Quenching inductor for threaded surface of shaft disc type parts

A technology of quenching inductors and threaded surfaces, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of complex installation and replacement of inductors, increase the overall investment of quenching equipment, uneven heating or cooling, etc., and achieve simple and reasonable structure , Firm and reliable fixation, convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

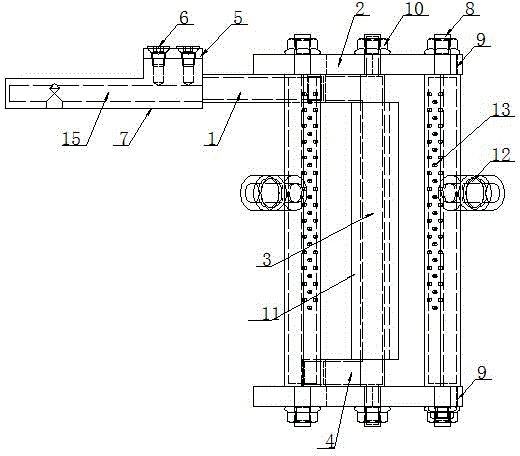

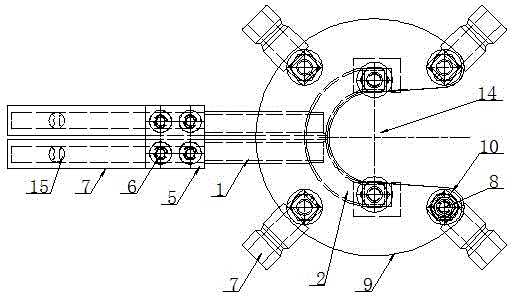

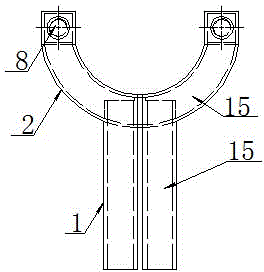

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a quenching inductor for the threaded surface of shaft-disk parts, the quenching inductor is mainly composed of an induction coil, a sprinkler, a magnetizer, a coil fixing plate and a sprinkler fixing plate; the induction coil is composed of a first connecting pipe 1 , the first connecting ring 2, the effective ring 3 and the second connecting ring 4, one end of a pair of first connecting pipes 1 arranged in parallel at intervals is connected to one end of the second connecting pipe 7 through a coil fixing plate 5 and a bolt 6, the second The other end of the second connecting pipe 7 is connected to the quenching equipment through the quick-change joint on the quenching equipment; the other end of the first connecting pipe 1 is connected to the two ends of the second connecting ring 4 through the first connecting ring 2 and the effective ring 3 in turn to form a circuit The induction coil, the first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com