Automatic tension balancing device and method of multi-rope winding hoisting steel wire ropes for deep vertical shaft

An automatic balancing and steel wire rope technology, applied in elevators, transportation and packaging, etc., to achieve the effects of reducing wear, improving efficiency and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with the embodiment in the accompanying drawings:

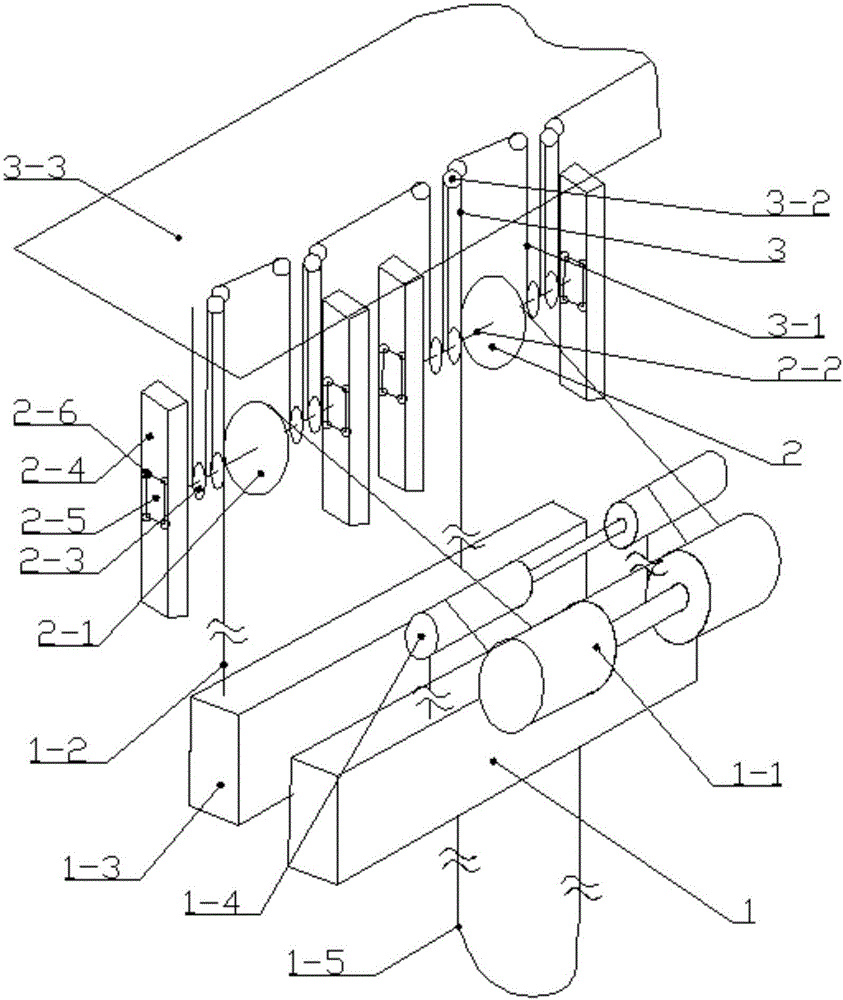

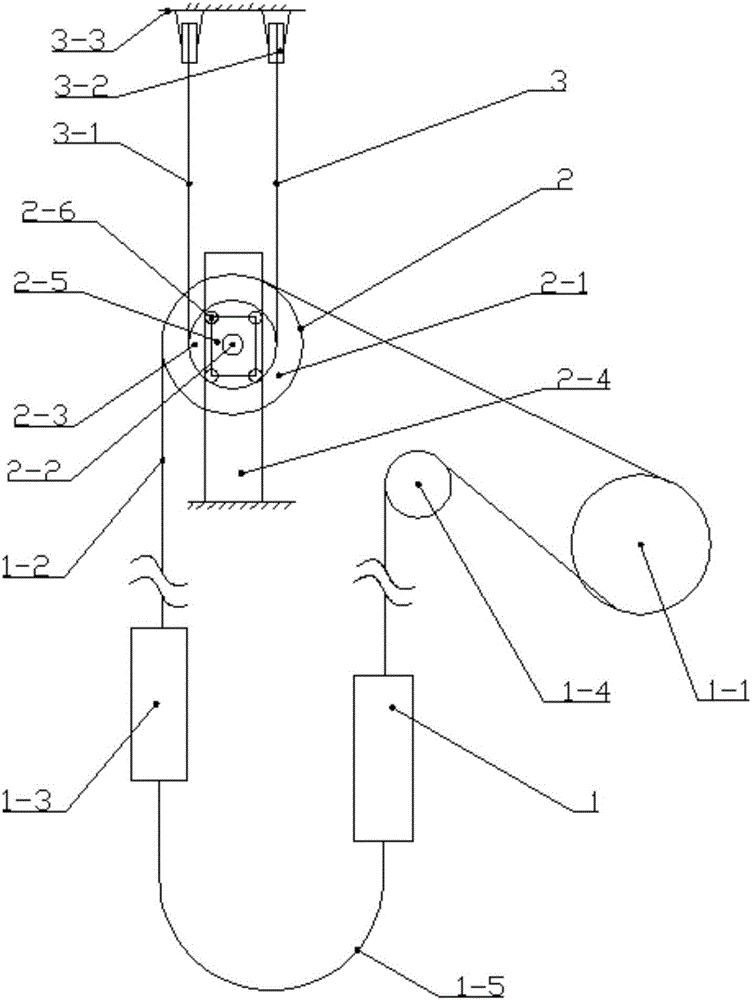

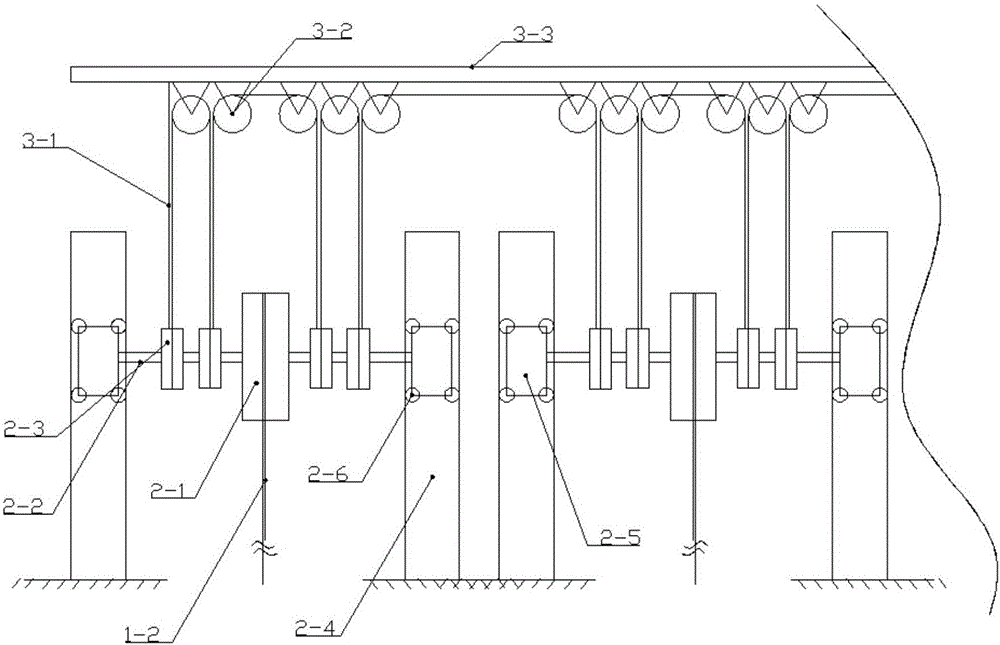

[0022] The multi-rope hoisting steel wire rope tension automatic equalization device of the present invention mainly passes through the drive system 1 and two sets of sliding guide sky wheels 2 arranged on the drive system 1, and the two sets of slide guide sky wheels 2 can run up and down on the drive system 1 , the two sets of sliding guide pulleys 2 are connected with a tension balance mechanism 3;

[0023] The drive system 1 includes a drum hoist 1-1, a hoisting wire rope 1-2, a hoisting container 1-3, a reverse rope wheel 1-4 and a tail rope 1-5, and the hoisting wire rope 1-2 is wound on the drum On the hoist 1-1 and the sliding guide pulley 2, the two ends of the hoisting wire rope 1-2 are respectively fixed above the two hoisting containers 1-3, above the hoisting container 1-3 on the side of the drum hoist 1-1 An anti-rope pulley 1-4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com