Heat uniform distribution and dissipation structure and heat uniform distribution and dissipation process for portable electronic equipment

A technology for electronic equipment and heat dissipation. It is applied to the structural parts of electrical equipment, electrical components, and decoration through conduction and heat transfer. It can solve problems such as poor user experience, insignificant heat dissipation effect, and slow crash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

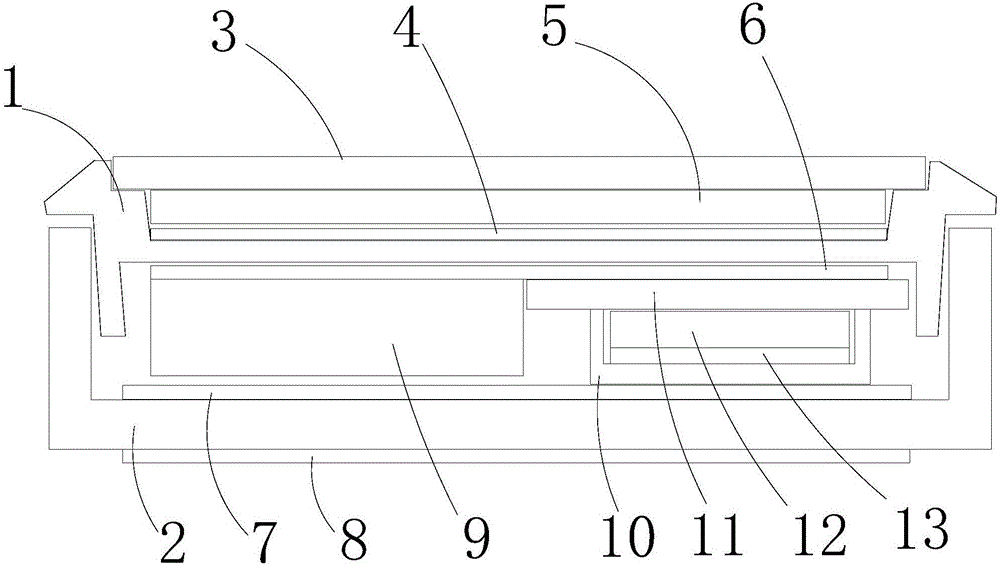

[0027] Such as figure 1 As shown, the outer surface of the front shell 1 is pasted with a first heat equalizing layer 4 , the first heat equalizing layer is made of silver material, and a display screen 5 and a touch screen 3 are pasted on the front of the first heat equalizing layer 4 .

[0028] The inner surface of the front shell 1 is pasted with a second heat equalizing layer 6, and the rear portion of the second heat equalizing layer 6 is pasted side by side with a battery 9 and a circuit board 11. The inside of the chip is a chip 12, and one side of the chip 12 is pasted on the circuit board 11.

[0029] A first heat dissipation layer 7 is pasted on the inner side of the rear case 2 , and a second heat dissipation layer 8 is pasted on the outer side of the rear case.

[0030] On the inner side and / or outer side of the front shell 1 above the circuit board 11, use paste, smear, electroplating, and spray related heat-conducting materials to evenly distribute the heat emit...

Embodiment 2

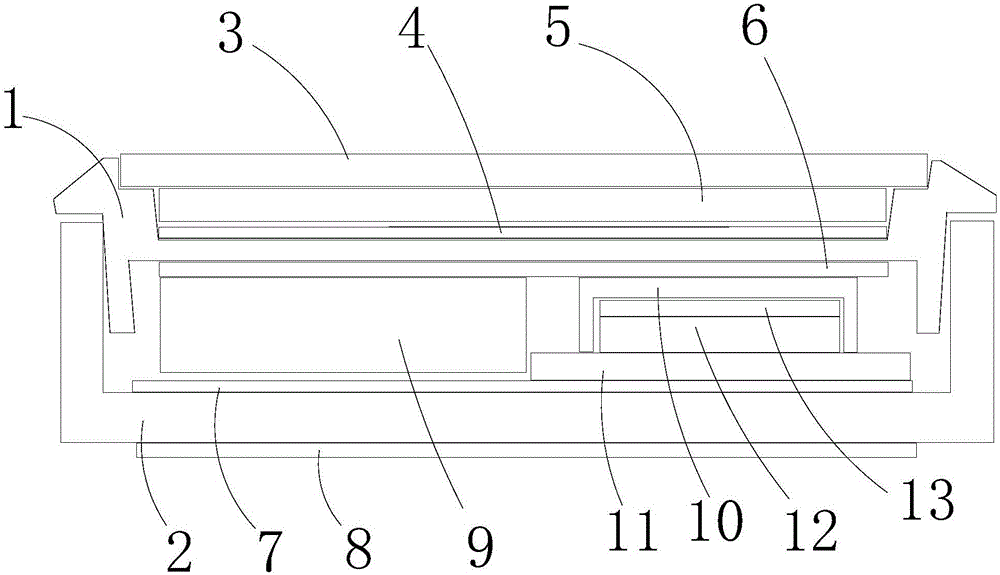

[0033] Such as figure 2 As shown, the outer surface of the front shell 1 is pasted with a first heat equalizing layer 4 , the first heat equalizing layer is made of silver material, and a display screen 5 and a touch screen 3 are pasted on the front of the first heat equalizing layer 4 .

[0034] A first heat dissipation layer 7 is pasted on the inner side of the rear case 2 , and a second heat dissipation layer 8 is pasted on the outer side of the rear case.

[0035] The inner surface of the front shell 1 is pasted with a second heat equalizing layer 6, and the rear portion of the second heat equalizing layer 6 is pasted side by side with a battery 9 and a shielding cover 10. The inside of the shielding case 10 is a chip 12, and one side of the chip 12 is pasted on the on the circuit board 11. The other side of the circuit board 11 is pasted on the first heat dissipation layer 7 .

[0036] On the inner side and / or outer side of the front shell 1 above the circuit board 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com