Quenching device for mechanical shaft parts

A technology of shaft parts and quenching devices, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of large limitations, achieve the effect of convenient adjustment and shorten the time required for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

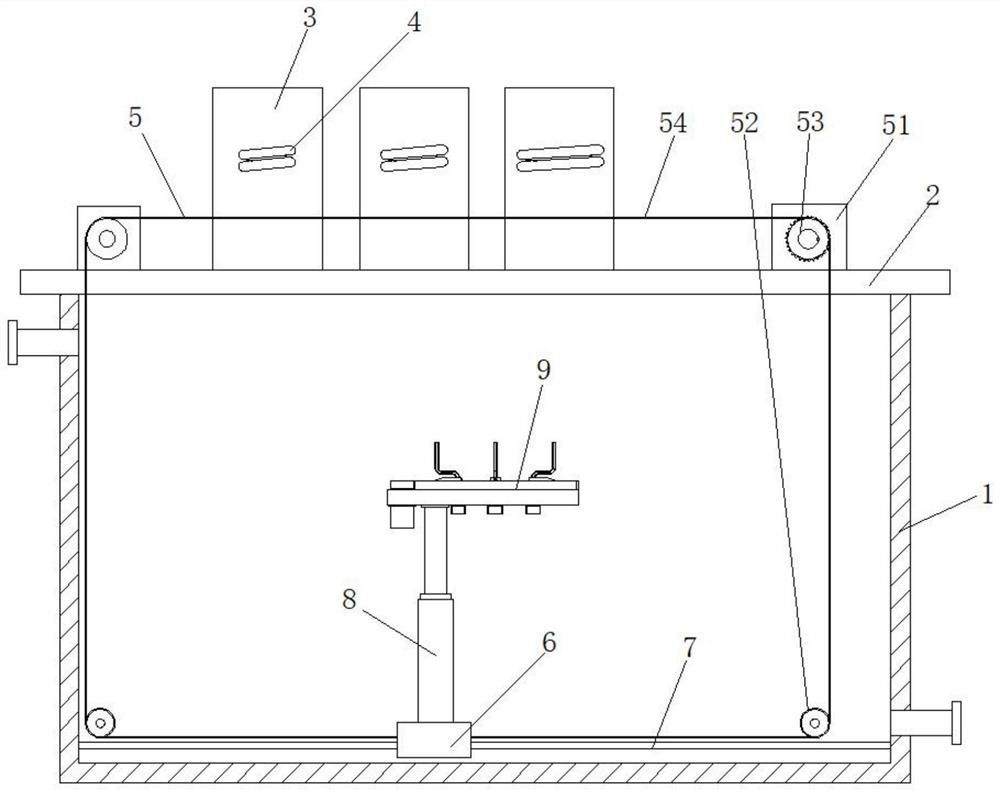

[0029] As an embodiment of the present invention, the drive assembly 5 includes a servo motor 51, a pulley 52, a sprocket 53 and a chain 54; the servo motor 51 is fixedly installed on the workpiece base 2, and the output shaft of the servo motor 51 is installed There is a sprocket 53, and the chain 54 is respectively wound on three pulleys 52 and a sprocket 53; the three pulleys 52 are respectively rotated and mounted on the water tank 1 and the workpiece base 2; the two ends of the chain 54 are respectively Fixedly connected to the two ends of the slider 6.

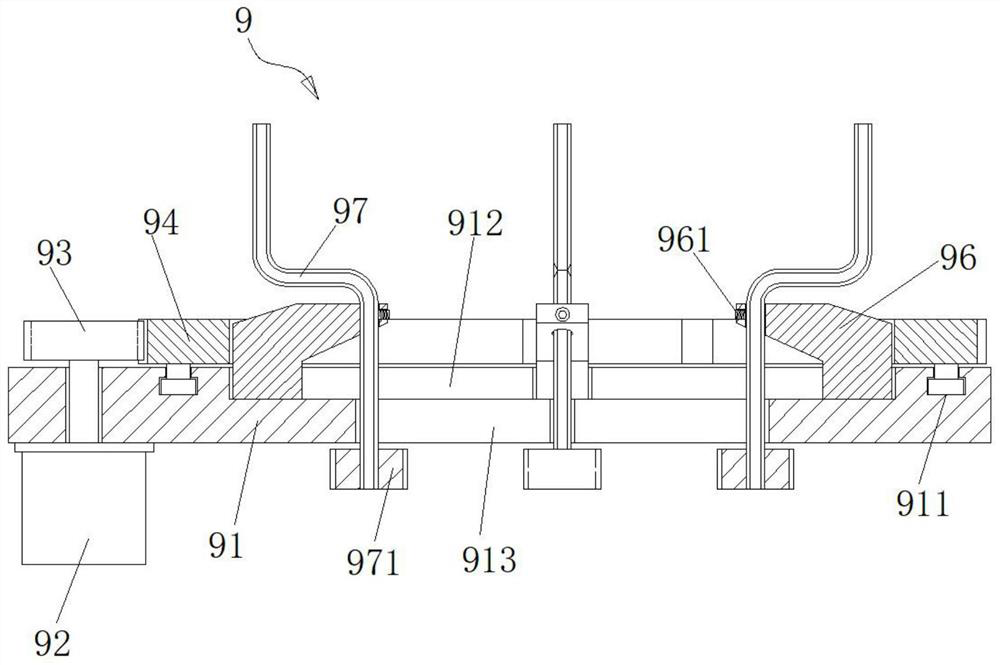

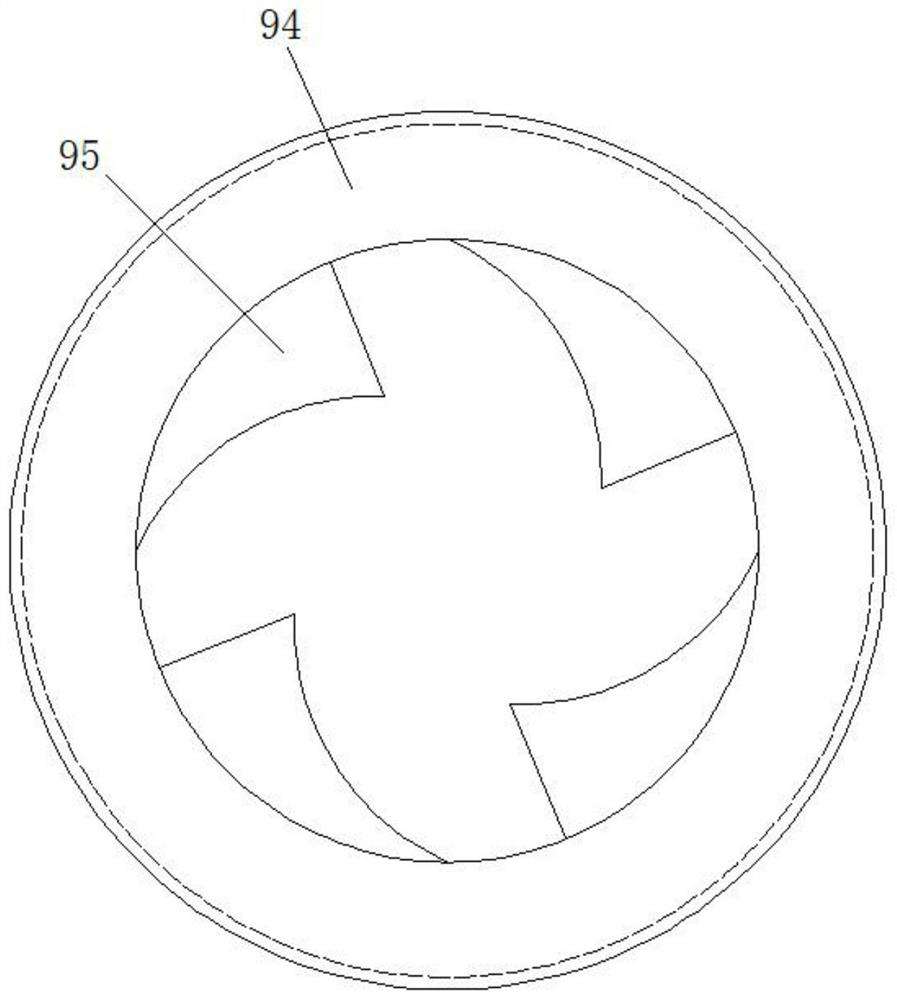

[0030] As an embodiment of the present invention, the clamping rod 97 has an S-shaped structure, the clamping rod 97 slides through the slider 96, and slides through the bar-shaped through hole 913 opened on the bottom wall of the bar-shaped chute 912, clamping The lower end of the holding bar 97 is fixedly connected with an adjusting gear 971, and the adjusting gear 971 is used to adjust the angle of the clamping bar 97...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com