2-7-series small-section sectional material shaping preparation process

A preparation process and small-section technology, which is applied in the field of metal material manufacturing, can solve the problems that bending and twisting deformation are not easy to be corrected, and achieve the effect of reducing shaping procedures and labor, reducing workload, and reducing quenching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

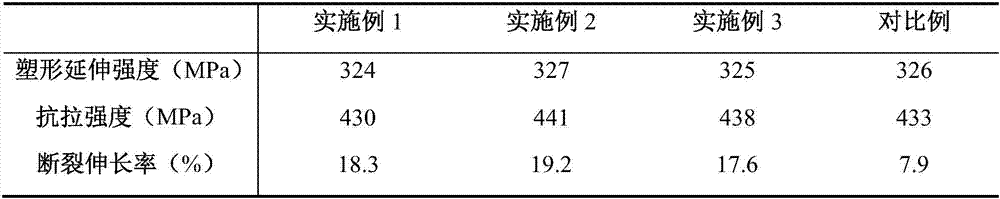

Embodiment 1

[0031] A 2, 7-series small-section profile shaping preparation process, the specific steps are as follows:

[0032] A. Furnace loading of ingredients: According to the process performance of aluminum alloy itself and the processing conditions of aluminum alloy processed products, the standard addition amount of each component of aluminum alloy ingredients is determined, and each component of aluminum alloy is preheated and added to the melting furnace. The temperature is 150°C, and the preheating time is 20 minutes;

[0033] B. Melting and casting: Use an electric heater to heat the melting furnace. The melting temperature of the melting furnace is 750 ° C. The aluminum alloy ingredients are melted and cast. The specific process of melting and casting is melting, stirring, slag removal, sampling and testing, standing heat preservation, refining, secondary Stirring, secondary slag removal, on-line refinement, degassing, filtration, casting, the aluminum alloy ingredient mixture...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that the deformation of the profile in step D in the length direction is 2%, and the load holding time is 20S.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that the deformation of the profile in step D in the length direction is 2.5%, and the load holding time is 30S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com