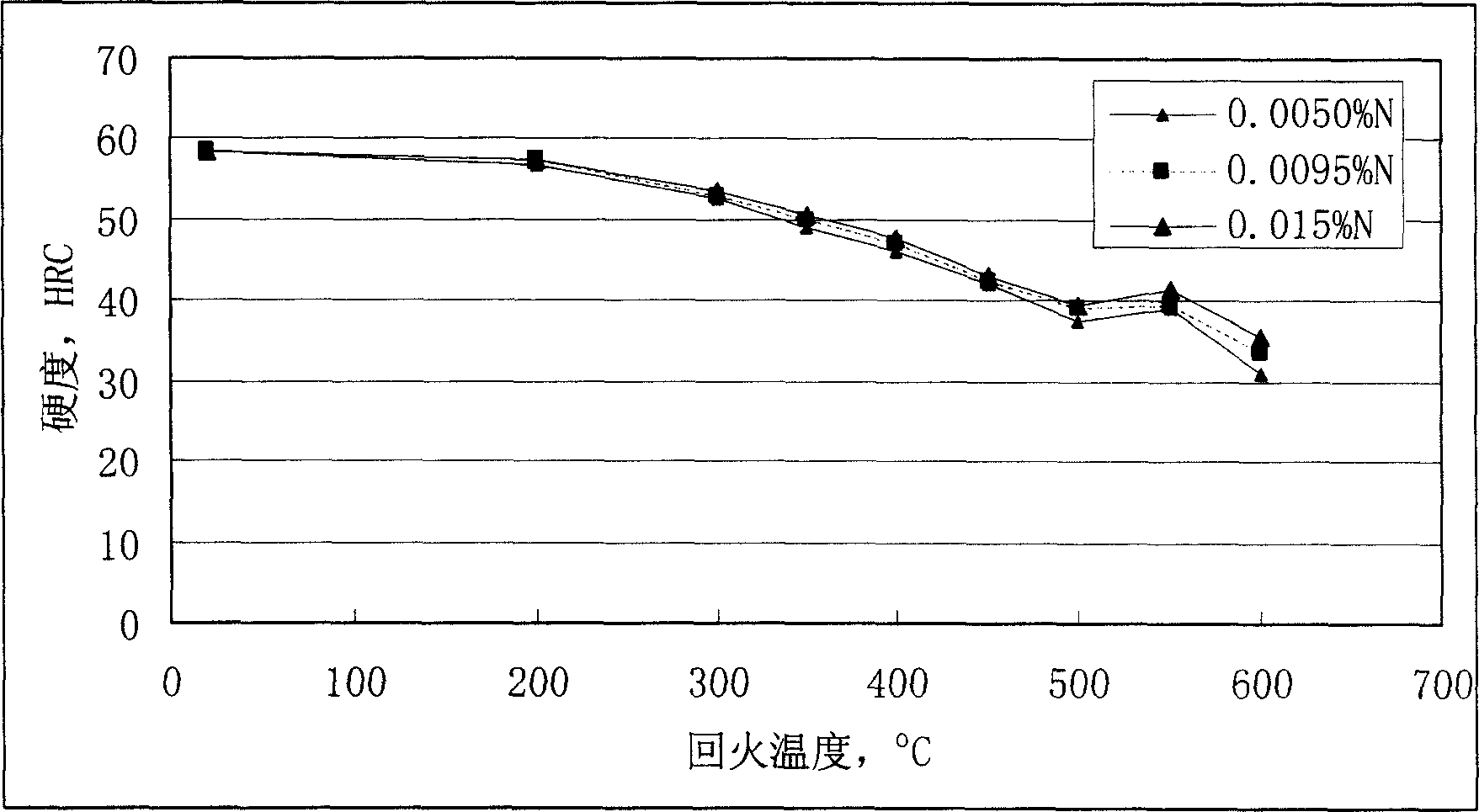

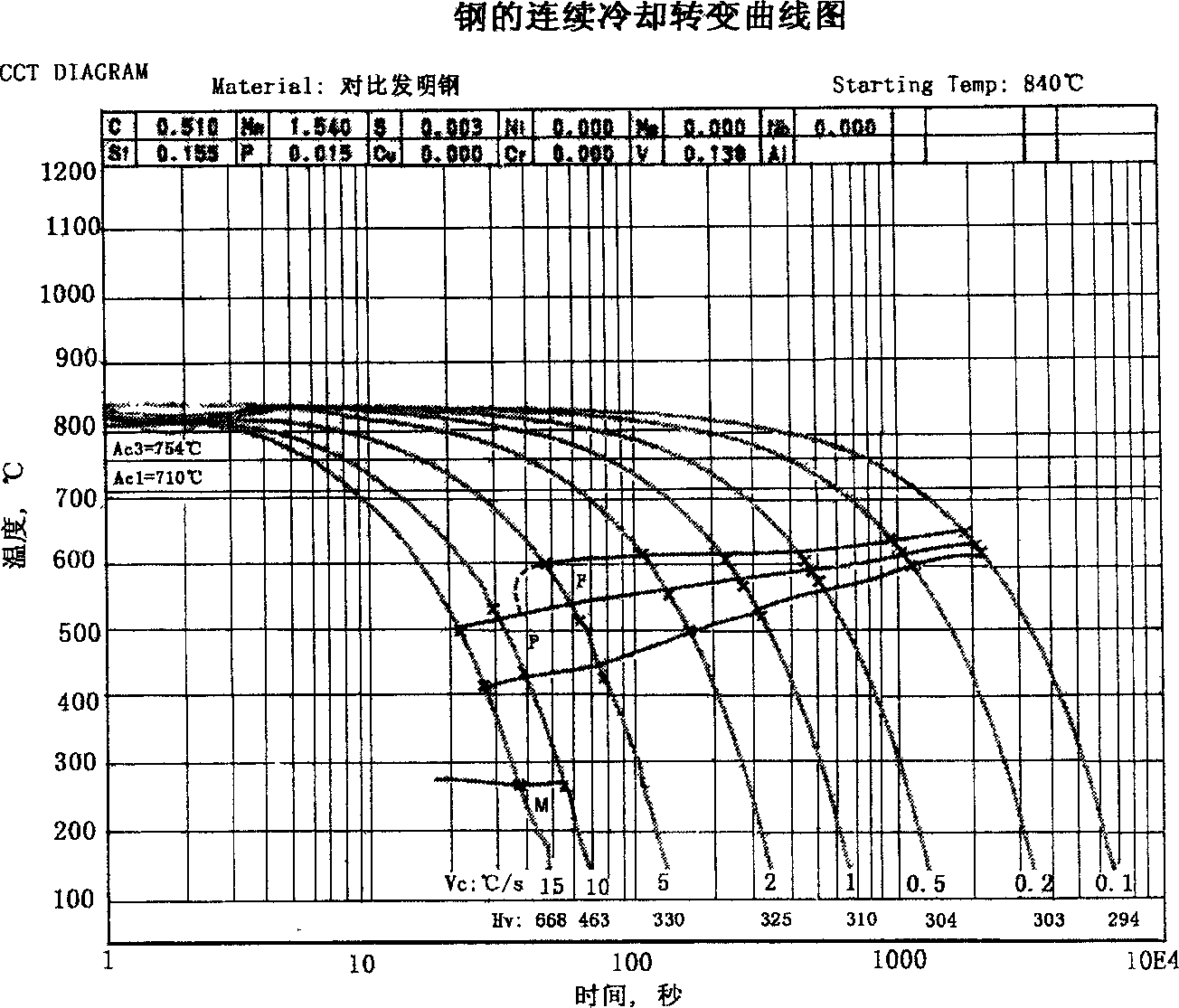

Stone material cutting saw blade steel and its manufacturing method

ActiveCN1904119AReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

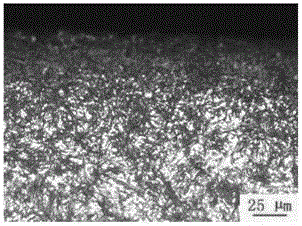

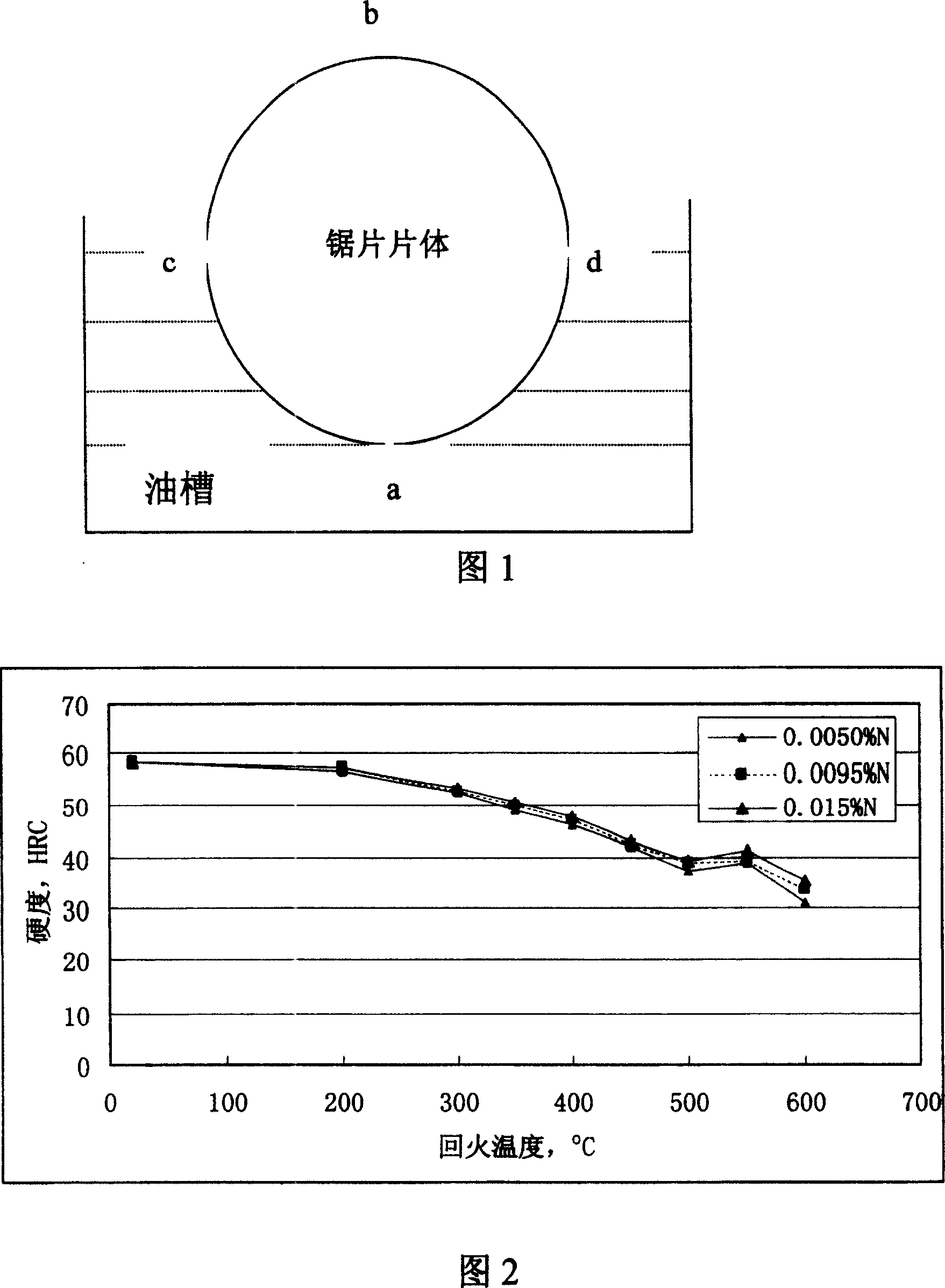

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

ActiveCN107513677APrevent collapseSmall quenching deformationFurnace typesHeat treatment process controlQuenchingAqueous solution

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

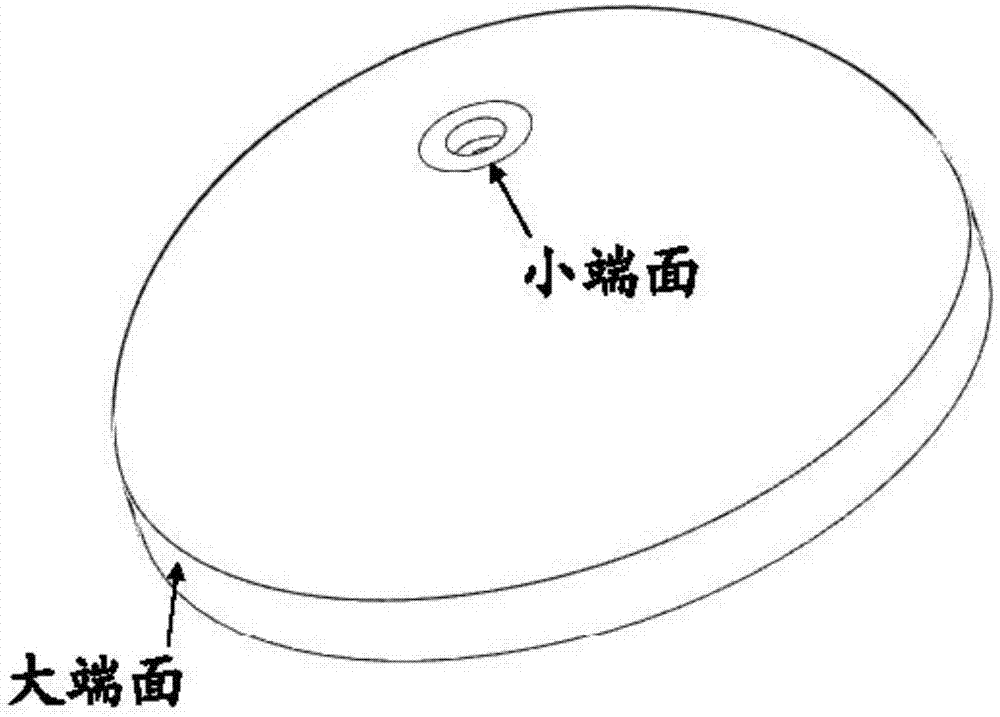

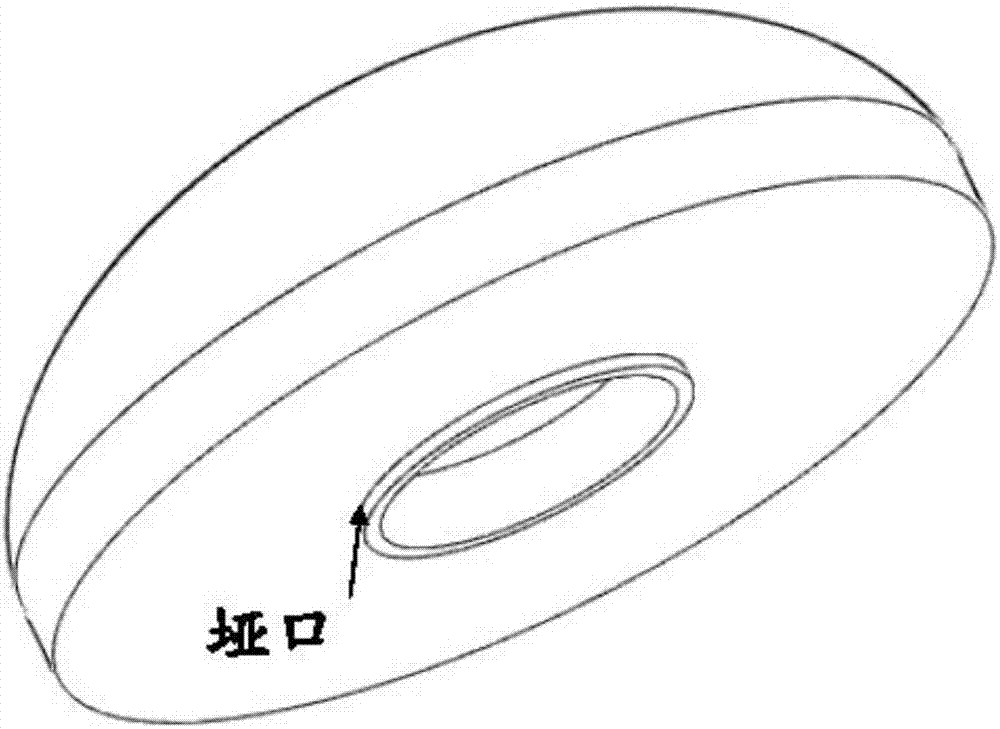

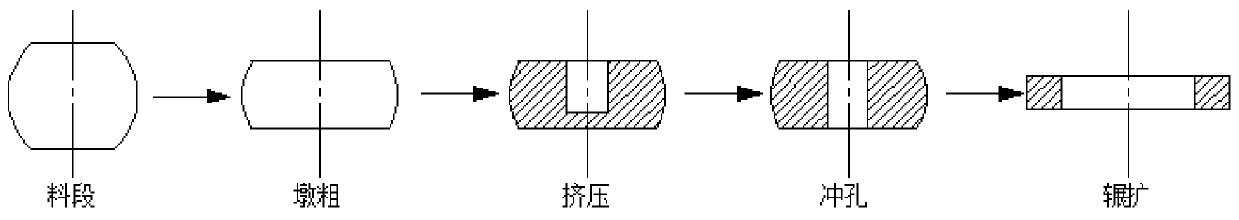

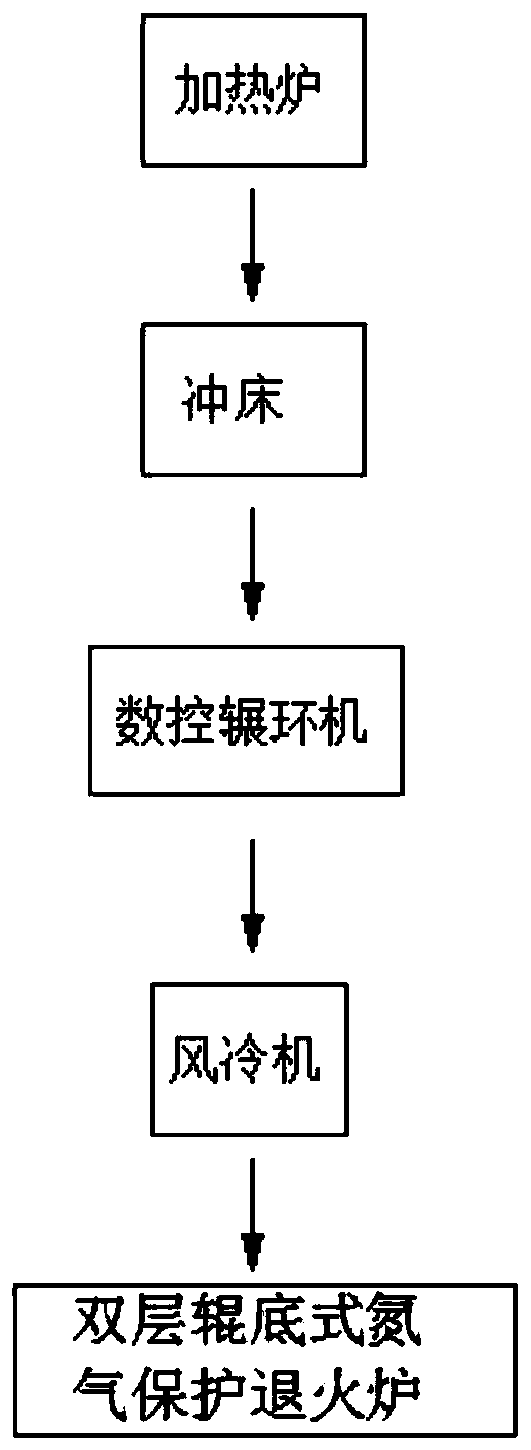

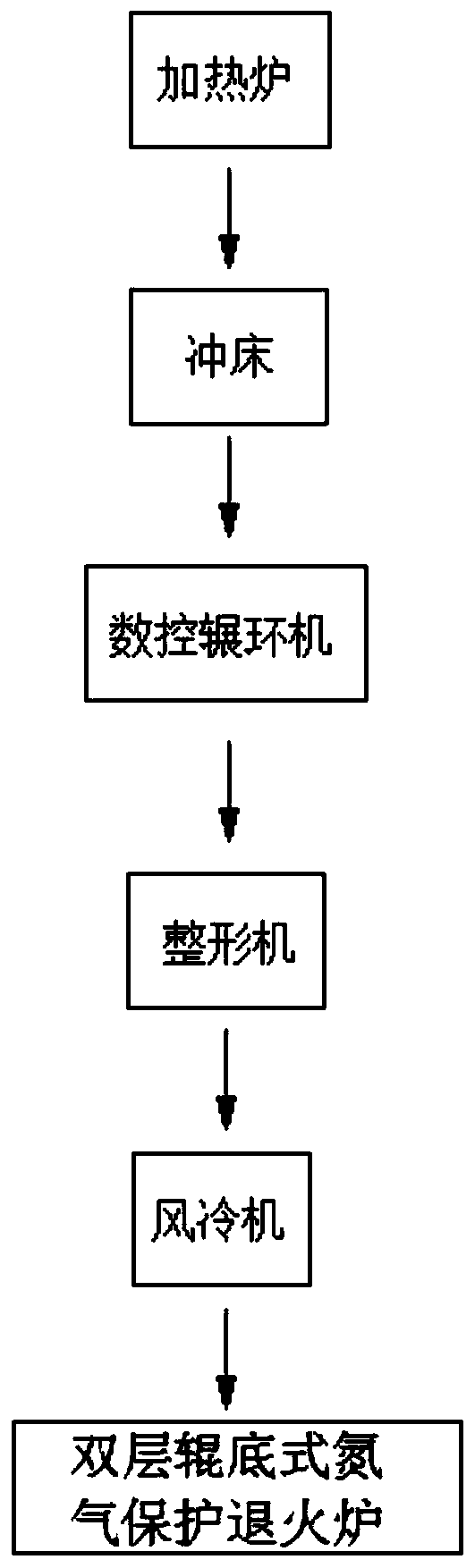

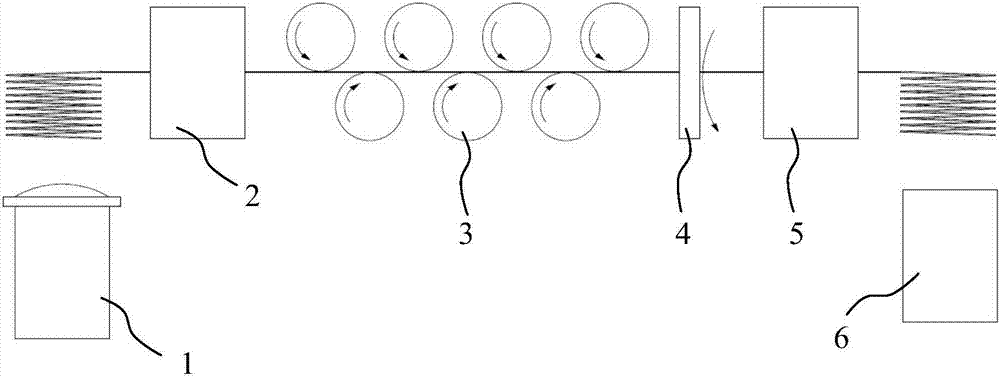

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

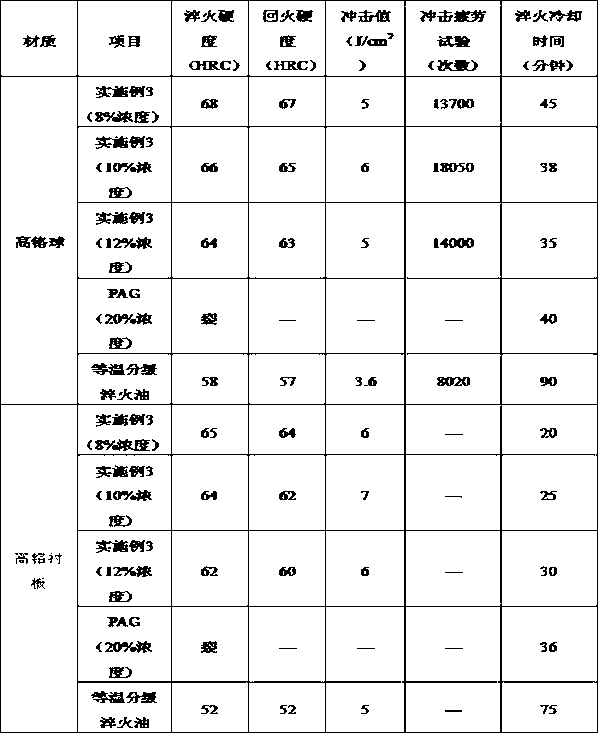

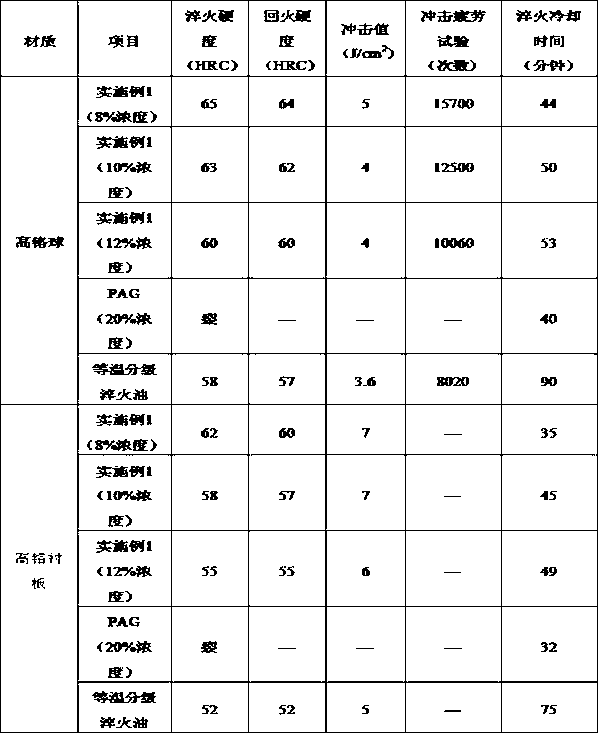

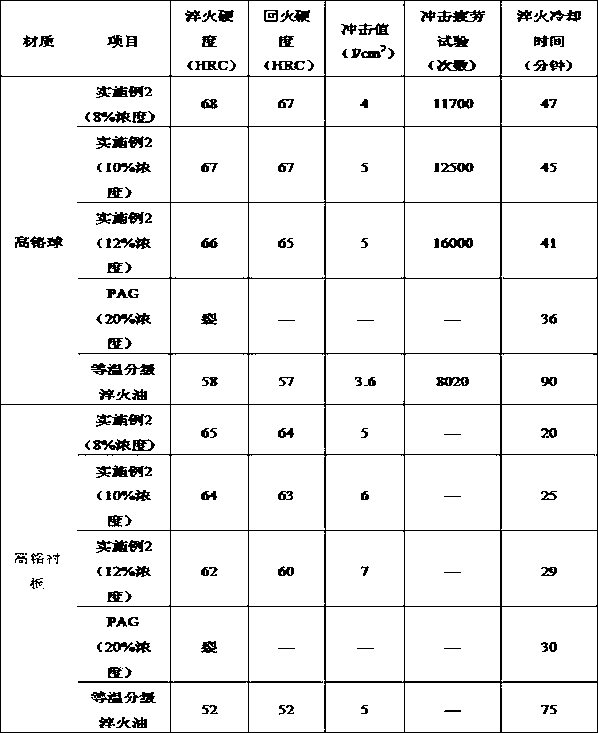

Water-soluble quenching medium used in high-chromium cast iron quenching

InactiveCN103233102ASmall quenching deformationAvoid breakingQuenching agentsPyrrolidinonesAqueous solubility

The invention discloses a water-soluble quenching medium used in high-chromium cast iron quenching. The medium comprises the blended materials of, by weight, 12-18 parts of polyvinyl pyrrolidone, 1-3 parts of sodium polyacrylate , 6-8 parts of an anti-rust agent, 0.5 parts of a bactericide, 5 parts of a pH adjusting agent, and 65.5-75.5 parts of water. The medium is suitable for high-chromium cast iron quenching, and is safe and environment-friendly. The medium has relatively low cooling speed, such that quenched product has good wear resistance, and heat treatment requirement of high-chromium cast iron quenching can be sufficiently satisfied.

Owner:LIAONING HAIMING CHEM PROD

Oil composition for heat treatment

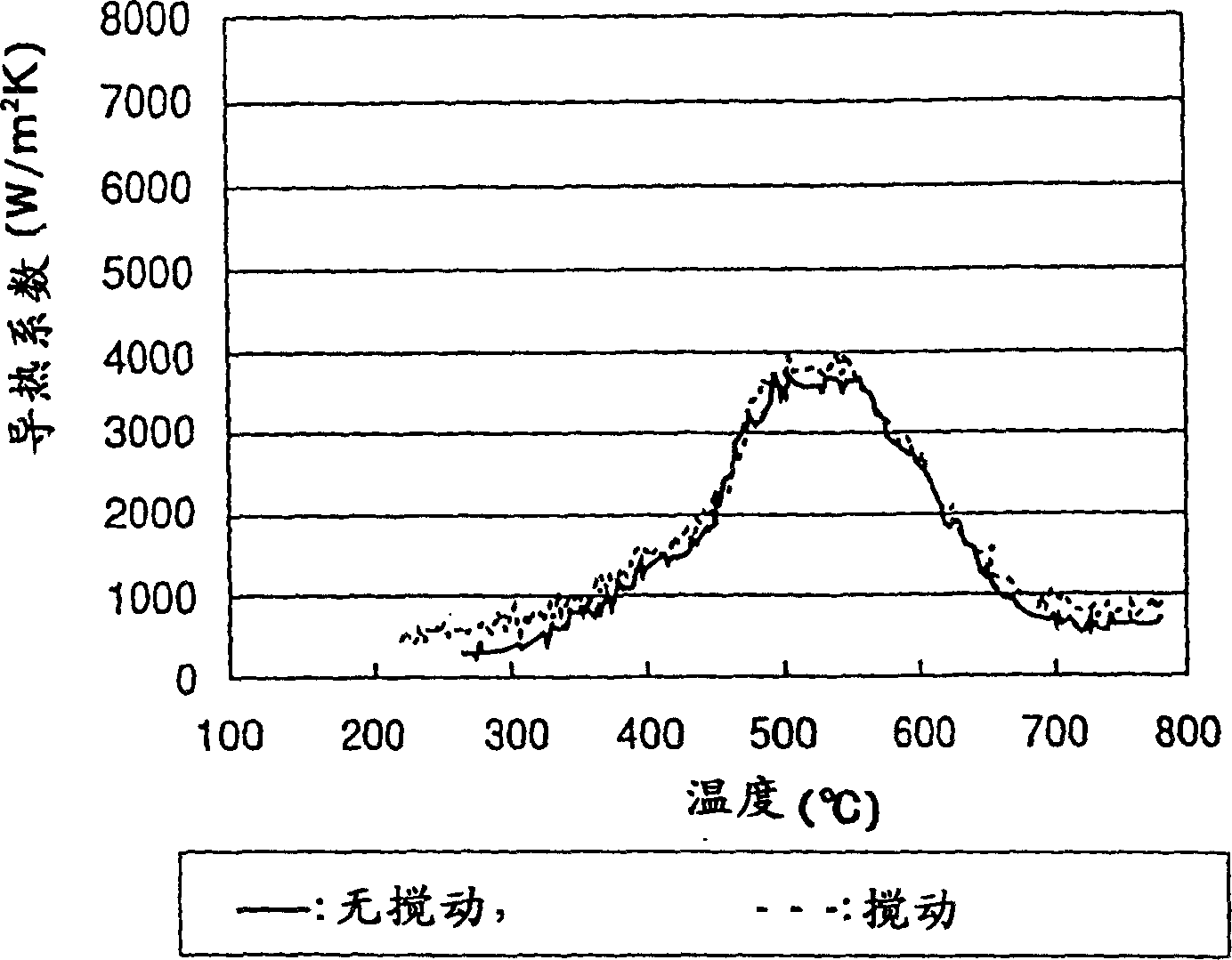

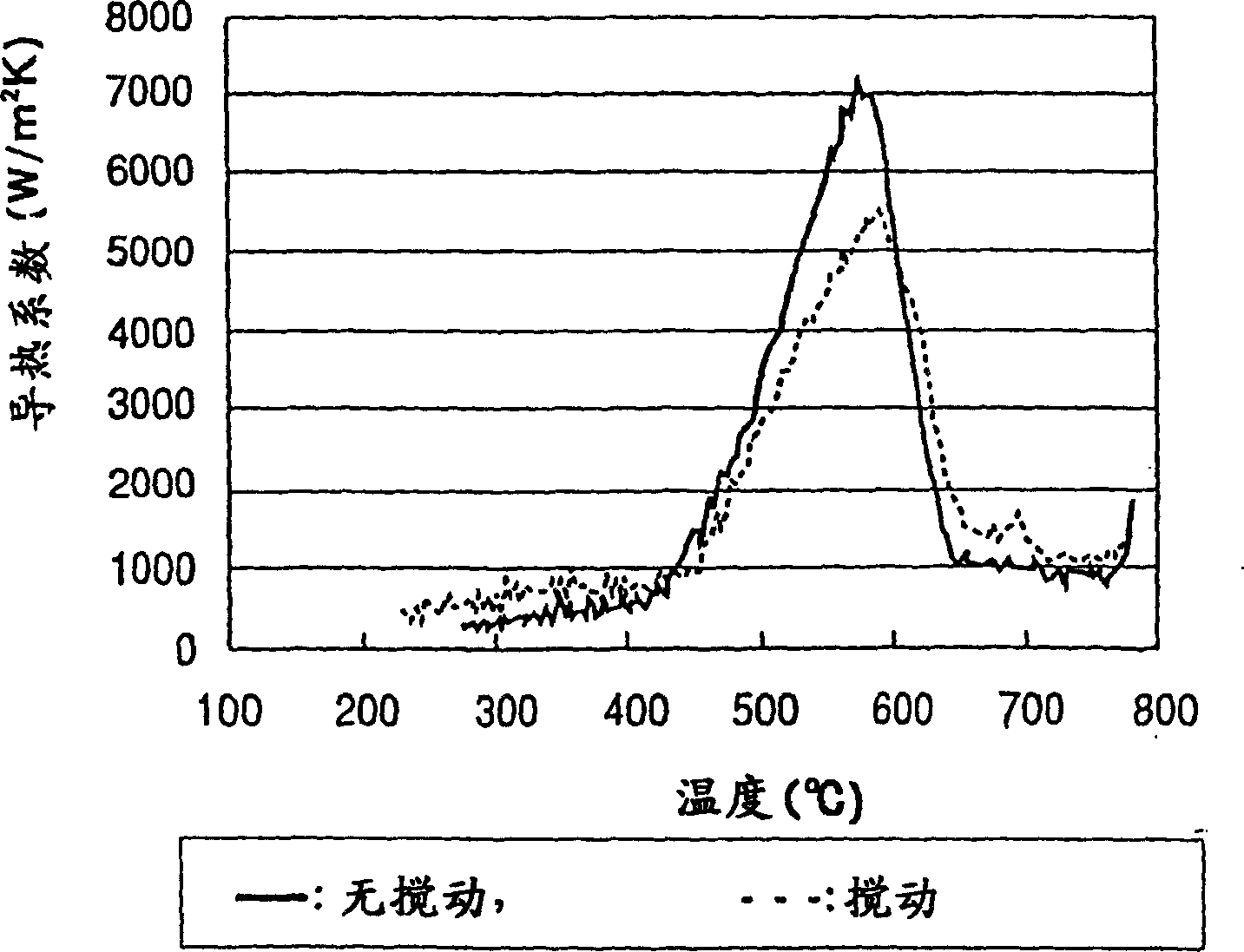

InactiveCN1462314ALess cooling non-uniformityGuaranteed hardnessAdditivesQuenching agentsChemical compositionMetallic materials

A heat treatment oil composition comprising a mixed base oil containing 50-95 weight % of (A) a low viscosity base oil with kinematic viscosity of 5-60 mm2 / s at 40° C., and 50-5 weight % of (B) a high viscosity base oil with kinematic viscosity of more than 300 mm2 / s at 40° C. is proposed. By the use of this heat treatment oil composition for hardening of metallic material, it enables to generate little cooling unevenness, to assure the hardness of hardening processed product, and to reduce quenching distortion.

Owner:IDEMITSU KOSAN CO LTD

Composite carburizing and quenching heat treatment method of gear

ActiveCN105239033AReduce quenching stressSmall quenching deformationSolid state diffusion coatingFurnace typesCarburizingCorrosion

The invention relates to a composite carburizing and quenching heat treatment method of a gear, and belongs to the technical field of heat treatment. The method comprises the steps of carburization, cooling, heating, quenching and tempering. The composite carburizing and quenching heat treatment method can effectively refine grains and martensite needles, improves the gear surface hardness, further improves the wear resistance, the fatigue strength and the corrosion resistance of the gear, and improves comprehensive mechanical performance of the gear.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Bearing heat treatment technology

InactiveCN108070703AImprove stabilityUniform particle sizeFurnace typesHeat treatment furnacesQuenchingAir cooling

A bearing heat treatment technology is characterized by comprising the steps that (1) spheroidizing annealing is performed, specifically, a, the first spheroidizing annealing is performed, and b, thesecond spheroidizing annealing is performed; (2) quenching is performed, specifically, the quenching temperature is firstly increased to 650-670 DEG C at a heating rate of 10-15 DEG C / h during quenching, preheating is carried out at 650-670 DEG C for 10-15 minutes, and the quenching temperature is further increased to 835-840 DEG C at the heating rate of 8-12 DEG C / h for quenching heat preservation for 35-40 minutes; and (3) cooling treatment is performed, specifically, tapping air cooling is carried out after the temperature is decreased to be below 160 DEG C by furnace cooling. The inventiondiscloses novel bearing steel and the heat treatment technology. The machining accuracy and impact toughness of the steel can be improved, and the fatigue life of the steel can be prolonged.

Owner:贵州宏博轴承有限公司

Tooth ring tooth surface laser induration processing method

ActiveCN101368226ASmall quenching deformationMeet hardening technical requirementsLaser quenchingLight guide

The invention relates to a laser hardening treatment method for a gear surface of a gear ring, which is characterized the in that: laser hardening treatment methods for the two side surfaces of each gear of the gear ring (1) and the top of the gear thereof are the same; the processing method thereof is described as follows: 1) the gear ring is arranged in the clamp of a rotary working platform; the direction of the length of the gear is vertical to the surface of the rotary working platform; 2) the upper end of the gear ring is provided with a light shielding ring; 3) the laser hardening treatment parameters, such as a laser power, a laser beam scanning speed, the focus of a focus lamp, are reasonably matched; 4) the center of a light guide cylinder deviates from the center of the gear ring; 5) the layer beam enters into the processing surface of the gear side of the gear ring; 6) a guide head moves up and down to match the periodic rotating of the rotary platform with small angle and scale division; or the light guide head moves up and down and rotates to form a laser hardening zone at the processing surface; 7) a primary switch is blocked by light to finish laser hardening treatment on all the gear surface of the gear ring (1). The rigidity and the wear-resistance when the two side gear surfaces of each gear of the gear ring are engaged with the gear surface of a planet gear are improved; simultaneously, as the self-owned characteristics of laser quenching, the quenching deformation of the gear ring is very small which completely meets the technical demands for design and production.

Owner:CHINA FIRST AUTOMOBILE

Stone material cutting saw blade steel and its manufacturing method

ActiveCN100366779CReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

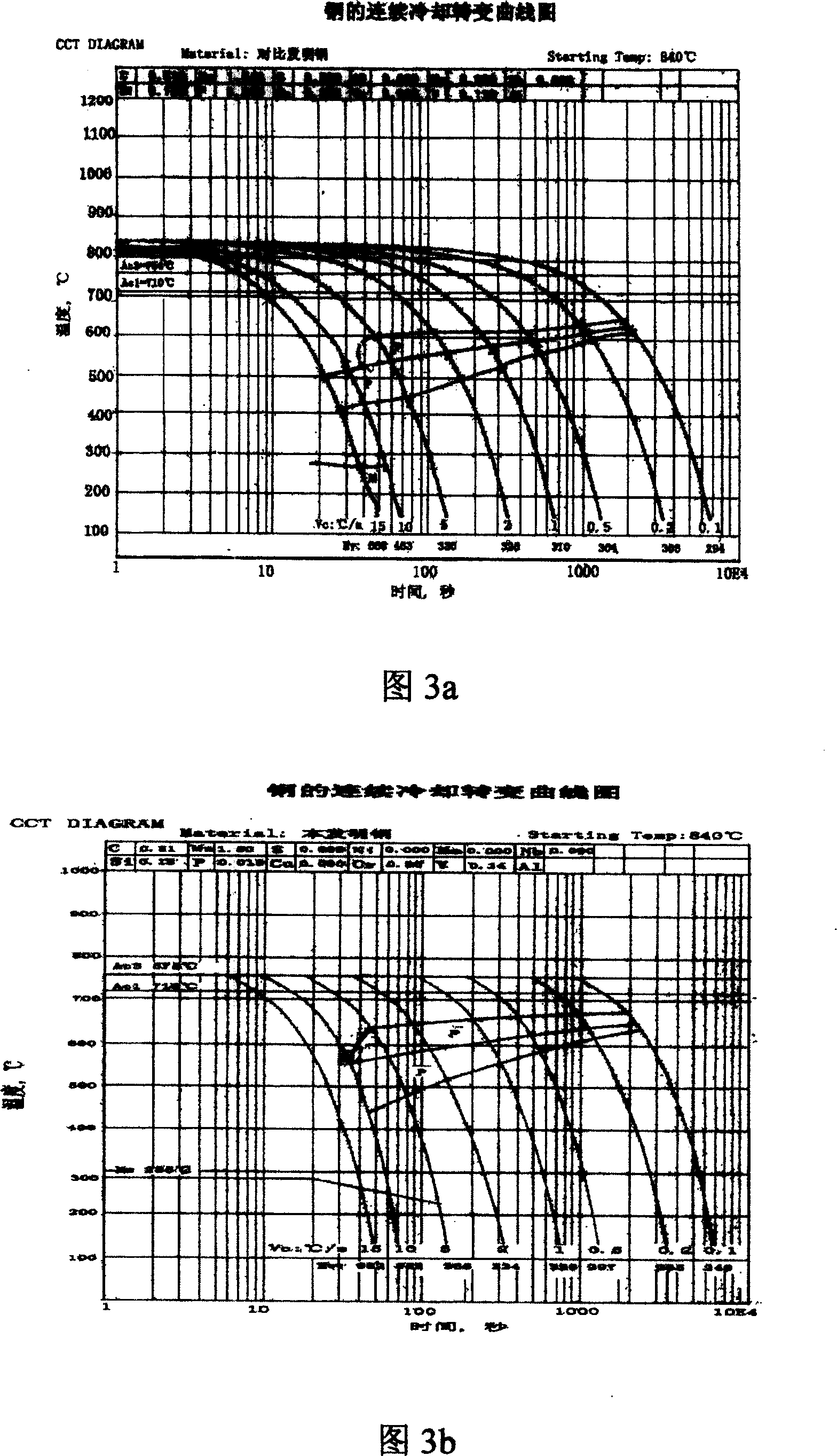

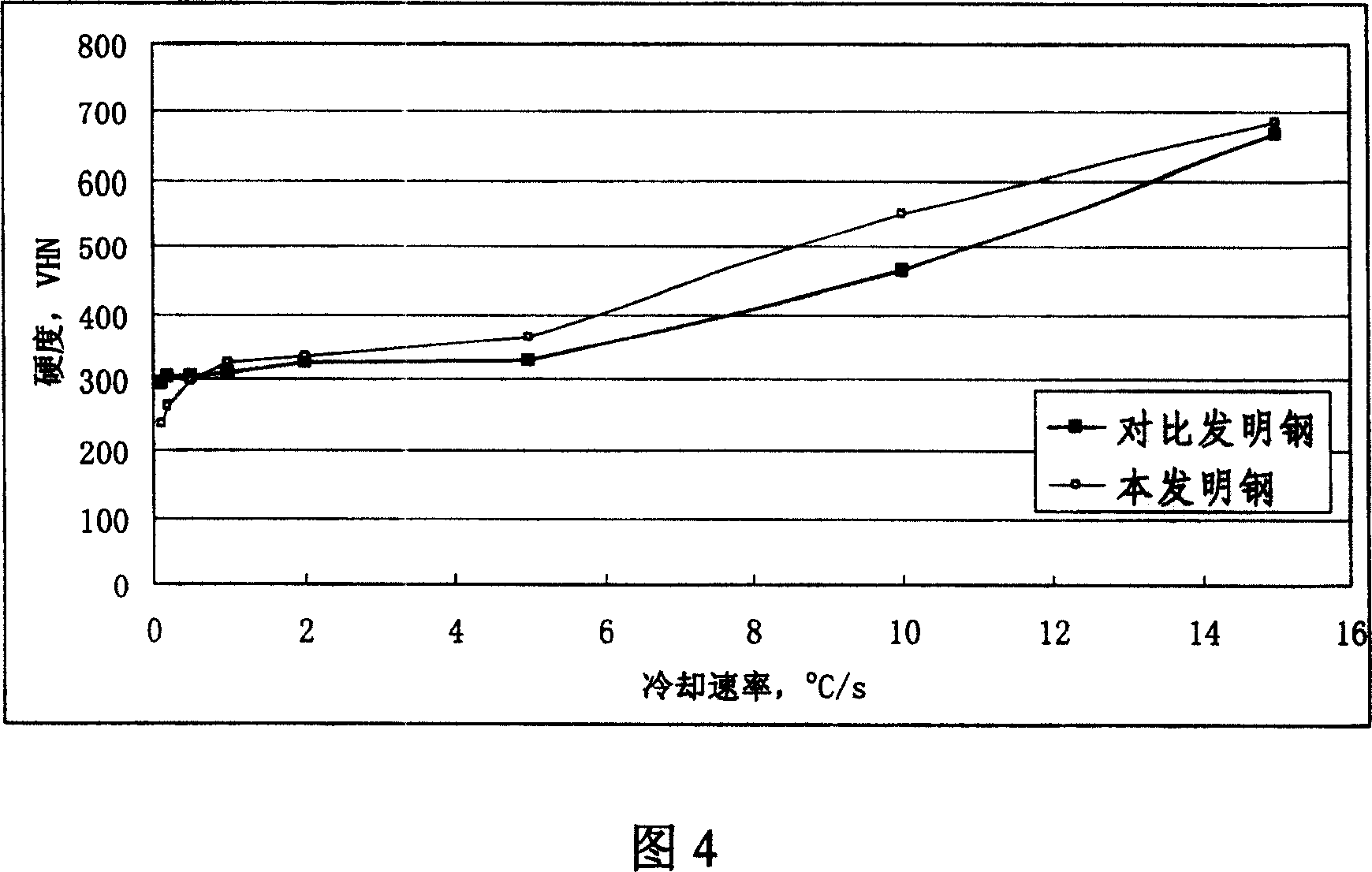

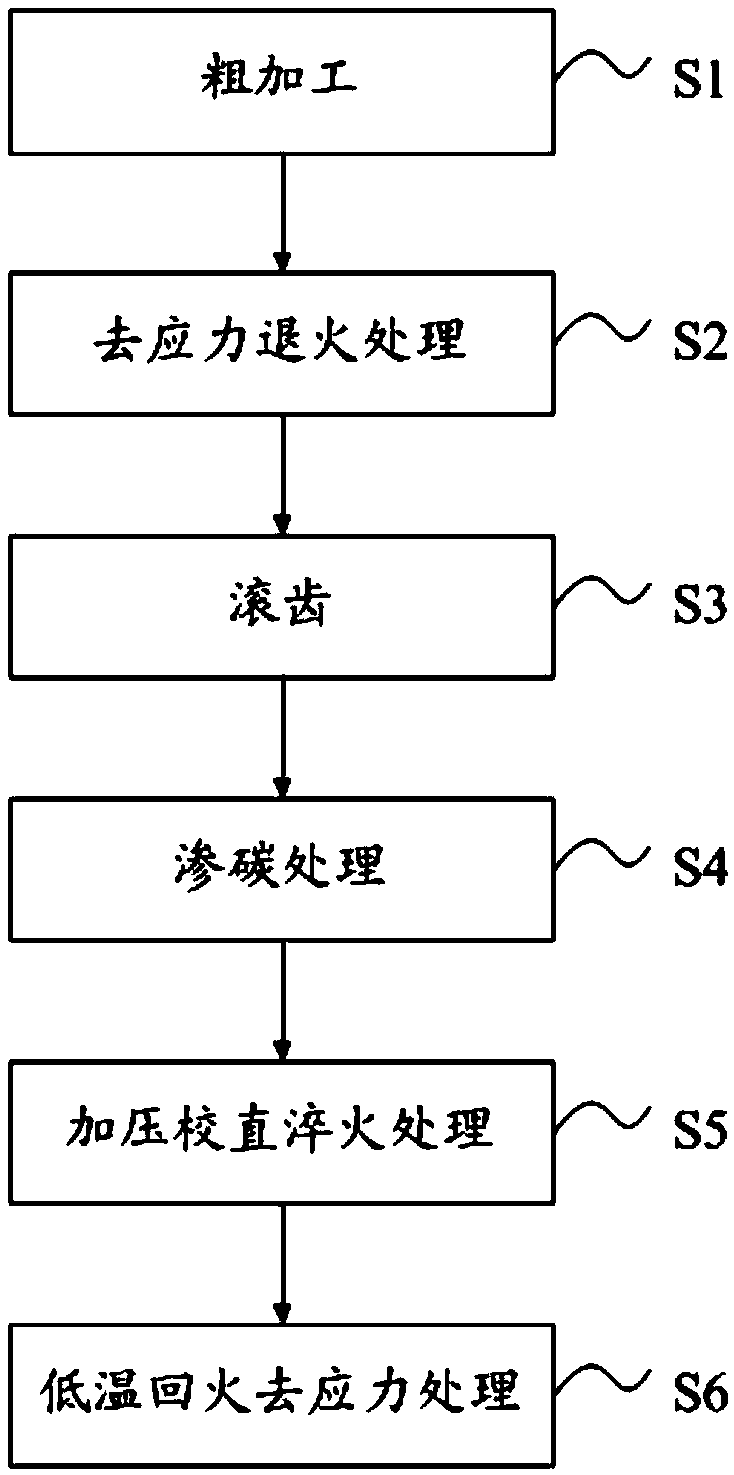

Elongated gear shaft heat treatment deformation control process method

ActiveCN109097551ASolving deformation control problemsSmall quenching deformationSolid state diffusion coatingFurnace typesHobbingStress relieving

The invention discloses an elongated gear shaft heat treatment deformation control process method. The method comprises the following steps that rough machining is carried out; stress-relieving and annealing treatment are carried out on a part after the rough machining; hobbing is carried out, the hobbing are carried out at the two ends of the part, and grinding allowance of the tooth surface is reserved; carburizing treatment is carried out, deformation direction and deformation quantity of the part are detected after carburization; pressurization, straightening and quenching treatments are carried out, according to the deformation direction and the deformation quantity of the part, a pressurizing position is selected, and a supporting part is correspondingly arranged; a pressurizing heavy object is placed at the upper end of the part corresponding to the pressurizing position; the part, the supporting part and the pressurizing heavy object are integrally hoisted into a quenching furnace for heat preservation, and then the quenching oil is wholly hoisted; and after quenching, low-temperature tempering and stress-relieving treatment are carried out. According to the technological process, a supporting point is arranged in the quenching process, pressurizing and quenching are carried out at the supporting point, so that deformation caused by quenching can be effectively reduced,the qualified rate is greatly improved, the rejection rate is remarkably reduced, and the problem that deformation control of the large-span herringbone-tooth long gear shaft is solved.

Owner:CHONGQING GEARBOX

Thermal treatment device and thermal treatment technology of ultra-long aluminum extrusion

ActiveCN109536683AAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesMaterials processingHeating furnace

The invention discloses a thermal treatment device and a thermal treatment technology of an ultra-long aluminum extrusion, and belongs to the technical field of material processing. The thermal treatment device comprises a heating furnace, a quenching water well, a feeding and discharge rail, a feeding trolley, a discharge trolley, a lifting device and a material basket, wherein a furnace body isan ultra-long horizontal furnace composed of a plurality of regions of which the temperature is independently controlled; and a product is horizontally stacked in the material basket, and enters the furnace body or the quenching water well through the feeding trolley, the discharge trolley and the lifting device to be subjected to thermal treatment. According to the thermal treatment device and the thermal treatment technology, horizontal furnace horizontal heating and inclined descend soaking quenching technologies are adopted to replace traditional vertical quenching and roller hearth type quenching technologies, the quenching cooling speed is high and uniform, quenching deformation of the product is low, surface quality is good, and performance is uniform; solid-solution quenching, annealing and ageing functions can be achieved, production scheduling is flexible, length of a biggest product of thermal treatment is large, charge batch is large, production efficiency and heat utilization rate are high, and operation is safe and reliable; and besides, deep well, heat-resistant roller, spraying devices, and the like are not required, basic requirements on equipment are low, and investment is low.

Owner:广西百矿冶金技术研究有限公司

Nitrogen gas quenching process for 25Cr2Ni4WA material

InactiveCN103834772ANo oxidationNo decarbonizationProcess efficiency improvementNitrogenNitrogen gas

The invention discloses a nitrogen gas quenching process for a 25Cr2Ni4WA material. The nitrogen gas quenching process comprises the following steps: a, processing a spare part into a finished product; b, loading the spare part into a vacuum furnace, controlling the vacuum degree at no more than 13.3Pa; c, keeping warm at 650-700 DEG C and preheating for 30-40 minutes; d, keeping warm at 870-890 DEG C for 150-180 minutes and quenching and heating; e, cooling by nitrogen, wherein the cooling pressure is 2*10<5> to 3*10<5>Pa; f, carrying out tempering after detecting that the related sizes of the spare part meet the technological requirements of the product, wherein the tempering temperature is 200-240 DEG C, and keeping warm for 180-210 minutes; and g, nitrogen cooling, wherein the cooling pressure is 2*10<5> to 3*10<5>Pa. The spare part processed by the technology disclosed by the invention is free of oxidation, free of decarburization, small in quenching deformation, fewer in manufacturing procedures after quenching, and easy to process, and the technology is free of pollution to environment.

Owner:CHONGQING JIANSHE IND GRP

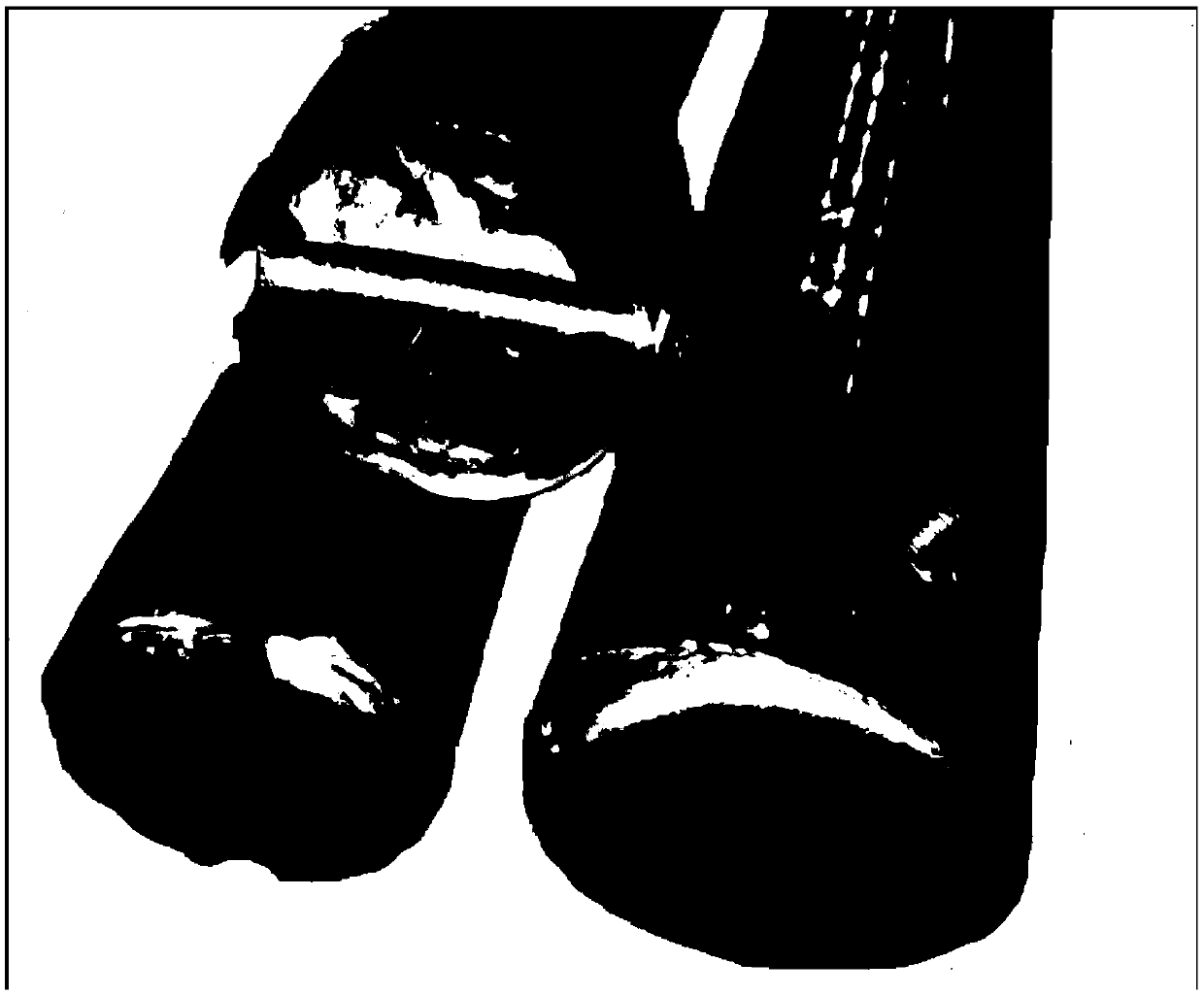

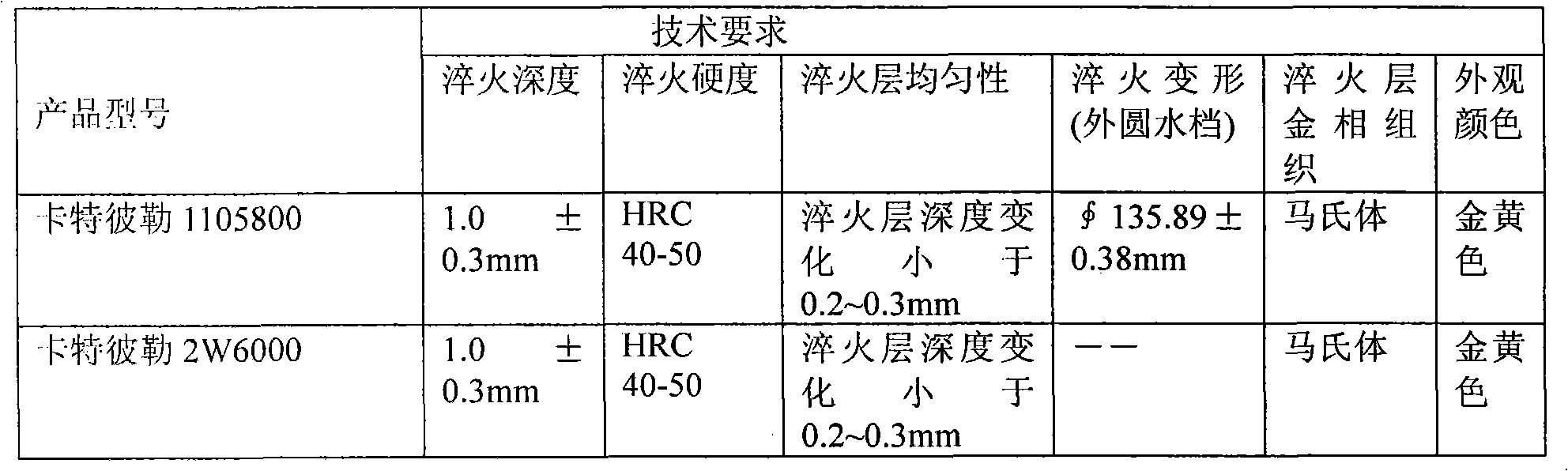

Manufacturing method of quenching cylinder sleeve with micro-deformation of inner holes, golden and high frequency

The invention discloses a manufacturing method of a quenching cylinder sleeve with micro-deformation of inner holes, golden yellow appearance and high frequency. The method comprises the following steps of: (1) selecting alloy gray cast iron containing chromium and copper, carrying out centrifugal casting and processing the cylinder sleeve; (2) adopting high-frequency quenching equipment to quench the cylinder sleeve; (3) spraying quenching cooling medium which is 8 to 12 percent of Houghton Q251 to the heated cylinder sleeve for quick cooling and quenching and adjusting the interval between a sensing ring and an external spraying ring to control and guarantee that the appearance is golden yellow; (4) adopting a car-type low-temperature tempering furnace for tempering with the tempering temperature controlled to be 250 to 280 DEG C and preserving the temperature for 2 hours; (5) carrying out exquisite processing to the tempered cylinder sleeve, saving cutting processing to the peripheral end surfaces and water retaining parts after high frequency quenching, preserving golden yellow appearance and warehousing after being inspected to be qualified. The invention has advanced technique and simple method and by compared with the common high frequency quenching cylinder sleeve, the appearance is beautiful, the hardness and deep uniformity of the quenching layer are good, the wear resistance is good and the service life is long.

Owner:YANGZHOU WUTINGQIAO CYLINDER LINER

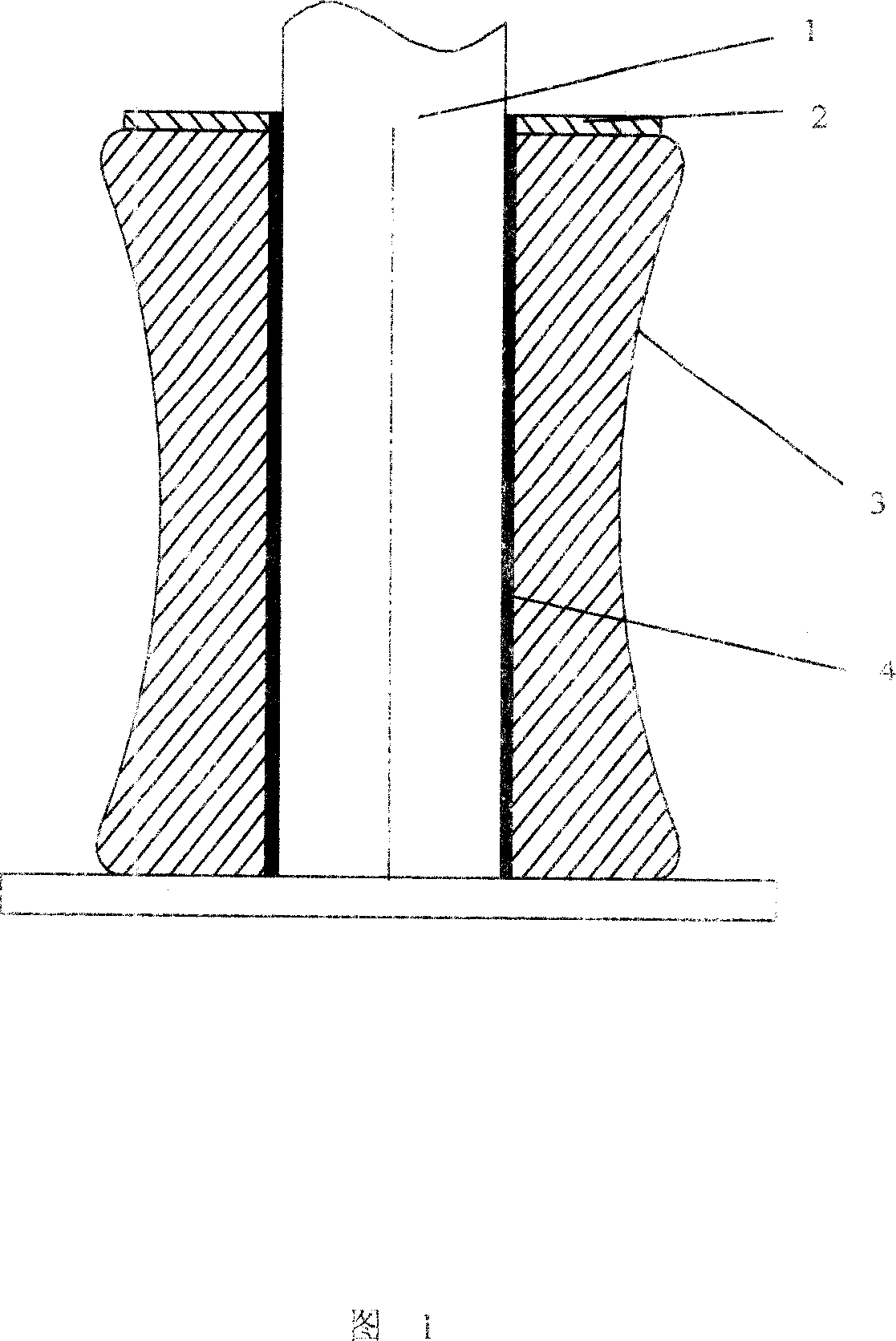

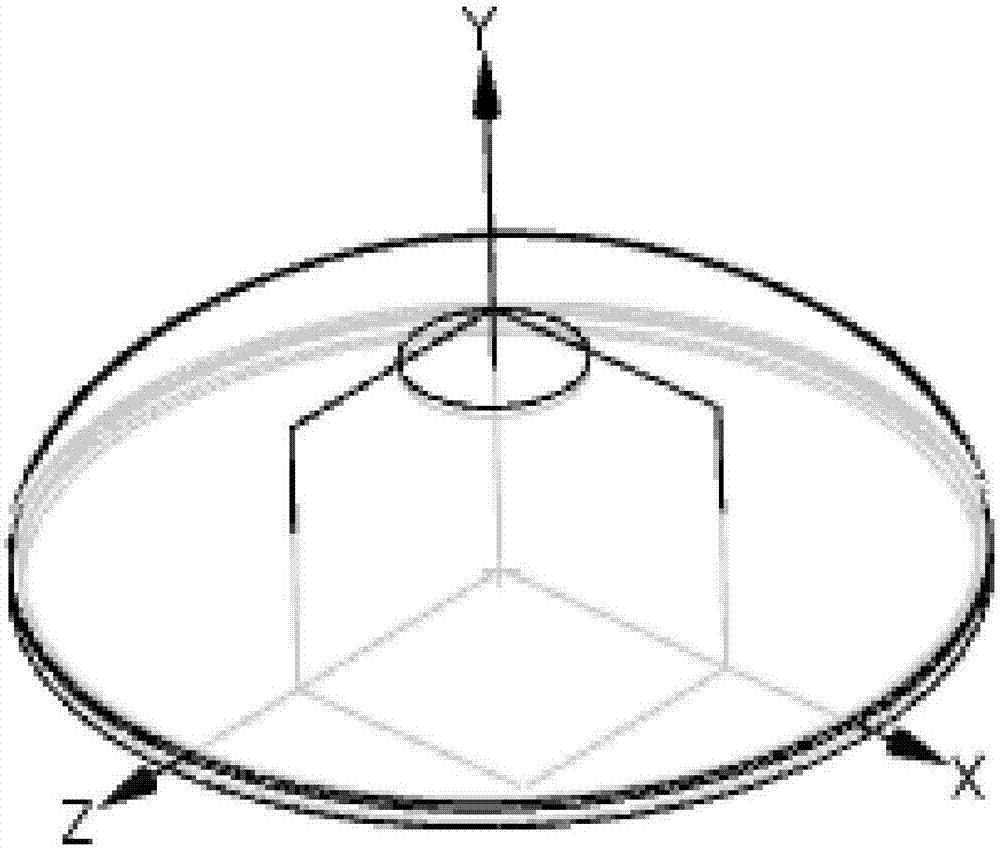

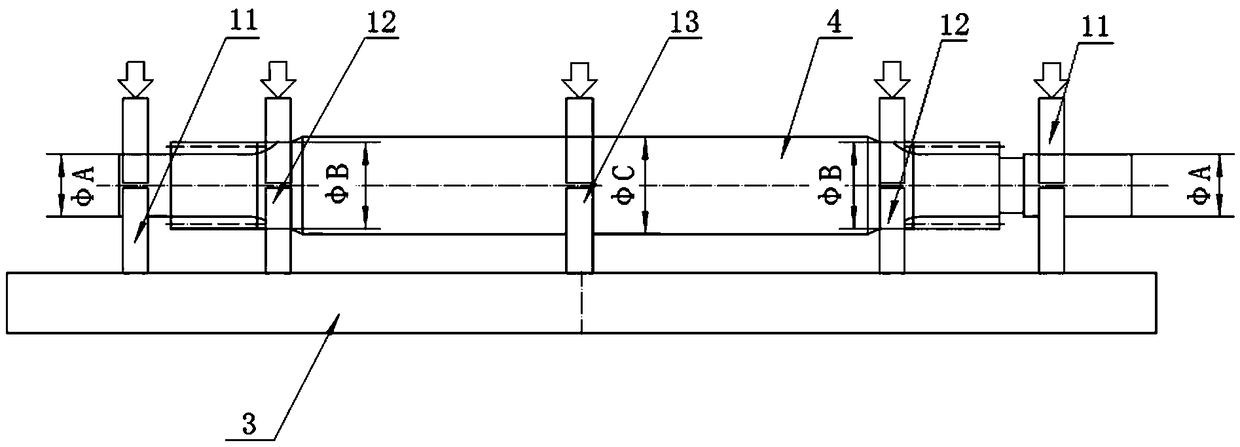

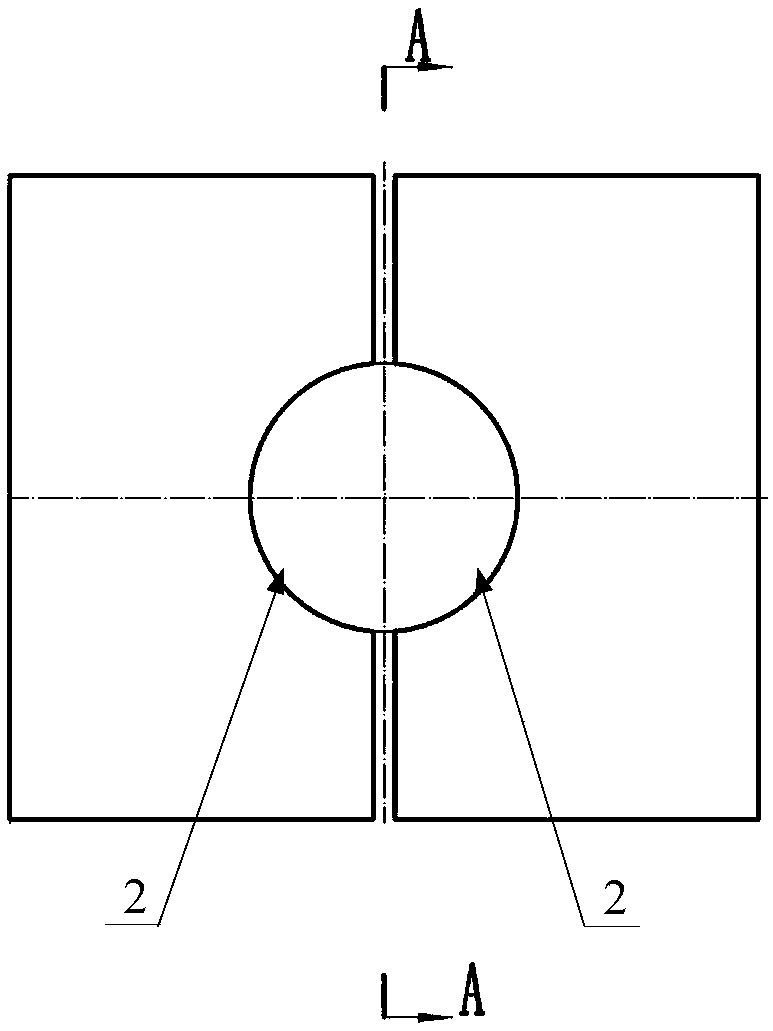

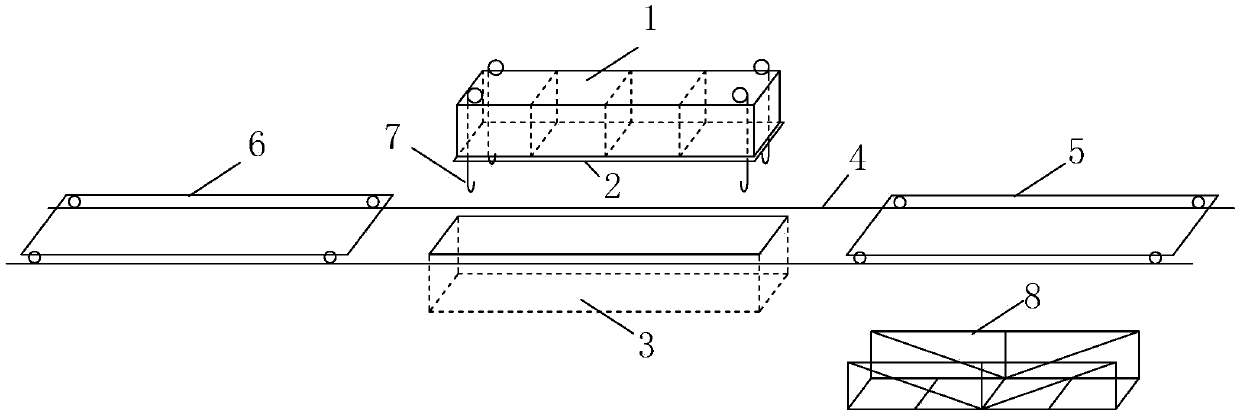

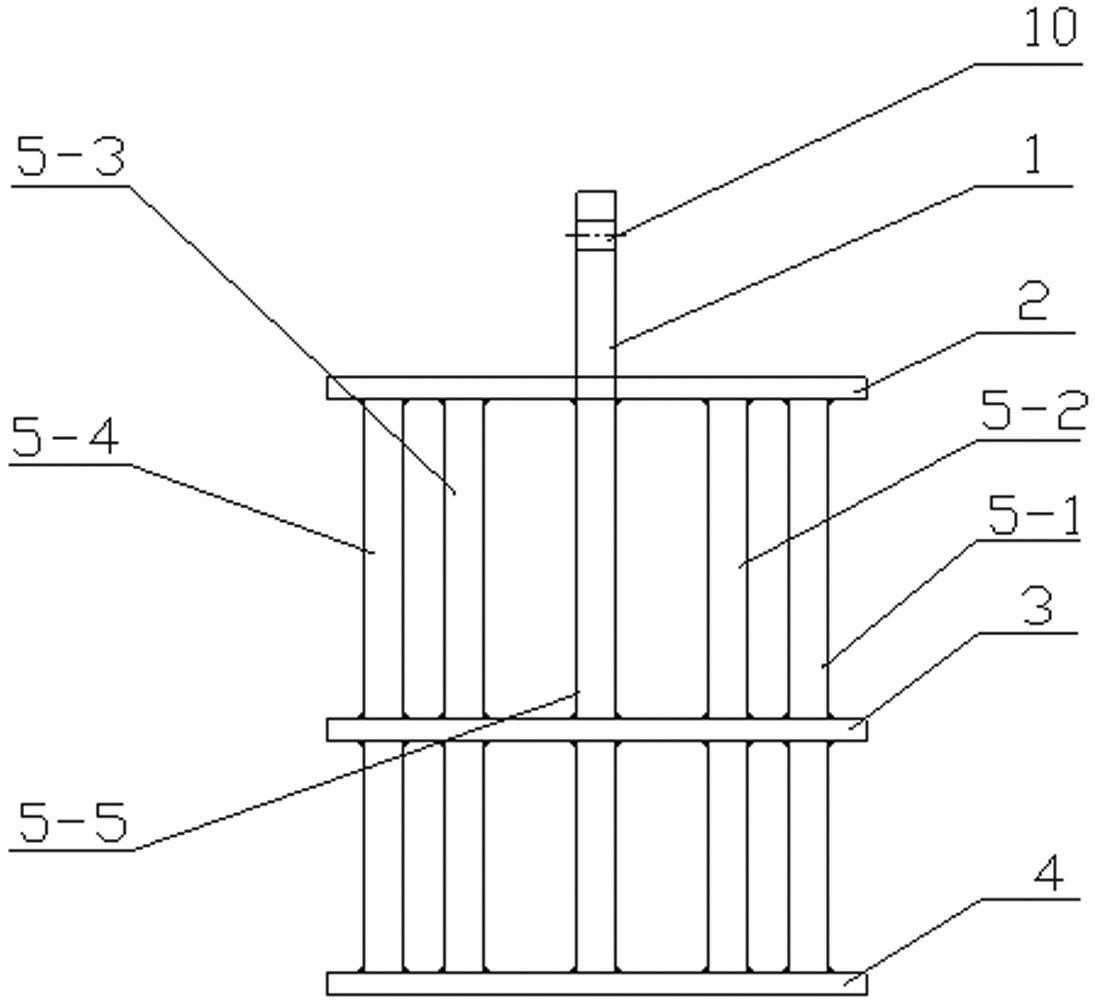

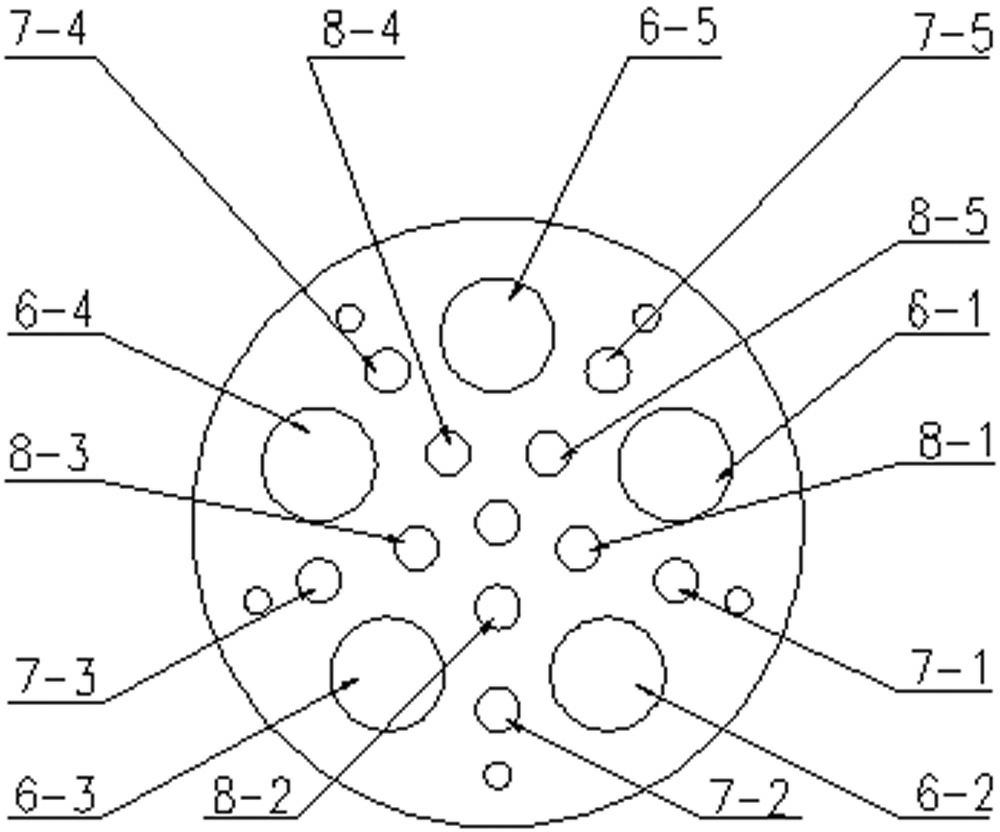

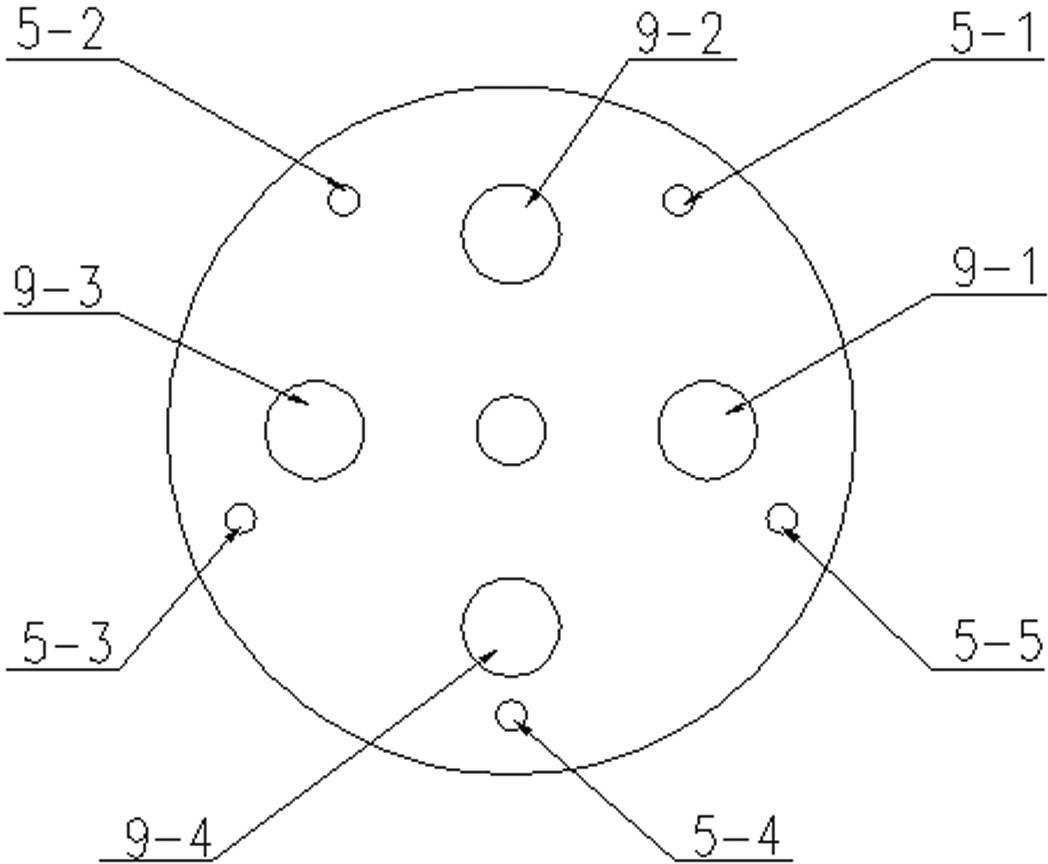

Suspension device for gearshaft carburizing and quenching

InactiveCN102312241ASmall quenching deformationUniform stress distributionSolid state diffusion coatingFurnace typesEngineeringCarburizing

The invention relates to a suspension device for gearshaft carburizing and quenching. The device comprises a hanging pillar, an upper support plate, a lower support plate, a base plate and five identical vertical columns; the hanging pillar passes through the center openings of the upper support plate and the lower support plate, and is fixed with the upper support plate, the lower support plate and the base plate through welding, and a hoisting opening is positioned at the top of the hanging pillar; the five vertical columns respectively pass through openings circumferentially and uniformly distributed on the upper support plate and the lower support plate, and are fixed with the upper support plate, the lower support plate and the base plate through welding, with the tops of the five vertical columns flush with the upper support plate, and the diameters of the five vertical columns equal to the diameter of the hanging pillar; the upper support plate is provided with five circumferentially and uniformly distributed through holes for placing the gearshaft, and is also equipped with five oil holes uniformly distributed on two circumferences of different diameters; the lower support plate and the upper support plate have the same structure; and the base plate is provided with four circumferentially and uniformly distributed oil holes. Employment of the device provided in the invention for carburizing and quenching a gearshaft can control the gearshaft deformation after carburizing and quenching, thus reducing the rejection rate of gearshafts.

Owner:XIANGTAN ELECTRIC MFG

Heat treating method of thin sheet steel type part

ActiveCN101381804AReduce deformationOmit the clamping and tempering processSolid state diffusion coatingFurnace typesProduction scheduleElectricity

The invention relates to a heat treatment method for a part of the thin steel sheet class. The method comprises the following steps: (1) exhaust; (2) lifting of carbon potential; (3) rapid carburization; (4) even cooling; (5) quenching; and (6) deoiling, low-temperature tempering to complete the process of heat treatment. The heat treatment method uses the process of low-temperature treatment, causes small deformation to a flake-type part, omits the trivial working procedures of flat clamping and tempering, accelerates the production schedule; compared with the prior art, the method reduces the production time by 40 minutes per furnace and shortens the production period by 20 percent; simultaneously, the low-temperature process reduces electricity consumption, saves energy and can not generate mass black carbon; and the obtained finished part has high surface hardness, slightly reduces the strength, and has good plasticity; and the method is suitable for treating the thin steel sheet type part which has small stress, requires wearing resistance and is easy to deform, thereby having large popularization and application potential.

Owner:NINGBO HONGXIE CLUTCH

Spheroidal graphite cast iron cast gear and machining process thereof

ActiveCN105331874AHigh thermal efficiencyHeating evenlyFurnace typesProcess efficiency improvementScrapMachining process

The invention discloses a spherodial graphite cast iron cast gear and a machining process thereof. The spherodial graphite cast iron cast gear mainly comprises, by weight, 3.5%-3.6% of C, 2.3%-2.4% of Si, 0.4%-0.45% of Mn, less than 0.1% of Cr, 0.4%-0.45% of Cu, 0.03%-0.045% of Mg, not larger than 0.02% of S, not larger than 0.05% of P and the balance Fe. The machining process of the gear includes the following steps of firstly, molten iron smelting, secondly, spheroidizing inoculation, thirdly, casting molding, fourthly, shot blasting, fifthly, thermal treatment, sixthly, rough machining, seventhly, surface hardening and eighthly, finish machining. According to the cast gear, low-manganese scrap steel serves as a raw material, production cost can be lowered, and the gear cast through spherodial graphite cast iron has the comprehensive performances of being high in strength, high in wear resistance and high in flexibility and can meet the requirement of a transmission gear.

Owner:山东惠宇汽车零部件有限公司

Cryogenic heat treatment technology for improving performances of countershaft gear

InactiveCN105400944ASmall quenching deformationHigh surface hardnessSolid state diffusion coatingFurnace typesHardnessCryogenic technology

The invention discloses a cryogenic heat treatment technology for improving performances of a countershaft gear. According to the technology, a salt bath quenching technology and a cryogenic technology are combined, so that the defects that the countershaft gear is liable to quenching deformation and is low in surface hardness are improved, and the service life of a countershaft is prolonged. The cryogenic heat treatment technology for improving performances of the countershaft gear is characterized by comprising the specific steps of cleaning, preheating, carburization, salt bath quenching, cryogenic treatment and secondary tempering. Compared with the prior art, the technology has the advantages that in the quenching stage, salt bath quenching is combined with a novel technology of cryogenic treatment, so that the deformation degree of the countershaft gear after carburization and quenching is enabled to be small, and the surface hardness is greatly improved.

Owner:张贺佳

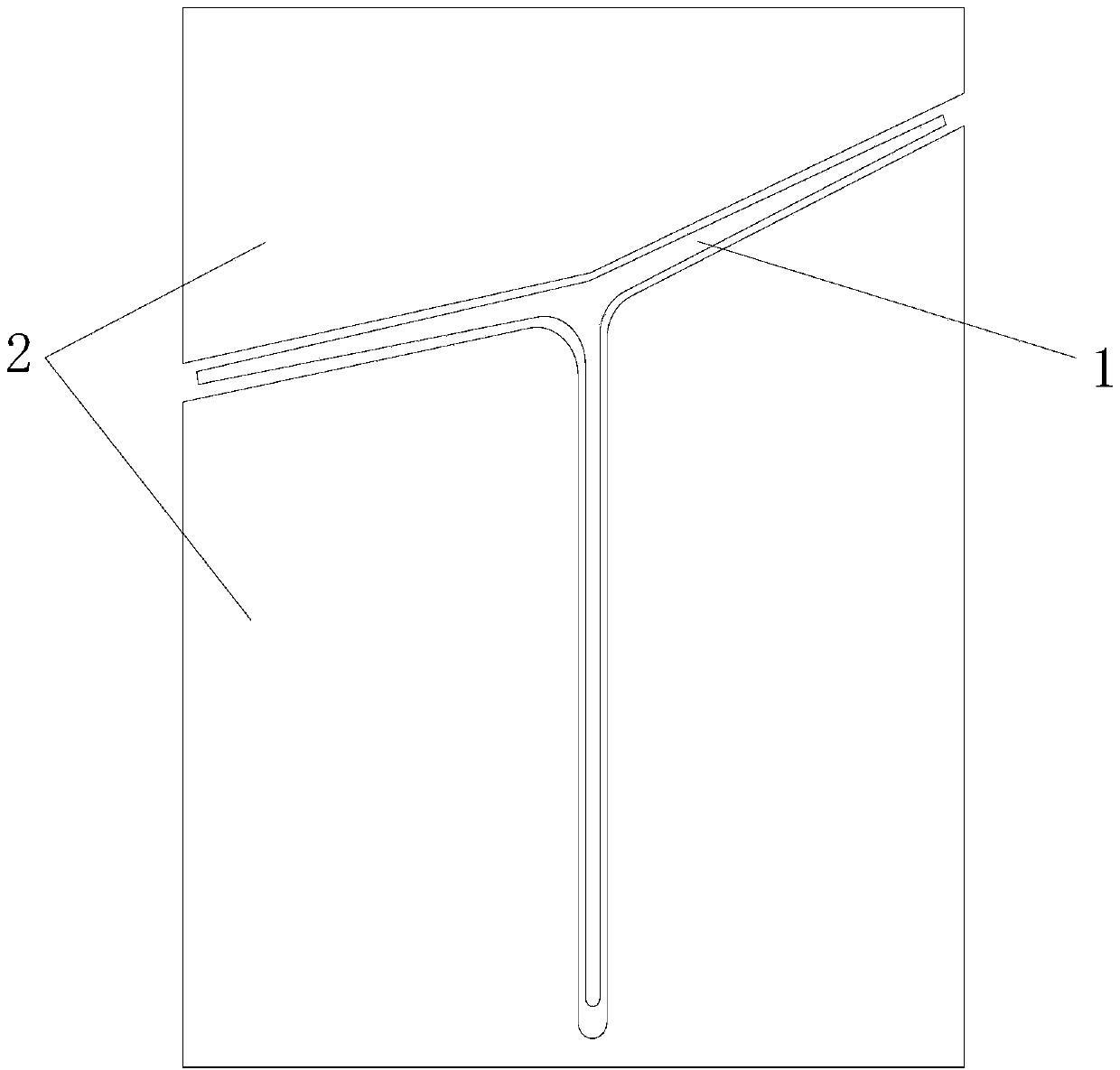

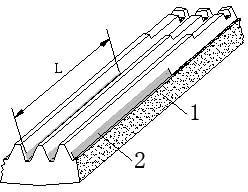

Laser quenching hardening method for tooth root of inner gear ring

InactiveCN102660668ASmall quenching deformationMeet hardening technical requirementsFurnace typesHeat treatment furnacesLaser quenchingLight guide

The invention relates to a laser quenching hardening method for a tooth root of an inner gear ring. The method is characterized by comprising the following specific steps of: placing the inner gear ring on a special clamp on a digital control precise rotary working table, and placing a light blocking ring at the upper end of the gear ring; allowing a single laser beam or double laser beams to enter the surface to be quenched of the bottom of the tooth space of the gear ring, and the connected tooth side at an angle of 20 to 90 degrees; and moving a light guide head up and down or moving the light guide head up and down and rotating, and forming a laser hardening belt on a treatment surface, wherein the tooth root of the gear ring is quickly scanned by the laser beam with highly concentrated energy to ensure that the surface temperature of the scanned tooth root of the gear ring is raised quickly to over a phase change point, the quenching deformation is small compared with that of the conventional thermal treatment process, and energy consumption is reduced.

Owner:CHINA FIRST AUTOMOBILE

Heat treatment process for die steel

InactiveCN105695700ASmall quenching deformationImprove organizational stabilityHardnessWear resistance

The invention discloses a heat treatment process for die steel. The heat treatment process is characterized in that the die steel is a 7CrSiMnMoV material which contains, by mass, 0.65 to 0.75% of C, 0.85 to 1.15% of Si, 0.65 to 1.05% of Mn, 0.90 to 1.20% of Cr, 0.20 to 0.50% of Mo, 0.15 to 0.30% of V, no more than 0.030% of P and no more than 0.030% of S, with the balance being Fe; and the heat treatment process comprises the following steps: (1) complete annealing; (2) under annealing; (3) quenching; and (4) tempering. The heat treatment process for the die steel can improve the structure stability of the die steel and comprehensive performance like hardness, wear resistance and toughness of the die steel.

Owner:CHONGQING CITY BANAN DISTRICT YONGXING MACHINERY FACTORY

Quenching medium containing aloe extract and preparation method thereof

InactiveCN104593562AGood compatibilitySmall quenching deformationQuenching agentsSodium bicarbonateSodium lactate

The invention discloses a quenching medium containing aloe extract. The invention is characterized in that the quenching medium is prepared from the following raw materials in parts by weight: 6-10 parts of aloe extract, 1-2 parts of hydroxypropyl methylcellulose, 0.3-0.5 part of hydroxyethyl cellulose, 0.05-0.1 part of gamma-polyglutamic acid, 0.5-1 part of glycerol, 0.5-1 part of sodium bicarbonate, 0.5-1 part of sodium lactate, 1-2 parts of potassium sodium tartrate, 0.1-0.2 part of polyoxypropylene glycerol ether, 0.1-0.2 part of sodium lauroyl hydroxy-ethyl sulfonate, 0.3-0.5 part of castor oil polyethenoxy ether, 0.1-0.2 part of sodium benzoate and 80-100 parts of water. The quenching medium uses the aloe extract as the main raw material, has favorable cooling performance, can effectively reduce the quenching distortion of the workpiece, and avoids the cracking and soft spots of the workpiece; and the processed workpiece has the advantages of high hardness and deep hardening layer. The quenching medium has the advantages of favorable rust resistance, favorable corrosion resistance, favorable bactericidal property, stable performance, fewer pollution emissions and favorable environmental compatibility, and conforms to the industrial policies on environmental protection and emission reduction.

Owner:安徽省杨氏恒泰钢管扣件加工有限公司

Preparing device and method for zero decarburization layer bearing steel wire rod

InactiveCN107322248AImprove wear resistanceImprove pitting resistanceOther manufacturing equipments/toolsWire rodAbutment

The invention discloses a preparing device and method for a zero decarburization layer bearing steel wire rod. The preparing device comprises a balling annealing furnace, a front cold drawing machine, a horizontal and vertical straightener, a centreless lathe, a rear cold drawing machine and a recrystallization annealing furnace. The outlet end of the front cold drawing machine is in butt joint with the inlet end of the horizontal and vertical straightener. The outlet end of the horizontal and vertical straightener is in butt joint with the inlet end of the centreless lathe. The outlet end of the centreless lathe is in butt joint with the inlet end of the rear cold drawing machine. The balling annealing furnace, the front cold drawing machine, the horizontal and vertical straightener, the centreless lathe, the rear cold drawing machine and the recrystallization annealing furnace are adopted in the preparing device and method for continuous machining of the bearing steel wire rod, a finished zero decarburization layer bearing steel wire rod high in strength and good in tenacity is obtained, and integral treatment of the large-specification bearing steel wire rod is achieved. The yield is high, the material utilization rate is high, the machining efficiency is improved, and the preparing device and method are suitable for industrial production.

Owner:洛阳鼎辉特钢制品股份有限公司

Ultralight bearing heat treatment process

InactiveCN105316455AImprove stabilityAvoid deformationFurnace typesHeat treatment furnacesCold treatmentQuenching

The invention discloses an ultralight bearing heat treatment process. The process comprises the steps of quenching, cold treatment and tempering, and is characterized by firstly increasing the temperature to 650-670 DEG C at a rate of temperature increase of 10-15 DEG C / h during quenching, carrying out preheating for 10-15 minutes at 650-670 DEG C, then increasing the temperature to 835-840 DEG C at a rate of temperature increase of 8-12 DEG C / h to carry out quenching holding for 35-40 minutes and carrying out discharging and air cooling after carrying out furnace cooling below 160 DEG C. By adopting the process, the deformation of thin-wall bearing rings can be reduced, the dimensional stability can be improved, the rework correction rate can be also reduced and the production efficiency can be improved.

Owner:CHANGSHU CHANGZHOU BEARING

2-7-series small-section sectional material shaping preparation process

ActiveCN107236914AAbility to resist twisting deformationSmall quenching deformationMaterials preparationPre deformation

The invention belongs to the technical field of metal material preparation and relates to a 2-7-series small-section sectional material shaping preparation process. The shaping preparation process comprises the steps that before a sectional material is squeezed and sectional material heat treatment is performed, a load in the length direction is exerted on the sectional material, the deformation of the sectional material in the length direction is 1.5-2.5%, unloading is performed after the load is maintained for 15-30 S, in other words, the squeezed sectional material is firstly subjected to stretching processing, pre-deformation is loaded on the sectional material in advance, and after heat treatment is completed, the sectional material is shrunk back in the length direction while bending and twisting deformation of the sectional material is reduced. The small-section sectional material shaping process is convenient to operate, and the finished product rate of the sectional material is increased to 80-90% from the original 20%.

Owner:CHINA ZHONGWANG

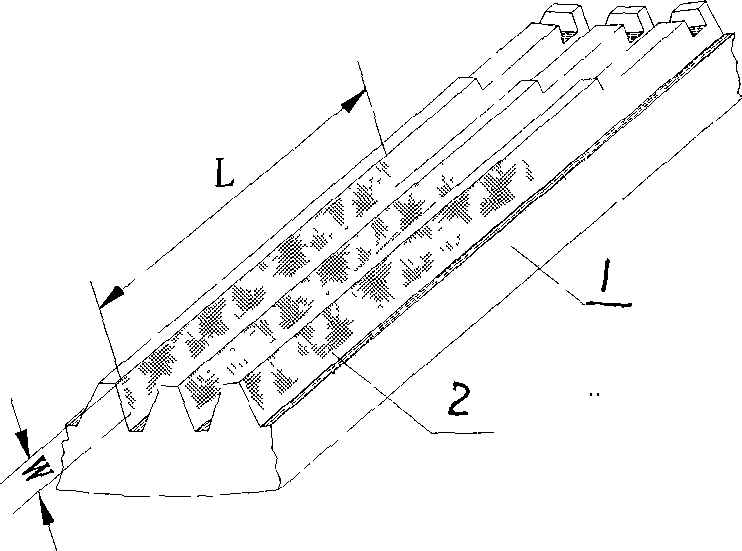

Novel quenching deformation control method for machine tool slide guide

InactiveCN103849718ASmall quenching deformationSmall amount of deformationIncreasing energy efficiencyFurnace typesEconomic benefitsQuenching

The invention discloses a novel quenching deformation control method for a machine tool slide guide. A slide guide that is made of an HT200 or HT300 cast iron material of a precision machine tool is subjected to surface high-frequency heating and quenching. The two ends of the slide guide (1) are fixed and a pressing force is applied on the middle part of a surface (5). The size of the pressing force is based on that the degree of deformation of the middle part of the guide is 1 mm. Then the slide guide is subjected to surface high-frequency induction quenching. By adjustment of process parameters, the pressing force and the stress are approximate and offset with each other so that an effect of micro-deformation or no deformation can be achieved, thus meeting technical requirements and production needs. The economic benefit of the method is significant.

Owner:DALIAN SHENGJIE VACUUM TECH DEV

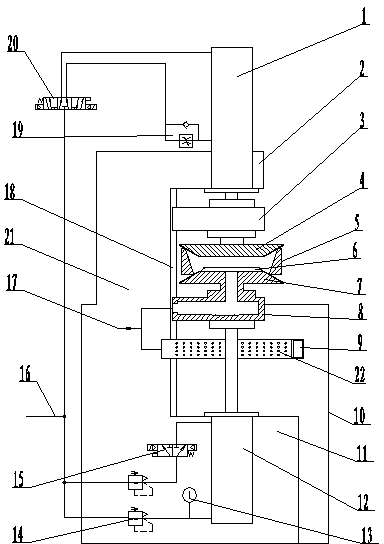

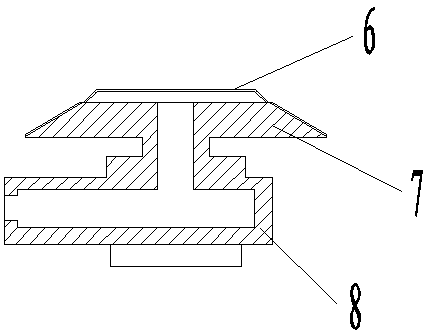

Die press quenching device for fully quenching steel ferrules

ActiveCN103451406AIncrease manufacturing costReduce manufacturing costsFurnace typesHeat treatment process controlHigh pressureQuenching

The invention relates to a heat treatment quenching device, in particular to a die press quenching device for fully quenching steel ferrules. The die press quenching device comprises a base, a stand column at one side of the base and a cross beam at the upper end of the stand column, wherein an upper sliding block and a lower sliding block are respectively arranged on a guiding rail of the stand column, and piston rods of an upper die cylinder and a lower die cylinder are respectively connected with the upper sliding block and the lower sliding block. The die press quenching device is characterized in that a high-pressure pipeline is connected with the upper die cylinder and the lower die cylinder respectively, a one-way speed regulating valve and a reversing valve I, which are used for controlling the speed and the direction of the upper die cylinder, are respectively arranged on a high pressure pipeline connected with the upper die cylinder, a pressure regulating valve and a reversing valve II, which are used for controlling the pressure and the direction of the lower die cylinder, are respectively arranged on a high pressure pipeline connected with the lower die cylinder, and cooling oil for quenching is connected with an oil outlet and an oil spraying ring on the lower die. According to the device, the press quenching force and the press quenching speed can be precisely regulated, the quenching time is short, the deformation of quenched workpieces is small, the quenching quality is effectively ensured, and existing quenching and controlling technologies are greatly improved.

Owner:NINGXIA MACHINERY RES INST

Method for controlling surface hardness of bearing spacer ring

PendingCN108754408ASmall quenching deformationReduce the amount of retained austeniteSolid state diffusion coatingFurnace typesHardnessHeat treated

The invention relates to a method for controlling the surface hardness of a bearing spacer ring, and belongs to the technical field of bearing spacer ring processing. The method for controlling the surface hardness of the bearing spacer ring comprises the following steps of carrying out primary machining on the surface of the bearing spacer ring; putting the bearing spacer ring into a mesh belt furnace, and carrying out carbonitriding heat treatment, wherein the heat treatment process adopts manners of rising the temperature in stages and heating symmetrically; and carrying out secondary machining on the heat-treated bearing spacer ring. According to the method for controlling the surface hardness of the bearing spacer ring provided by the invention, by adopting the treatment process combining primary machining, carbonitriding and secondary machining, the surface hardness of the bearing spacer ring is dynamically controlled, so that the surface hardness of a finished product and the thickness of a hardening layer are promoted to be uniform and within the tolerance range of the technical requirement, the occurrence of the phenomenon that the surface hardness is too low or too high is avoided, and the generation of batch wastes caused by unqualified surface hardness of the finished product is avoided.

Owner:JINING JINGYI BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com