Wide bandgap power module packaging structure suitable for a severe environment

A power module and packaging structure technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of breakdown of power chips, low heat dissipation efficiency, different failure rates of adhesive layers, etc., to eliminate common emitter inductance, The effect of reducing the degree of thermal coupling and reducing parasitic inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

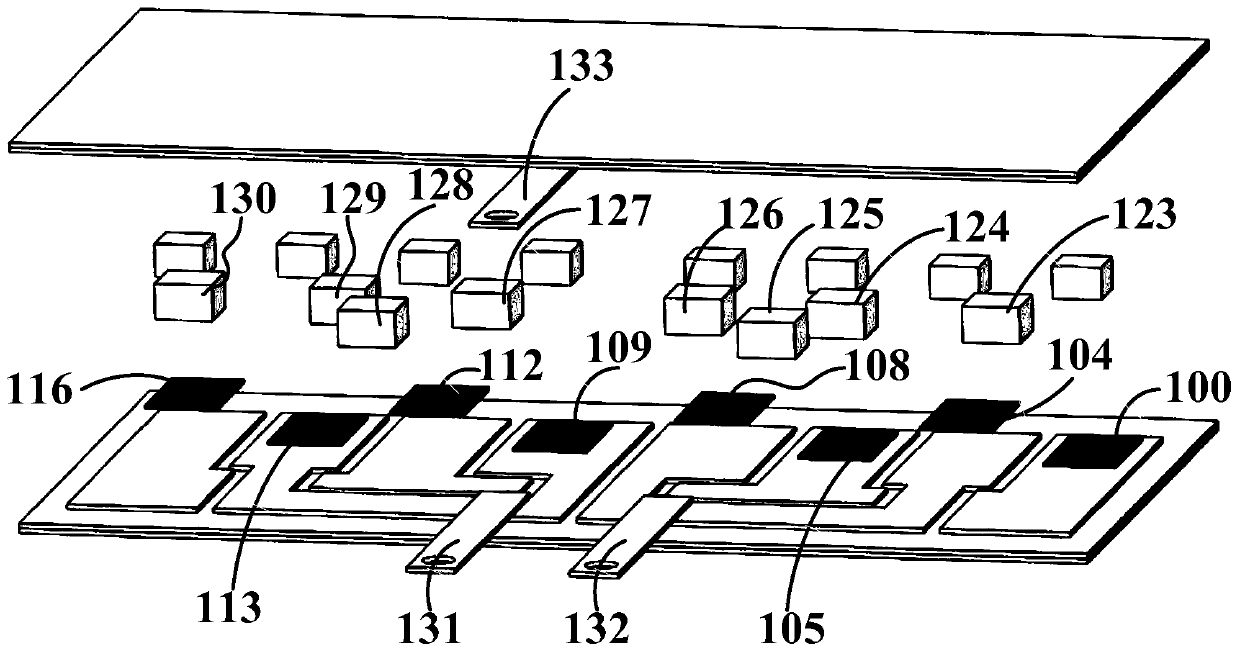

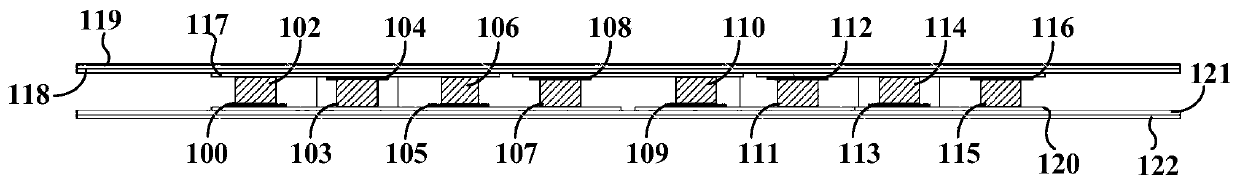

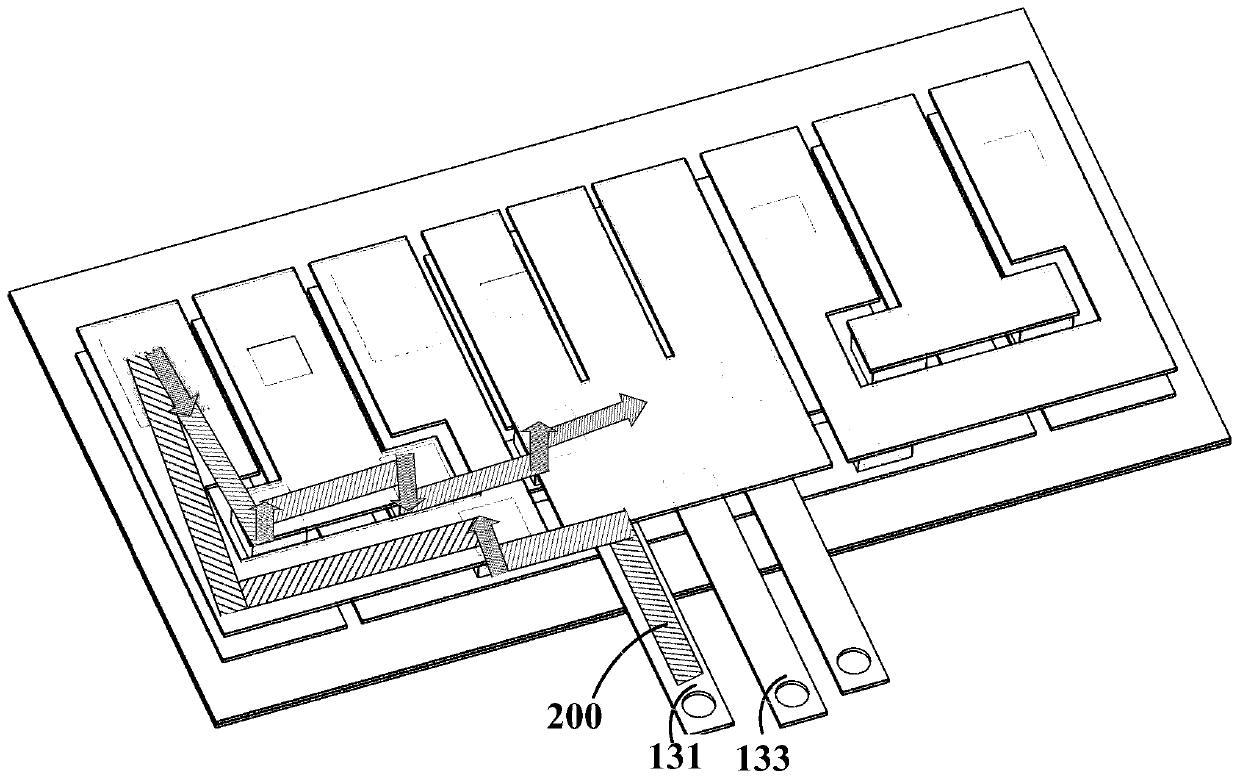

[0057] Such as figure 1 with figure 2 As shown, the packaging structure of this embodiment is mainly composed of 8 power electronic power semiconductor chips, 16 power pads, 6 power substrates and 3 power terminals;

[0058] The eight power electronic power semiconductor chips are specifically a semiconductor chip 100, a semiconductor chip 104, a semiconductor chip 105, a semiconductor chip 108, a semiconductor chip 109, a semiconductor chip 112, a semiconductor chip 113, and a semiconductor chip 116;

[0059] The 16 power pads are specifically power pad 102, power pad 103, power pad 106, power pad 107, power pad 110, power pad 111, power pad 114, power pad 115, power pad 123, power gasket 124, power gasket 125, power gasket 126, power gasket 127, power gasket 128, power gasket 129 and power gasket 130;

[0060] The six power substrates are specifically the top conductive metal substrate 117, the first insulating dielectric substrate 118, the first conductive metal substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com