Cooler of wind power generator

A technology for coolers and generators, which is applied in the manufacture of motor generators, wind power generation, cooling/ventilation devices, etc. It can solve the problem of lengthening the overall length of generators, poor heat transfer effect of heat transfer tubes, and affecting heat transfer effects and other problems, to achieve the effect of convenient motor design, uniform wind speed and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

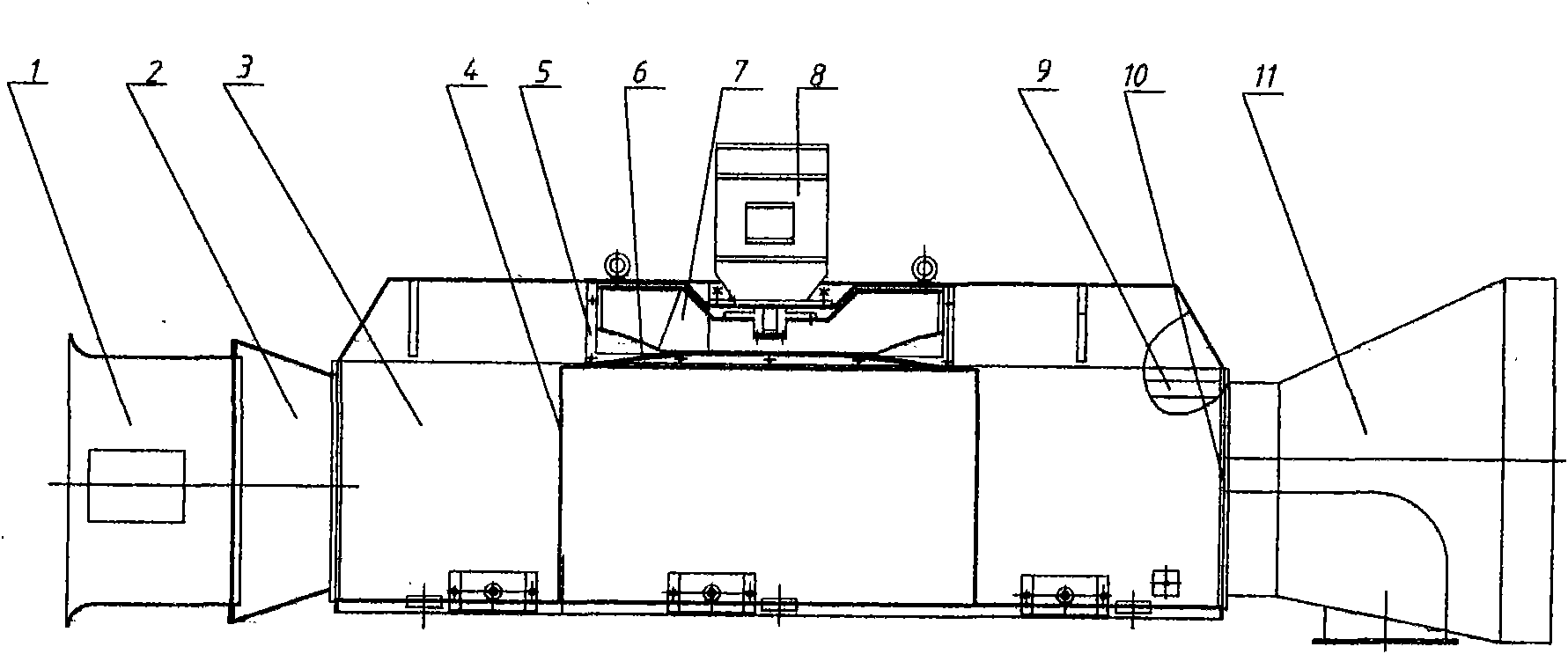

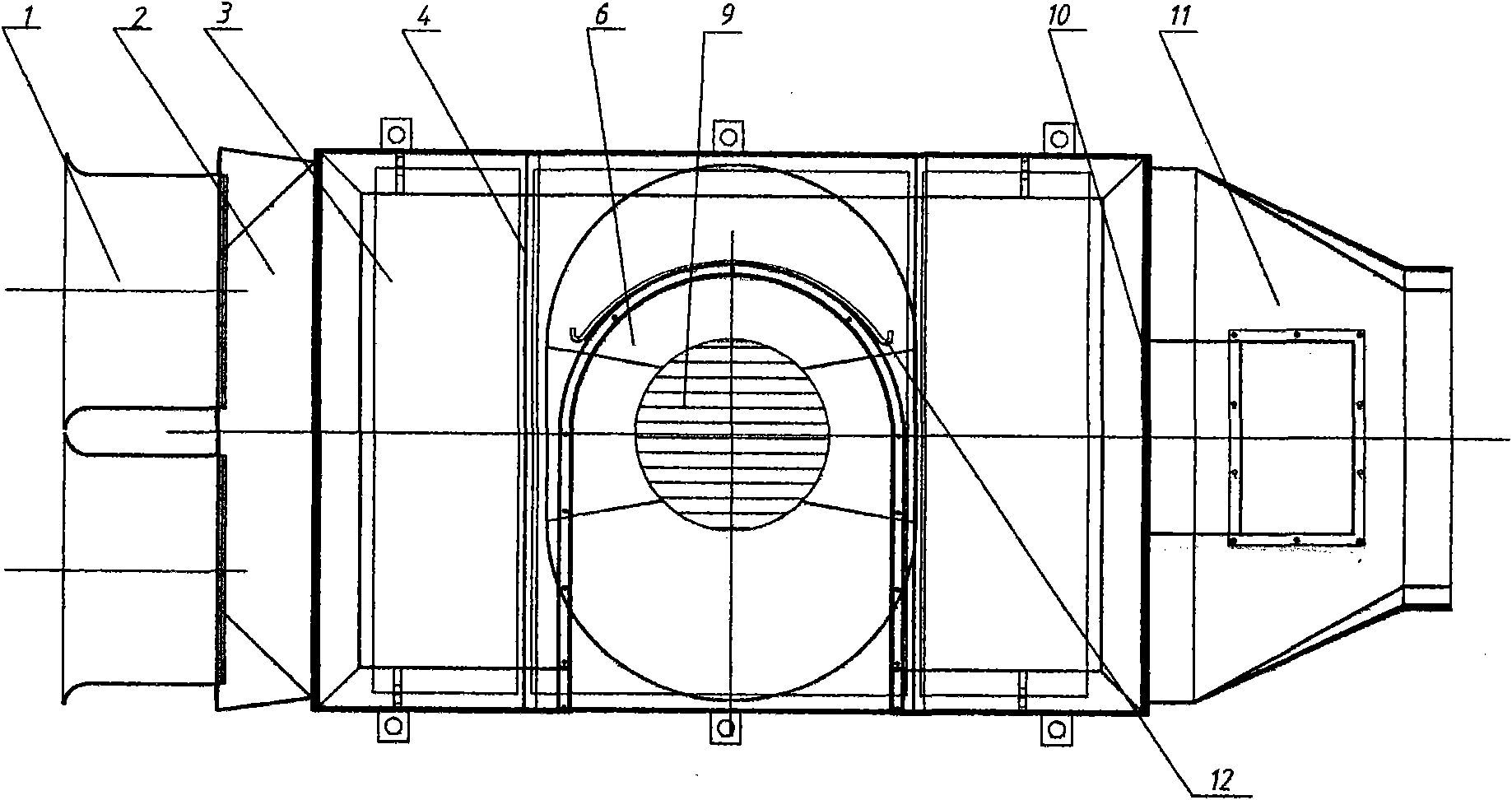

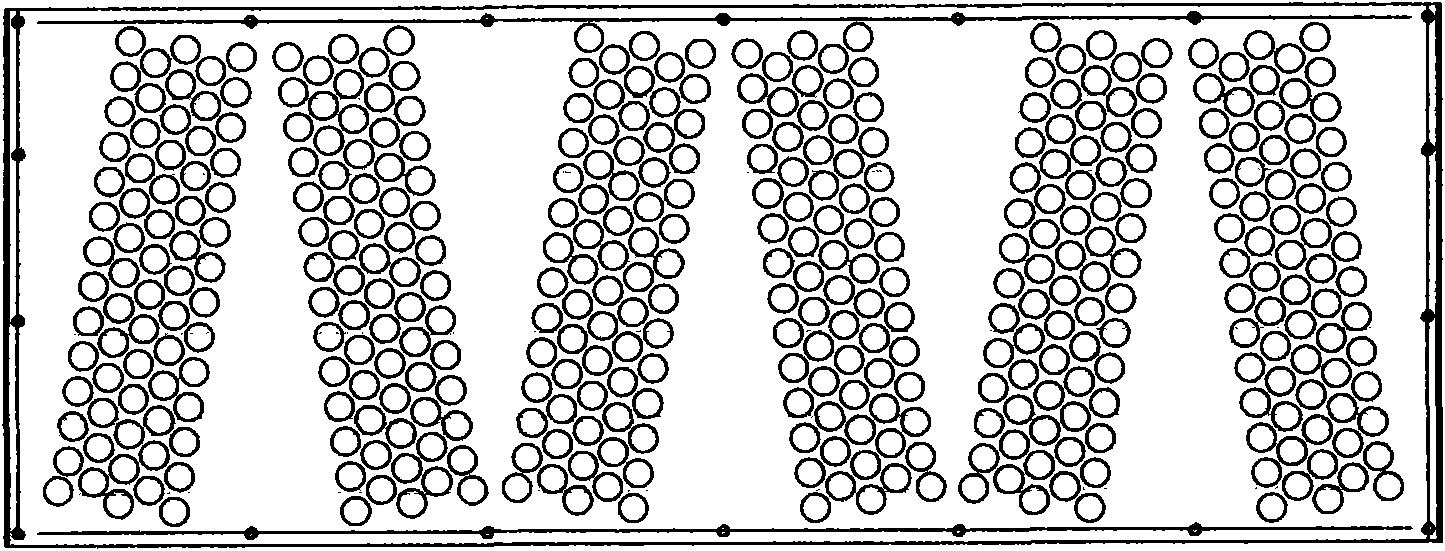

[0011] The cooler and the wind generator are installed in a knapsack style, the entire cooler is buckled above the wind generator, and the cooler and the motor are tightly connected with gaskets. Such as figure 1 , 2 As shown, the cooler includes an external air path fan 1, a fume hood 3, a cover plate 5 with a molded disc-shaped motor mounting seat, a tube plate 10, an M-shaped arrangement of heat exchange tubes 9, air inlets and outlets 11, 2 and a The centrifugal fan and the motor form the inner air path fan. The heat exchange tube 9, the tube plate 10 and the separator 4 form the core body of the cooler. The heat exchange tube 9 passes through the tube plate 10 and the separator 4. The gap between the plates 4 is small to ensure that the leakage on both sides of the partition is small, such as image 3 As shown, the two ends of the heat exchange tube 9 and the tube sheet 10 are connected by expansion joints; the core of the cooler is divided into three parts by two parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com