Cooling device, cooling system and experimental system and method of cooling device

A heat dissipation device and pressure chamber technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of uneven heat dissipation, poor heat dissipation efficiency, easy corrosion, etc., and achieve large contact area, good heat dissipation effect, Strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

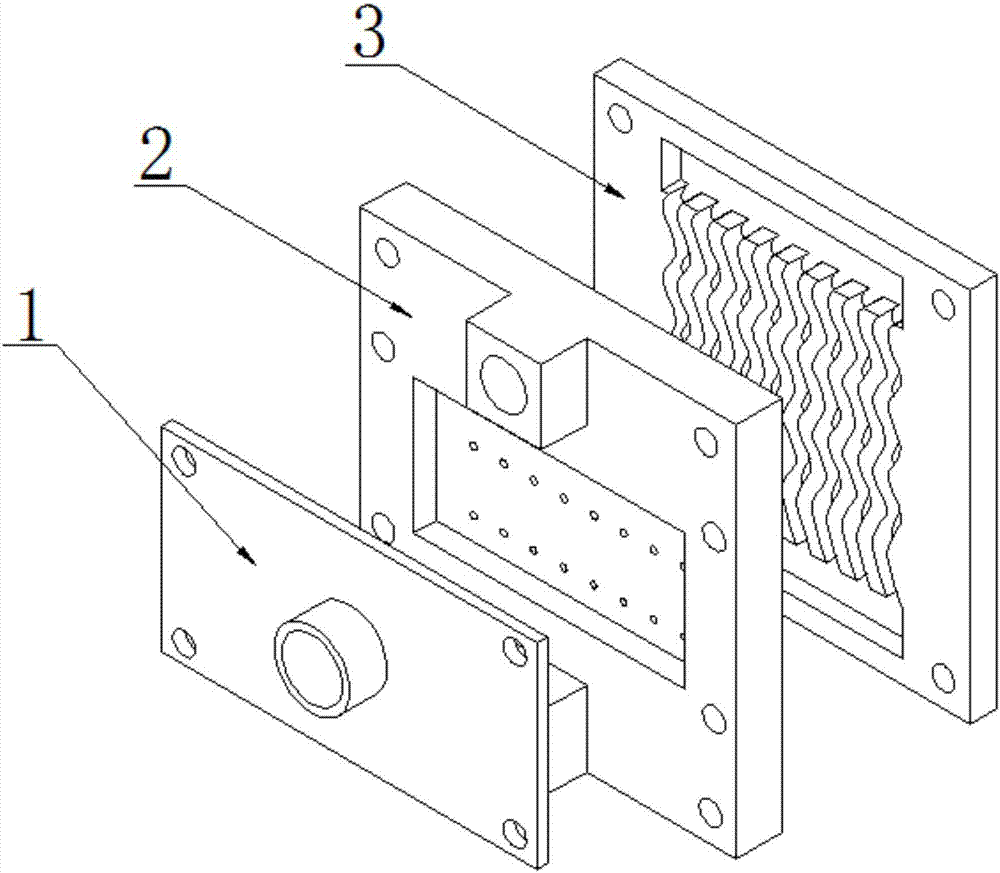

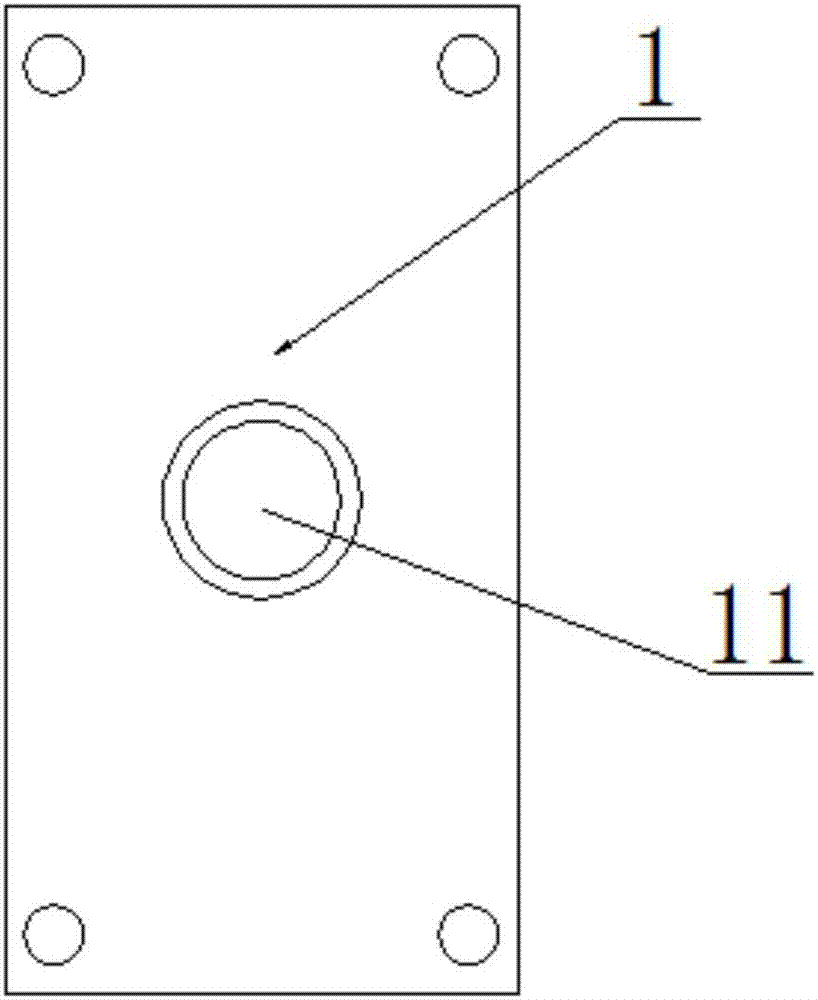

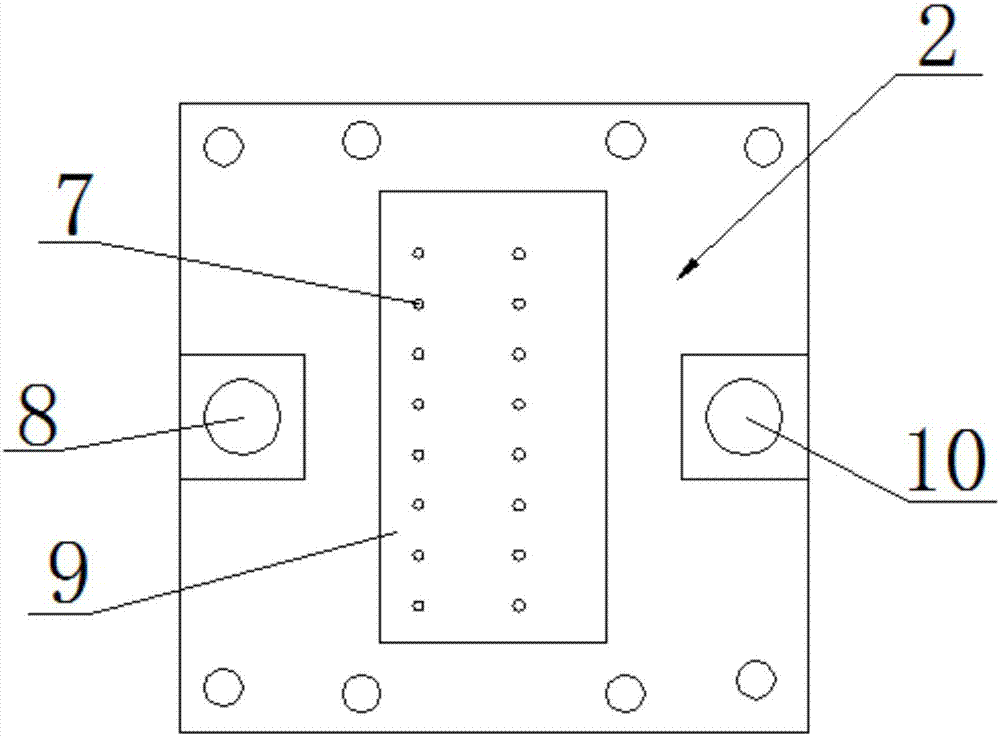

[0049] Such as Figure 1-7 As shown, a heat dissipation device includes a pressure chamber cover 1, a perforated plate 2, and a micro-channel base plate 3 that are sequentially sealed and connected by waterproof silicone grease; the side of the micro-channel base plate 3 connected to the perforated plate 2 is symmetrically opened There are a first liquid collection chamber 4 and a second liquid collection chamber 6, and the first liquid collection chamber 4 and the second liquid collection chamber 6 communicate through several tiny channels 5; the perforated plate 2 is connected to the pressure chamber cover 1 One side is concave to form a cavity 9, and the cavity 9 is sealed by the pressure chamber cover 1 to form a pressure chamber; the bottom of the pressure chamber runs through a plurality of jet holes 7 corresponding to and communicating with the micro channels 5; the perforated plate 2 is located at Both sides of the cavity are also provided with a first liquid outlet 8 ...

Embodiment 2

[0055] In this embodiment, on the basis of the technical solution in Embodiment 1, the micro-channel structure is optimized, specifically: the side walls of the micro-channel 5 are arranged in a sinusoidal or cosine curve to form a wave-wall microchannel.

[0056] The microchannel of this embodiment is a wave-wall microchannel, and the surface shape of the wave-wall microchannel adopts a new microchannel heat dissipation structure of a sine curve or a cosine curve. Compared with other microchannel heat dissipation structures, not only the contact area is large, but the flow rate of the flow channel Uniform, faster flow rate, less pressure loss, can maximize the use of heat dissipation performance.

Embodiment 3

[0058] In this embodiment, on the basis of the technical solution of embodiment 1 or embodiment 2, the following optimization is made: each of the micro channels 5 is connected with at least two jet holes 7 .

[0059] In this embodiment, each tiny channel 5 is connected with a plurality of jet holes 7, that is to say, each jet field affects each other as mentioned above, thereby affecting the overall flow and heat transfer, improving the heat transfer effect and efficiency.

[0060] Preferably, each of the tiny channels 5 is connected with two jet holes 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com