Magnetic damping tension precision adjustment device

A precision adjustment and magnetic damping technology, applied in the field of winding wire wrapping, can solve the problems that affect the stability of the production process and product quality, the tension of the paper tape cannot be kept constant, and the tension of the paper tape remains constant, so as to achieve a good working environment, The effect of stable work and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

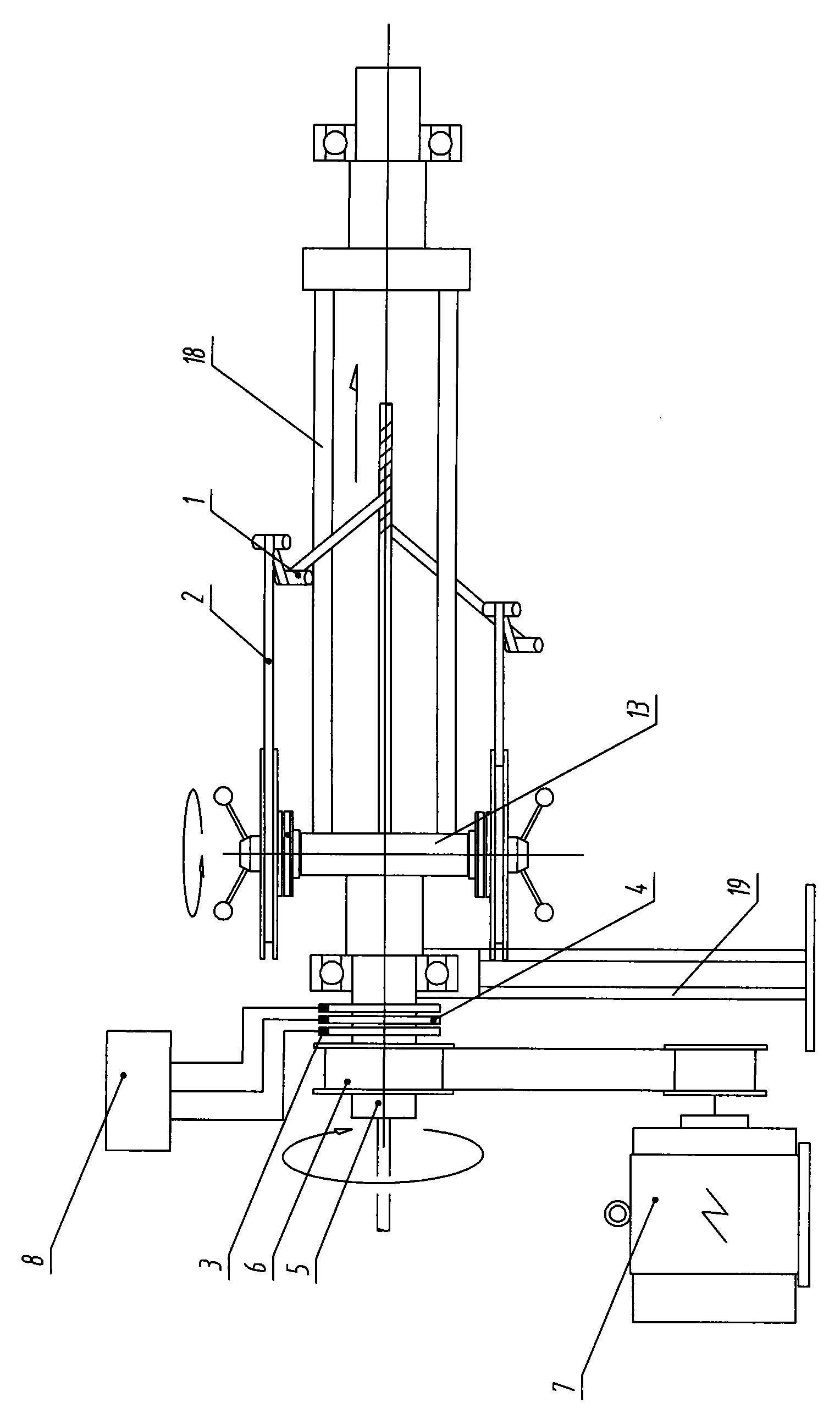

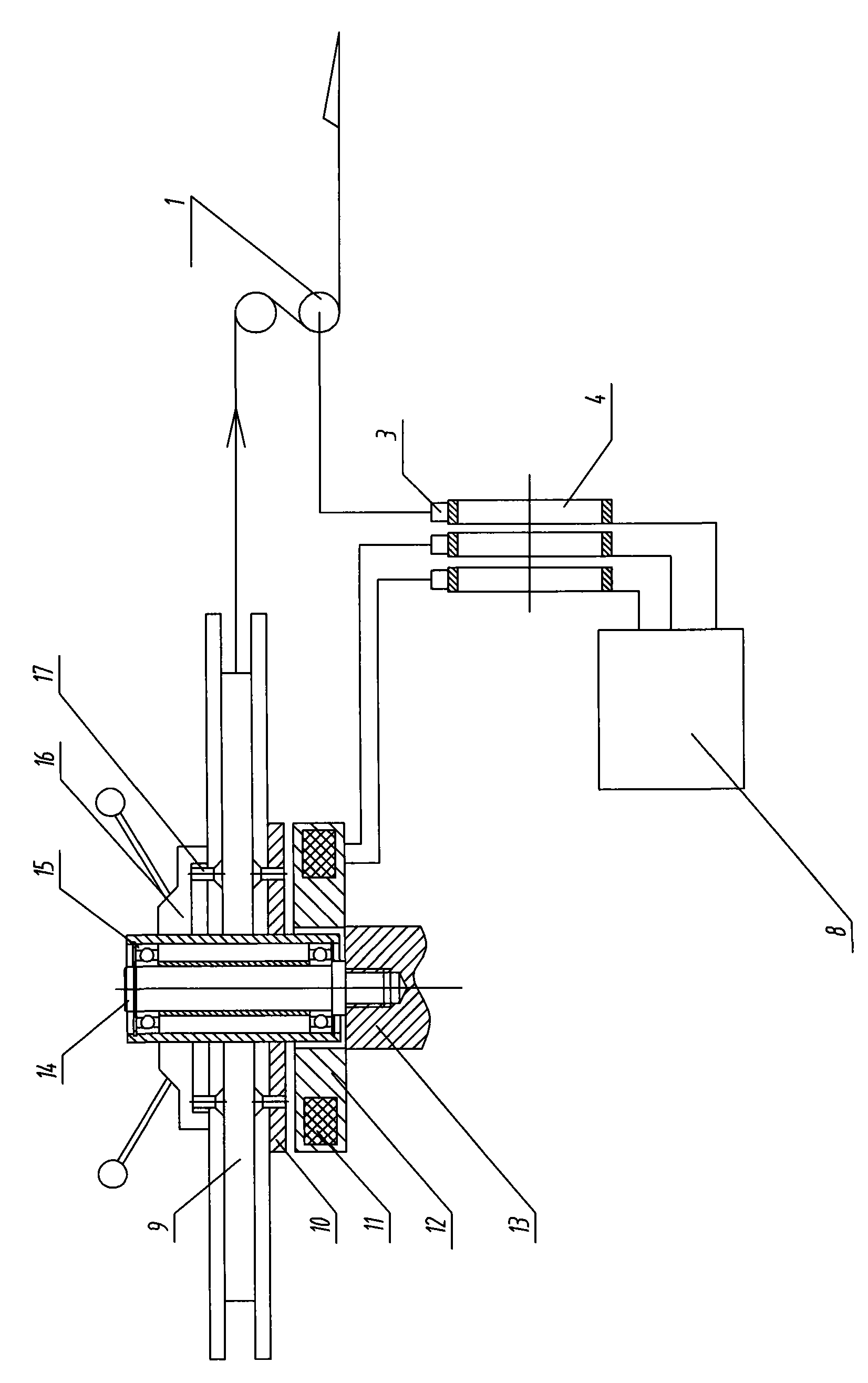

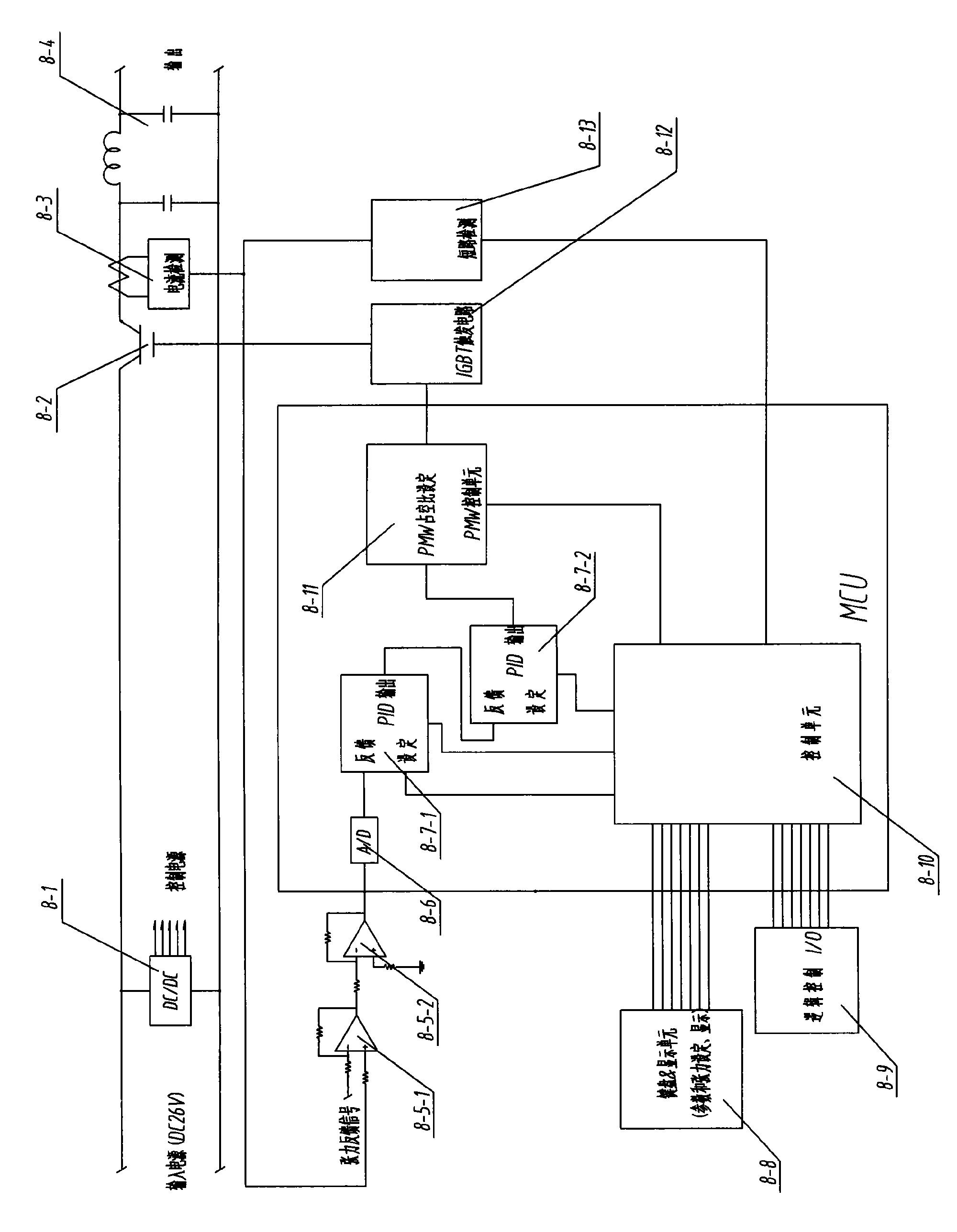

[0013] like figure 1 , figure 2 Shown: including tension sensor 1, wrapping belt 2, carbon brush 3, slip ring 4, main shaft 5, synchronous pulley 6, DC motor 7, controller 8 (function is to calculate and adjust voltage output after collecting signals), amplifier Tape reel 9, damping disc 10, electromagnetic coil 11, magnetic fixed disc 12, revolving body 13, autobiographical body 14, rotating bearing 15, pressure plate 16, connecting nut 17, connecting polished rod 18, support 19.

[0014] The invention changes the size of the braking force by changing the structure of the existing device and using a DC voltage of 0-24Vdc to control the size of the magnetic damping flux.

[0015] In the present invention, the wrapping tape 2 is placed between the tape release reels 9 and fixed by the paper platen 16. After the wrapping tape 2 is pulled out, it passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com