Heat treating method of thin sheet steel type part

A heat treatment method and thin steel sheet technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as product quality requirements and cost conflicts, and achieve the effects of shortening the production cycle, saving energy, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

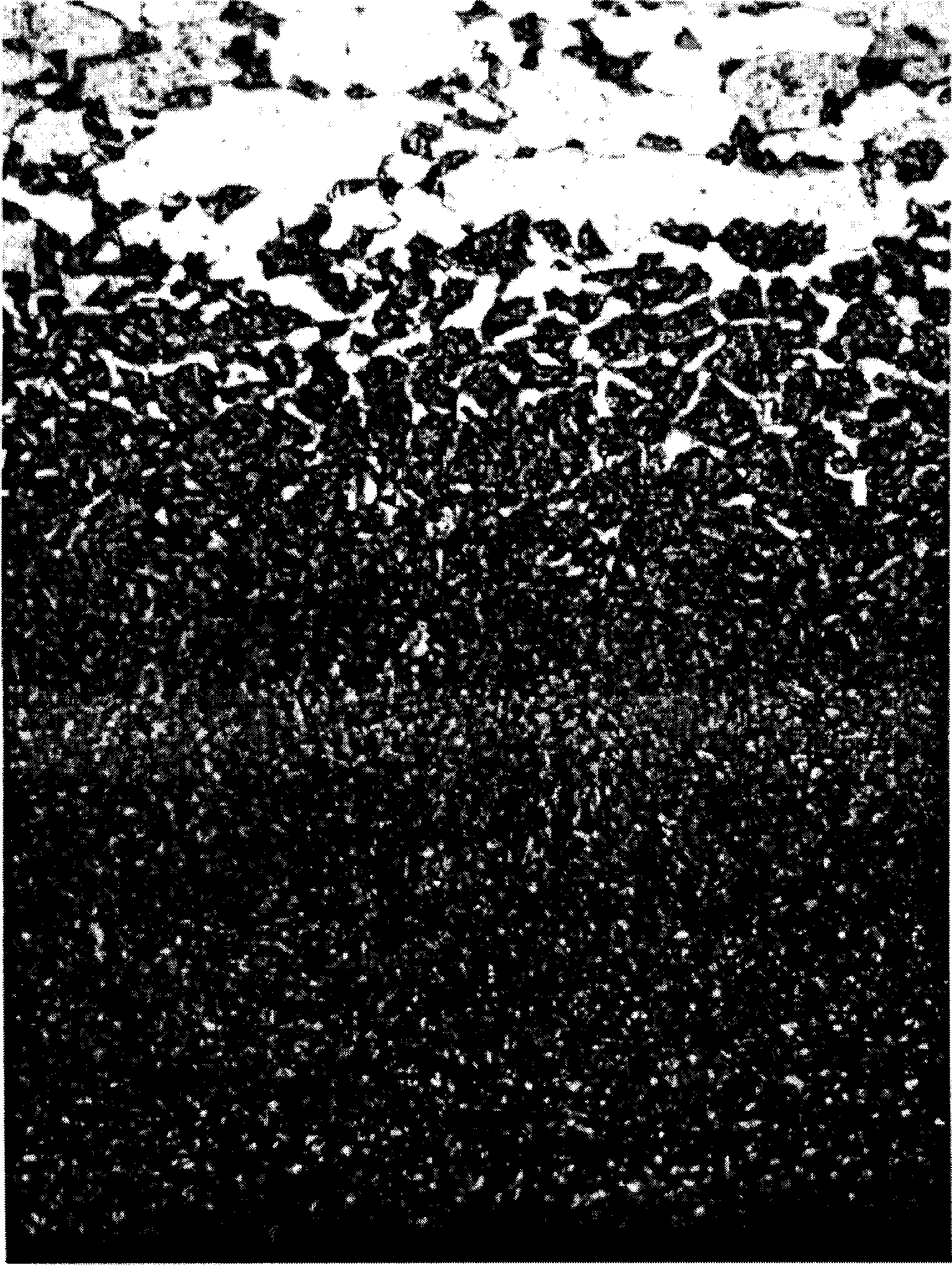

Examples

Embodiment 1

[0026] A heat treatment method for thin steel sheet parts, comprising the following steps:

[0027] 1) Exhaust, send methanol and ammonia gas to discharge the air in the furnace, and close the exhaust hole after the air is exhausted;

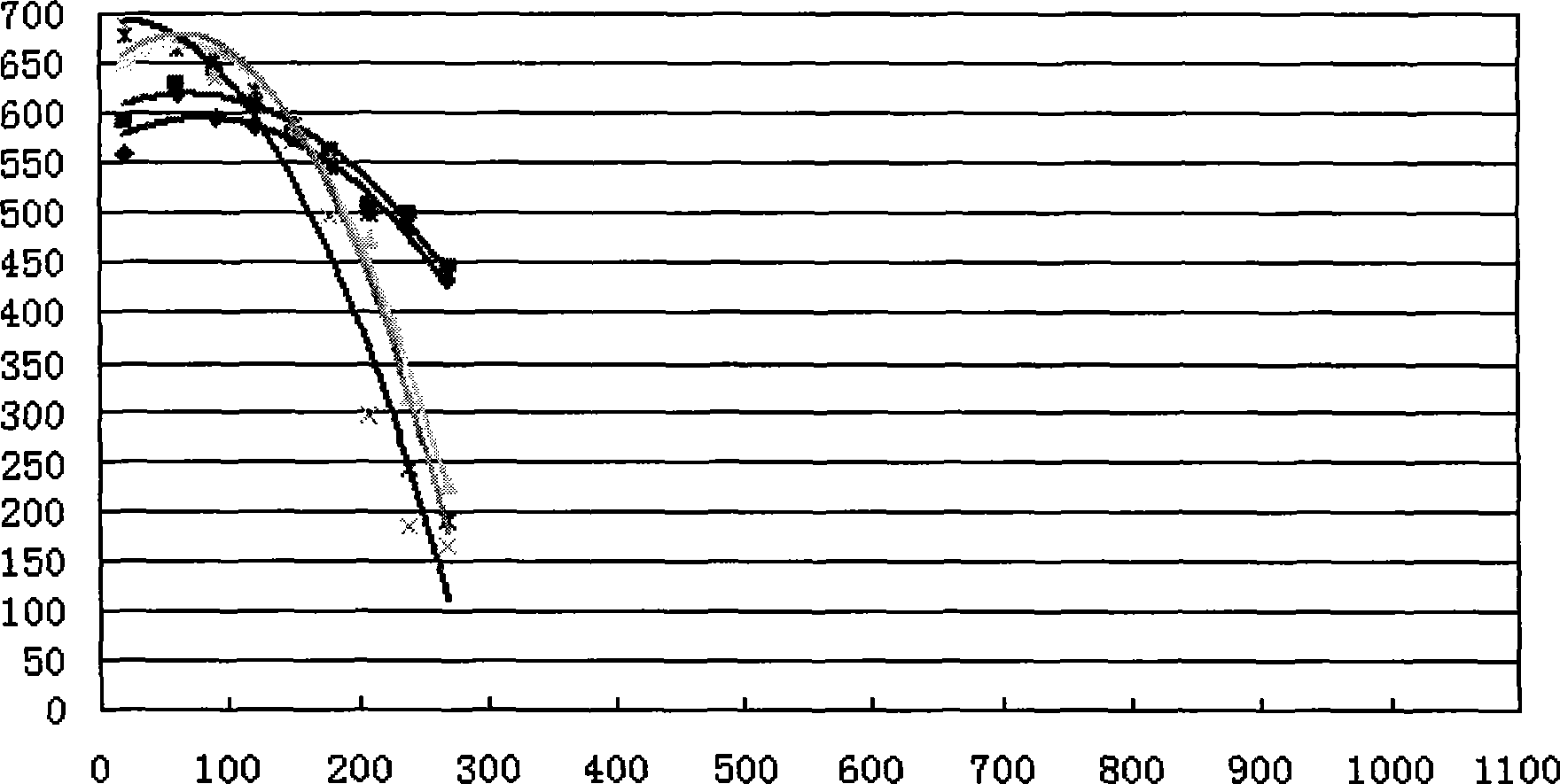

[0028] 2) On the carbon potential, evenly heat the parts for 25~35 minutes, the temperature is 790℃~800℃, use acetone as co-infiltration, and the dosage is 160~200 drops / hour;

[0029] 3) Rapid carburizing, co-infiltration temperature 790°C-800°C, carbon potential 1.8%-1.9%, time 30-45 minutes, use acetone, methanol, ammonia gas mixture, the content is 80 drops / hour of acetone, 200 drops of methanol drops / hour, ammonia 150 liters / hour;

[0030] 4) Cool down in both, the cooling time is 30 minutes to 45 minutes to drop to a temperature of 760 ° C ~ 770 ° C, keep warm for 1 ~ 2 minutes and start the dilution pump at the same time, and stabilize the carbon potential at 1.4% ~ 1.5%;

[0031] 5) Quenching, the quenching transfer time is ≤20 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com