Radiating treatment structure

A heat sink and heat dissipation material technology, applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating modification, etc., can solve the problems affecting the production progress and high cost, and achieve the effect of optimizing the shell temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

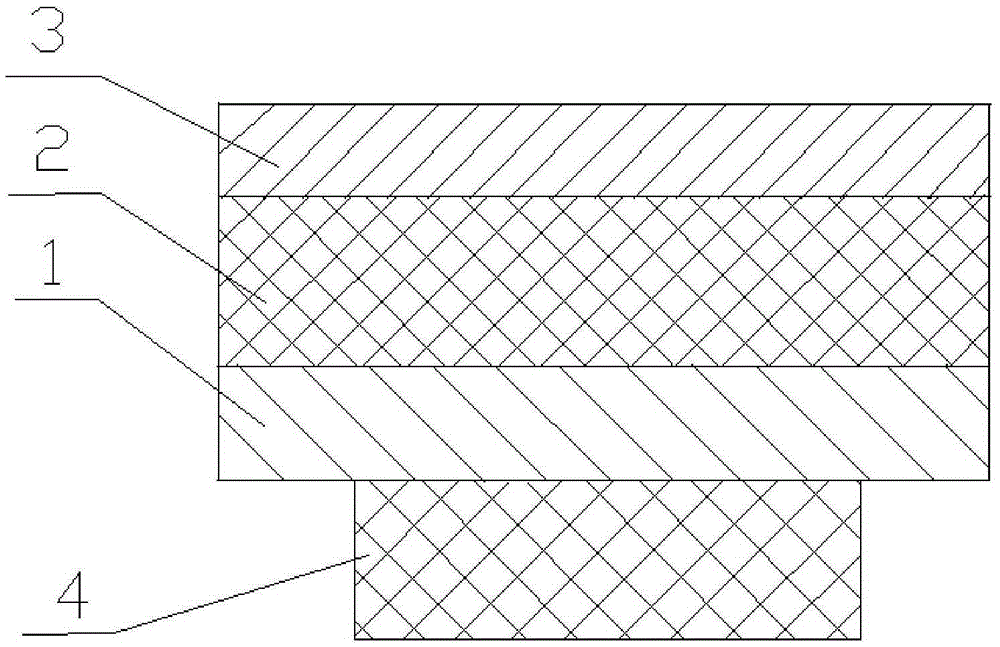

[0024] A heat dissipation treatment structure as shown in the attached drawing includes a heat sink that is close to the heat source 4 of the product, the heat sink is a "sandwich" structure, and the heat dissipation in the horizontal direction and the heat insulation in the vertical direction are adopted to reduce the heat source of the product. The temperature of each point on the outer surface of the product is determined, and the heat source of the product is subjected to an isothermal cooling treatment to optimize the heat treatment of the product.

[0025] The bottom layer in the shape of a "sandwich" structure is the first heat dissipation material 1 that is close to the product heat source 4, the surface layer is the second heat dissipation material 3, the middle layer between the bottom layer and the surface layer is the heat insulation material 2, the bottom layer, the middle layer and the surface layer in turn. Connected by lamination, the first heat dissipation mate...

specific Embodiment approach 2

[0029] A heat dissipation processing structure as shown in the accompanying drawings includes a heat sink that is close to the product heat source 4, and the heat sink is a "sandwich" structure, which is basically the same as the first embodiment. The difference is:

[0030] The bottom layer, the middle layer and the surface layer are connected with glue in turn;

[0031] The first heat dissipation material 1 is a copper sheet with a thermal conductivity of 100 W / m·K and a thickness of 0.05 mm.

[0032] The heat insulating material 2 is a silica aerogel having a thermal conductivity of 0.024 W / m·K and a thickness of 0.6 mm.

[0033] The second heat dissipation material 3 is an aluminum sheet with a thermal conductivity of 100 W / m·K and a thickness of 1.00 mm.

[0034] Embodiment 2 Compared with Embodiment 1, the temperature of the product shell is about 2°C higher, and the heat dissipation treatment effect is slightly worse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com