After-roll reinforced cooling process for 82B wire rod steel strand

A technology of forced cooling and process method, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of cooling speed reduction, drawing fracture, insufficient cooling speed, etc., to reduce the broken wire rate and reduce the transverse temperature The effect of poor and uniform mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention can be used in the high-carbon steel wire rod production in a high-speed wire factory.

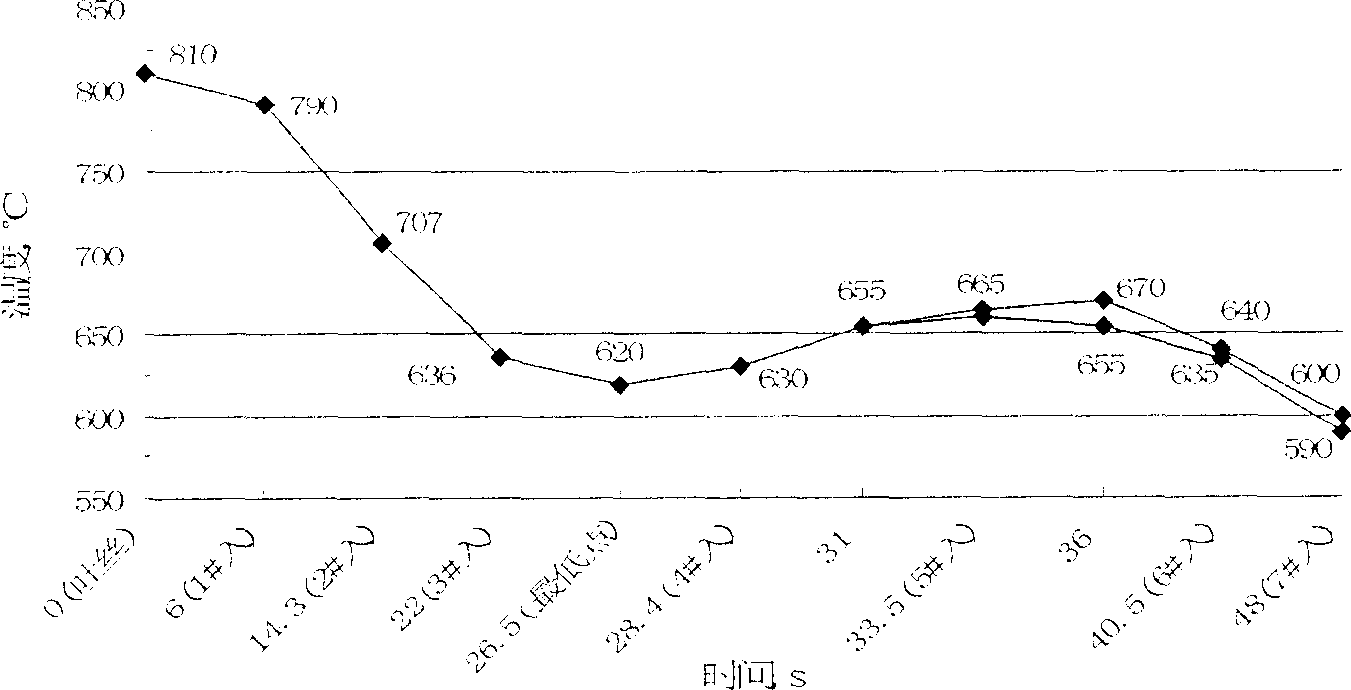

[0018] By adopting the cooling control process of the present invention, φ12?4mm 82B wire rods meeting the requirements have been mass-produced in Shougang. The process route of Shougang’s production of 82B is as follows: 80-ton converter and F furnace refining? 30mm square continuous casting Standard Stelmore controlled cooling. The chemical composition of the wire rod is as follows: 0.77-0.81% C, 0.60-0.90% Mn, 0.15-0.35% Si, 0.30-0.43% Cr, 0.02-0.08% V. The starting rolling temperature of the wire rod is 1050-1100°C, the finishing rolling temperature is 1000-1040°C, and the spinning temperature is 810-850°C. The structure and performance of the produced wire rod are stable, the average lamellar spacing is 0.18μm, the average diameter of pearlite pellets is 8.4μm, the tensile strength of the wire rod is 1160-1220MPa, and the shrinkage rate is 30-36%, which is bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com