Laser quenching hardening method for tooth root of inner gear ring

An internal gear and laser technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of large deformation randomness, large heat treatment deformation, high energy consumption, high limit torque and fatigue life, and small quenching deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

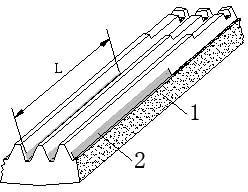

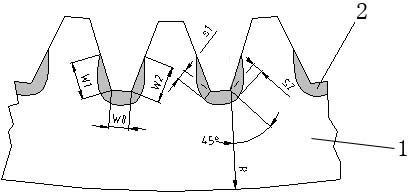

[0010] Such as figure 1 , 2 As shown, the laser quenching and hardening method of the bottom of each tooth groove and the two sides of the tooth root of the ring gear 1 is the same. The specific method is as follows: (1) Place the ring gear on the fixture of the rotary table, and the teeth The long direction is perpendicular to the table top of the rotary table; (2) A diaphragm is placed on the upper end of the ring gear 1; (3) The laser power is reasonably matched to 1500W, the scanning speed of the laser beam is 25mm / min, the focal length of the focusing mirror is 500mm, and the absolute value of the defocus amount is <50mm, the protective gas is argon and nitrogen; (4) The laser beam is incident along the diameter of the ring gear to the bottom of the tooth groove of the ring gear and the surface to be quenched on the sides of the two connected tooth roots; (5) The light guide head moves up and down, Coupled with the periodic small-angle indexing rotation of the rotary tab...

Embodiment 2

[0012] Such as figure 1 , 2 As shown, the laser hardening treatment method for the surface of each alveolar bottom of the ring gear 1 and the two connected tooth root sides that need to be quenched is the same, and the specific treatment method is as follows: (1) Place the ring gear 1 on the rotary table clamp On the tool, the tooth length direction is perpendicular to the table top of the rotary table; (2) A diaphragm is placed on the upper end of the ring gear 1; (3) The laser power is reasonably matched to 1600W, the laser beam scanning speed is 20mm / min, the focal length of the focusing lens is 500mm, and the defocus The absolute value of the volume is <60mm, and the protective gas is argon and nitrogen; (4) The two laser beams coming out of the beam splitter are incident on the bottom of the tooth groove of the ring gear and the quenched surface of the tooth sides of the ring gear at 40°~70°; ( 5) The light guide head moves up and down, coupled with the periodic small-an...

Embodiment 3

[0014] Such as figure 1 , 2 As shown, the laser hardening treatment method for the surface of each tooth groove bottom of the ring gear 1 and the two connected tooth root sides that need to be quenched is the same, and the specific treatment method is as follows: (1) Place the ring gear on the fixture of the rotary table above, the tooth length direction is perpendicular to the table top of the rotary table; (2) A stop ring is placed on the upper end of the ring gear 1; (3) Reasonably match the laser power to 4000W, the laser beam scanning speed to 30mm / min, the focal length of the focusing mirror to 600mm, and the defocus The absolute value of the volume is <70mm, and the protective gas is argon and nitrogen; (4) The two laser beams coming out of the beam splitter are incident on the surface of the ring gear tooth root to be quenched at 40°~70°; (6) The light guide head moves up and down , coupled with the periodic small-angle indexing rotation of the rotary table, forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com