Process for smelting and continuously casting boron-containing high carbon steel for wire production

A continuous casting process and high carbon steel technology, applied in the field of iron and steel metallurgy, can solve problems such as the beneficial effect of unfavorable B elements, and achieve the effect of preventing aggregation and deterioration of steel quality and promoting uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below by way of examples.

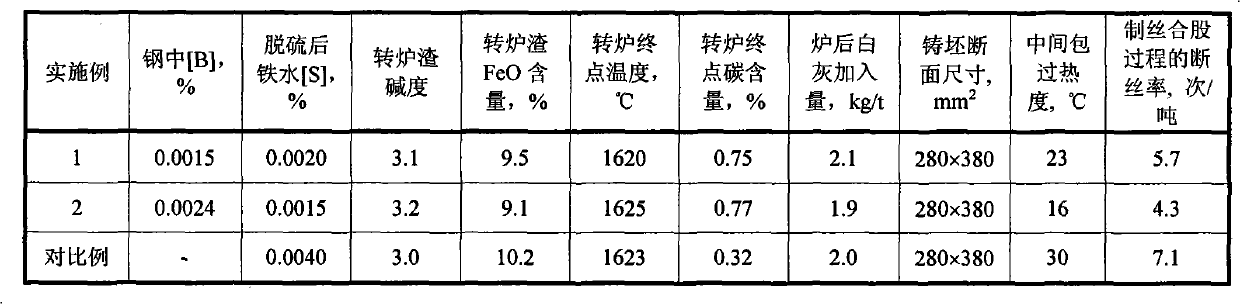

[0010] In the embodiment of the present invention, steel grade SWRH82A is taken as an example. The target carbon content of the steel grade is 0.80% by weight, and 0.0015% and 0.0024% by weight of boron are respectively added to the steel, as shown in Table 1. In order to make full use of the beneficial effect of boron on improving steel quality, hot metal pretreatment desulfurization and converter dephosphorization processes are used in the smelting process of boron-containing steel to reduce the sulfur and phosphorus content in steel and improve the processing performance of steel. At the same time, large-section billet continuous casting and low superheat casting are adopted to prevent the center segregation of boron element in billet. A comparative example is also given for comparing the effects of the present invention.

[0011] Table 1 Embodiment of the present invention smelting and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com