Water-soluble quenching medium used in high-chromium cast iron quenching

A technology of high chromium cast iron and quenching medium, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of not meeting the heat treatment requirements of high chromium cast iron, quenching cracks, etc., to improve wear resistance, increase hardenability, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A polyvinylpyrrolidone (PVP) (molecular weight: 3000) 12.0 parts

[0025] B sodium polyacrylate (PAAS) (molecular weight: 25000000) 3.0 parts

[0026] C rust inhibitor 8.0 parts

[0027] D fungicide 0.5 parts

[0028] E pH adjuster 5.0 parts

[0029] F water 71.5 parts.

[0030] The higher the chromium content of the high chromium ball, the higher its hardenability, so in order to ensure that the high chromium ball does not crack during quenching, it is necessary to increase the content of sodium polyacrylate and reduce the cooling rate of the medium V300.

Embodiment 2

[0032] A polyvinylpyrrolidone (PVP) (molecular weight: 3000) 18.0 parts

[0033] B sodium polyacrylate (PAAS) (molecular weight: 25000000) 1.0 parts

[0034] C rust inhibitor 6.0 parts

[0035] D fungicide 0.5 parts

[0036] E pH adjuster 5.0 parts

[0037] F water 65.0 parts.

[0038] For the high chromium cast iron liner, in order to ensure that the deformation is reduced during heat treatment, the content of polyvinylpyrrolidone is increased, and the colloid protection can reduce the internal stress and effectively control the deformation during the metallographic transformation of the workpiece.

Embodiment 3

[0040] A polyvinylpyrrolidone (PVP) (molecular weight: 3000) 15.0 parts

[0041] B sodium polyacrylate (PAAS) (molecular weight: 25000000) 2.0 parts

[0042] C rust inhibitor 7.0 parts

[0043] D fungicide 0.5 parts

[0044] E pH adjuster 5.0 parts

[0045] F water 70.5 parts.

[0046] It is more suitable for simultaneous quenching of high chromium balls and high chromium liners.

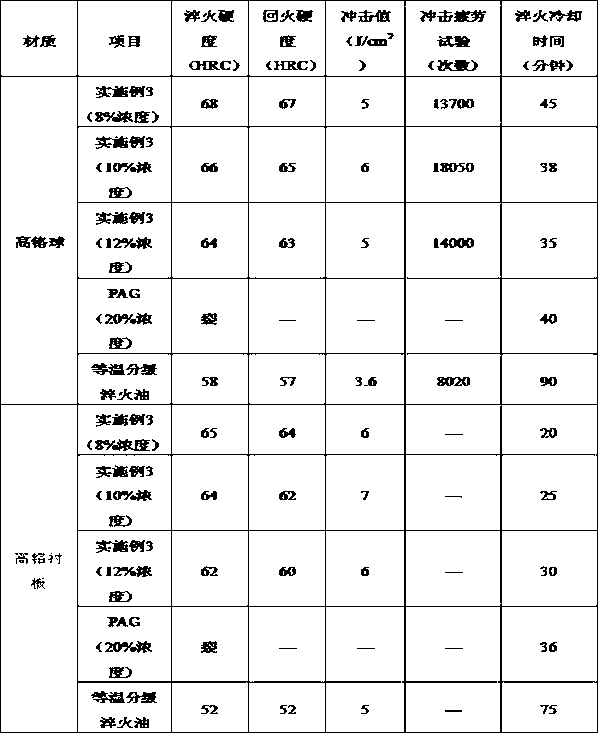

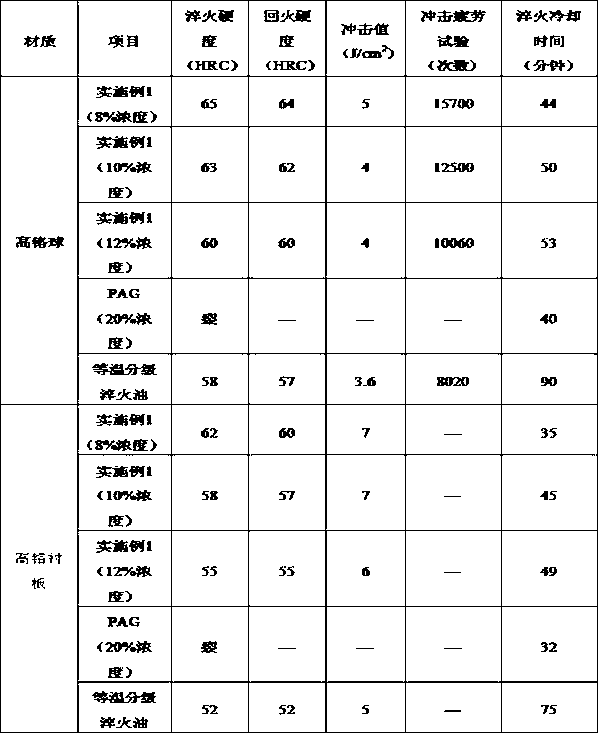

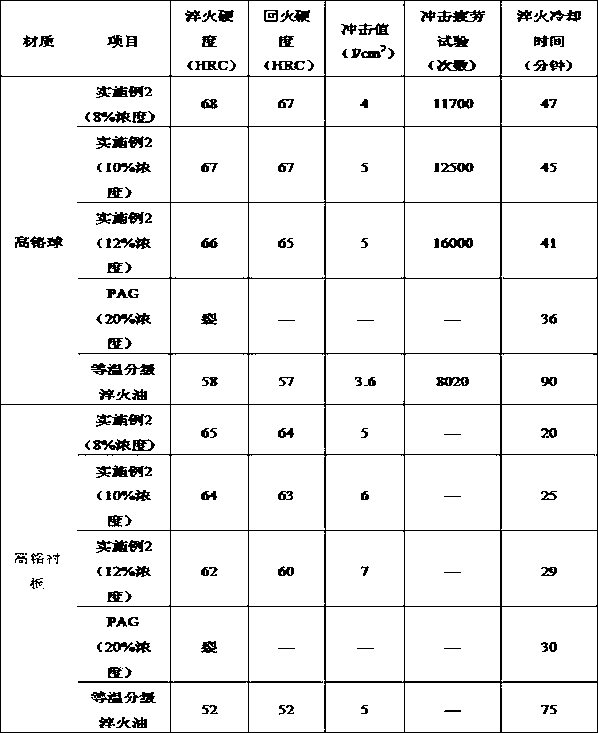

[0047] Table 1 Comparison of typical values of technical indicators

[0048] Index item Example 1 Example 2 Example 3 Existing PAGs in the market Isothermal graded quenching oil Exterior Colorless to yellow viscous liquid Colorless to yellow viscous liquid Colorless to yellow viscous liquid Colorless to yellow viscous liquid homogeneous oily liquid pH value 10.28 10.01 10.15 9.35 — Flash point — — — — ≥200 Kinematic viscosity (mm 2 / s, 40℃) 956 889 936 289 ≤14(100℃) Freezing point (°C) -9℃ -9℃ -9℃ -11℃ ≤-5 Density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com