High-universality reduction gearbox special for draught fan

A universal, reduction box technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem that lubrication technology cannot change the lubrication effect, reduce the efficiency of lubricating oil use, and increase gear wear and other problems, to achieve the effect of compact structure, improved cleaning performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

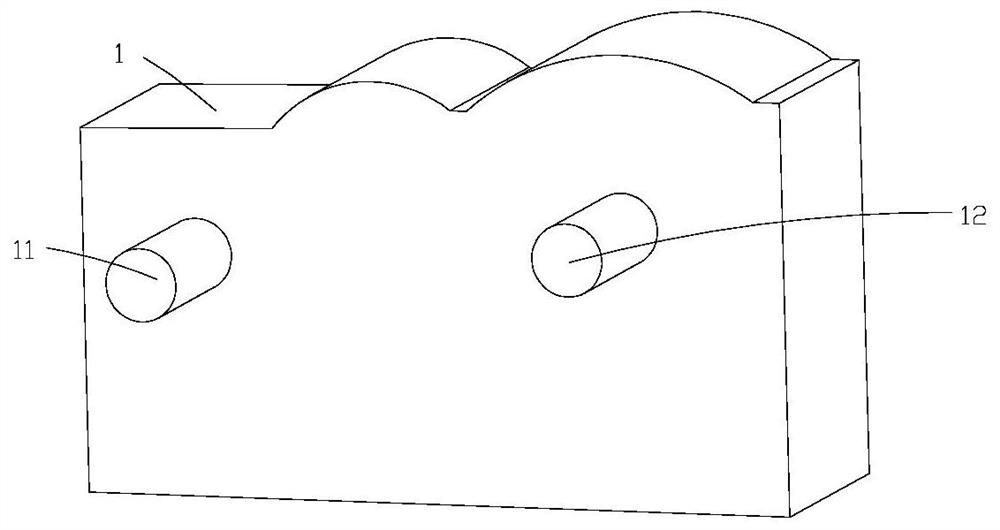

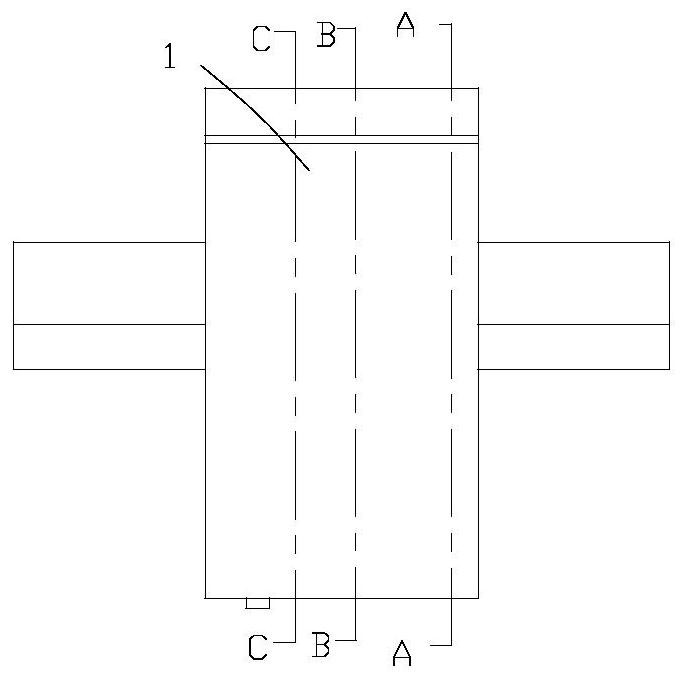

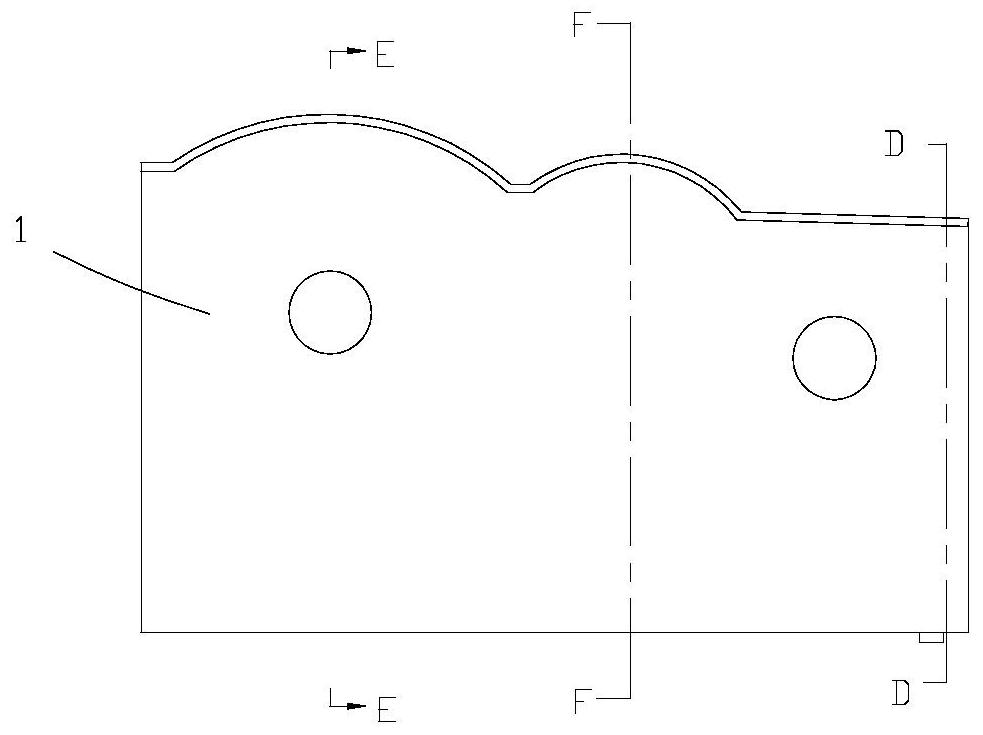

[0041] like Figure 1-22 As shown, a special reduction box for fans with strong versatility includes a main body 1, a driving wheel 11, a reduction wheel 12, an oil storage chamber 13, a filter device 2, a driving wheel 3, and a lubricating device 4; the filter device 2 includes a partition Plate 21, guide hole 22, filter block 23, filter hole 24, filter spring 25, stationary plate 26, louver plate 27, convection hole 28, cleaning mechanism 5; the driving wheel 11 is rotatably embedded in the main body 1; The deceleration wheel 12 is rotatably embedded in the main body 1 and engages with the driving wheel 11; the oil storage cavity 13 is set in the main body 1; the filter device 2 is set in the oil storage cavity 13; The driving wheel 3 is rotatably embedded in the main body 1 and meshes with the reduction wheel 12; the partition plate 21 is arranged in the oil storage chamber 13; Evenly arranged; the longitudinal section of the filter block 23 is arc-shaped, and is movably e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com