Large-size carburizing steel double-row self-aligning roller bearing outer ring quenching mold

A self-aligning roller bearing, large-size technology, applied in the field of heat treatment, can solve the problems of increased impurities on the surface of the outer ring, the surface cannot be kept smooth, and reduced performance, so as to reduce the impact of impurities, improve performance, and ensure quenching quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

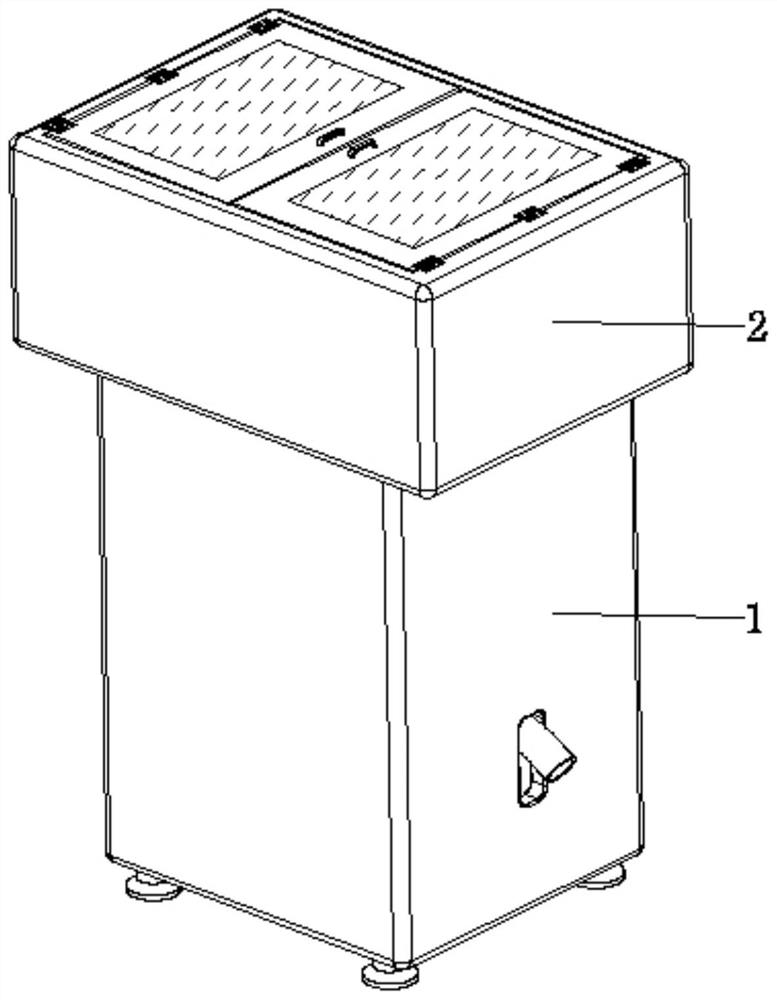

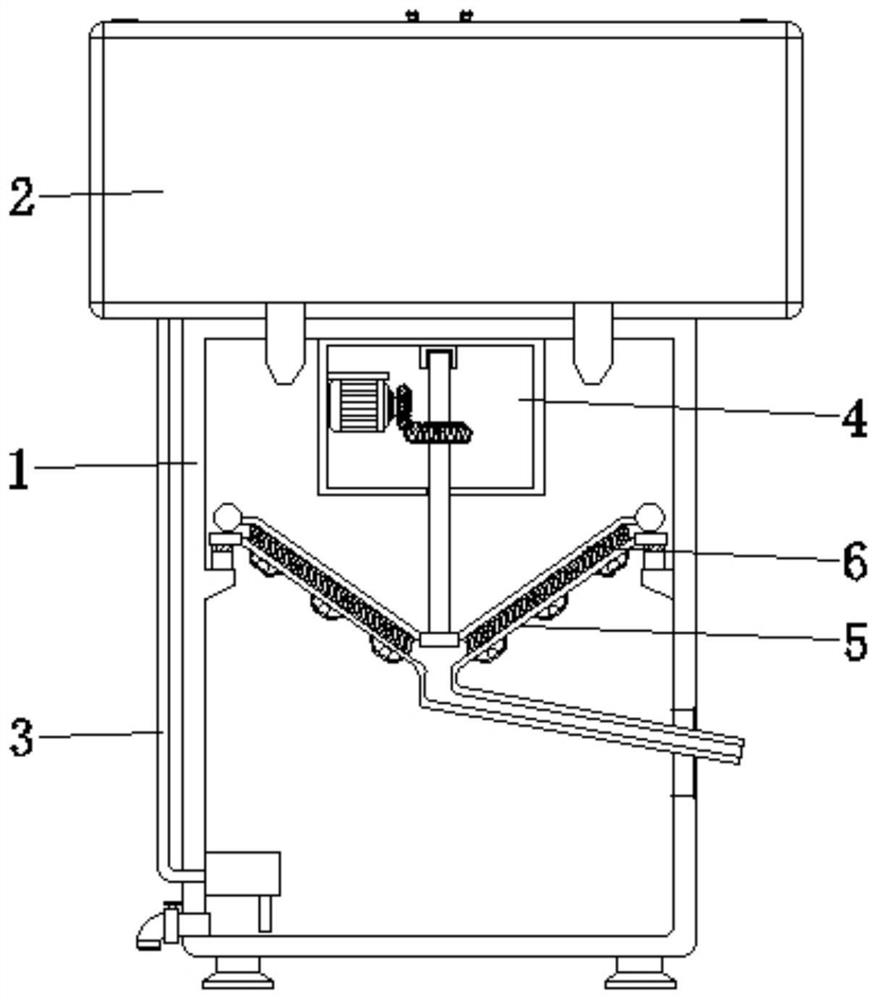

[0030] see Figure 1-6 , the present invention provides a technical solution: a quenching mold for the outer ring of a double-row spherical roller bearing made of large-size carburizing steel, including a box body 1, a quenching mechanism 2, and a spray connecting pipe 3, and the quenching mechanism 2 is arranged in the box On the top of the body 1, the spray connecting pipe 3 is arranged on the surface side of the box body 1 and connected with the quenching mechanism 2;

[0031] The inside of the box body 1 is provided with a driving mechanism 4, a cleaning device 5, and a cleaning device 6. The driving mechanism 4 is arranged at the top center of the inner wall of the box body 1, and the cleaning device 5 is arranged at the inner wall of the box body 1 and is located at the center. The cleaning device 6 is cooperatively connected to the bottom of the driving mechanism 4, and the bottom of the cleaning device 6 is connected with the impurity removal device 5, which can filter...

Embodiment example 2

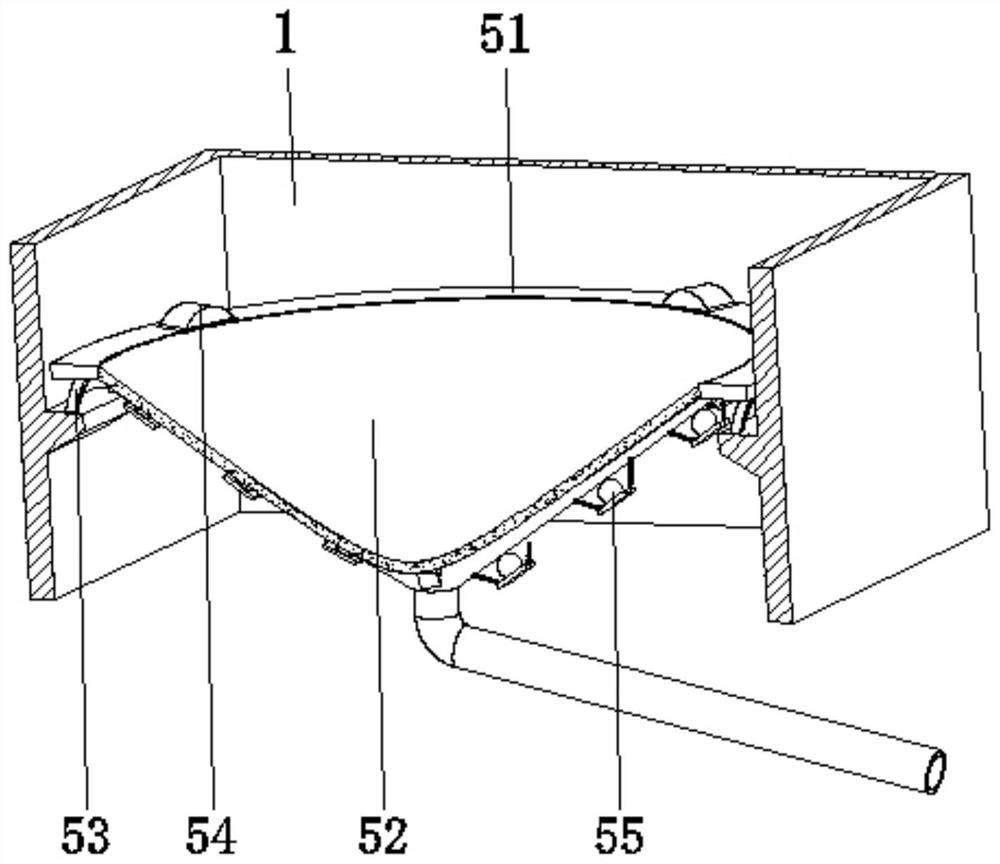

[0033] The impurity removal device 5 is provided with a support ring 51, a conical filter screen 52, an arc-shaped elastic member 53, an arc surface protrusion 54, and a high-frequency elastic member device 55. The support ring 51 is arranged on the inside of the casing 1, and the conical filter screen The top edge of 52 is fixedly connected with the inner wall of the support ring 51, the arc elastic member 53 is fixed between the bottom of the support ring 51 and the corresponding two sides of the inner wall of the box body 1, and the arc protrusion 54 is fixed on the top of the support ring 51, The high-frequency elastic device 55 is arranged on the surface bottom of the conical filter screen 52. When the spray water in the quenching mechanism 2 falls on the conical filter screen 52, impurities such as debris and dust can be filtered out in time, and the drive The mechanism 4 drives the cleaning device 6 to clean up the filtered impurities in time, and under the elastic force...

Embodiment example 3

[0036] The cleaning device 6 is provided with a rotating shaft 61, a brushing device 62, and a pressing ball 63. The top of the rotating shaft 61 is connected with the drive mechanism 4. The brushing device 62 is fixed on the surface bottom of the rotating shaft 61, and the pressing ball 63 is fixed on the brushing device. 62 away from the end of the rotating shaft 61, when the rotating shaft 61 rotates under the drive of the driving mechanism 4, the brushing device 62 will rotate on the surface of the conical filter screen 52, and the filtered impurities will be quickly cleaned to avoid the accumulation of impurities , there will be no blockage, and the pressing ball 63 will also be driven to rotate at the same time, and then the support ring 51 and the conical filter screen 52 will be pressed downward through the arc surface protrusion 54, so that the conical filter screen 52 will shake up and down, and then Helps shake out impurities with vibration.

[0037] The brushing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com