Method for controlling flow fields in quenching water tank of large cylindrical workpiece

A technology for large cylinders and workpieces is applied in the field of flow field regulation in quenching water tanks, which can solve the problems of poor circulation performance of quenching medium, poor practical applicability and difficulty, and achieve good operability and ensure the effect of quenching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

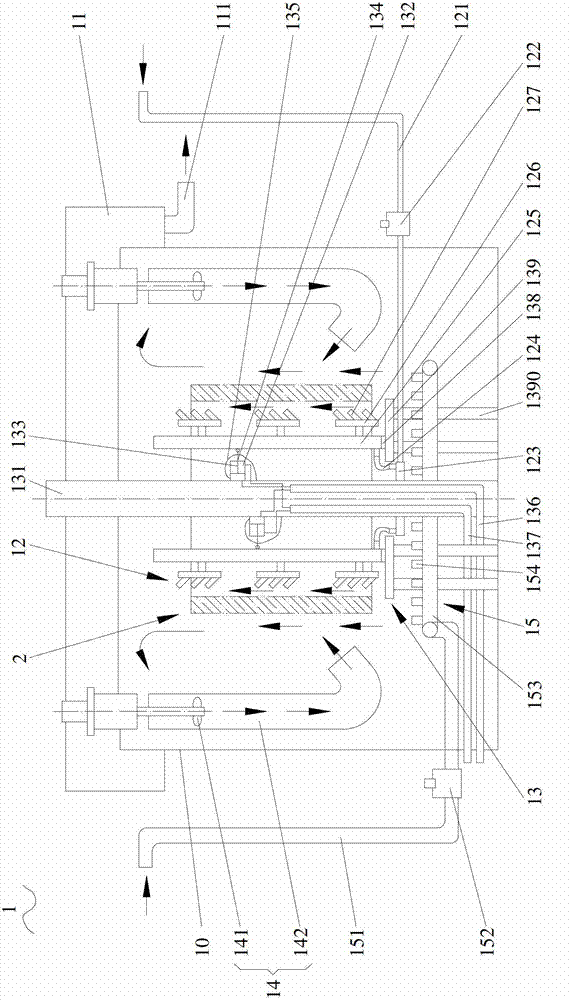

[0015] see figure 1 , figure 1 It is a schematic diagram of the flow field control method in the quenching water tank of a large cylindrical workpiece of the present invention, including a quenching water tank 1 and a large cylindrical workpiece 2 . The large cylindrical workpiece 2 can be hoisted by a crane and placed in the quenching water tank 1 for quenching operation. The quenching water tank 1 includes a tank body 10, an overflow tank 11, an overflow pipe 111, an inner nozzle jet device 12, an inner nozzle diameter adjustment device 13, a propeller agitating jet device 14, and an outer nozzle jet device 15. The overflow tank 11 has an overflow pipe 111 and is arranged on the upper end of the tank body 10 .

[0016] The quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com