Oil composition for heat treatment

A technology for heat treatment oil and composition, which is applied in the field of heat treatment oil composition for quenching metal materials, and can solve the problems of increased quenching deformation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

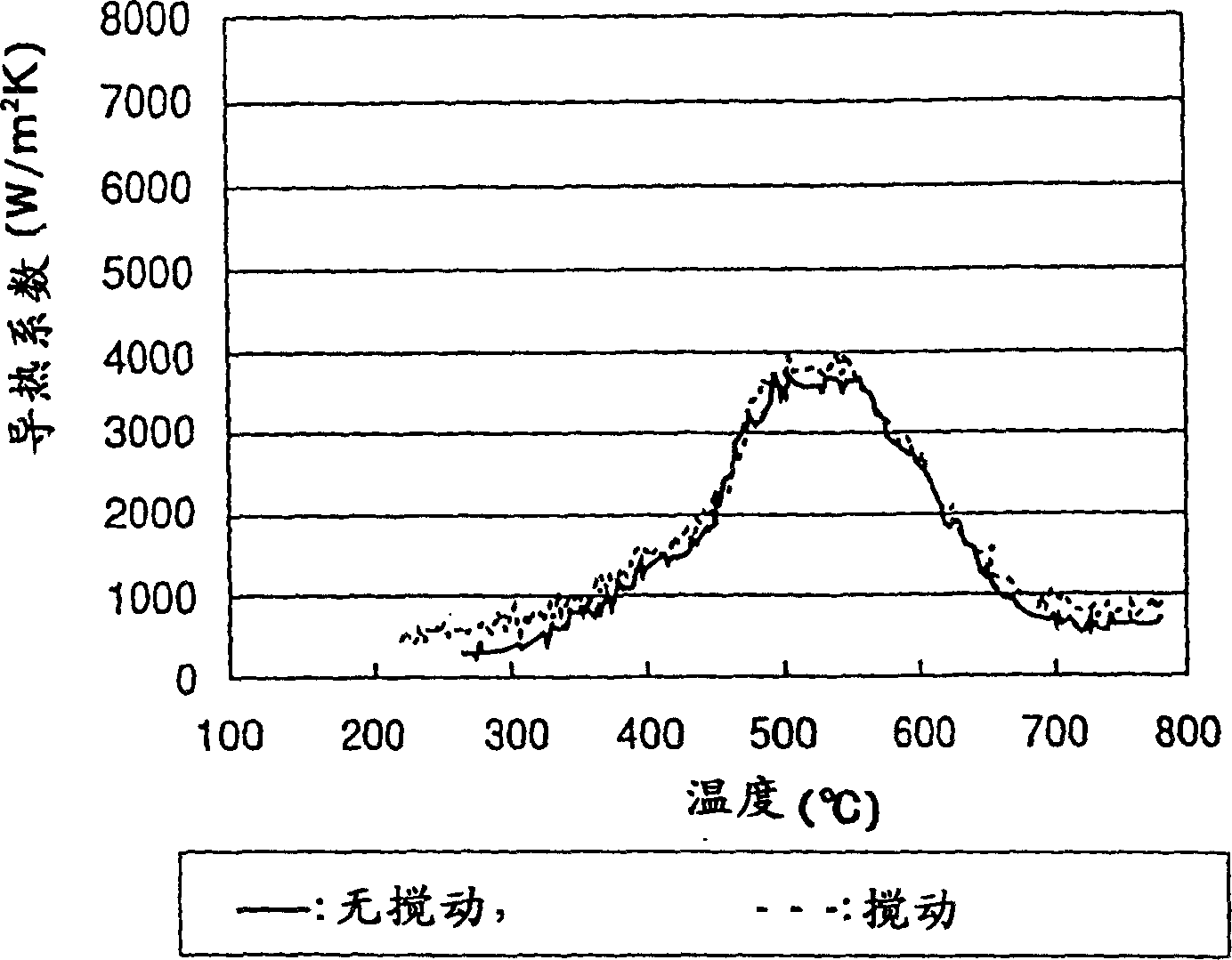

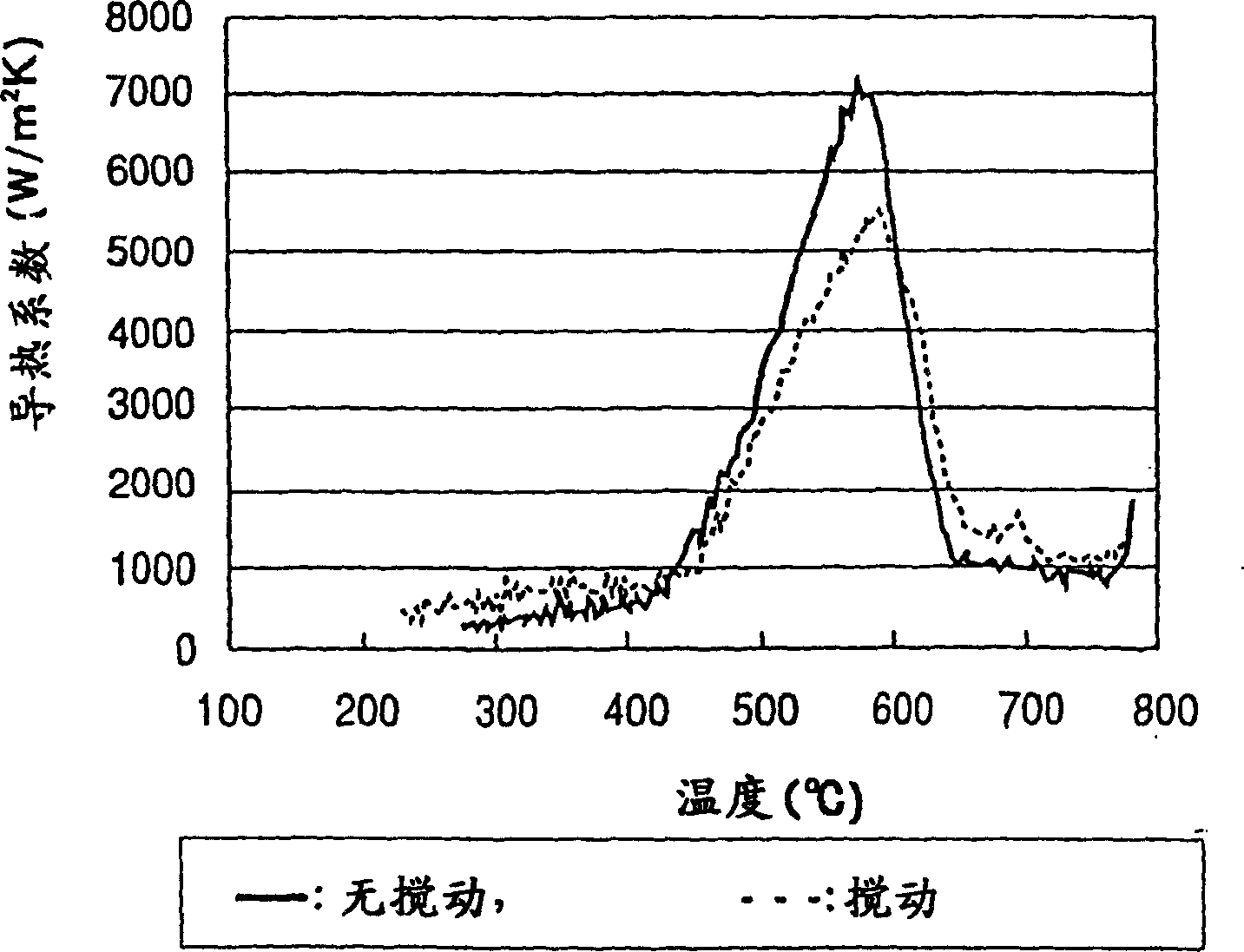

Image

Examples

Embodiment 1-4 and comparative example 1-4

[0032] Carburizing for 2.5 hours at 930°C with a carbon potential of 1.1% on a test piece made of SCM420 with an outer diameter of 80 mm, a height of 44 mm, and a thickness of 5 mm. Thereafter, the test piece was subjected to a diffusion treatment for 1.0 hour at a carbon potential of 0.8%. Then the temperature of the test piece was lowered to 850° C., and after 20 minutes of ignition, the test piece was quenched using the heat treatment oil composition (100° C.) of the mixed composition shown in Table 1. The results are shown in Table 1. In Table 1, data in parentheses represent kinematic viscosities at 40°C.

[0033] (annotation)

[0034] Low viscosity base oil A-1: 13.5mm 2 / s(40℃) paraffin series mineral oil

[0035] Low viscosity base oil A-2: 90.5mm 2 / s(40℃) paraffin series mineral oil

[0036] High viscosity base oil B-1: 435mm 2 / s(40℃) paraffin series mineral oil

[0037] High viscosity base oil B-2: 781mm2 / s(40℃) paraffin series mineral oil

[0038] Stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com