Automatic wire feeding apparatus of evaporation system

The technology of a wire feeding device and an evaporation system is applied in the field of automatic wire feeding device of an evaporation system, which can solve the problems such as affecting the effect of vacuum coating film, inaccurate wire feeding, inability to ensure the vaporization of aluminum wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

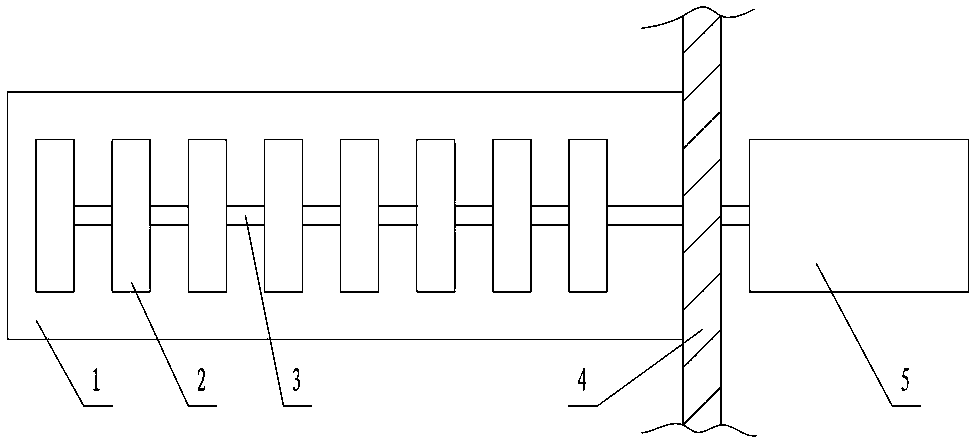

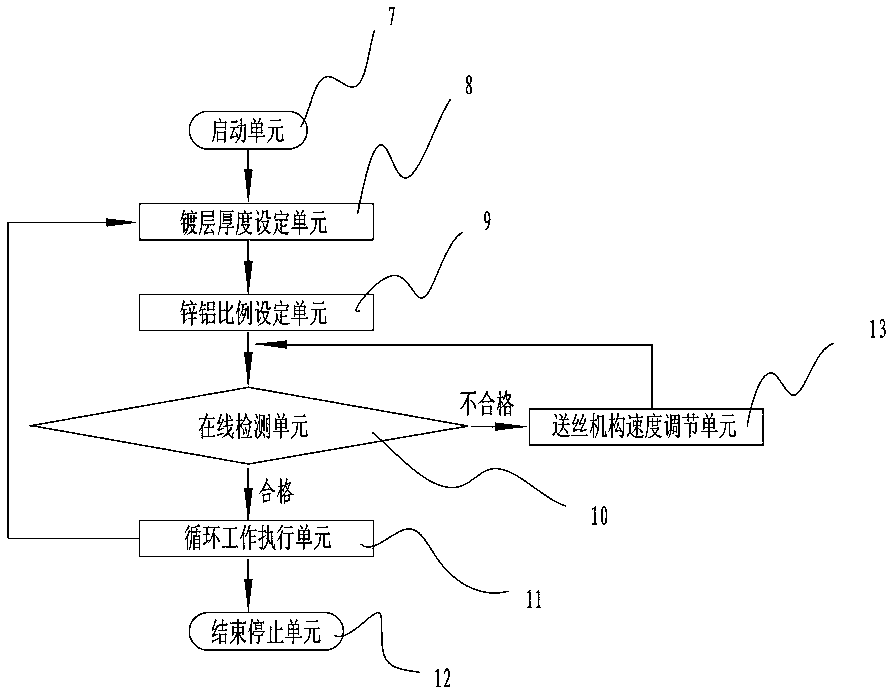

[0011] An automatic wire feeding device for an evaporation system described in this embodiment 1, such as figure 1 and figure 2 As shown, it includes a vacuum support 1, a vacuum sealing end face 4 that is installed and connected to one end of the vacuum support and cooperates with its end face to form a vacuum state, a variable frequency motor 5 arranged outside the vacuum support and the vacuum sealing end face, and the variable frequency motor is installed and connected to pass through the vacuum seal. The drive shaft 3, which is placed in the vacuum support, is covered with a wire feeding mechanism 2; the wire feeding mechanism is connected with an automatic wire feeding which can monitor the thickness of the film coating and the linear speed of the coating online and can adjust the speed of the wire feeding mechanism. Integrated controller; the automatic wire feeding integrated controller includes a start-up unit 7, a coating thickness setting unit 8 that is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com