Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

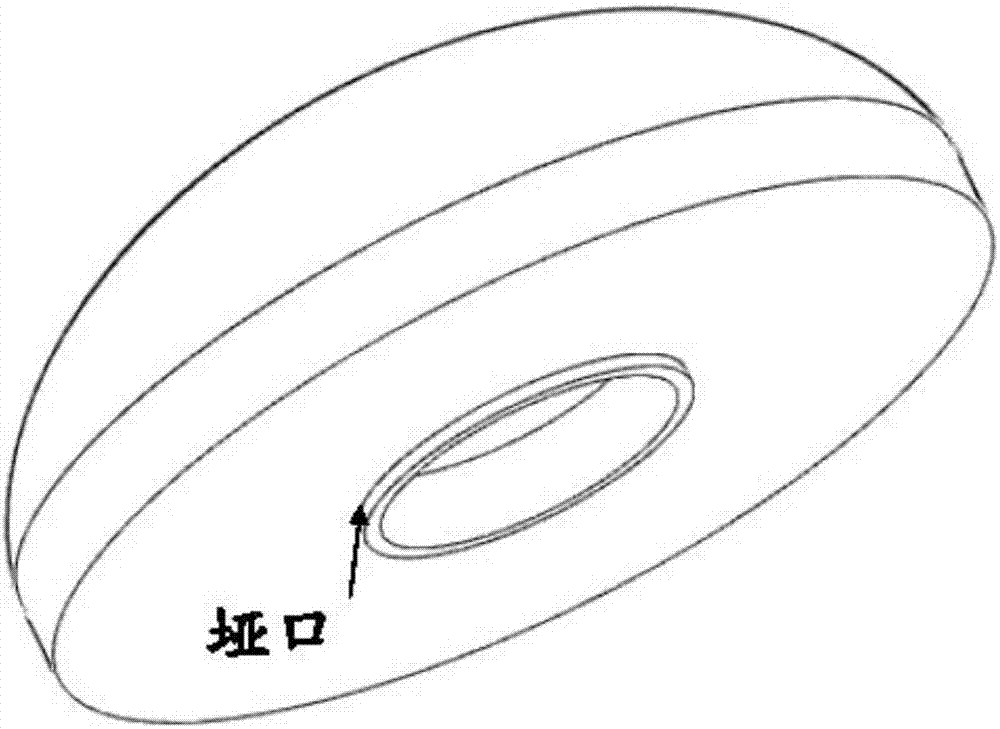

A heat treatment deformation and control method technology, which is applied in heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of pits in the circumferential direction of the shell, affect the machining process, and small port collapse, etc., to achieve strong operability and practicability, reduce the quenching transfer time, and reduce the effect of aging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

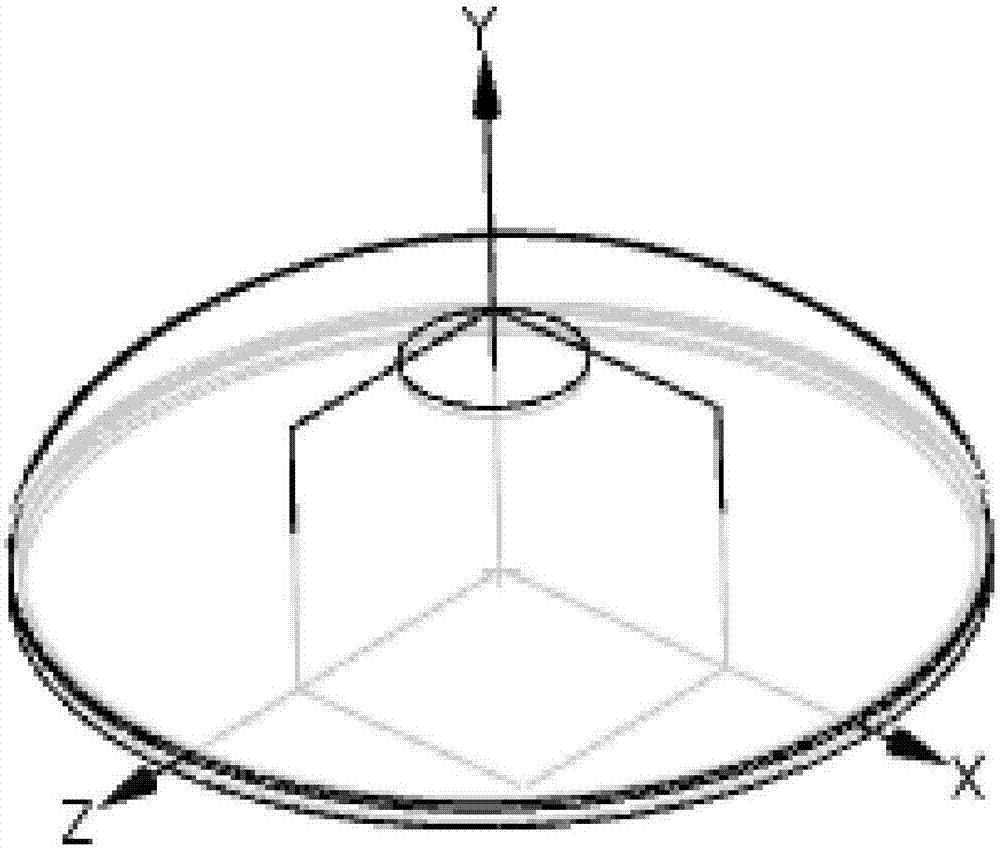

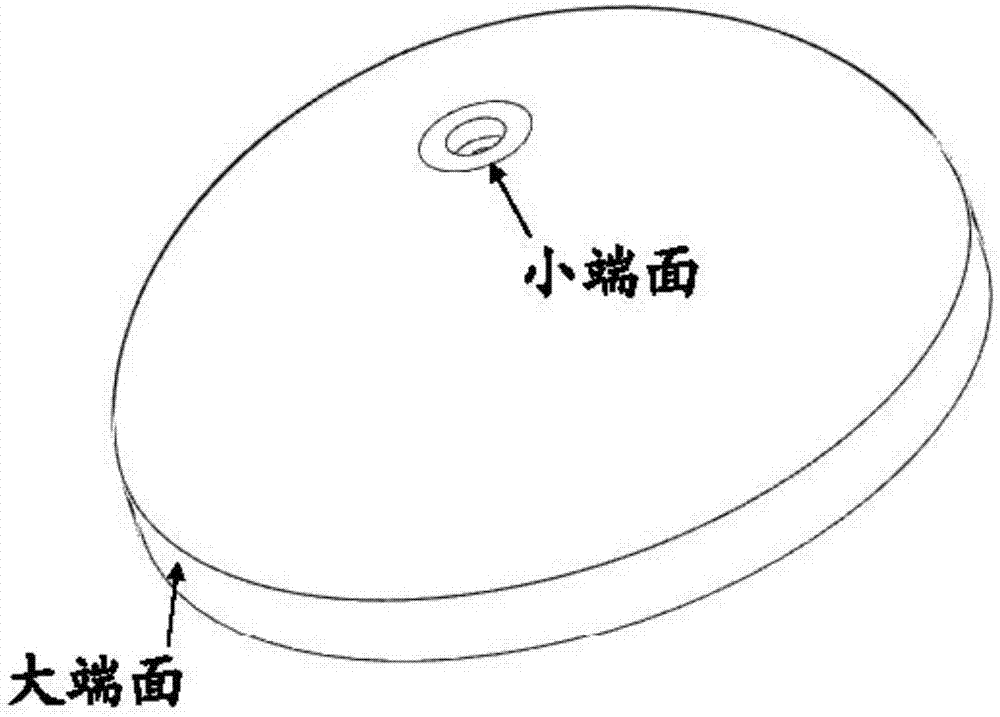

[0101] In this embodiment, the hemispherical shell of the storage tank with ellipsoidal surface is 2219 aluminum alloy, and the ellipsoid modulus is 2. The 2219 aluminum alloy plate is formed into a hemispherical blank with ellipsoidal surface after spinning, and the inner diameter is Ф1399~1400mm. The wall thickness is 7-13mm. The following is the specific process of the heat treatment deformation control method:

[0102] Step (1), fixing the hemispherical shell of the 2219 aluminum alloy ellipsoidal storage tank on the integrated quenching and aging heat treatment tooling;

[0103] Step (2), put the large-diameter, large-modulus ellipsoidal surface tank hemispherical shell 6 installed on the integrated quenching and aging heat treatment tooling into a heat treatment furnace for solid solution treatment, and keep it warm for 100 minutes at 535±5°C , after the treatment is completed, the integrated quenching, aging heat treatment tooling and the hemispherical shell 8 of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com