Impregnated tire fabric thermal treatment device and implementing method thereof

A technology of heat treatment device and dipped cord fabric, which is applied in the field of chemical fiber, can solve the problems of high energy consumption, fire, broken cloth, etc., and achieve the effect of reducing the defective rate of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

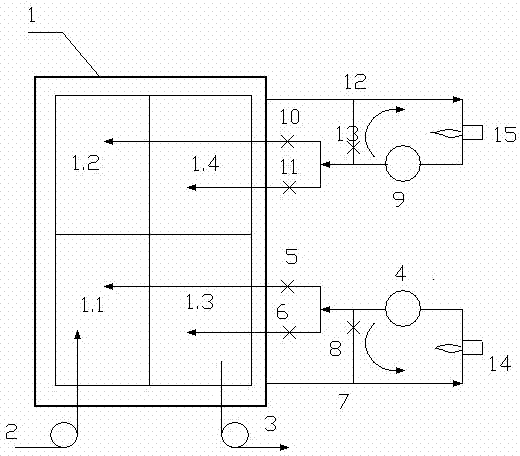

[0031] see figure 1 , the present invention relates to a heat treatment device for dipped cord fabrics, comprising a main oven 1, a first heating device 14 and a second heating device 15, and the inlet and outlet of the main oven 1 are respectively provided with cord introduction Roller 2 and cord fabric exporting roller 3, the inside of the main oven 1 is equally provided with the first drying zone 1.1 at the lower part, the third drying zone 1.3 and the second drying zone 1.2 and the fourth drying zone 1.4 at the upper part;

[0032] The first drying area 1.1 and the third drying area 1.3 are respectively connected to the air outlet of a low-power fan 4 through an air duct. The power of the low-power fan 4 is 30KW, and the first drying area 1.1 and the third drying area 1.3 A first damper 5 and a third damper 6 are respectively arranged on the connecting pipeline with the low-power fan 4 , the air inlet of the low-power fan 4 is connected with the air outlet of the first hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com