A beverage bottle conveying system

A conveying system and beverage bottle technology, applied in the field of beverage bottle conveying system, can solve the problems of excessive bottle extrusion, bottle blocking, multi-row chain and single-row chain bottle jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

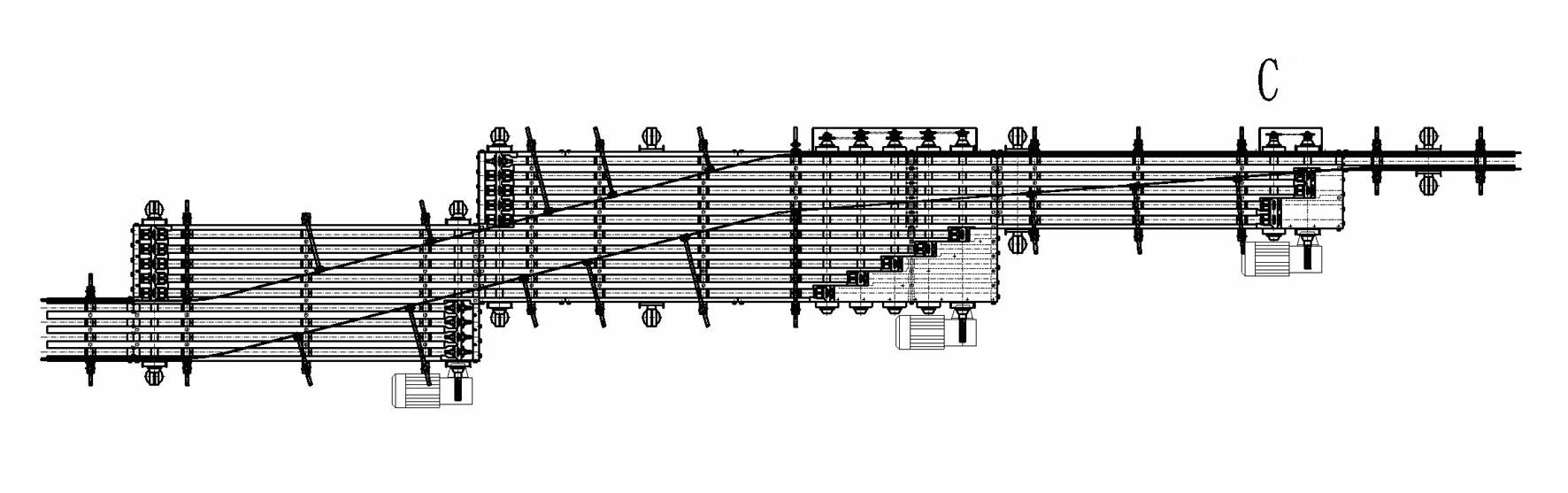

[0019] figure 1 For the existing multi-row to single-row device, it mainly relies on the joint action of double guardrails with gradually reduced width and conveyor belts to gradually convert multi-row bottles into single-row bottles for subsequent operations, but its disadvantage is that when When the downstream equipment temporarily shuts down, it is easy to cause excessive extrusion between the bottles and the guardrail at the same time, resulting in deformation of the guardrail and bottle blocking. Bottle jamming occurs at the junction of row chains and single row chains. The traditional multi-row to single-row device is a double guardrail mode, which is not conducive to troubleshooting and daily maintenance.

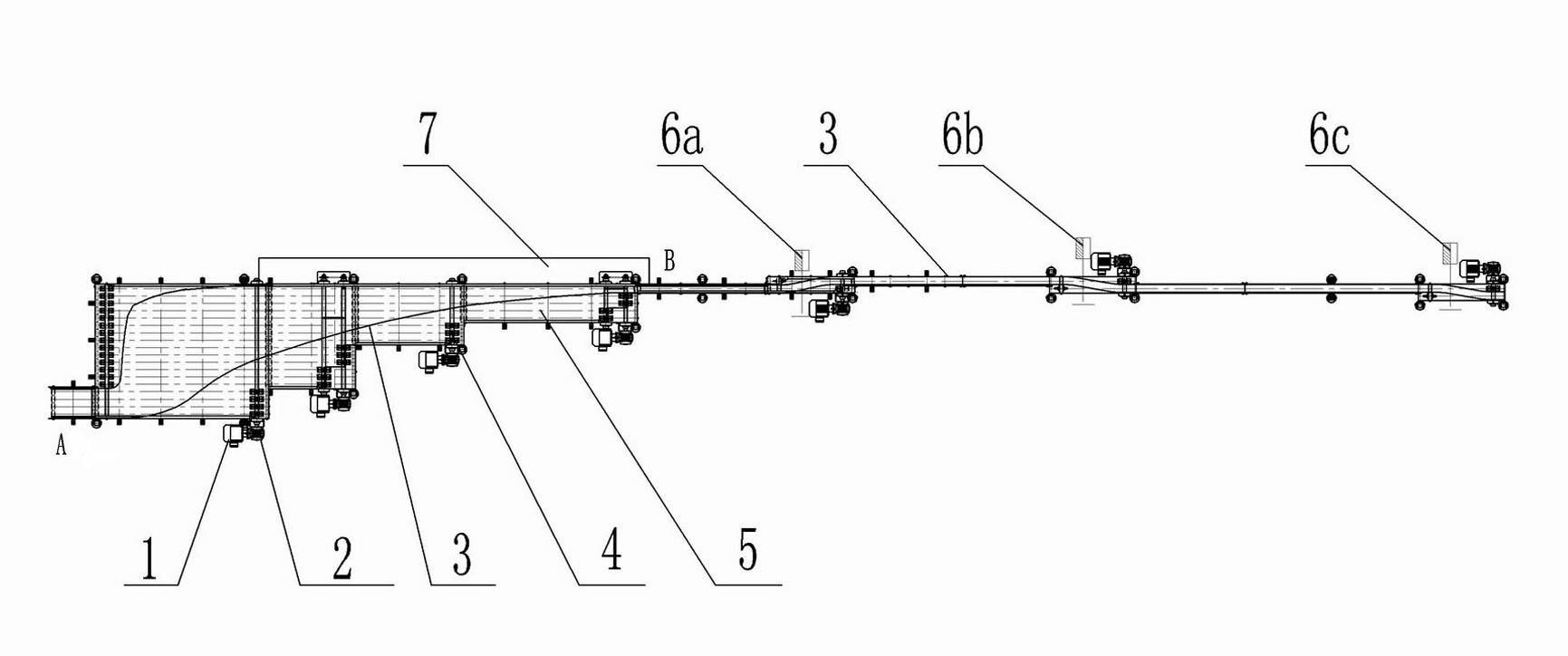

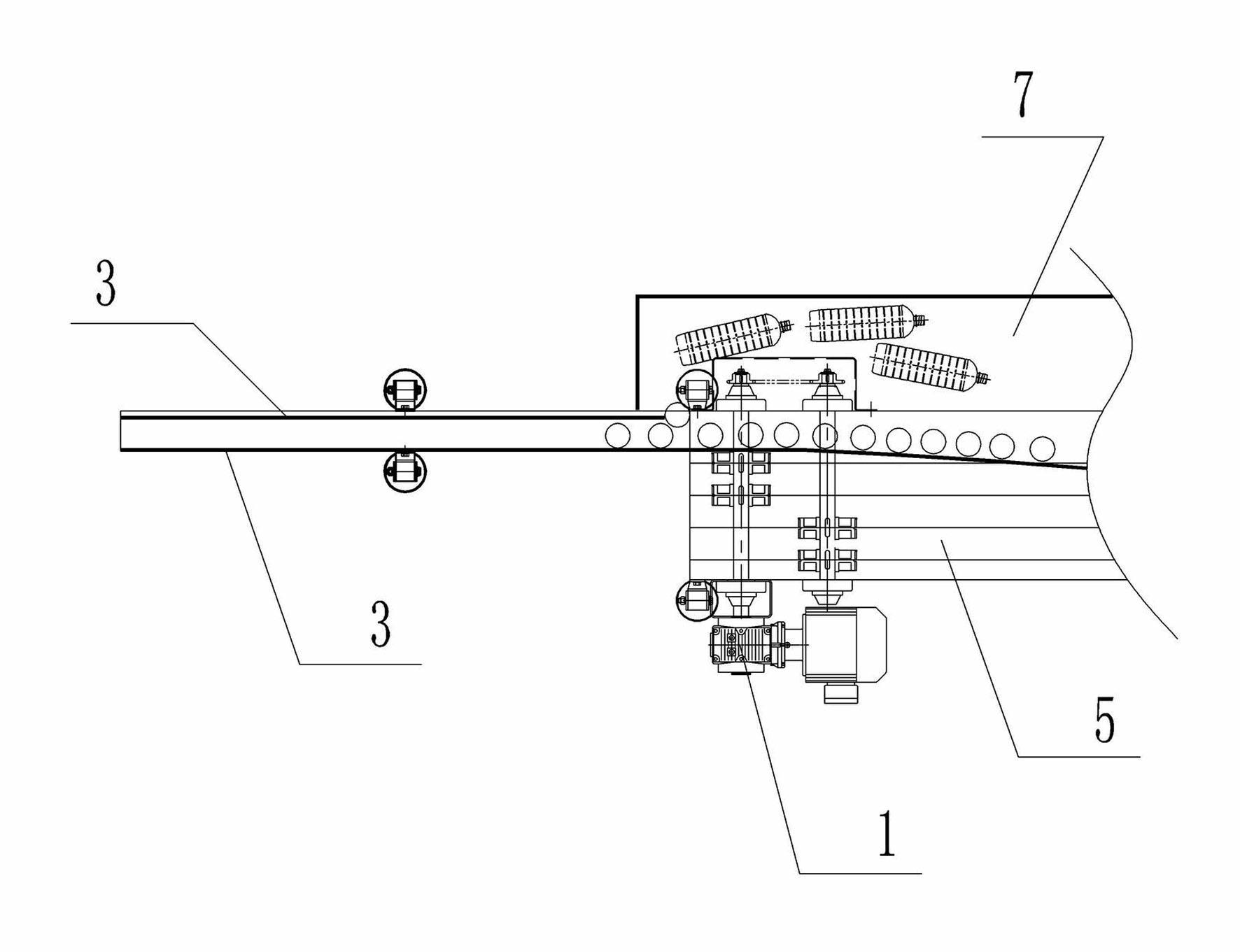

[0020] like figure 2 As shown, Port A is the entrance of the conveying device, and Port B is the entrance to the downstream equipment. From Port A to Port B, a plurality of chain plates 5 are connected to transport bottles. The width of the chain plates from Port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com