Long pipe inner wall quenching device

A technology of quenching device and long tube, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of poor corrosion resistance, low hardness, short life, etc., and achieve the goal of ensuring quenching quality, low manufacturing cost and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

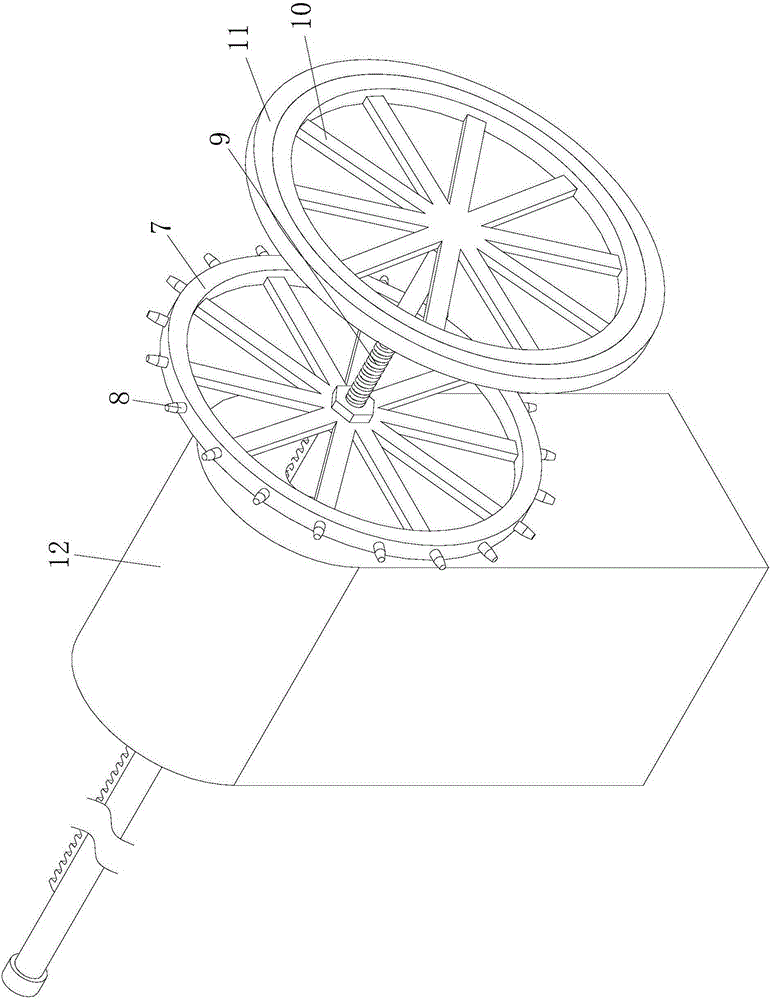

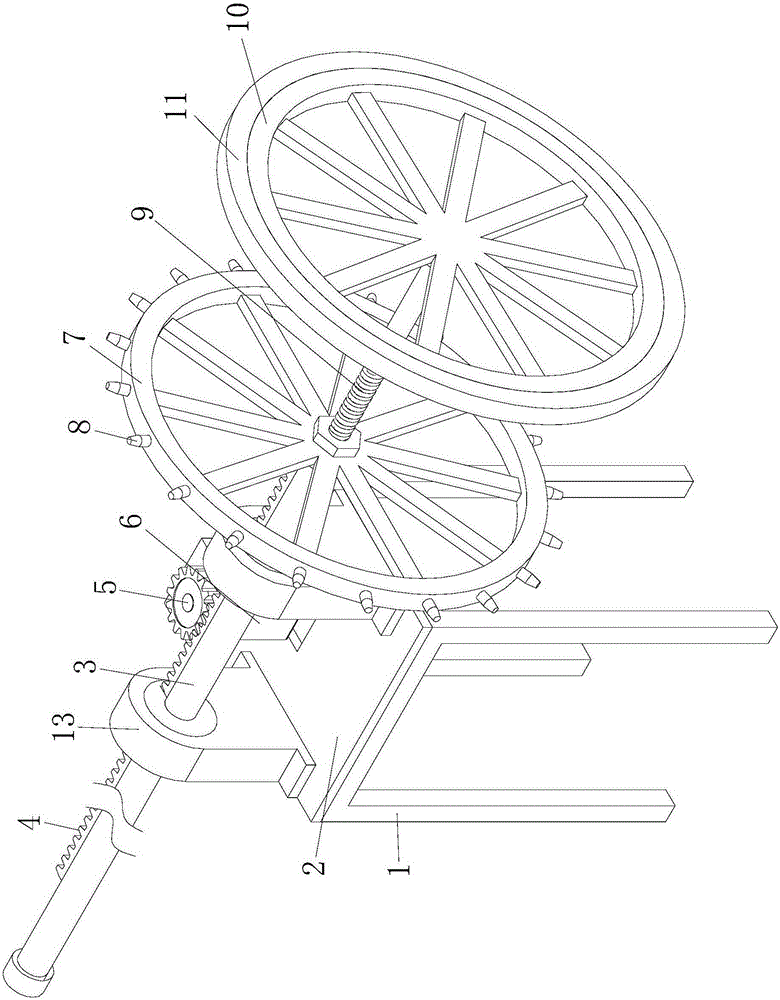

[0013] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

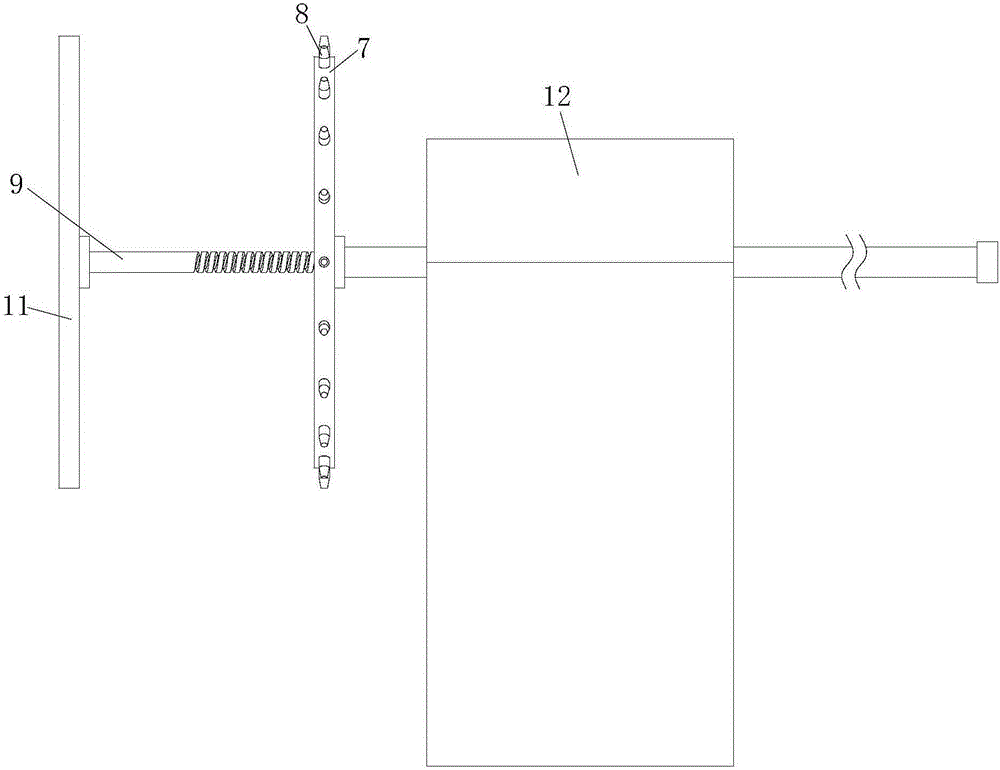

[0014] like Figure 1 to Figure 5 As shown, a long tube inner wall quenching device includes a support frame 1, the upper end of the support frame 1 is fixed with a mounting plate 2, and the left and right ends of the mounting plate 2 are fixed with support seats 13, the support A slide bar 3 that can move laterally is installed in the seat 13, the front end of the slide bar 3 is provided with a rack 4, the upper end of the mounting plate 2 is equipped with a motor 6, and the shaft of the motor 6 is connected by a key. A gear 5 is fixed in a fixed way, and the gear 5 is meshed with the rack 4. A No. 1 ring-shaped fixing fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com