Suspension device for gearshaft carburizing and quenching

A technology of carburizing quenching and hanging devices, which is applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of fast cooling speed, slow cooling speed, and low service life, and achieve small quenching deformation, small deformation of workpieces, and easy use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

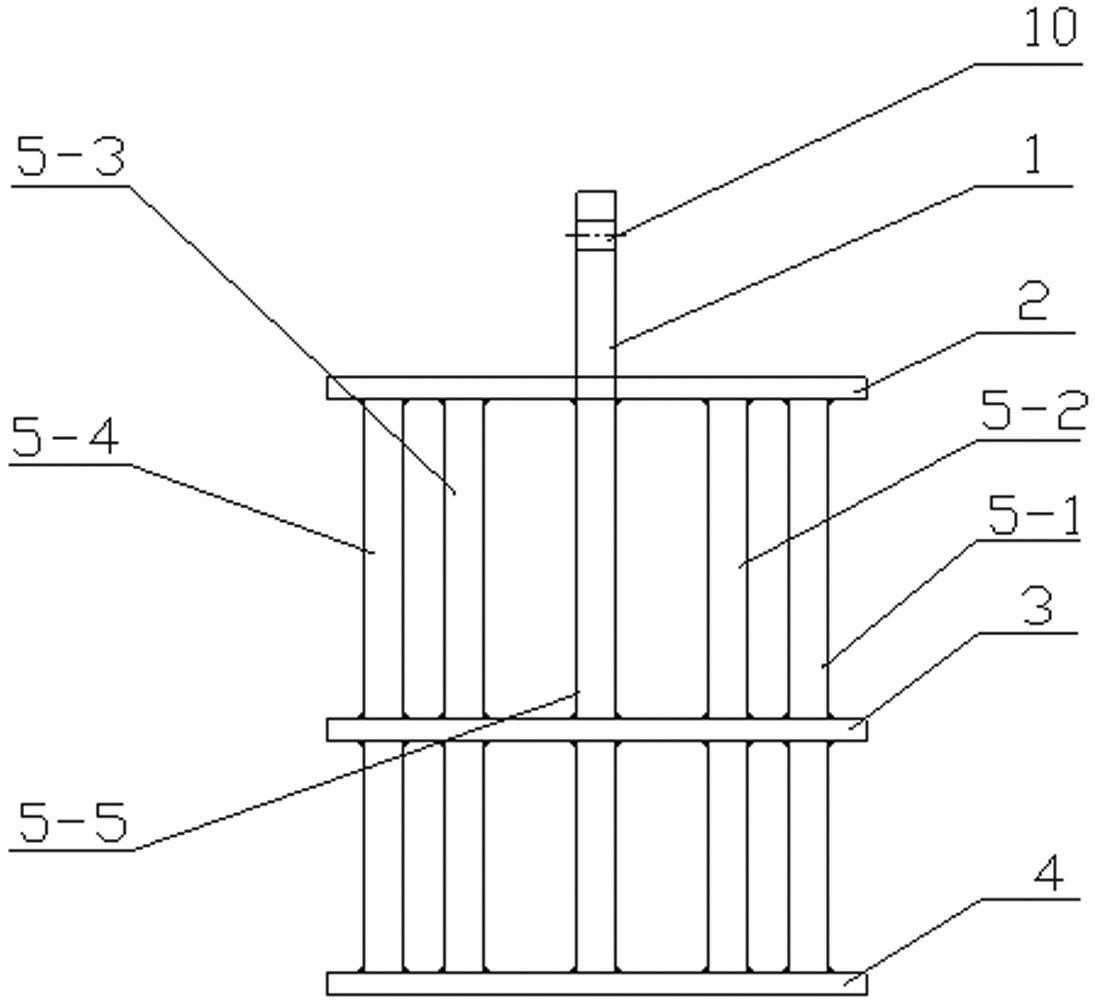

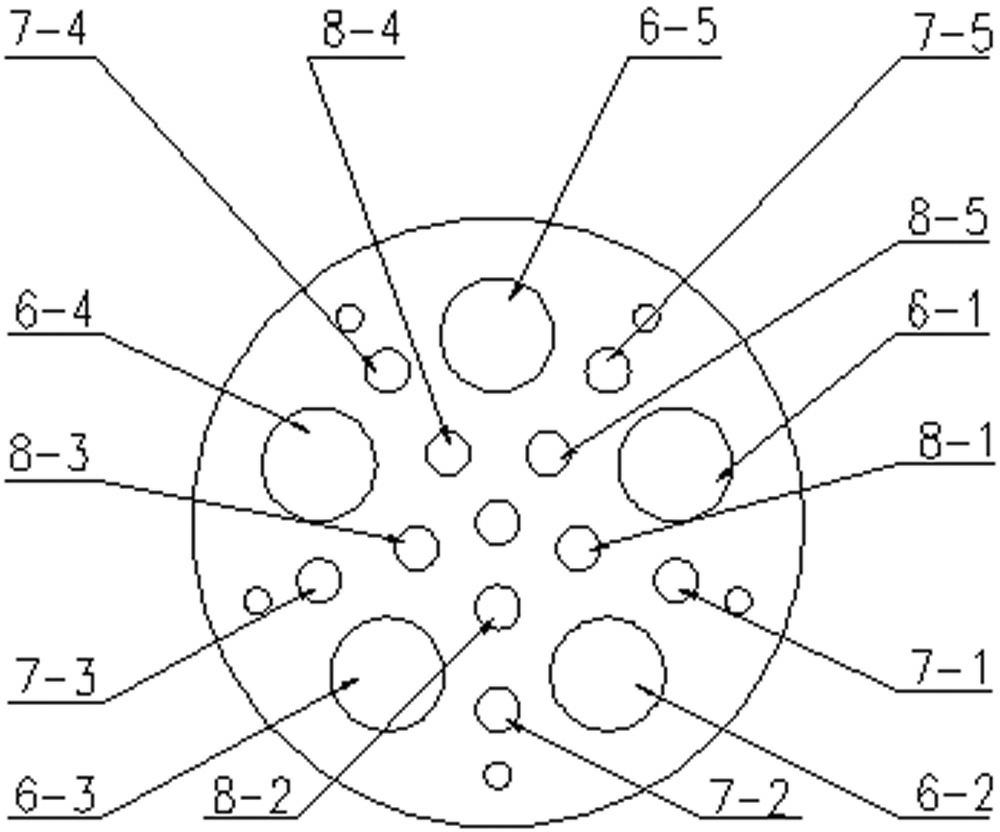

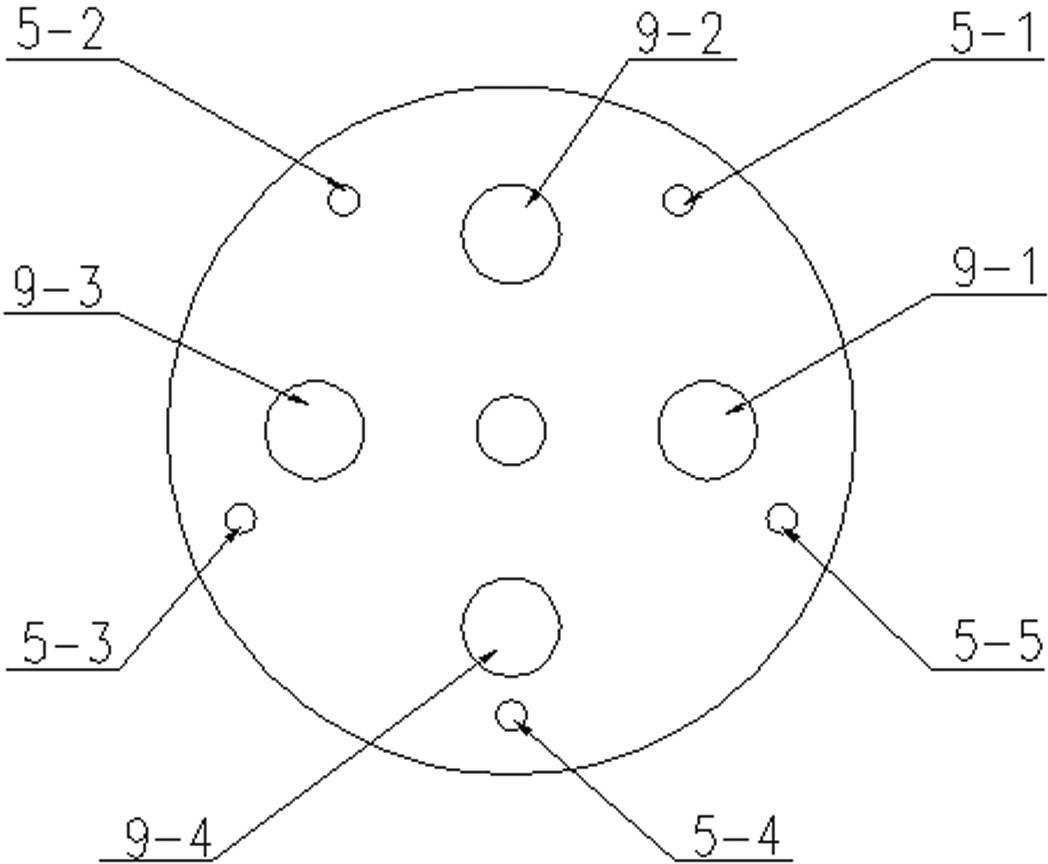

[0011] With reference to the accompanying drawings, this embodiment consists of a hanging column 1, an upper support plate 2, a lower support plate 3, a bottom plate 4, and five identical columns I 5-1, II 5-2, III 5-3, and IV 5- 4. Upright column Ⅴ 5-5; said hanging column 1 passes through the center hole of upper support plate 2 and lower support plate 3 and is welded and fixed with upper support plate 2, lower support plate 3 and bottom plate 4; The top is provided with a hoisting hole 10; the column I 5-1, column II 5-2, column III 5-3, column IV 5-4, and column V 5-5 pass through the upper support plate 2 and the lower support plate 3 respectively. Holes evenly distributed around the circumference, and welded with the upper support plate 2, the lower support plate 3, and the bottom plate 4, the column I 5-1, the column II 5-2, the column III 5-3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com