Patents

Literature

73results about How to "Lower core temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

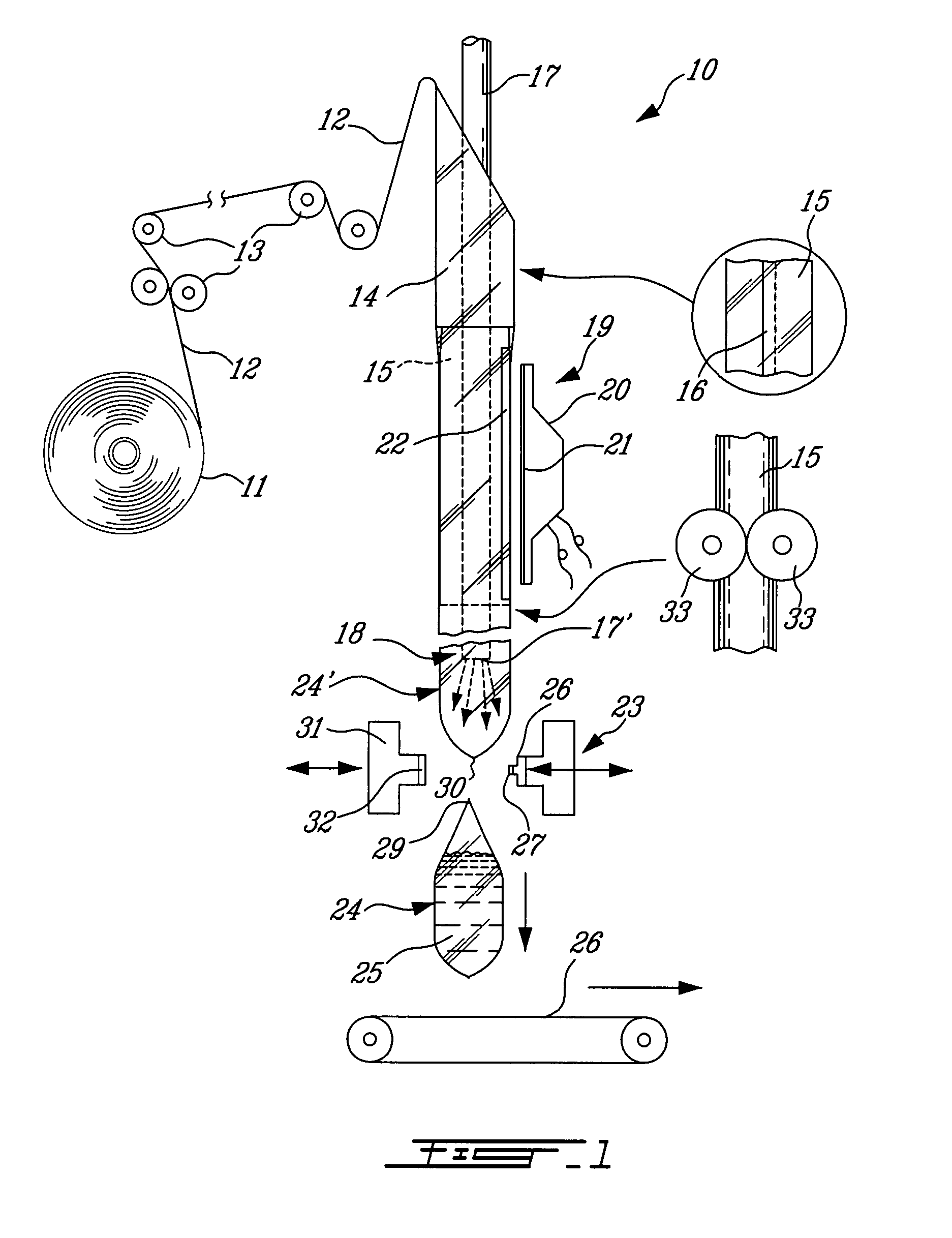

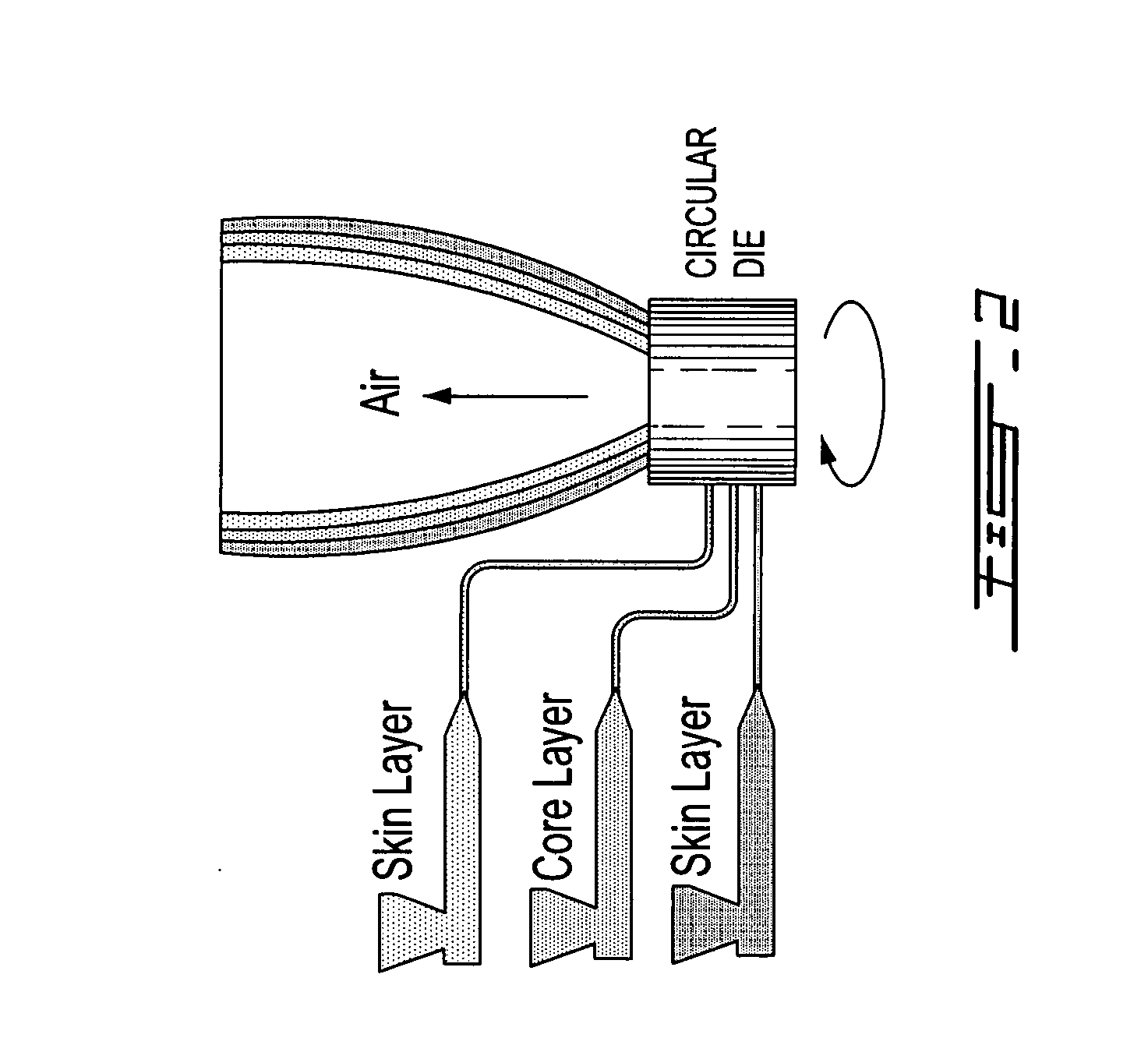

Thin film for vertical form fill and seal packaging of flowable materials

InactiveUS20070252276A1Quick sealImprove heat transfer characteristicsSemiconductor/solid-state device detailsSynthetic resin layered productsPolypropyleneLow-density polyethylene

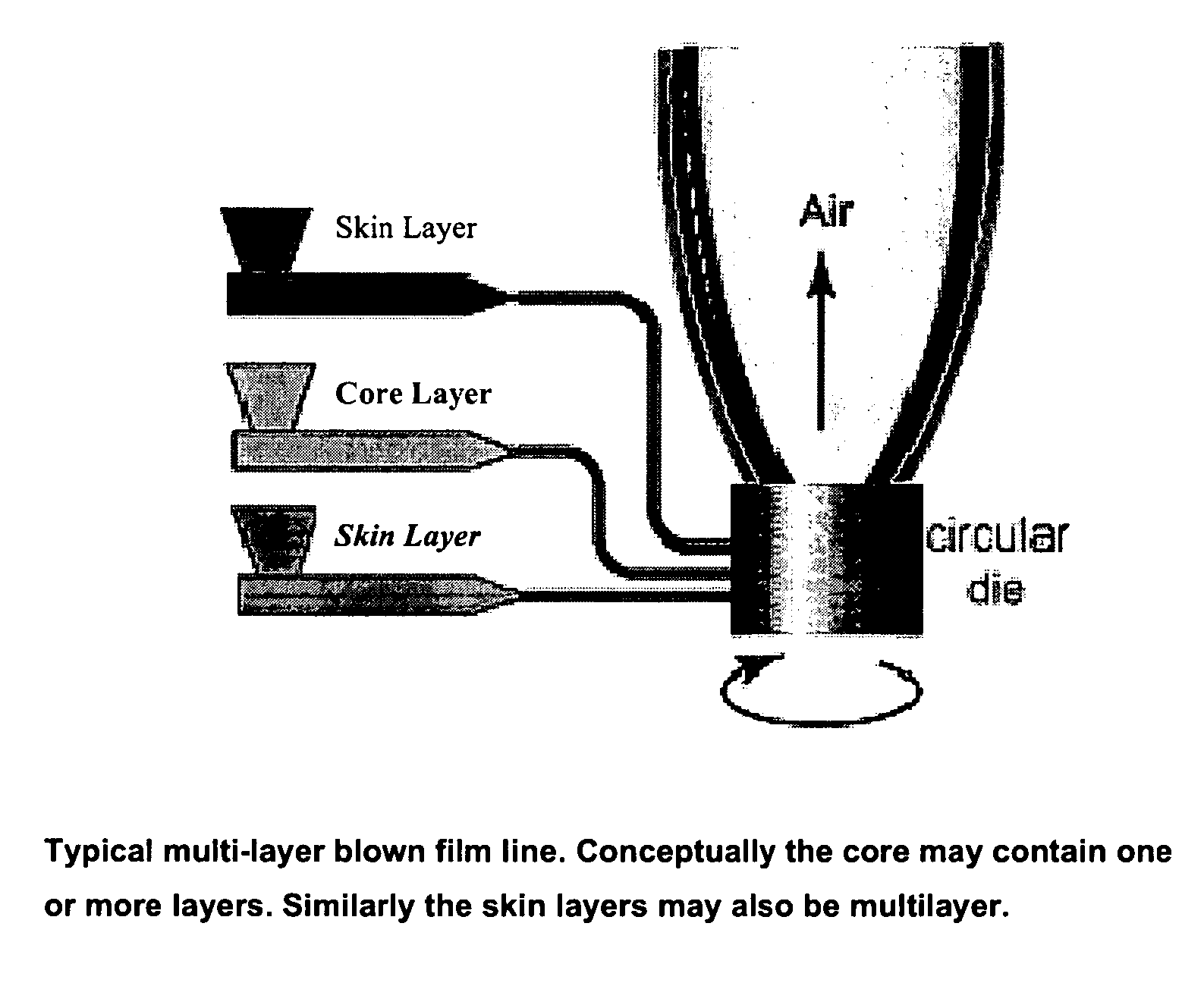

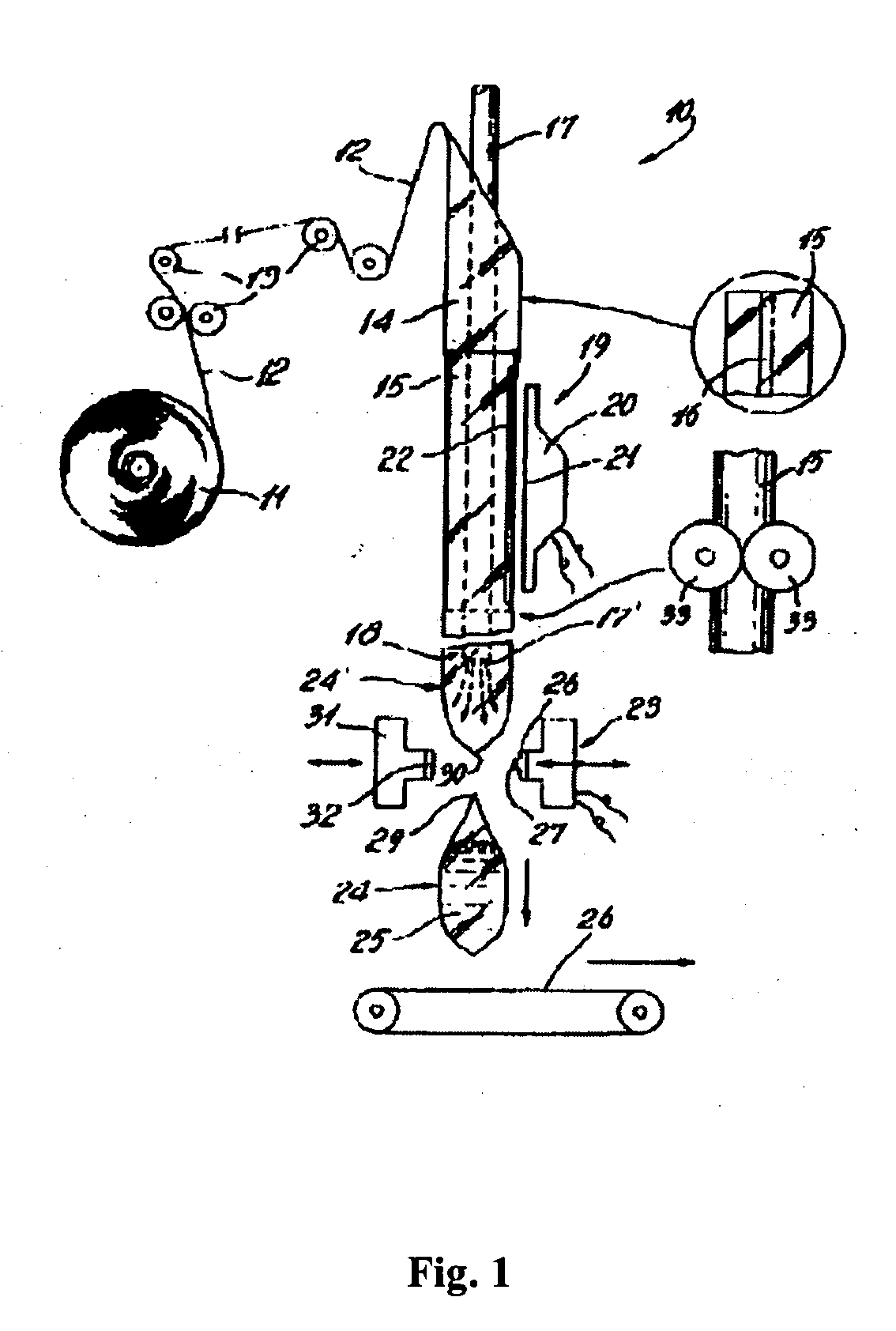

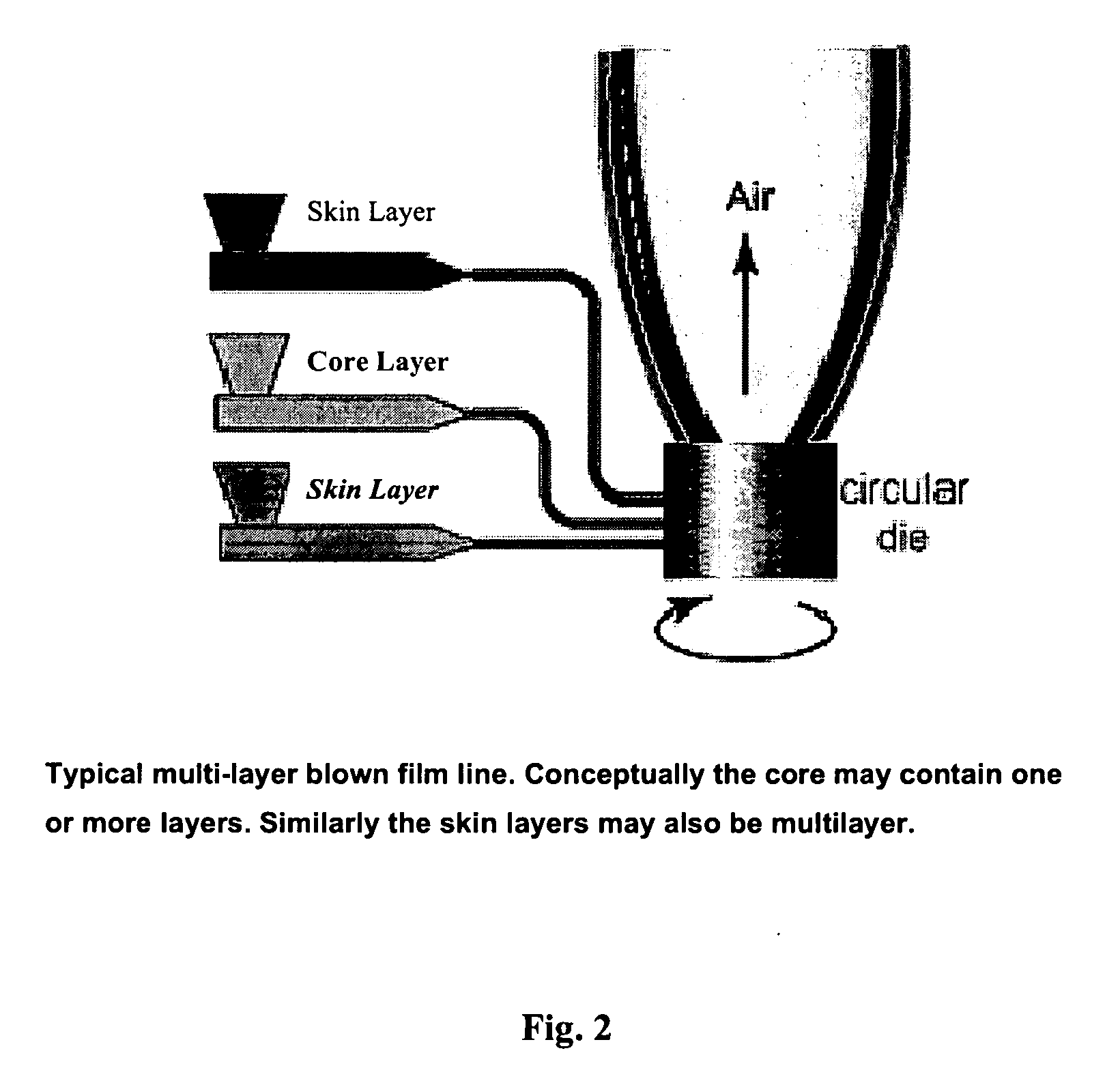

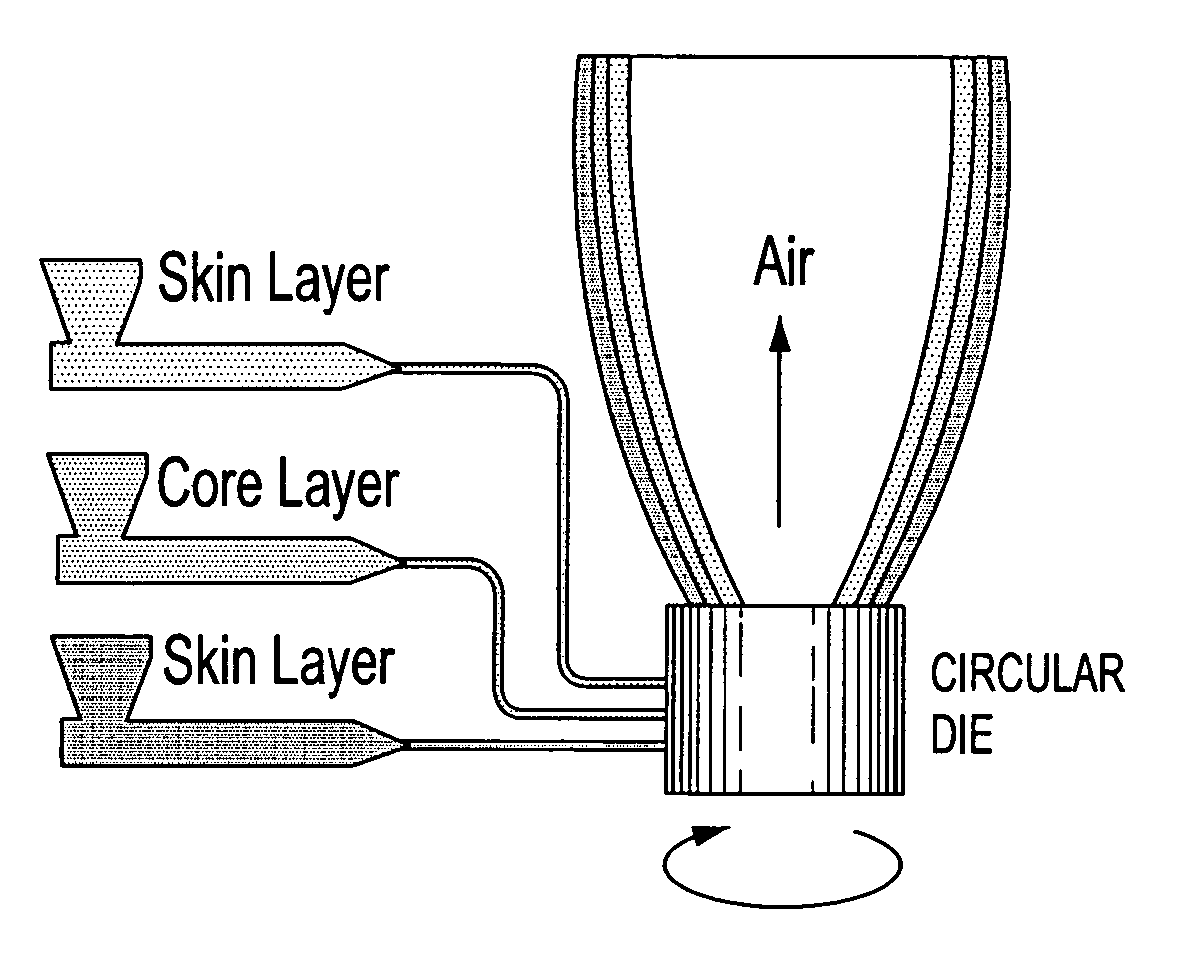

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film direction) varying from 79000 psi to 140000 psi; a tensile strength at yield of from 2100 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4700 to 6700 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:LLOYD GEORGE IAN

Thin film for vertical form fill and seal packaging of flowable materials

InactiveUS20070254119A1More sealEnhance heat transfer characteristicSynthetic resin layered productsCeramic shaping apparatusPolypropyleneEngineering

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film machine direction) varying from 3500 psi to 150000 psi; a tensile strength at yield of from 1700 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4300 to 7400 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:GLOPAK INC

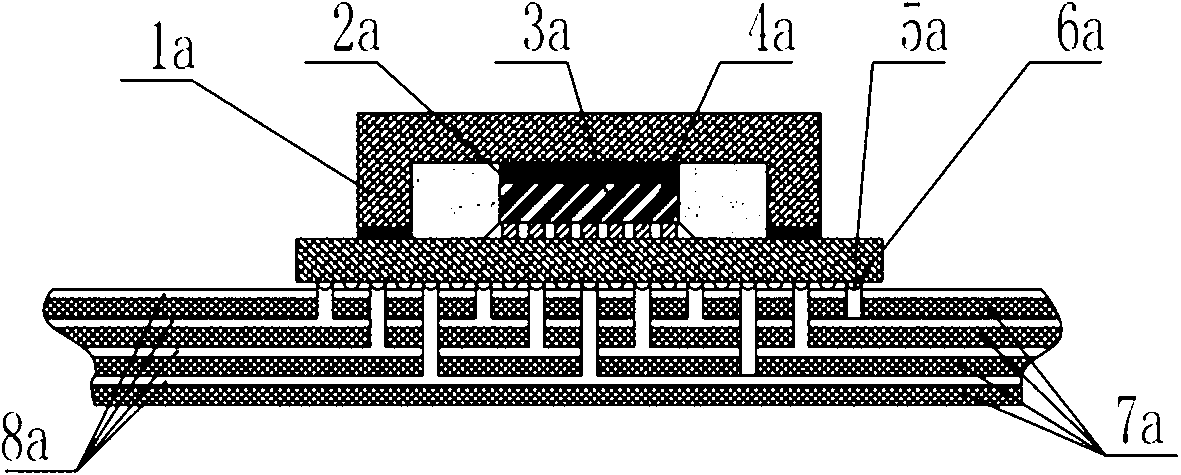

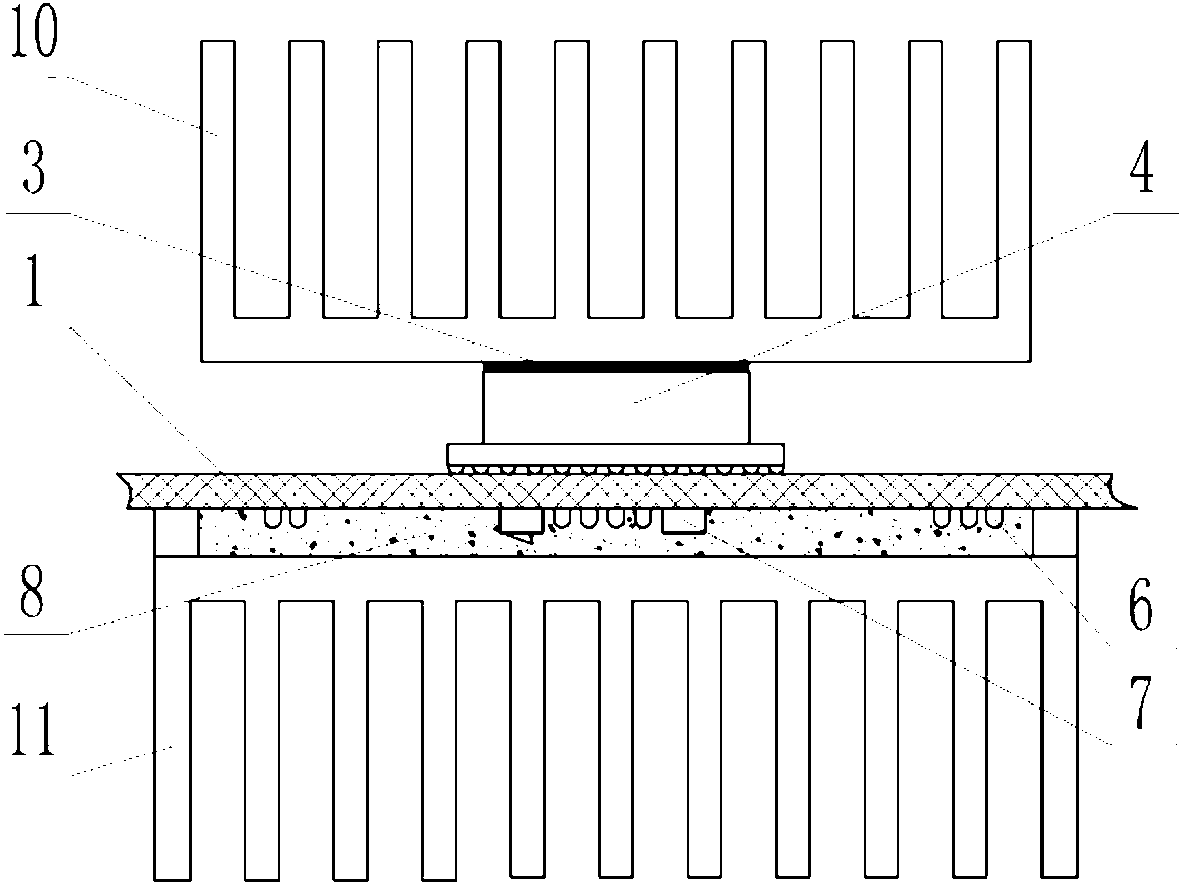

High-density chip radiating method by dual-path heat transfer

ActiveCN103021877AImprove heat transfer performanceSolve heat buildupDigital data processing detailsSemiconductor/solid-state device detailsHigh densityCore temperature

Disclosed is a high-density chip radiating method by dual-path heat transfer. Each heat transfer path comprises a chip, a printed board, thermally conductive and insulating media and radiators. The high-density chip radiating method is characterized by including the steps: firstly, welding the chips on the printed boards; secondly, mounting the radiators on the surfaces of the chips and bottom surfaces of the printed boards; and finally, filling the thermally conductive and insulating media among the chips and the radiators and among the printed boards and the radiators. The high-density chip radiating method has the advantages that heat on the heat transfer paths of the chips is distributed by setting up two parallel heat transfer paths, the thermal flux density on the heat transfer paths is reduced, the radiating capacity of the chips can be improved, the problem of thermal accumulation of the high-density chips is solved, and the core temperature of the chips is reduced.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

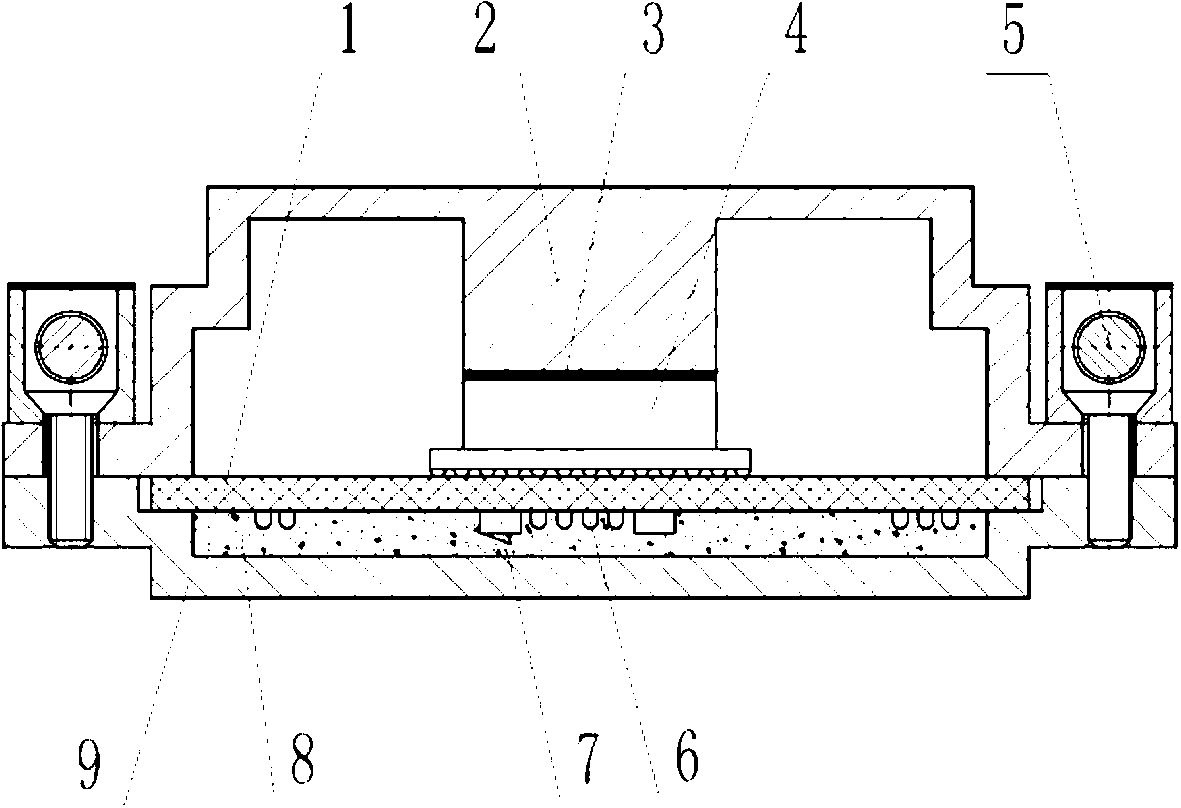

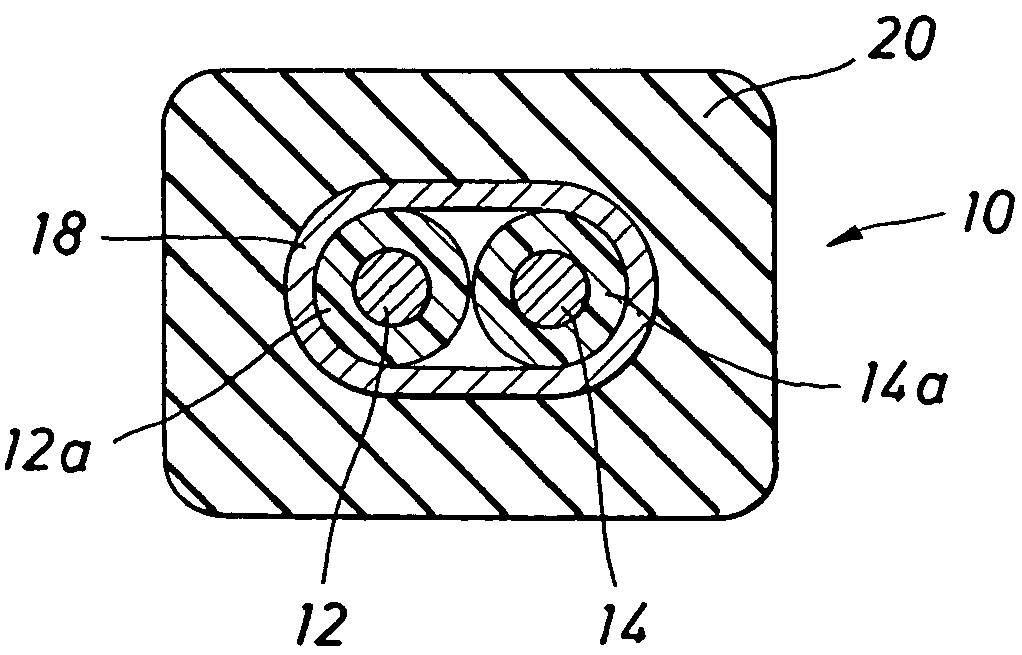

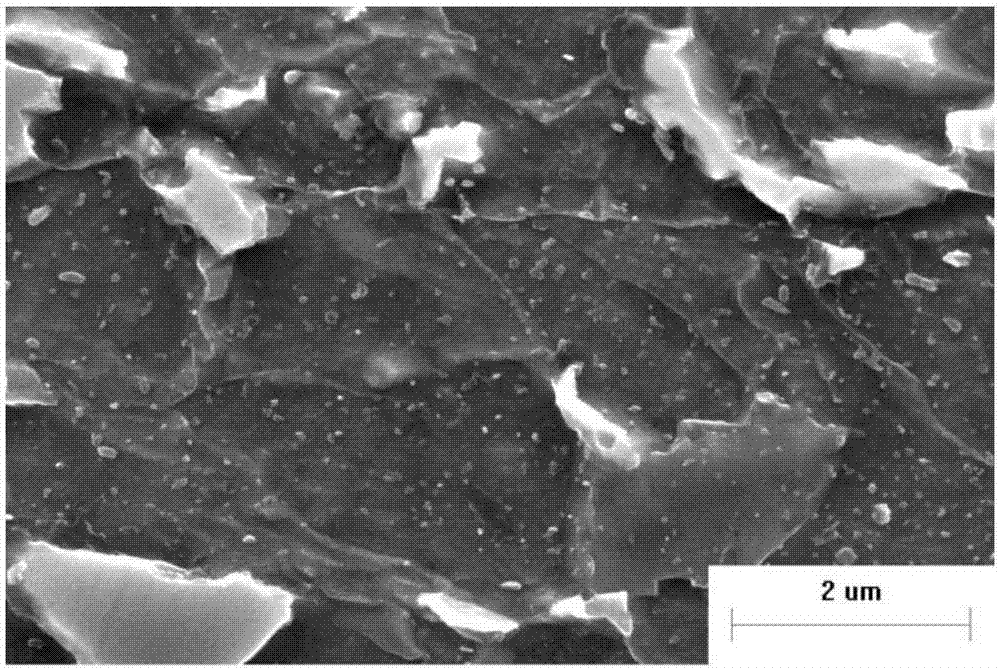

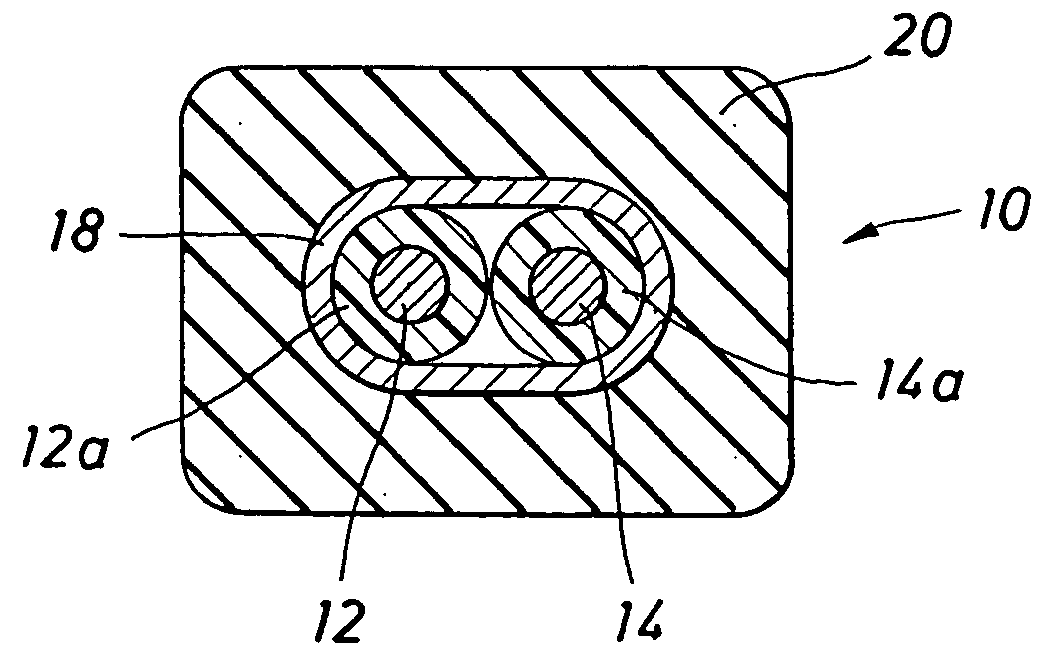

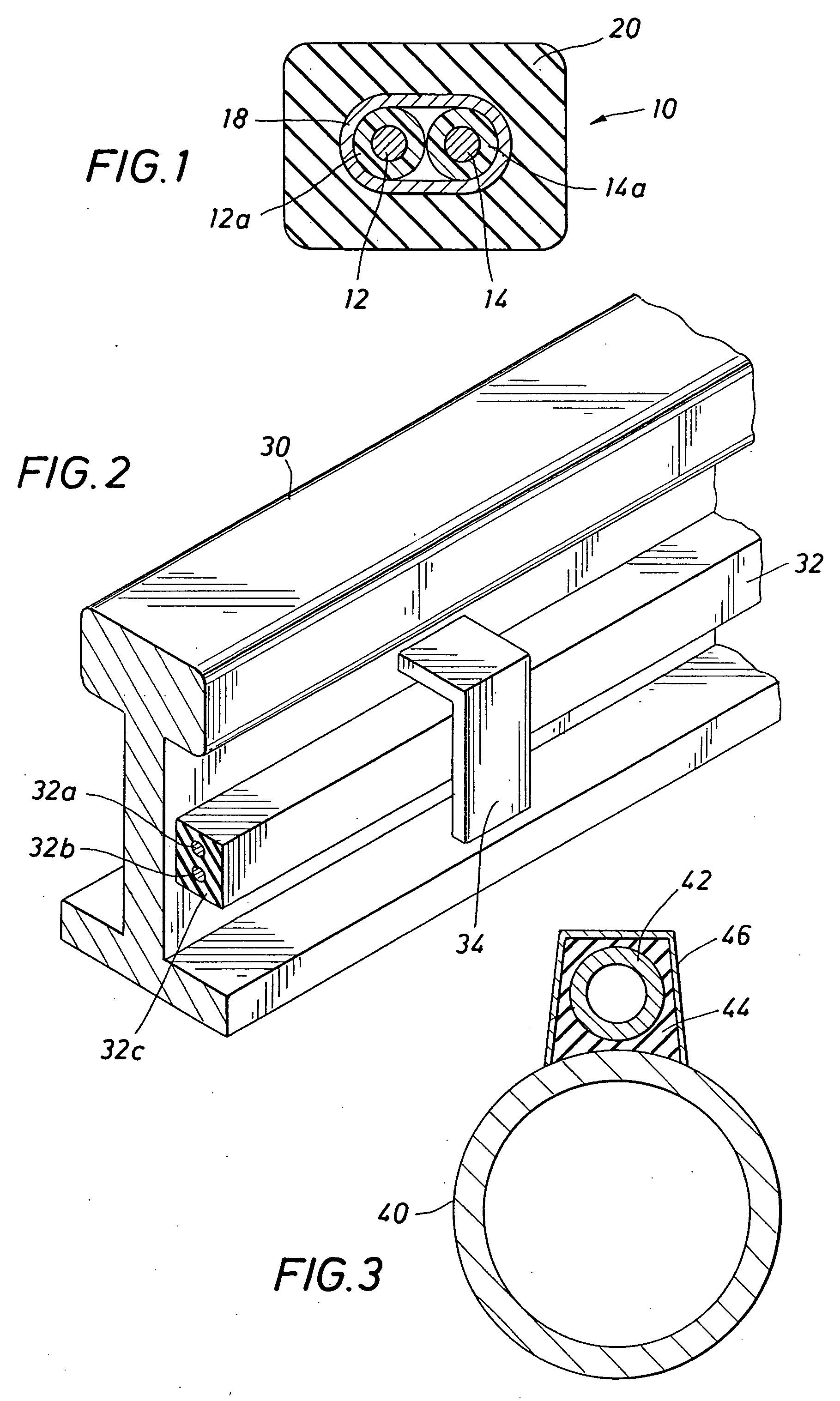

Thermally-conductive, electrically non-conductive heat transfer material and articles made thereof

InactiveUS7321107B2Improve conductivityLower core temperatureHeater elementsHeating element shapesPlasticizerBoron nitride

A heat transfer material comprised of a polymeric material and a nitride or oxide is provided and is thermally conductive, but electrically non-conductive. The polymeric material may be silicone rubber, and the nitride or oxide may be aluminum nitride, boron nitride, silicon nitride, aluminum oxide or beryllium oxide. The material is made flexible by adding plasticizer and remains flexible after an extended period of use. A dielectric jacket for an electrical heating cable is thermally conductive and remains flexible so that it can be reused. The heat transfer material can be used on heating devices such as steam tubes and panels, where the heat transfer material does not bond to or adhere to the heated surface, which allows the heating device to be reused.

Owner:THERMON INC

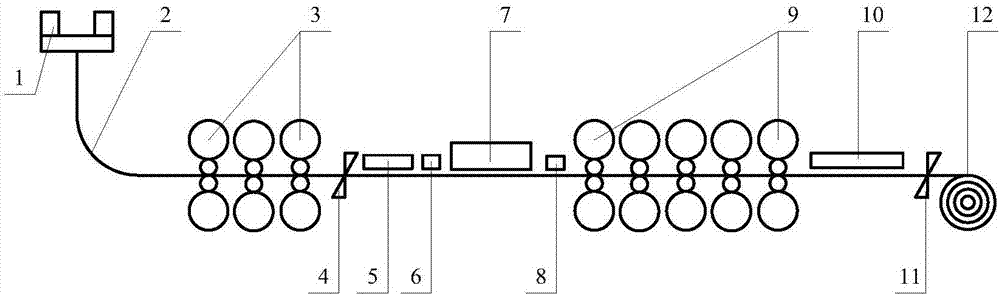

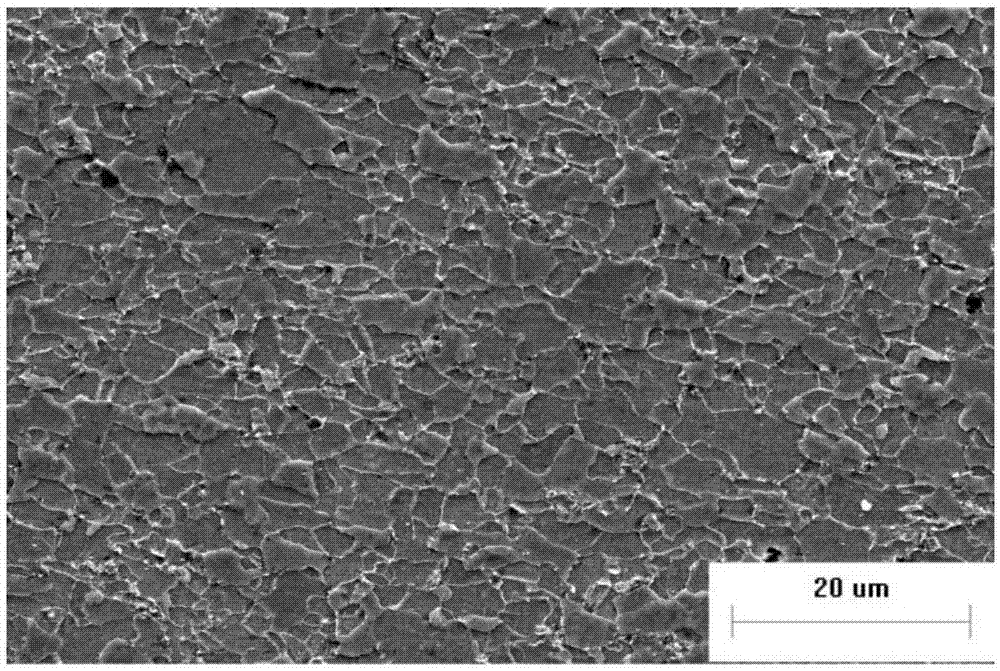

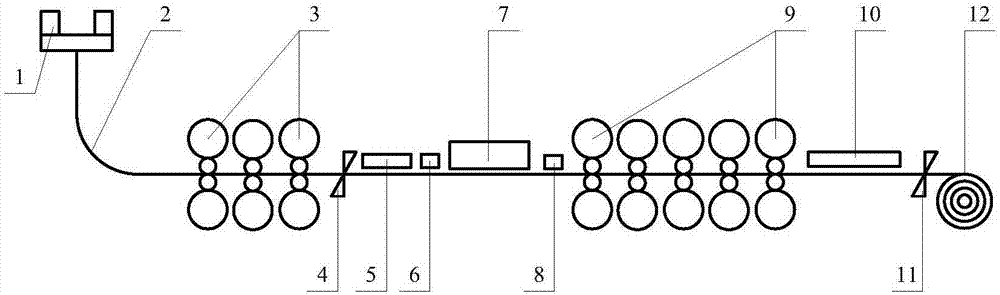

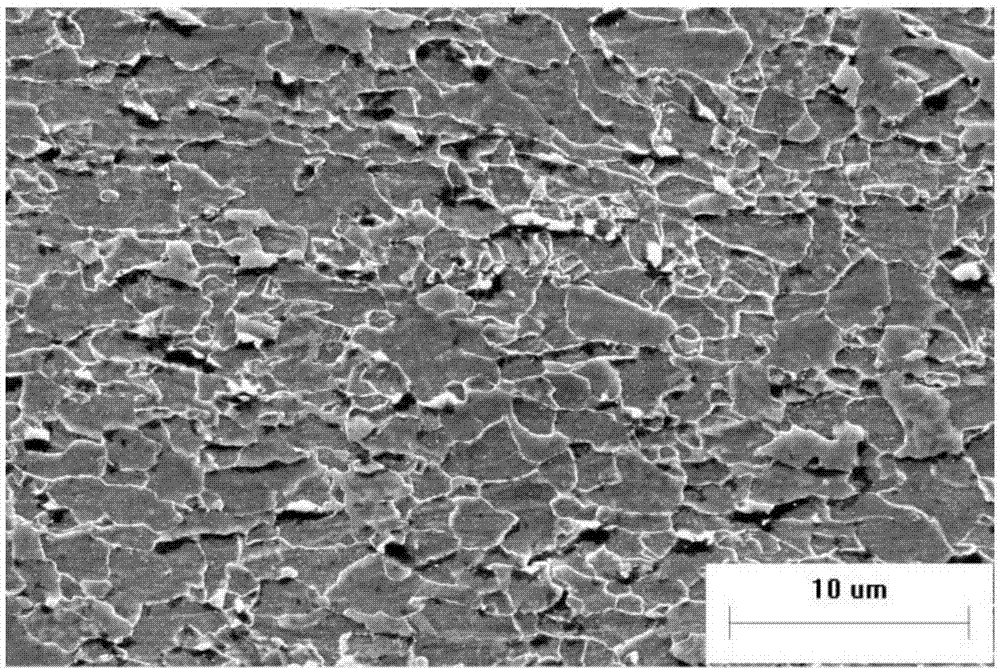

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

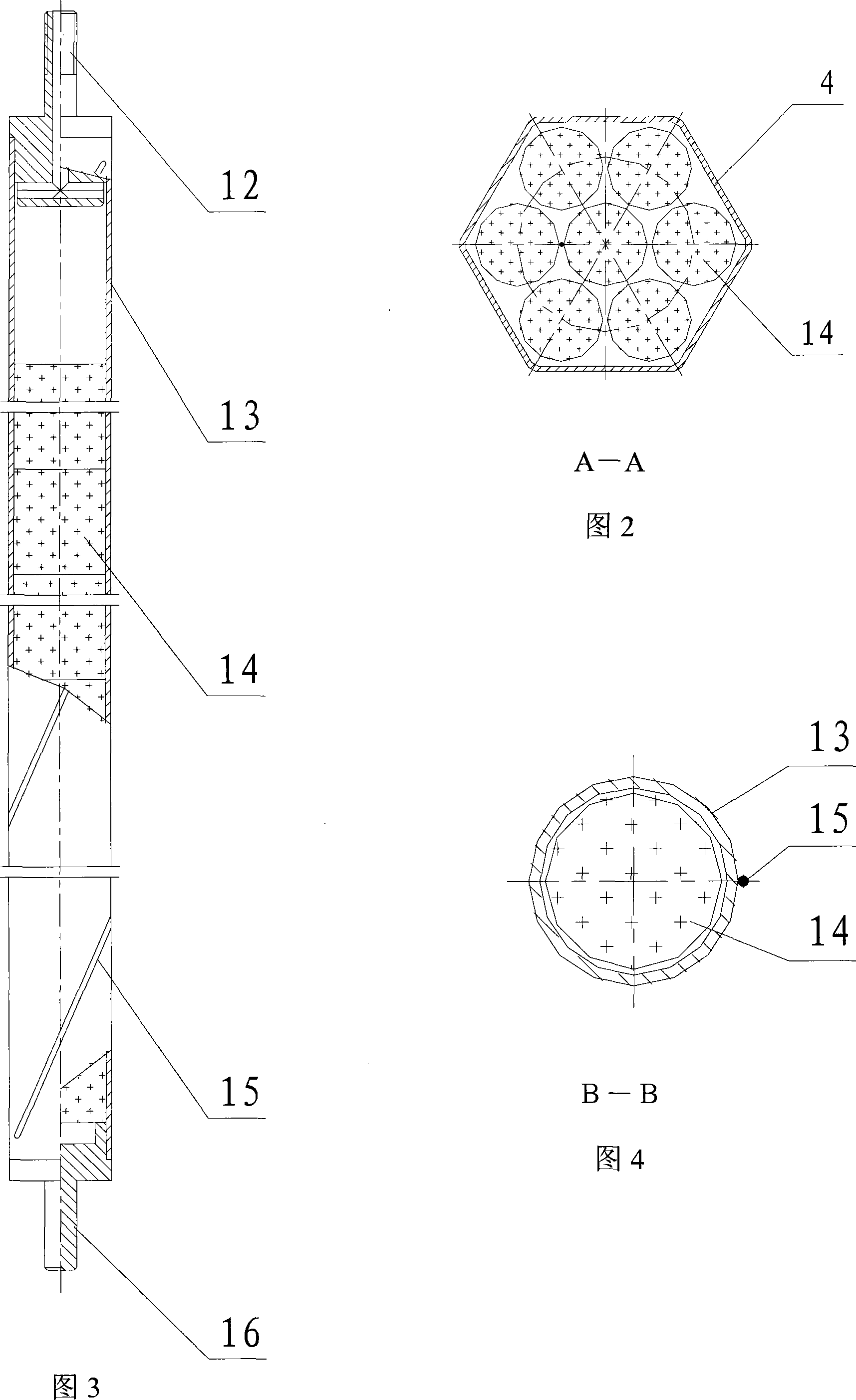

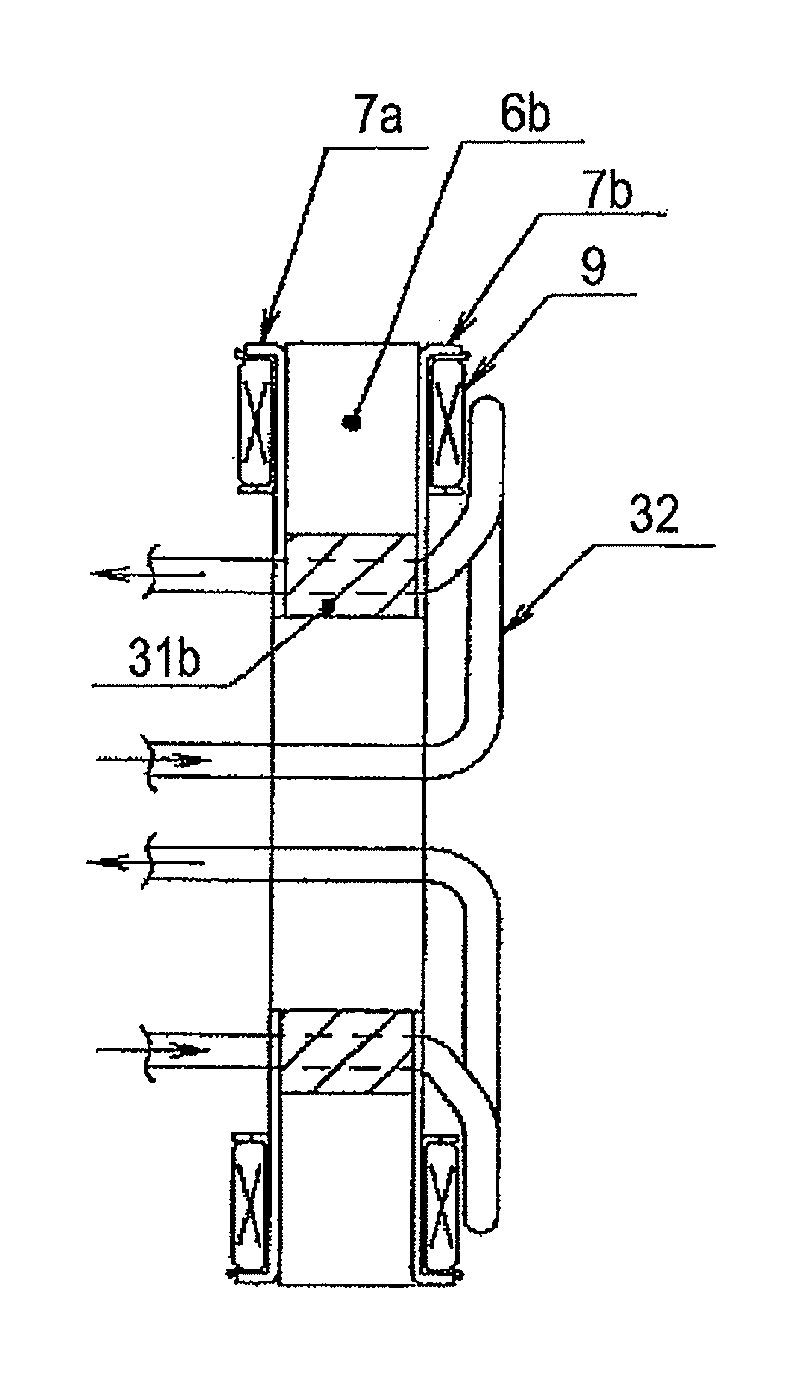

Boron carbide shielding assembly

ActiveCN101178947APrevent self-weldingImprove wear resistanceNuclear energy generationShieldingHigh densityBoron carbide

The invention discloses a component for shielding neutronic reactor core. The component consists of three parts: a head part, a middle part and a tail part; wherein, the head part is composed of a manipulation head and an upper transitional joint. The manipulation head is inosculated with component handling equipment and is also provided with an outlet hole for sodium; the external side of the upper transitional joint is provided with a locating block to guarantee the radial positioning among components, and the upper transitional joint is welded on the upper surface of a hex wrapper tube. The middle part is composed of a hex wrapper tube and a shield which is arranged in the wrapper tube. The tail part is composed of a lower transitional joint and a pin. The lower transitional joint is welded on the bottom surface of a hex wrapper tube and the pin is provided with an inlet hole for sodium. The invention uses high-density and hot-pressing a boron carbide pellet to guarantee that the boron carbide pellet dose not escape out of a rod after cracking, and at the same time an absorbing rod adopts a ventilation-typed top end plug to extract the helium gas produced in the B-10 (n, Alpha)reaction. The technical proposal of the invention is not only practical but also solves the bearing pressure of a casing on the absorbing rod effectively.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Fast drying cellulosic fabric and process to produce same

InactiveUS20130067629A1Fast dryingFast hydrophilicNon-fibrous pulp additionInsolesCelluloseEngineering

Cellulosic fabrics and articles are disclosed that include a treatment to provide the fabric that has a balance of comfort, absorbency, wicking, and fast drying. Methods to produce the fabrics and articles are also disclosed.

Owner:OPTIMER

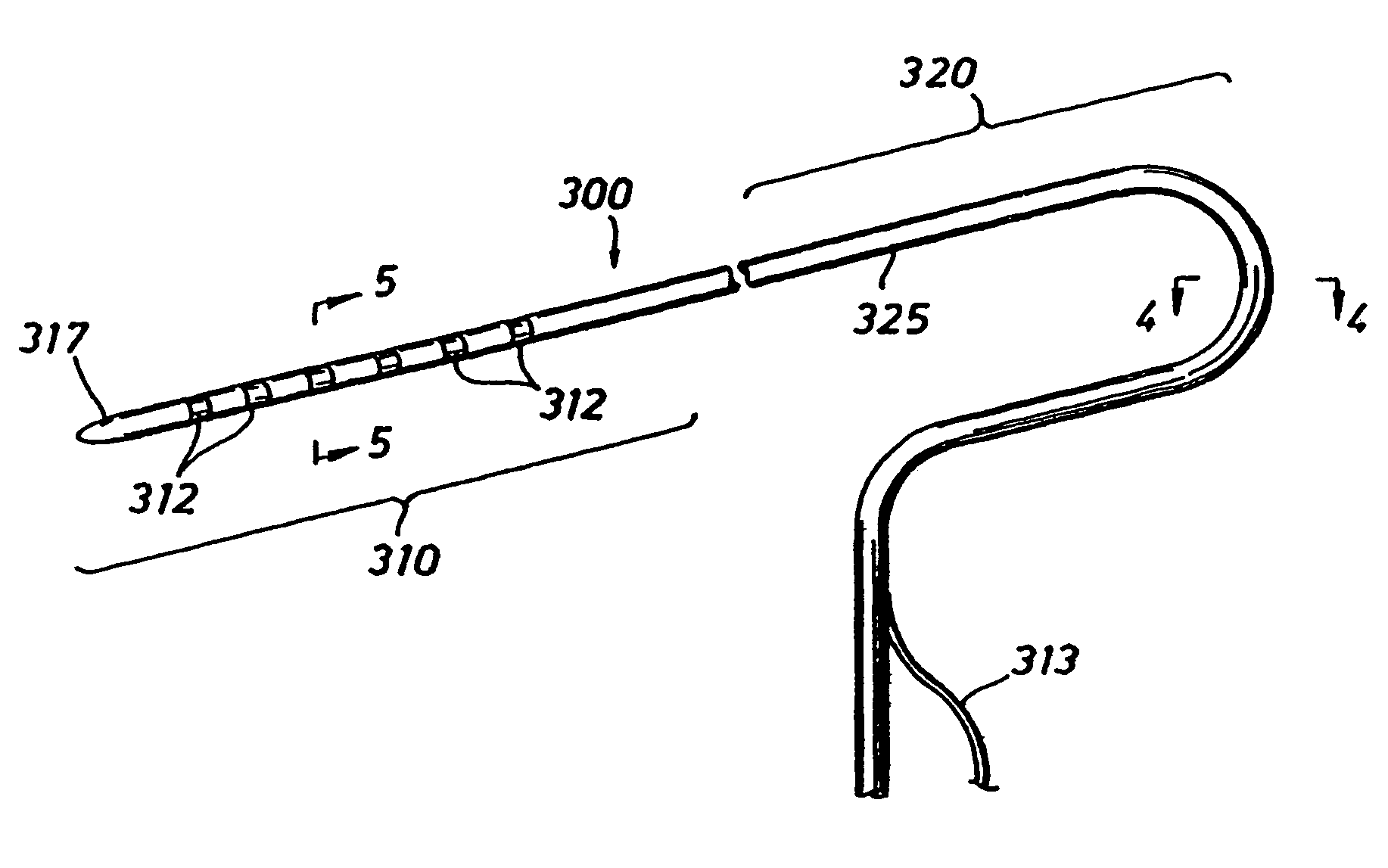

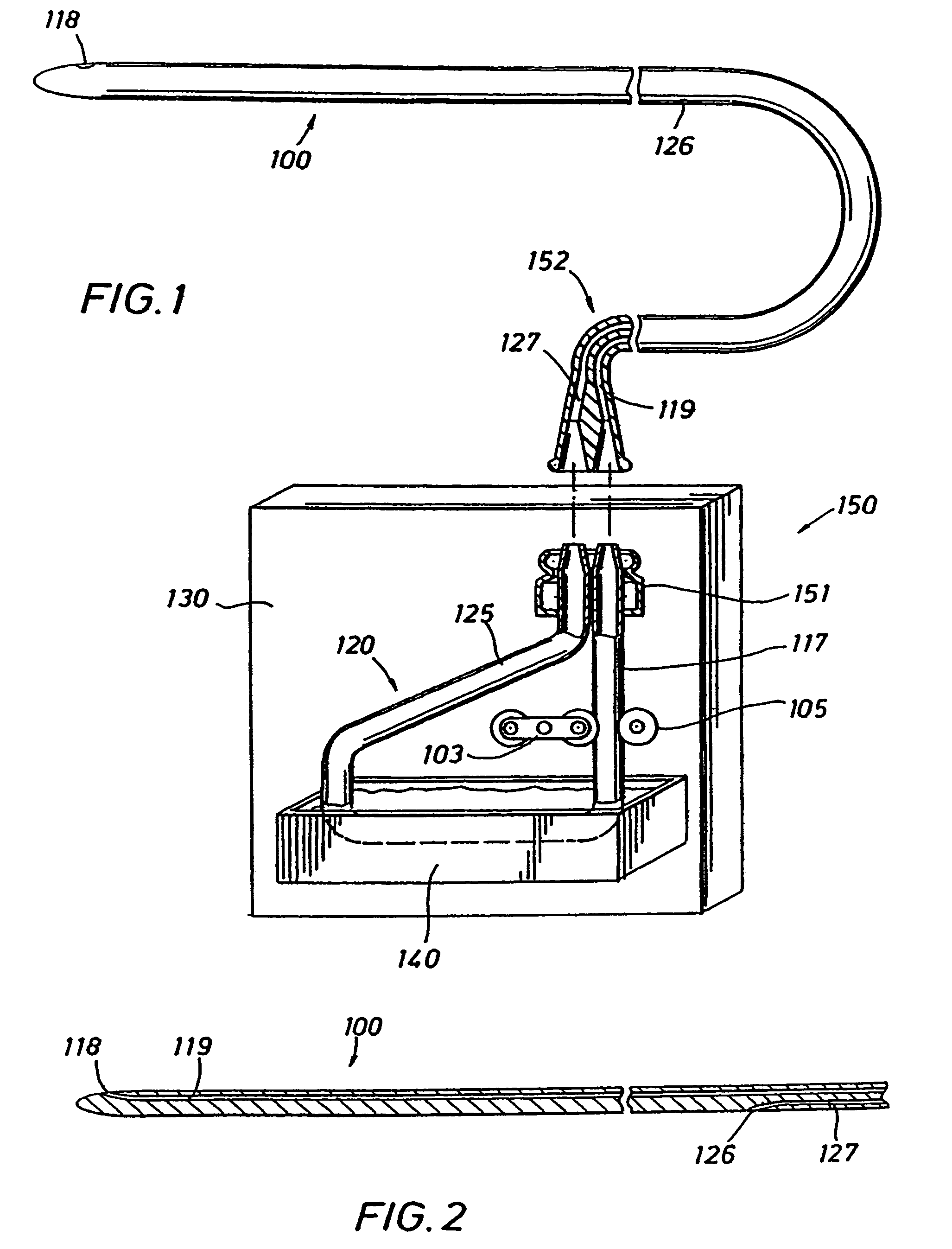

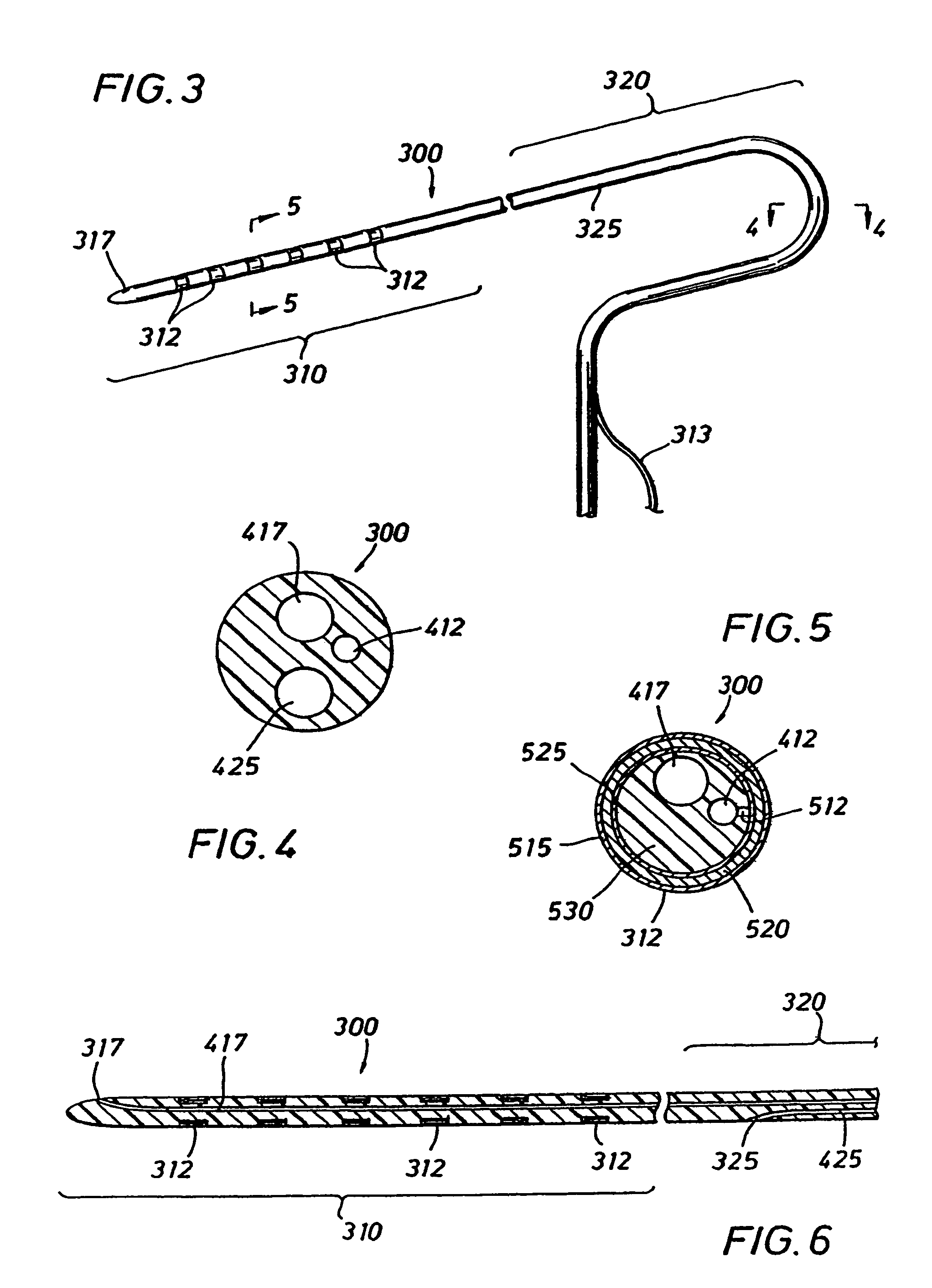

Method of cooling an organ

A method of cooling an organ. A portion of a body fluid bathing an organ is withdrawn while a cool fluid is infused. A separate portion of the body fluid can be cooled during the withdrawing. A volume of up to about 5% of the body fluid can be withdrawn. A catheter is provided with a cooling mechanism to contact and cool the body fluid. The catheter can have an inlet port to withdraw body fluid and an outlet port to allow infusion of a cool fluid. Additionally, an organ cooling pump assembly is provided including a pump and a catheter.

Owner:ORIGIN MEDSYST

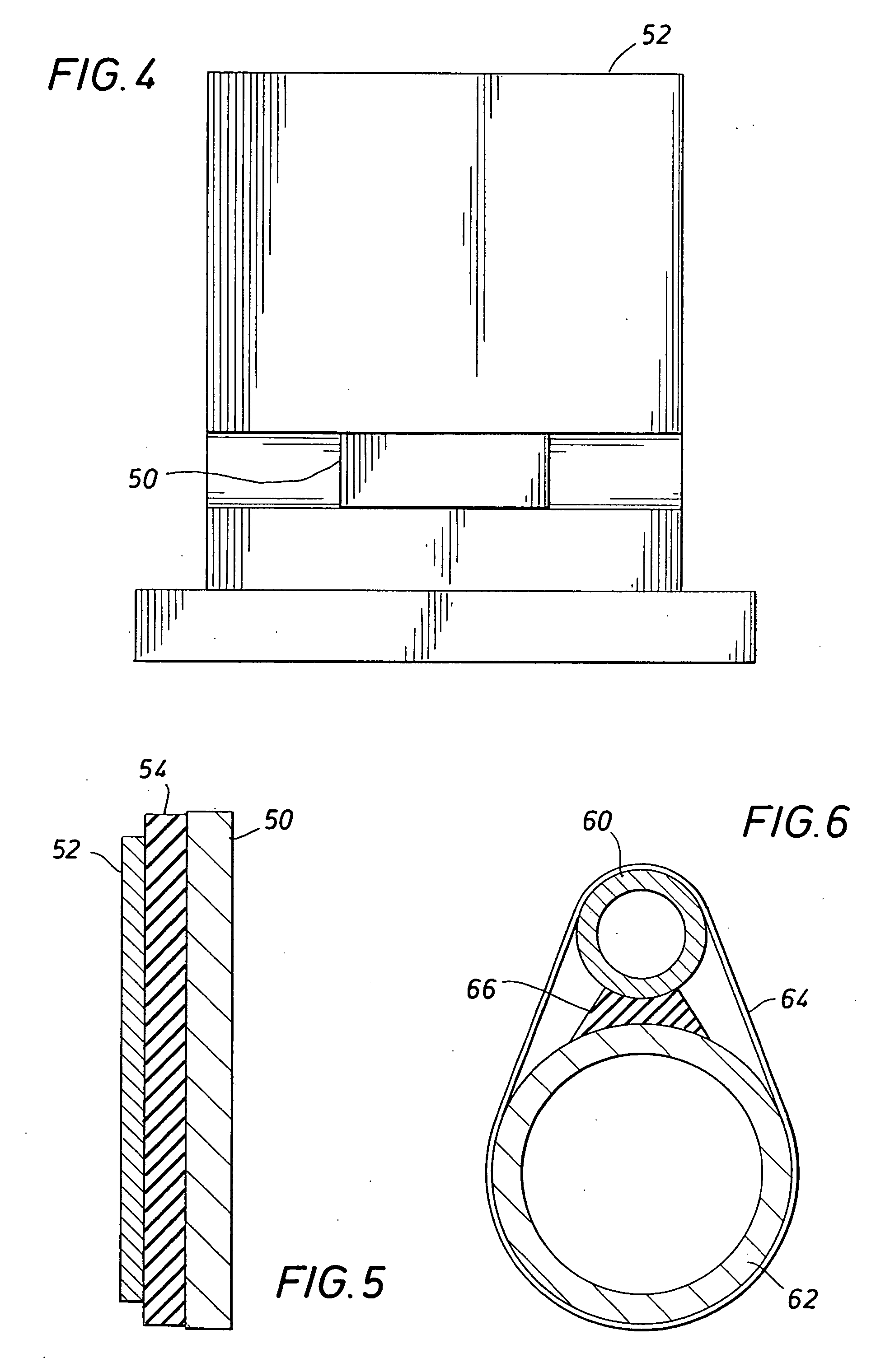

Water basins for heat strain reduction

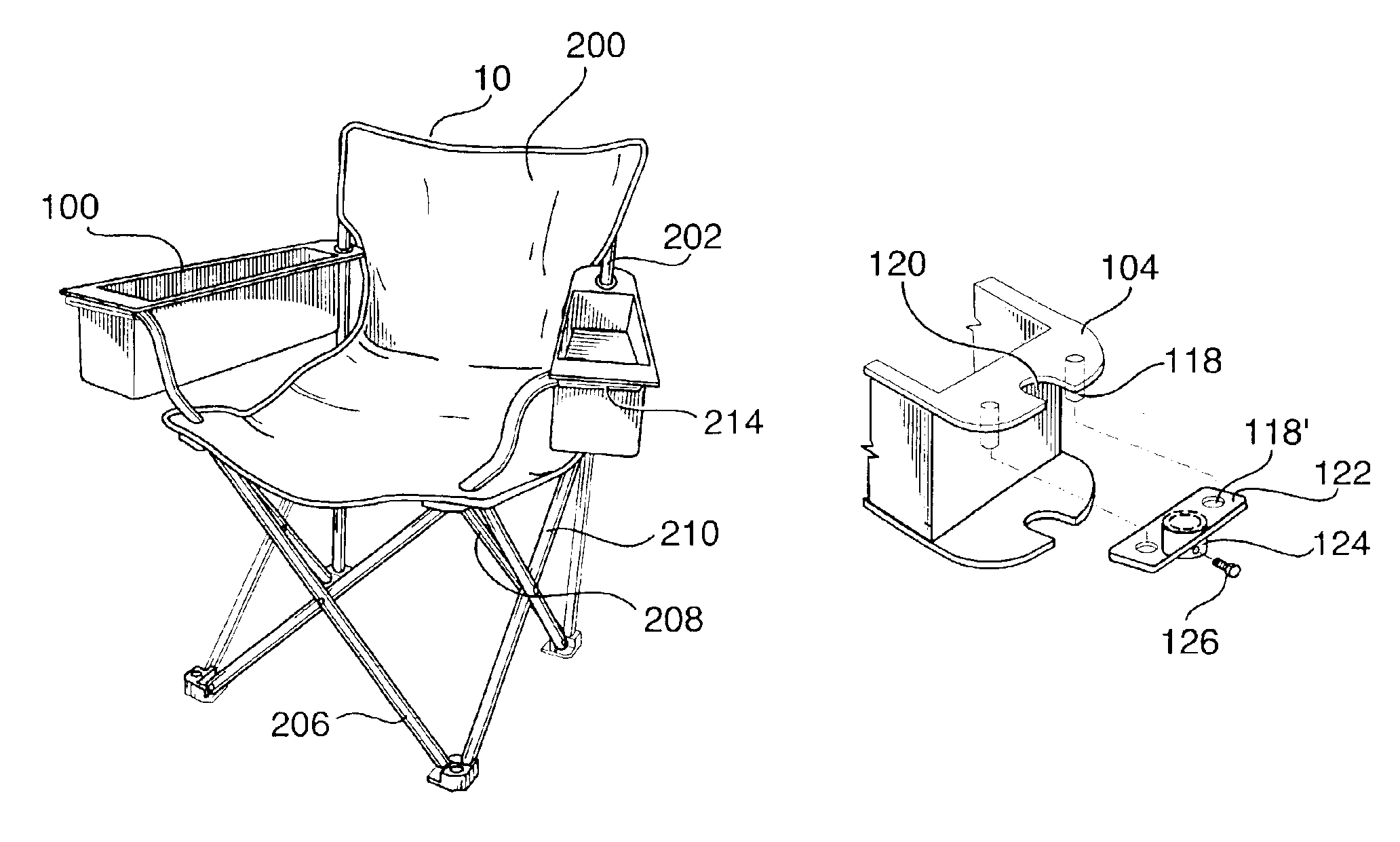

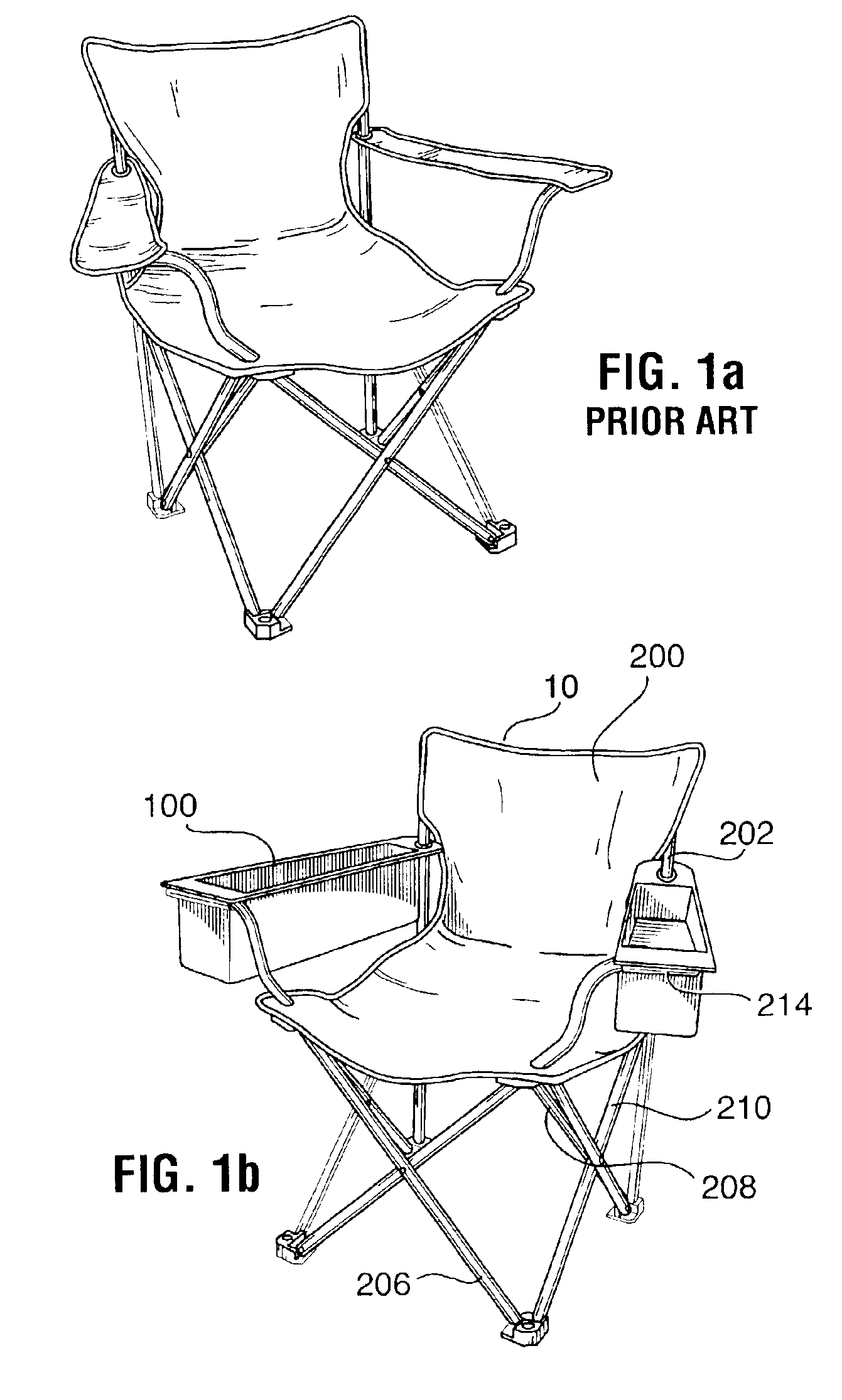

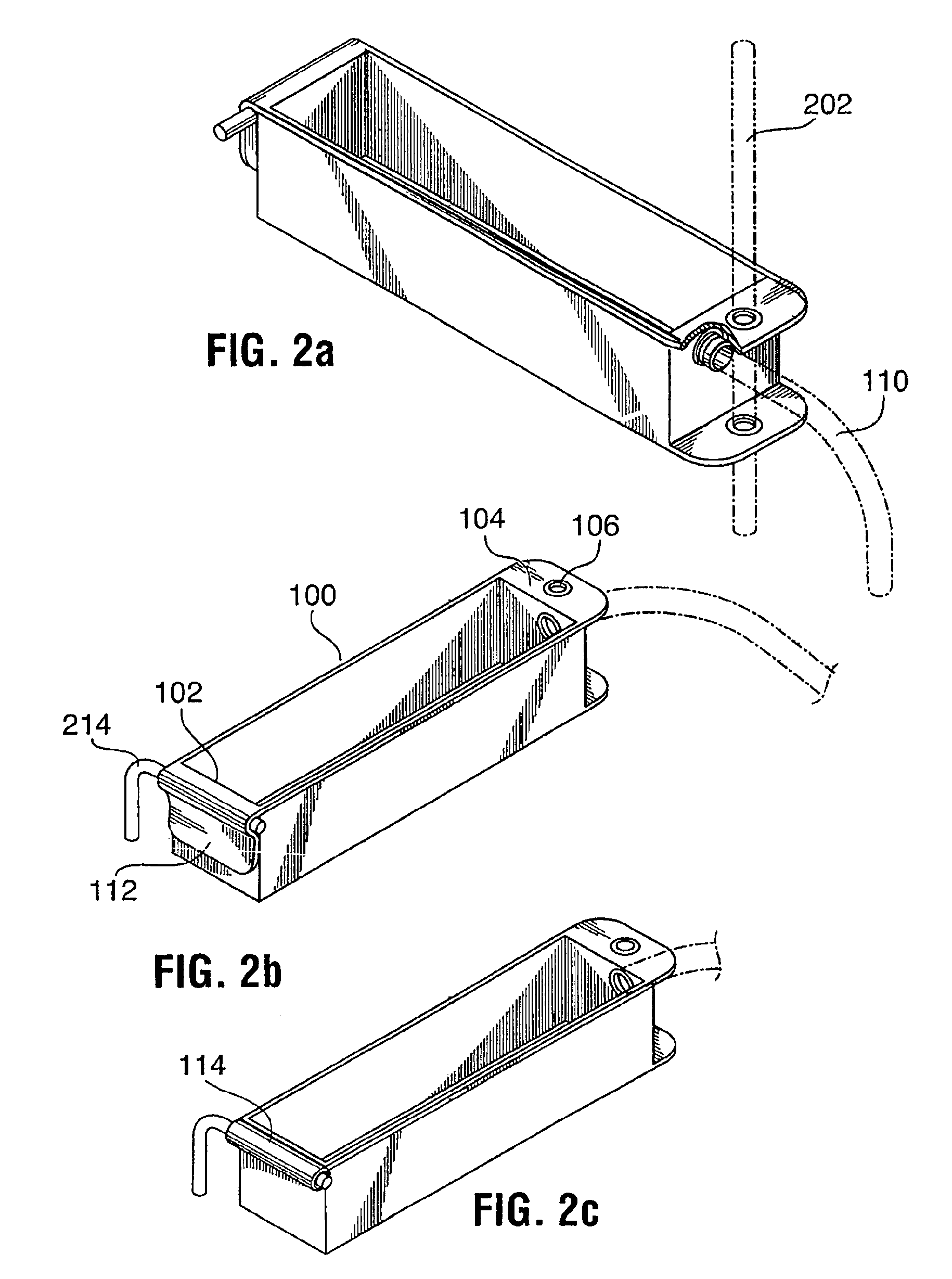

ActiveUS6942289B2Lower core temperatureVehicle seatsDismountable chairsHandrailBody core temperature

A chair with water basins for heat strain reduction purpose is disclosed. The chair is provided with built-in or attachable water basins at the armrest level for the user to immerse his forearms and hands in the basins while seating on the chair. Another embodiment of the chair provides foot basin module detachably coupled to the chair with or without the hand basins, thereby enabling the user to immerse his feet in the water to enjoy the cooling effect. In the event where the user is standing up, the invention also teaches a hand and / or foot pool system so that an individual user or multiple users can immerse their extremities in water to cool off the body core temperature while standing up.

Owner:MCBRIDE PETER

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

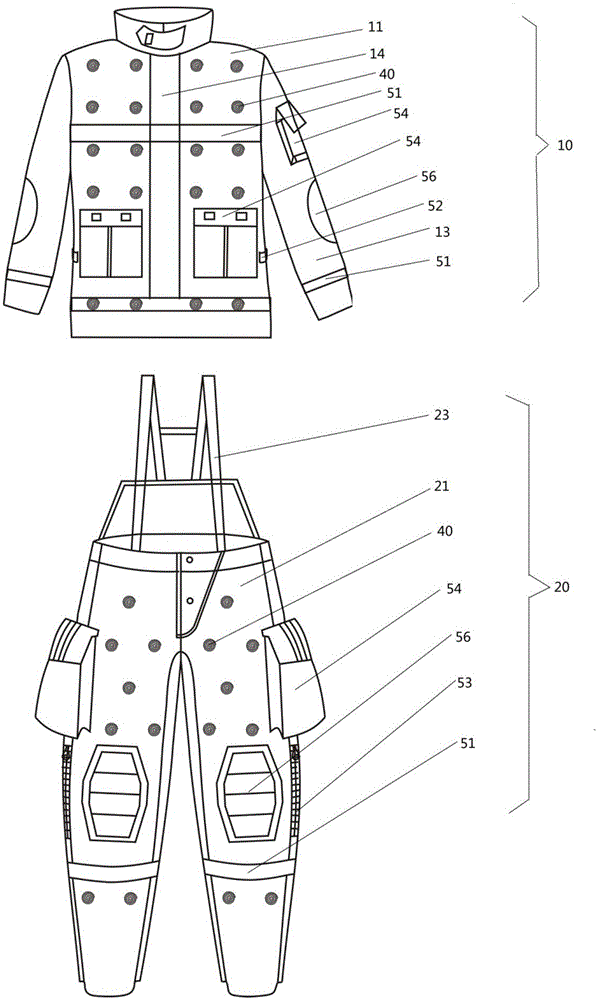

Firefighter uniform with intelligent heat and humidity transmission adjusting function

InactiveCN105457179AImprove cooling effectImprove practicalityChemical protectionHeat protectionEngineeringDriven element

The invention relates to a firefighter uniform with the intelligent heat and humidity transmission adjusting function. The firefighter uniform comprises a top and / or trousers. An outer layer, a waterproof breathable layer and a comfortable layer are sequentially arranged in the top and / or the trousers from outside to inside. Multiple temperature-sensing drive elements are arranged between the outer layer and the waterproof breathable layer and between the waterproof breathable layer and the comfortable layer. The temperature-sensing drive elements are shape memory springs. According to the firefighter uniform with the intelligent heat and humidity transmission adjusting function, shape memory spring arrays are arranged, and the thickness of the firefighter uniform can be adjusted automatically, so that the heat and humidity transmission adjusting performance is adjusted, wear comfort is achieved, and motion of limbs is not affected.

Owner:SUZHOU UNIV

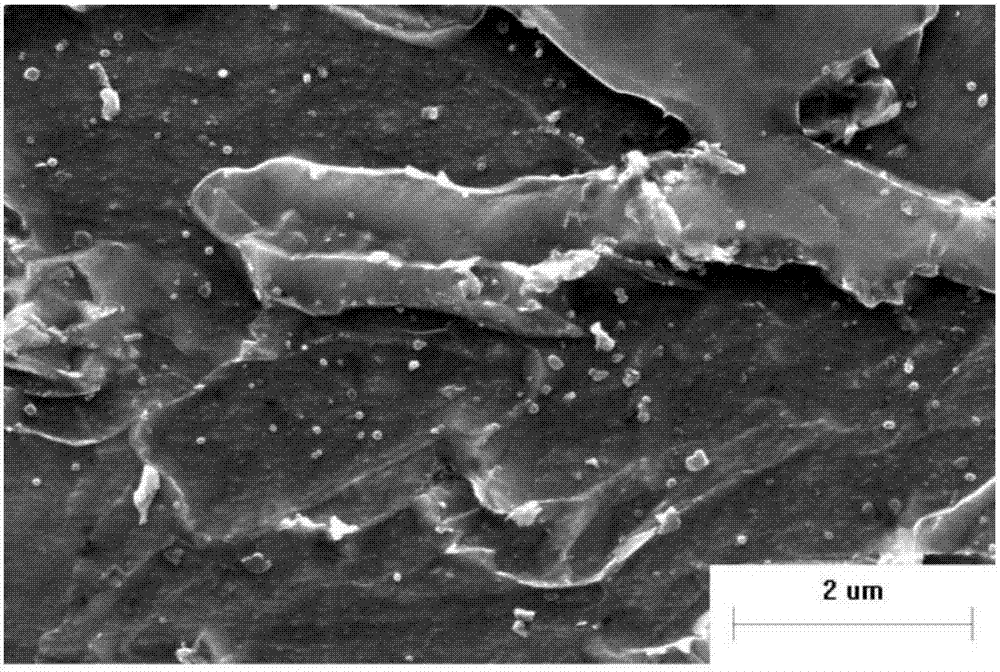

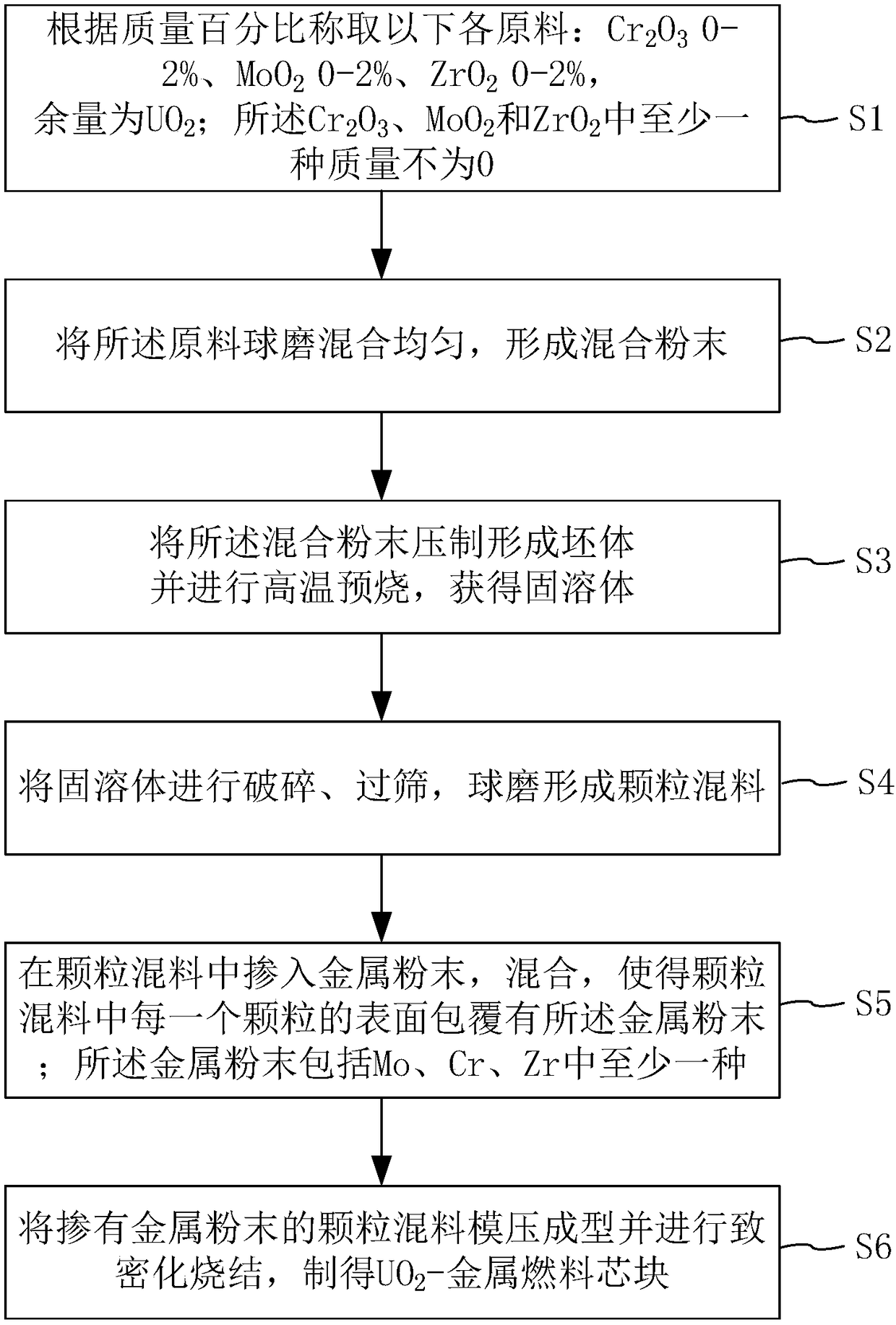

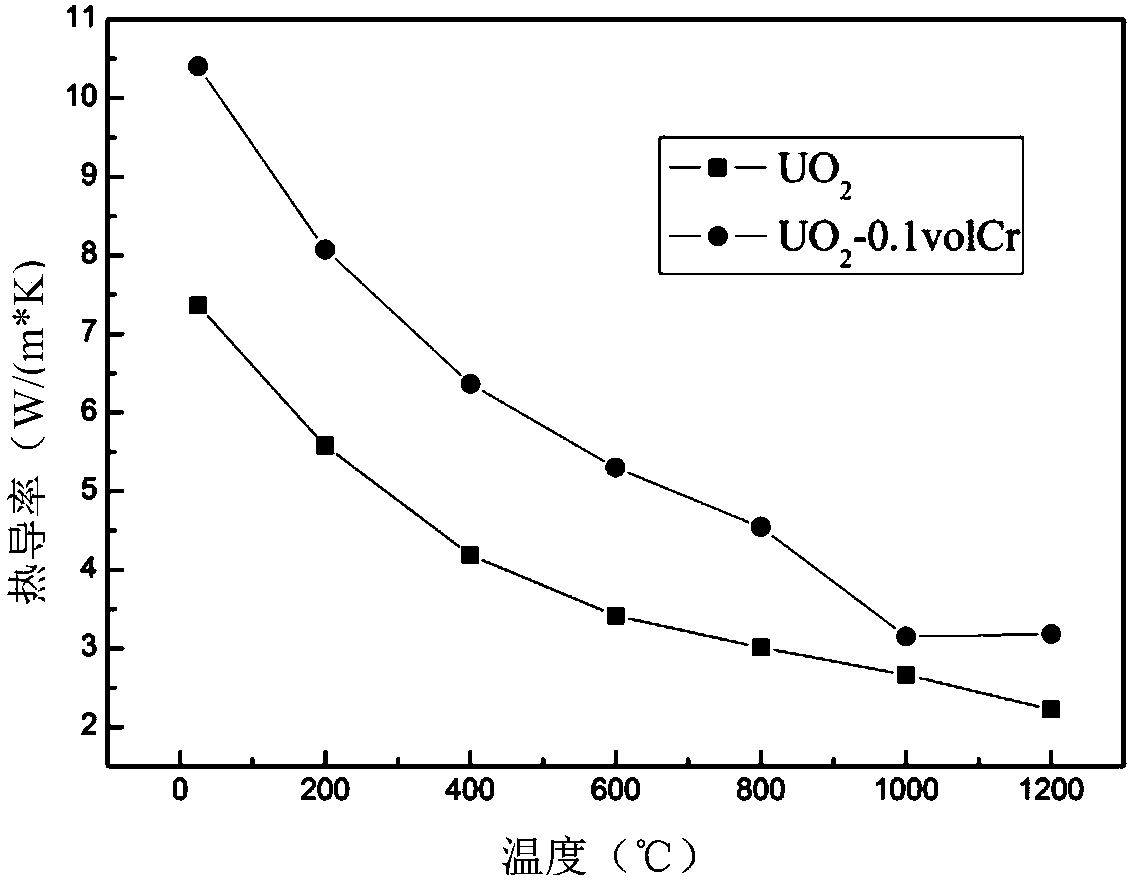

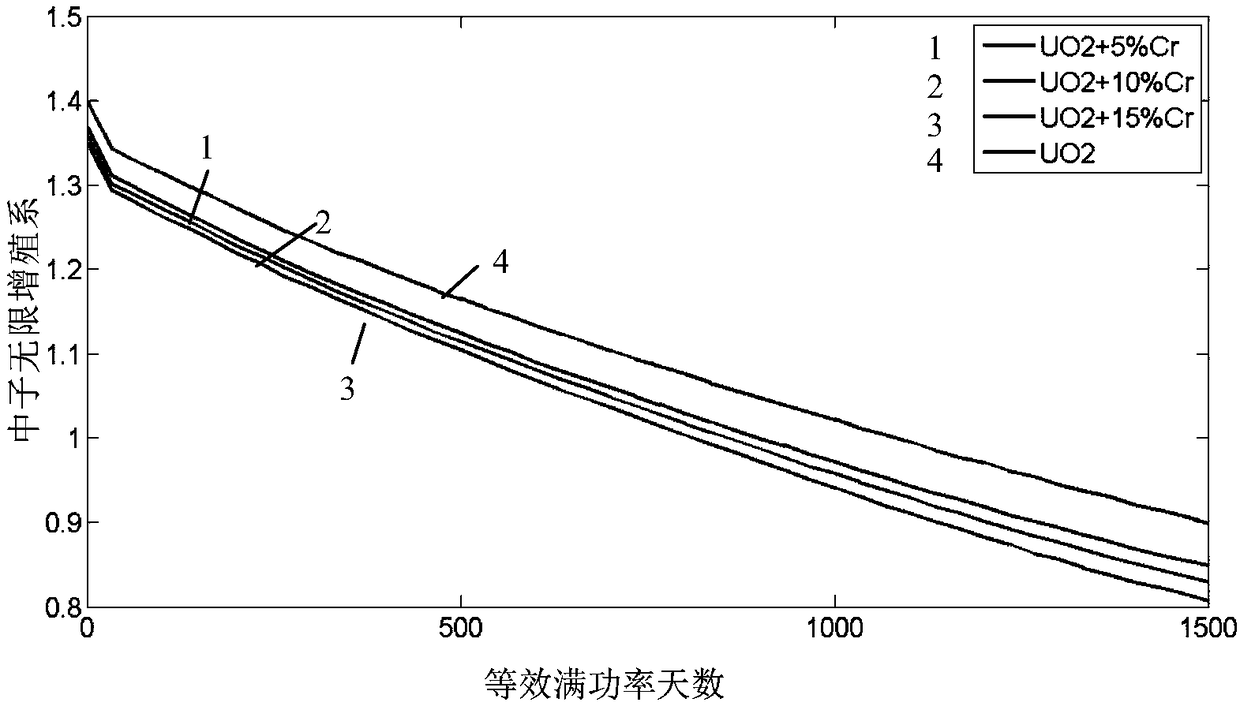

UO2-metal fuel pellet and production method thereof

InactiveCN108565032AImprove thermal conductivityRefine the grain sizeNuclear energy generationReactors manufactureCompression moldingPrill

The invention discloses a UO2-metal fuel pellet and a production method thereof. The production method comprises the following steps: S1, weighing the following raw materials in mass percent: 0-2% ofCr2O3, 0-2% of MoO2, 0-2% of ZrO2 and the balance of UO2; S2, ball-milling and uniformly mixing the raw materials to form mixed powder; S3, pressing the mixed powder to form a billet, and performing high-temperature pre-sintering to obtain a solid solution; S4, crushing the solid solution, and performing sieving and ball milling to form granular mixture; S5, doping metal powder into the granular mixture, and performing mixing to ensure that the surface of each granule in the granular mixture is coated with the metal powder; and S6, performing compression molding on the granular mixture doped with the metal powder, and performing densification sintering to obtain the UO2-metal fuel pellet. The UO2-metal fuel pellet disclosed by the invention has the advantages that the thermal conductivityof the pellet is increased by 50% or above due to addition of the metal, the grain size of the pellet is increased, the core temperature of the pellet fuel in service is obviously reduced, the temperature gradient is reduced, the release of fission products of the pellet fuel is inhibited, and the performance of a fuel rod is enhanced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

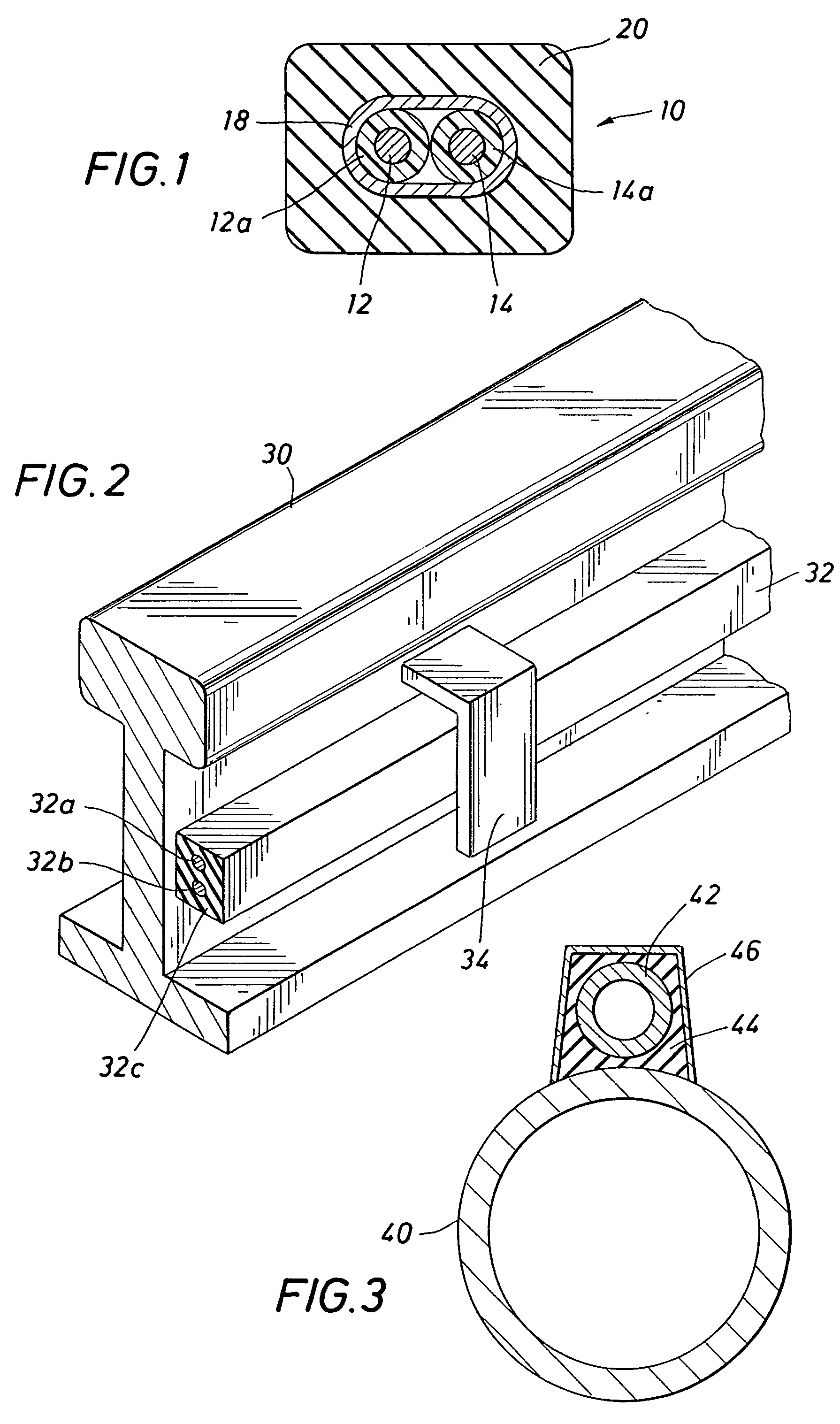

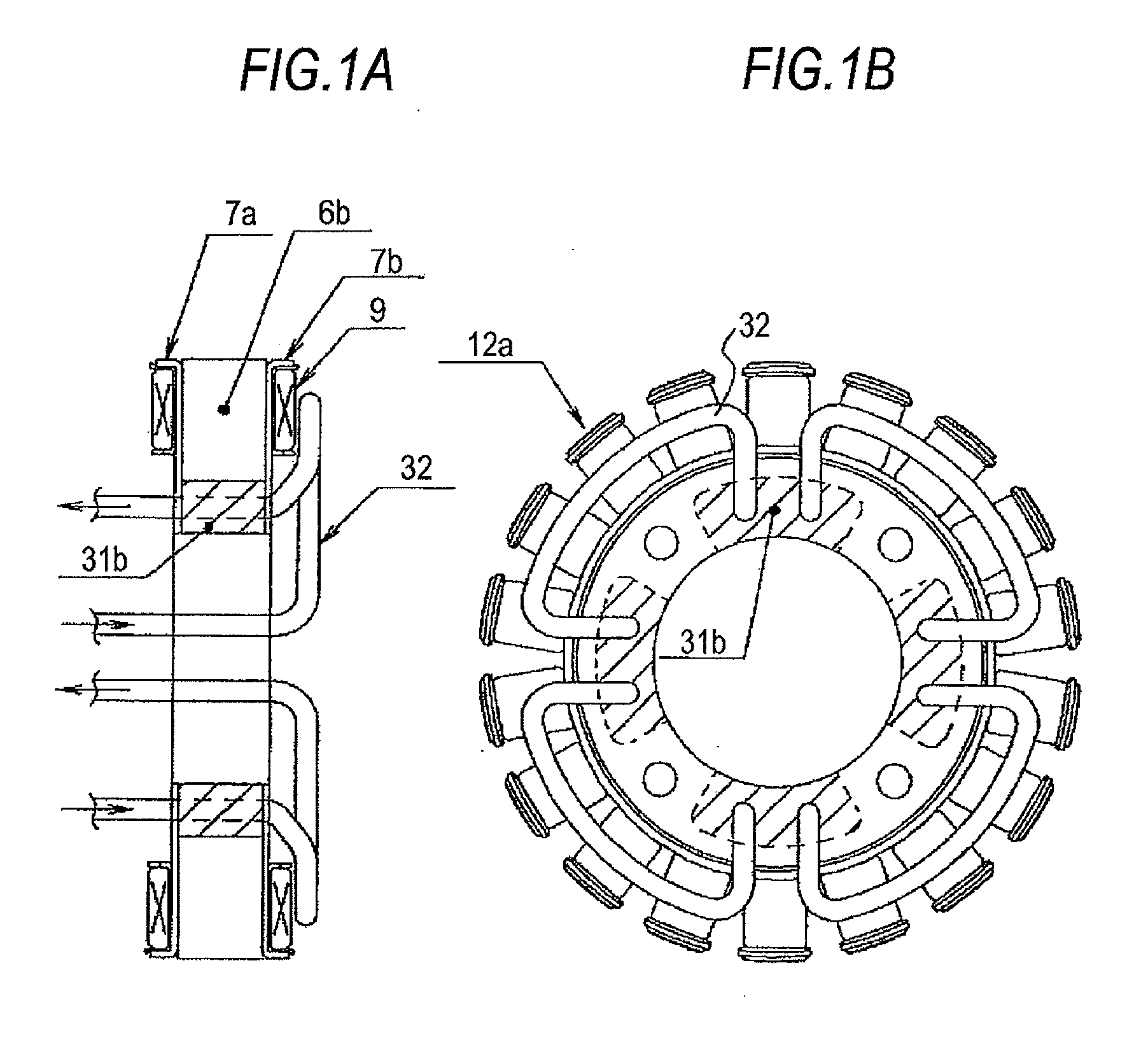

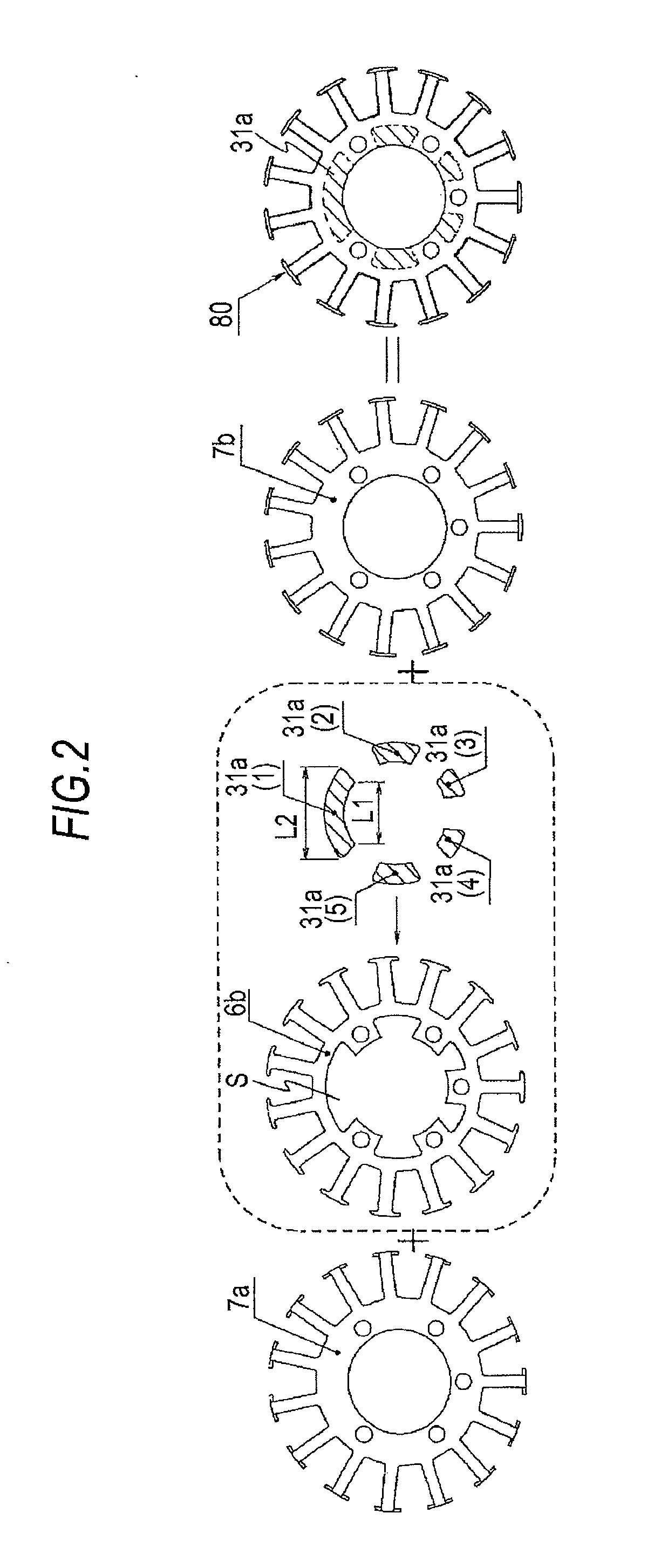

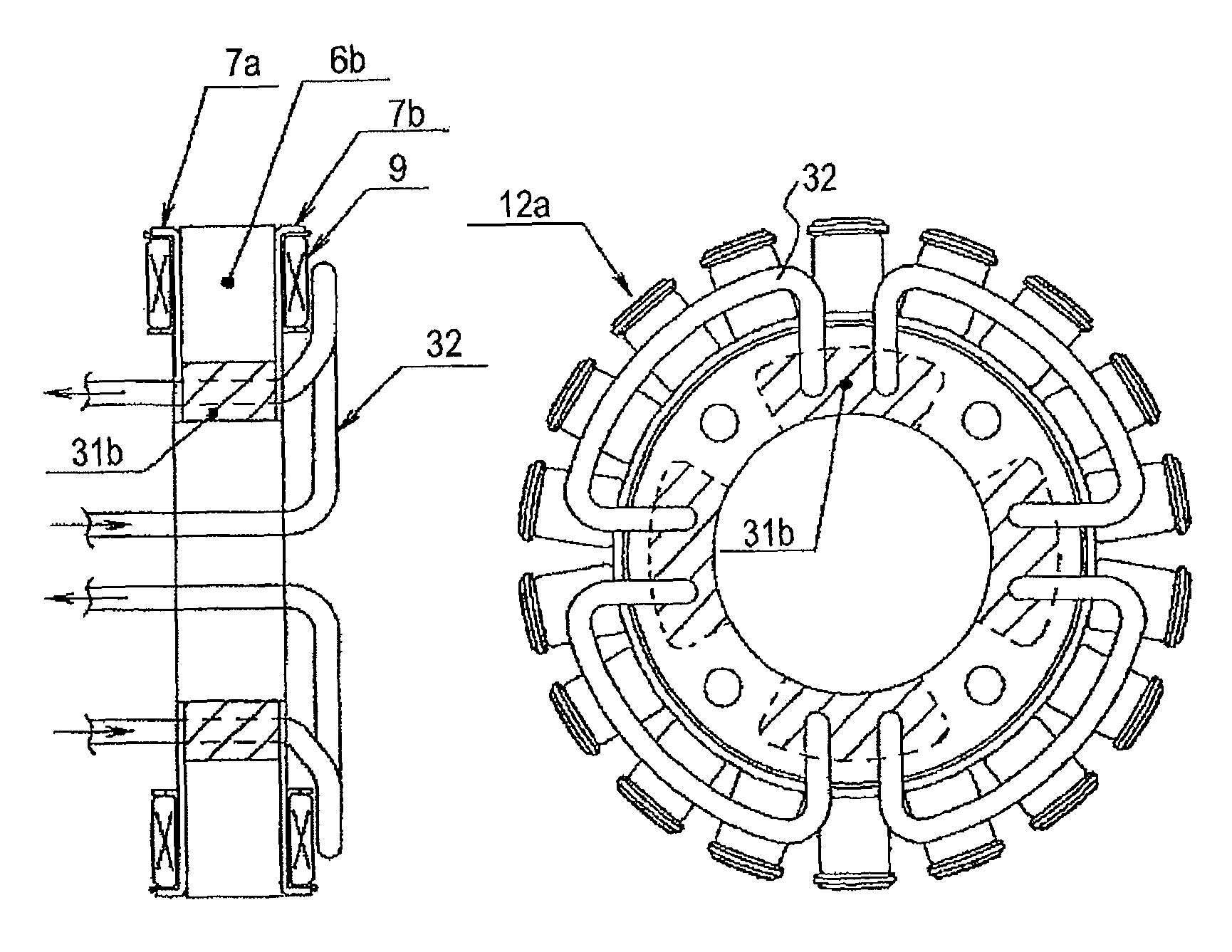

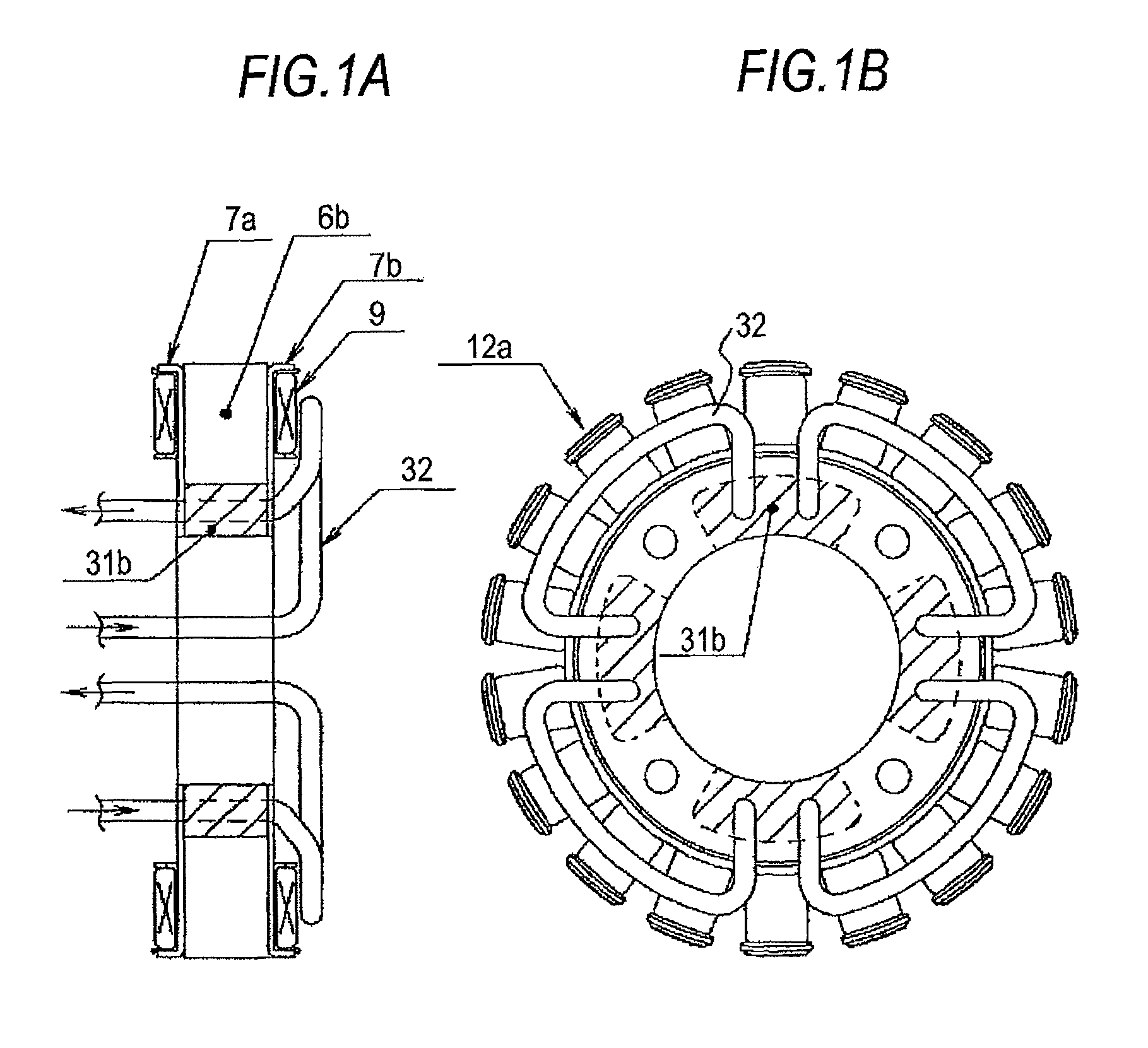

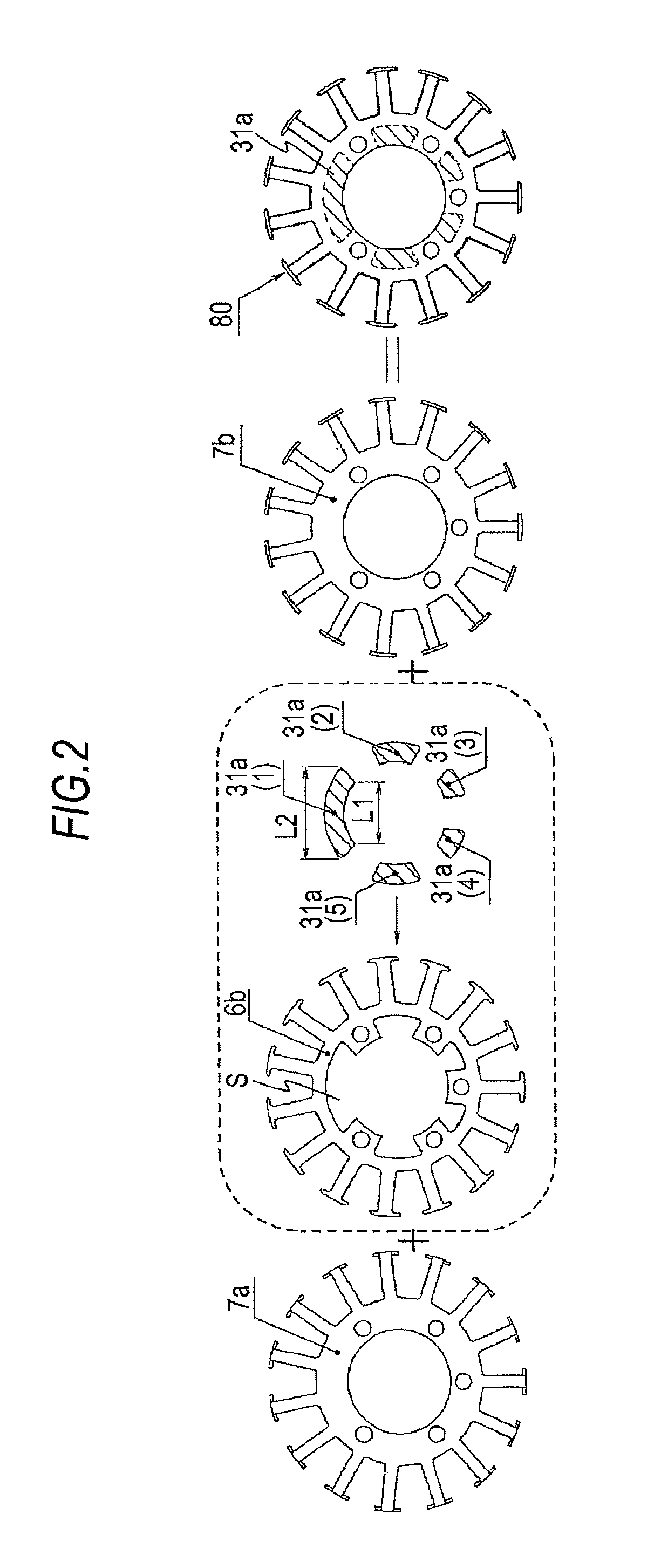

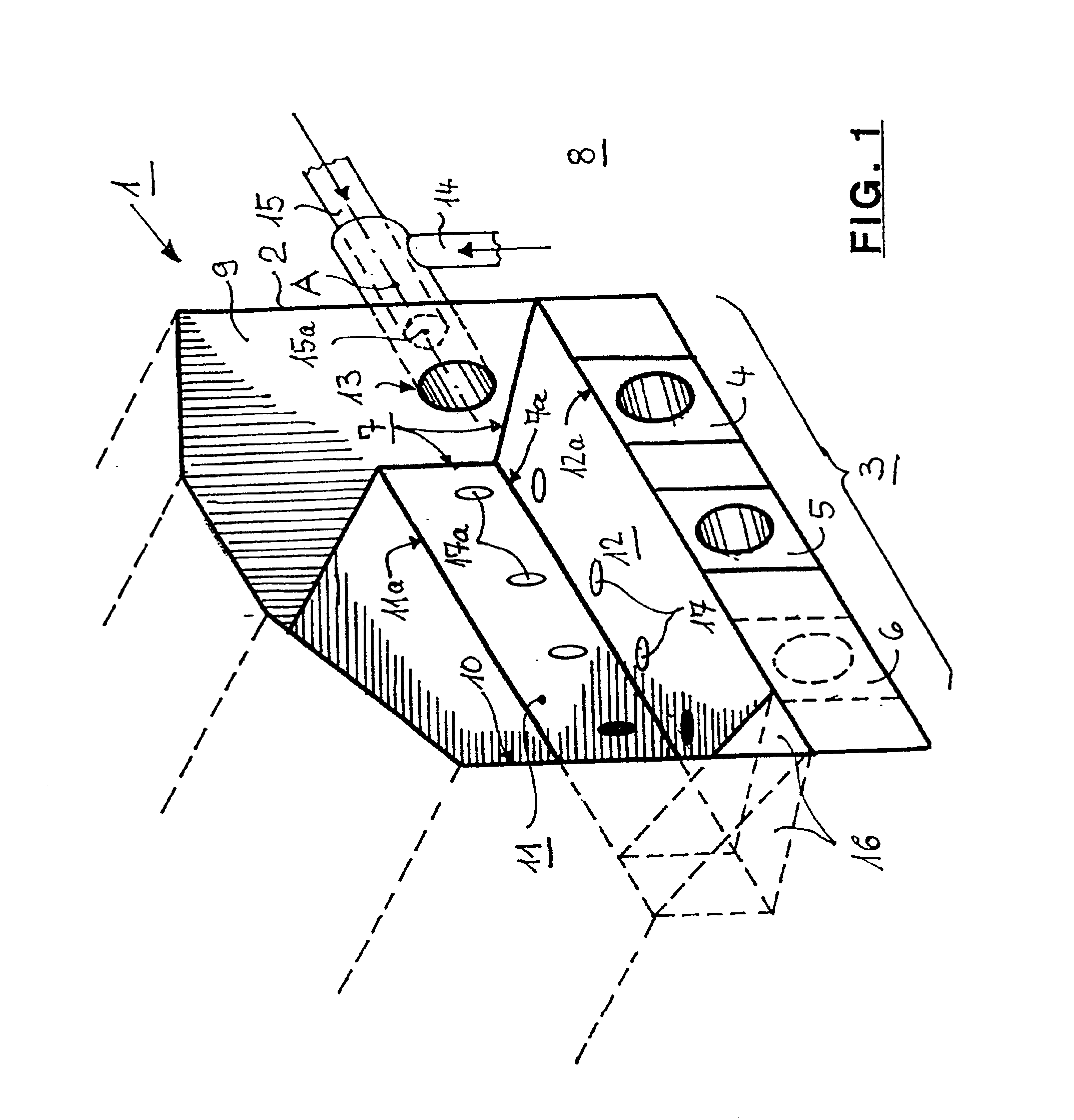

Magnet generator

ActiveUS20110241459A1Avoid temperature riseStay productiveMagnetic circuit rotating partsSynchronous machinesCooling mediumStator

In a flywheel-type magnet generator, a heat dissipation member which has no relation with a magnetic circuit is fitted into a space formed by cutting a bulk of a laminating core used for configuring the magnetic circuit, a cooling tube installed to be inserted into or penetrate the heat dissipation member is provided, and by supplying a cooling medium to the cooling tube, cooling performance of the stator is enhanced.

Owner:MITSUBISHI ELECTRIC CORP

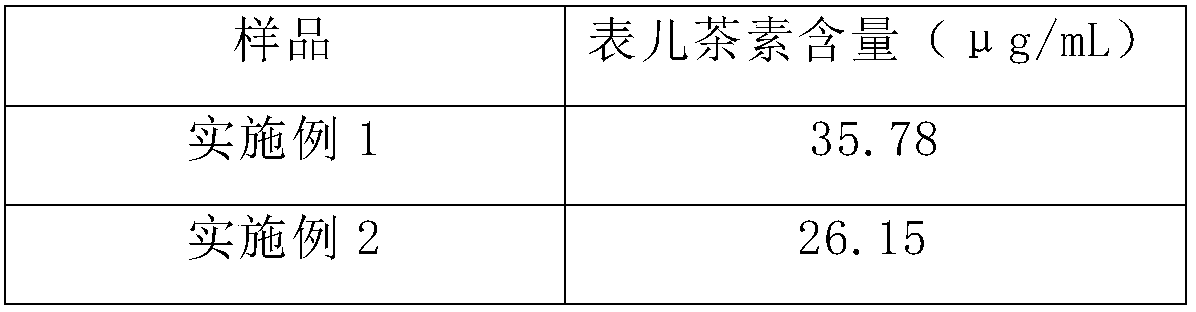

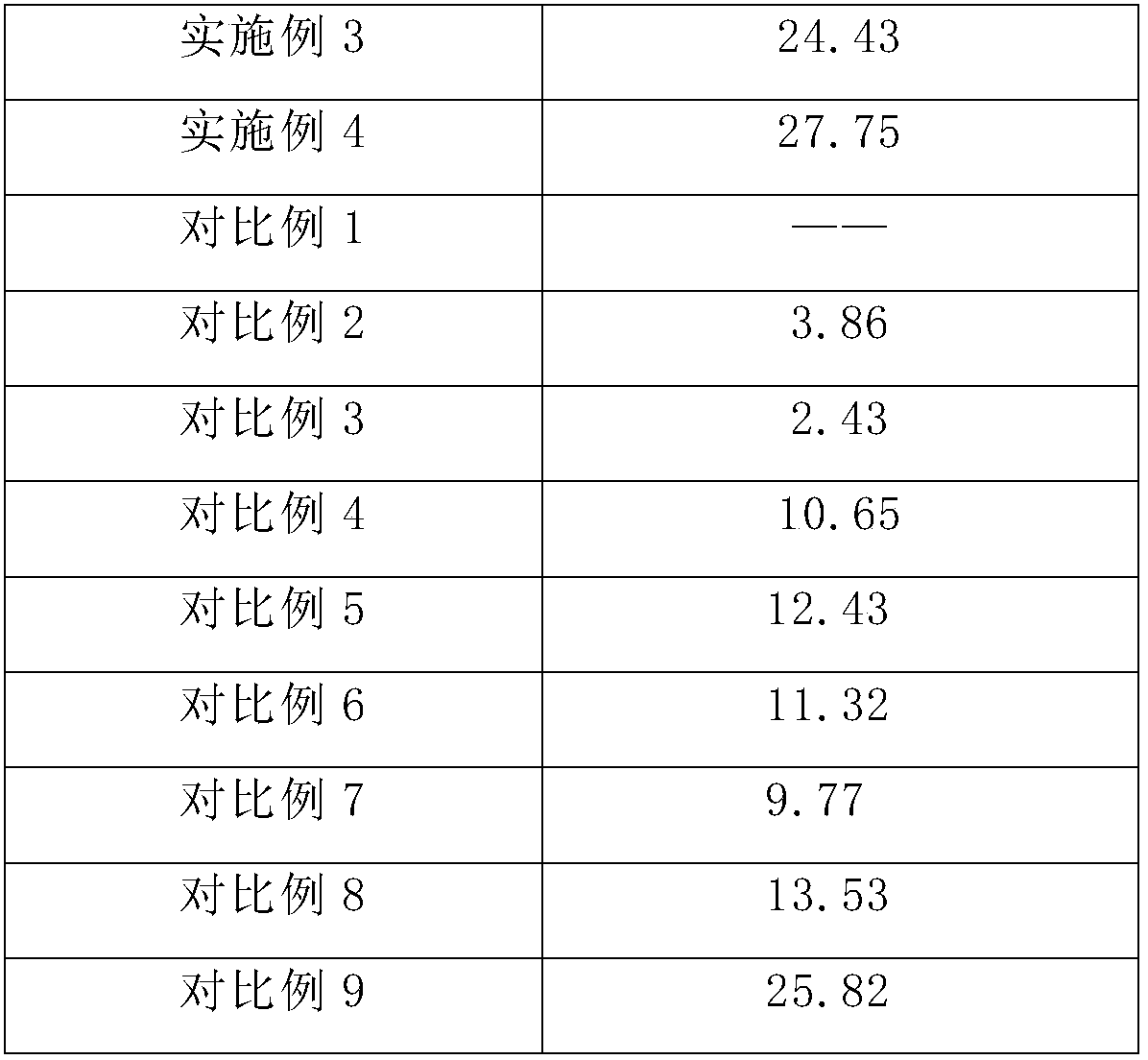

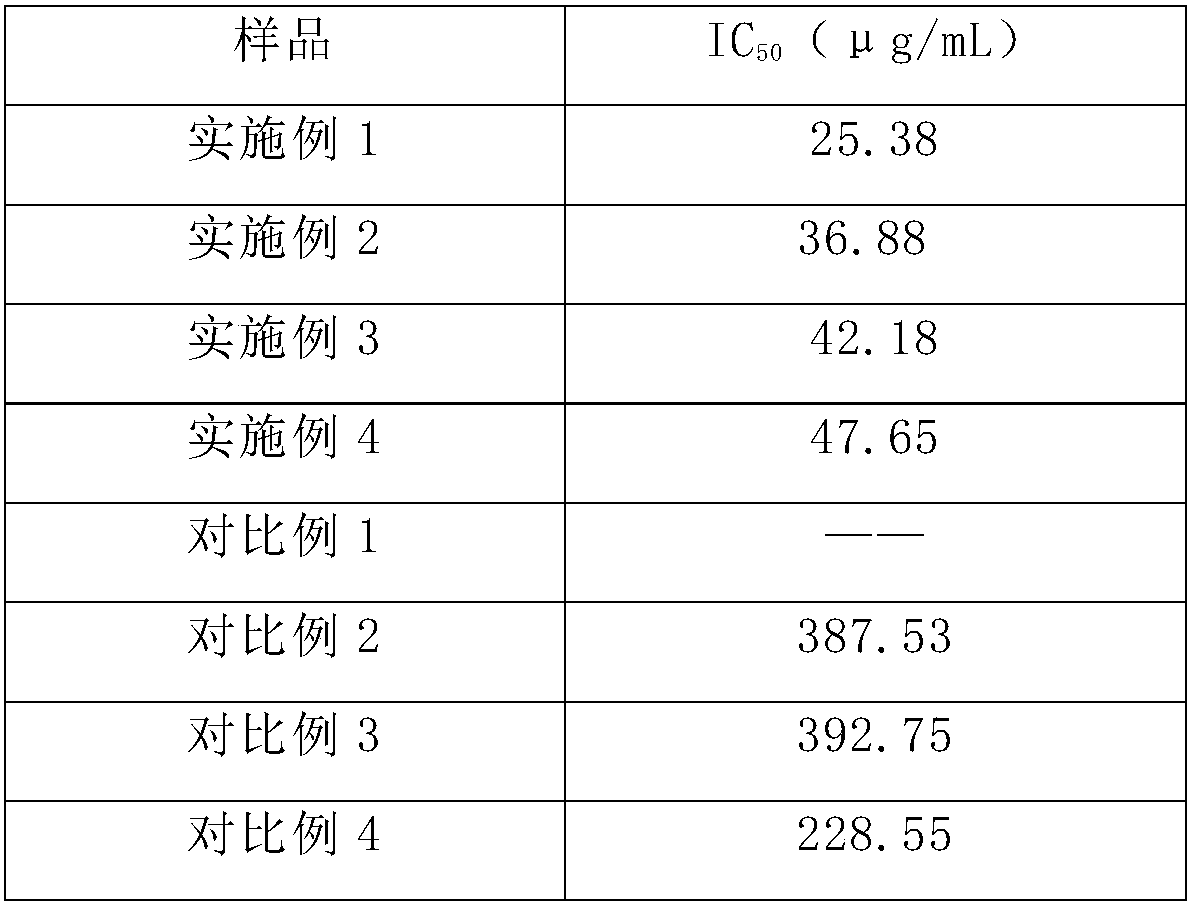

Preparation method and application of camellia flower extracting solution

ActiveCN109044913ARetain colorRetain activityCosmetic preparationsToilet preparationsDiseaseOrganic solvent

The invention provides a preparation method and an application of a camellia flower extracting solution. The method comprises steps as follows: A, selecting fresh camellia flowers without damage and diseases, and drying the camellia flowers with a refraction window drying technology to obtain a dried camellia flower product; B, performing airflow superfine crushing and sieving on the dried camellia flower product, and adding a quaternary system deep-eutectic solvent for ultrasonic extraction to obtain an extracted mixture; C, mixing the extracted mixture and deionized water, regulating pH, andadding enzyme for enzymolysis; D, leaving a product to stand for a certain time after enzymolysis, and filtering the product to obtain the camellia flower extracting solution. According to the method, drying is performed with the refraction window drying technology, superfine crushing is performed, the non-toxic deep-eutectic solvent is taken as an extracting agent, and the production process issimple, efficient, safe and green; the defects that a large quantity of toxic organic solvents and complicated column separation processes are required for production of conventional epicatechin are overcome. The obtained extracting solution has the skin repairing efficacy, the bacteriostasis function and high antioxidation capability and is safe and non-irritant.

Owner:SHANGHAI FOREST CABIN BIOLOGICAL TECH +1

Thermally-conductive, electrically non-conductive heat transfer material and articles made thereof

InactiveUS20050067403A1Reducing core temperatureIncrease power outputDiffusion transfer processesHeater elementsPliabilitySilicon nitride

A heat transfer material comprised of a polymeric material and a nitride or oxide is provided and is thermally conductive, but electrically non-conductive. The polymeric material may be silicone rubber, and the nitride or oxide may be aluminum nitride, boron nitride, silicon nitride, aluminum oxide or beryllium oxide. The material is made flexible by adding plasticizer and remains flexible after an extended period of use. A dielectric jacket for an electrical heating cable is thermally conductive and remains flexible so that it can be reused. The heat transfer material can be used on heating devices such as steam tubes and panels, where the heat transfer material does not bond to or adhere to the heated surface, which allows the heating device to be reused.

Owner:THERMON INC

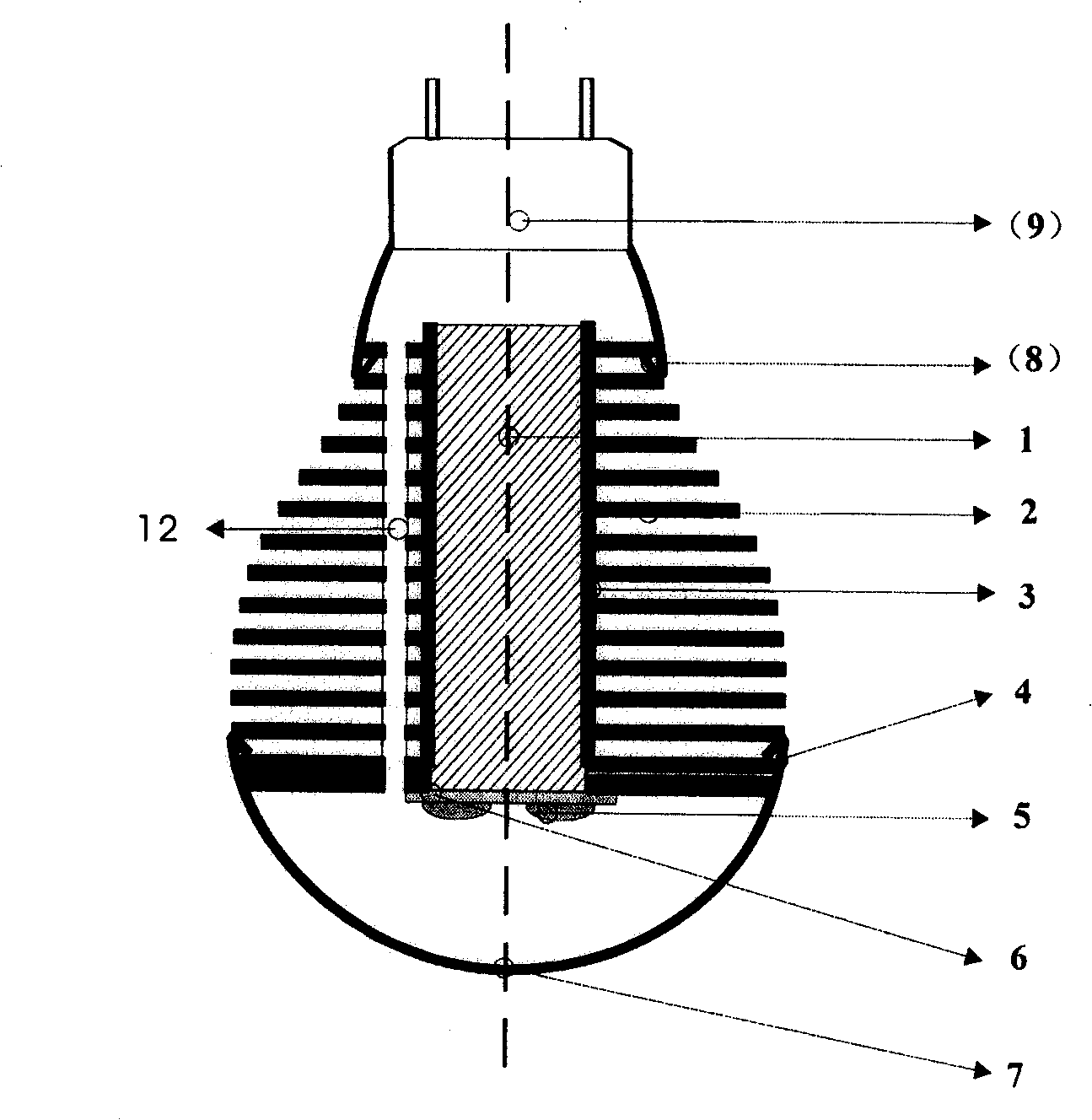

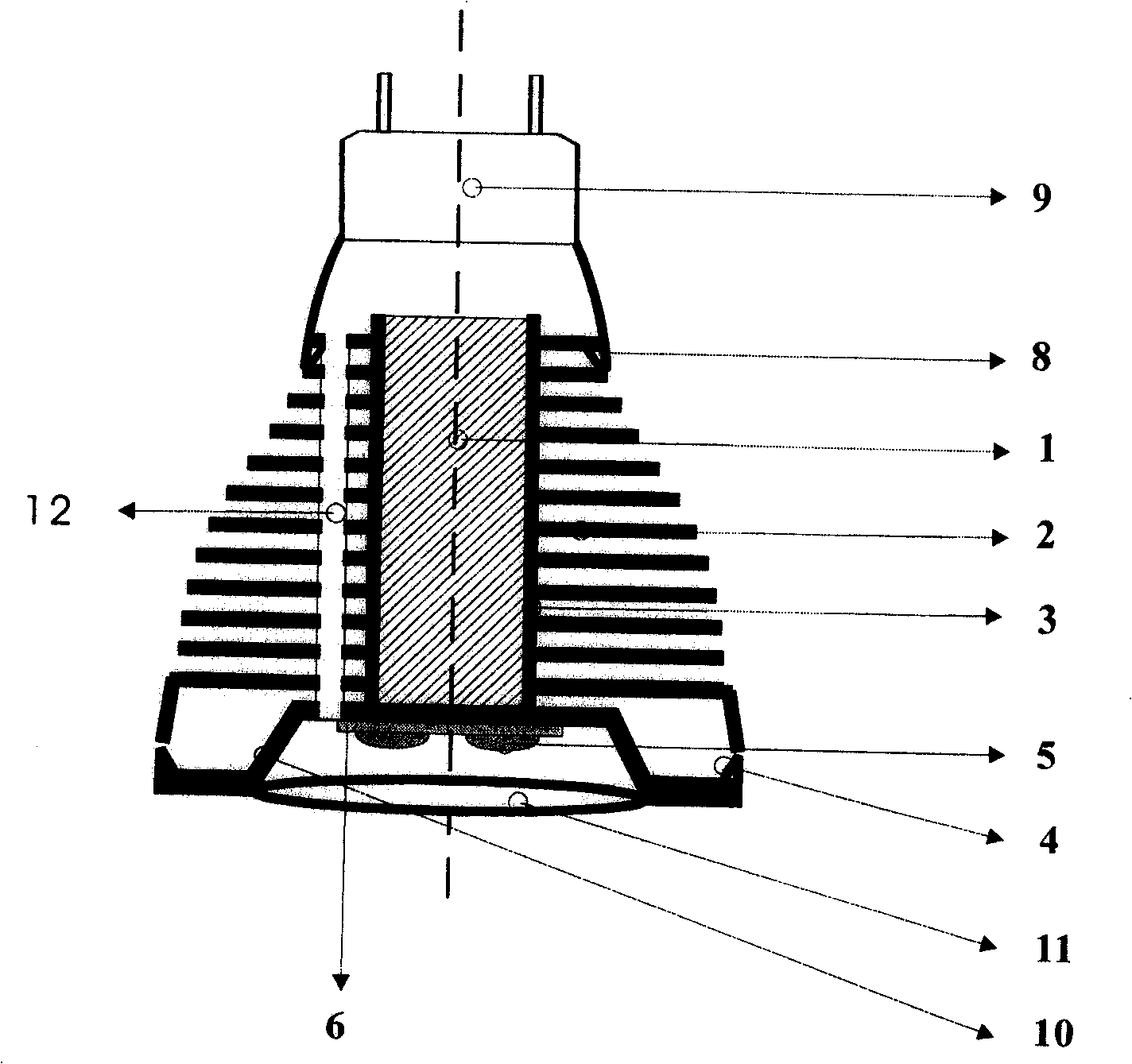

Semiconductor LED lamp housing

InactiveCN101338886AExtend your lifeImprove work efficiencyPoint-like light sourceLighting heating/cooling arrangementsLateral angleEngineering

The invention discloses a method for preparing a semiconductor luminescent LED lamp shell with heat radiating function. The invention mainly resolves the technical problems of the existing cast-aluminum lamp shells, such as insufficient heat conductivity, small radiating area, poor quality, etc. Heat pipes or metal dead-hole pipes and solid cylindrical materials are adopted for the central connection-shaft basal-body of the LED lamp shell; the central connection-shaft basal-body is pressed into the fastening holes in the transverse radiating fins by interference adaption and successive penetration; the radiating fin is made of aluminum or copper sheets by punch forming; the diameters of the radiating sheet fins transversely overlapped evenly reduce from bottom to top, and thereby, the outline of an overall LED lamp shell is formed; the lamp shell looks like a cup, an isosceles triangle or other geometric shape seen from a lateral angle. An LED lamp fabricated by the method has the advantages that the heat produced during the operation of the LED element can be absorbed quickly by the central connection-shaft basal-body of the lamp shell, and then heat radiation by exchanging air between the radiating sheet fins and the environment is realized.

Owner:胡凯

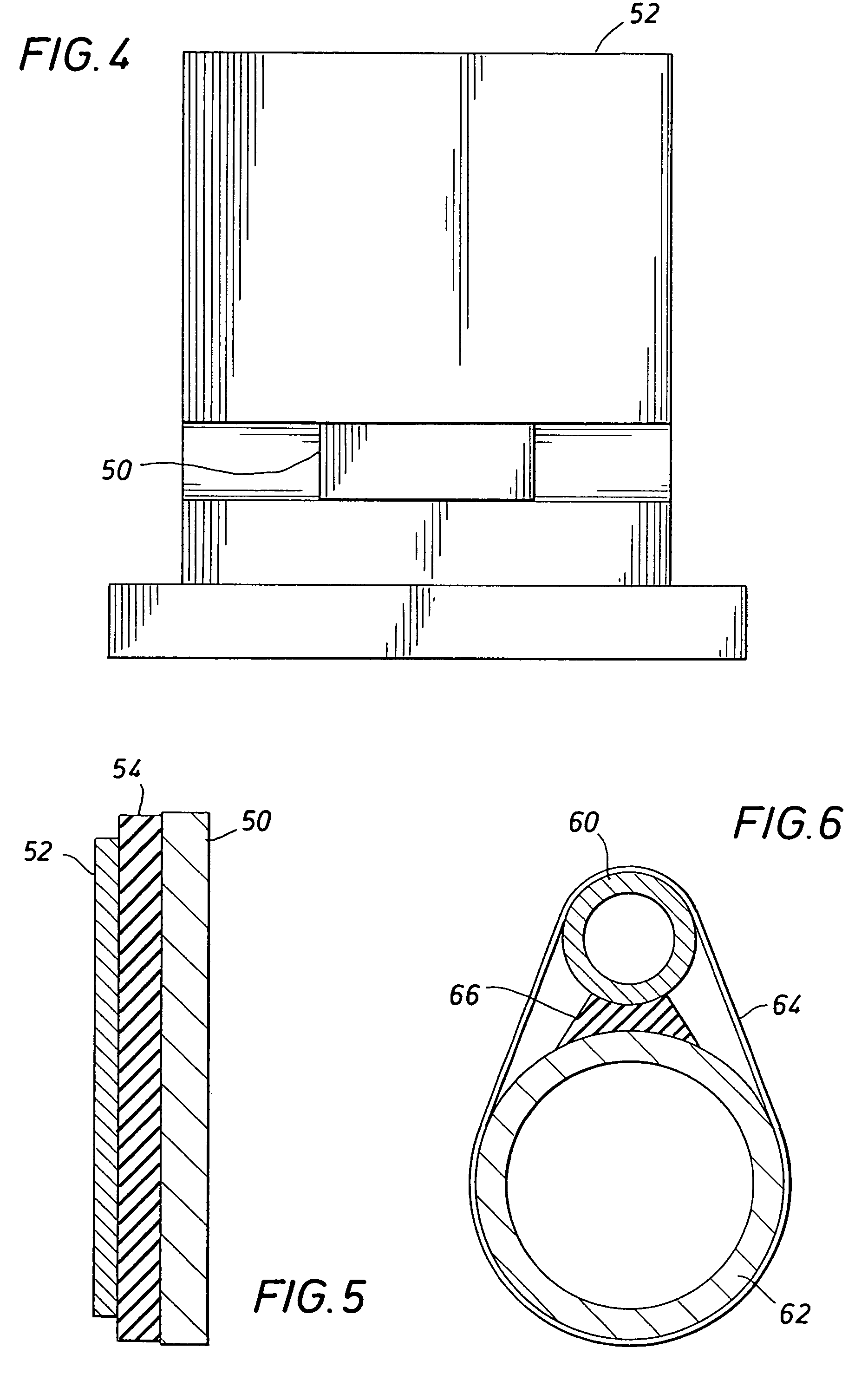

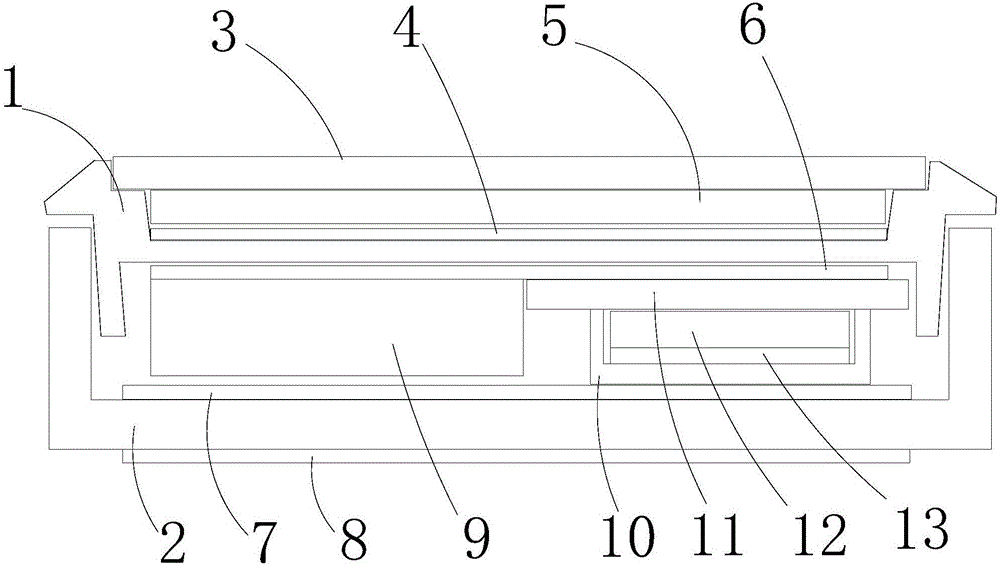

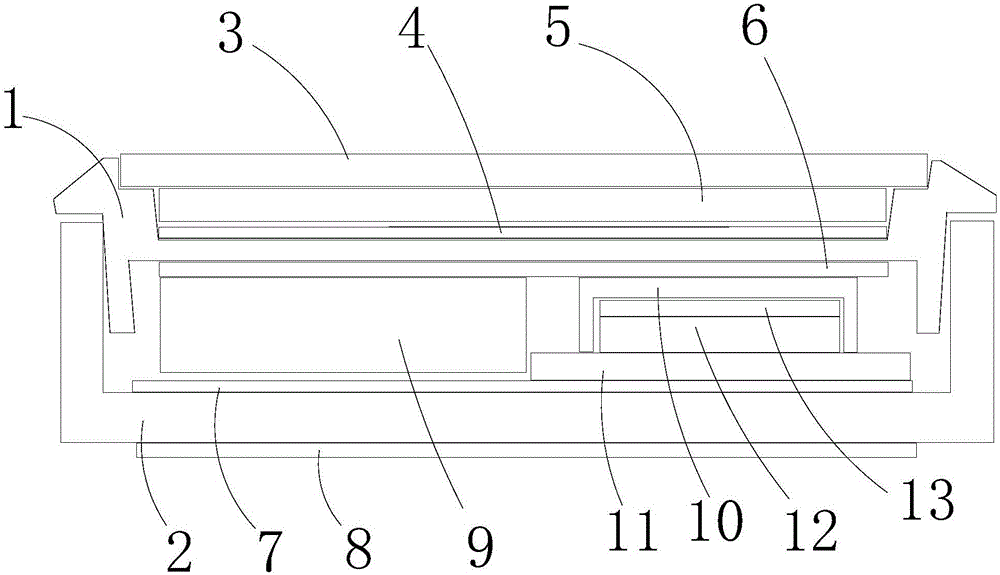

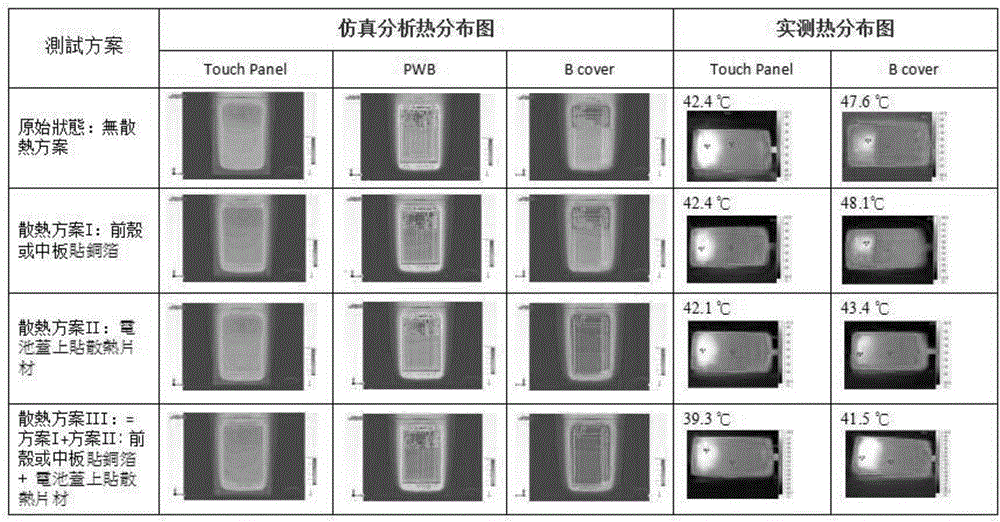

Heat uniform distribution and dissipation structure and heat uniform distribution and dissipation process for portable electronic equipment

PendingCN106793710AImprove performanceGood man-machine experienceModifications by conduction heat transferMan machineEngineering

The invention provides a heat uniform distribution and dissipation structure and a heat uniform distribution and dissipation process for portable electronic equipment. The heat uniform distribution and dissipation structure comprises a front shell and a rear shell. The rear shell is fastened at the rear of the front shell, a display screen and a touch screen are arranged at the front of the front shell, and electronic components are arranged inside a shell comprising the front shell and the rear shell. The heat uniform distribution and dissipation structure is characterized by further comprising heat uniform distribution layers and heat dissipation layers, the heat uniform distribution layers are arranged at the front of the portable electronic equipment, the heat dissipation layers are arranged at the rear of the portable electronic equipment, and a composite membrane is arranged on each electronic component. The heat uniform distribution and dissipation structure and the heat uniform distribution and dissipation process have the advantages that heat diffused by heat sources of the handheld equipment can be uniformly dispersed in integral cavities (by the heat uniform distribution layers), heat exchange can be carried out on the external (and the heat dissipation layers), accordingly, core temperatures can be definitely reduced, the problem of heating of machine bodies or breakdown can be solved, the performance of the electronic equipment can be relatively sufficiently played, and consumers can have excellent man-machine experience.

Owner:M VICTORY SPECIFIC MATERIAL

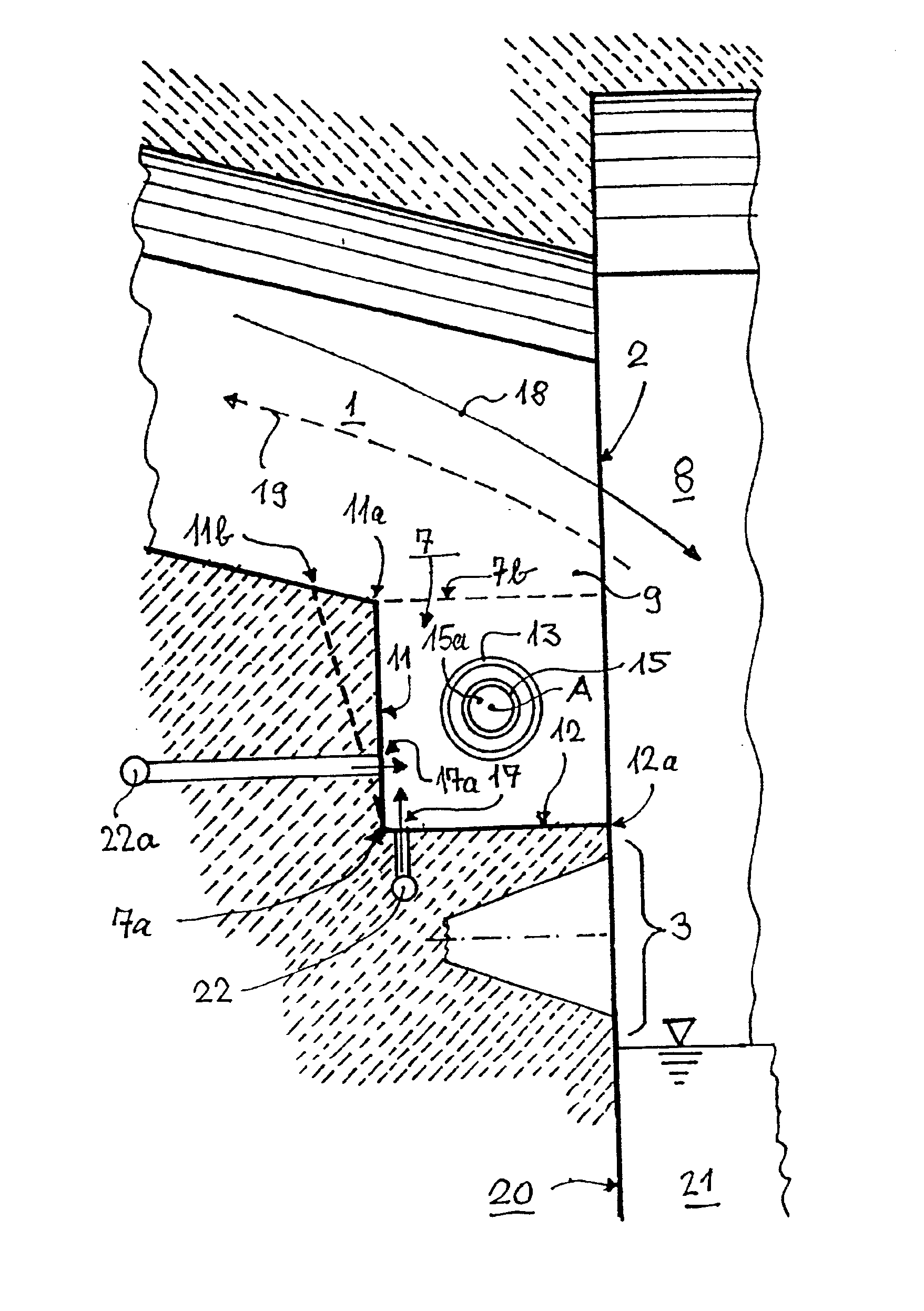

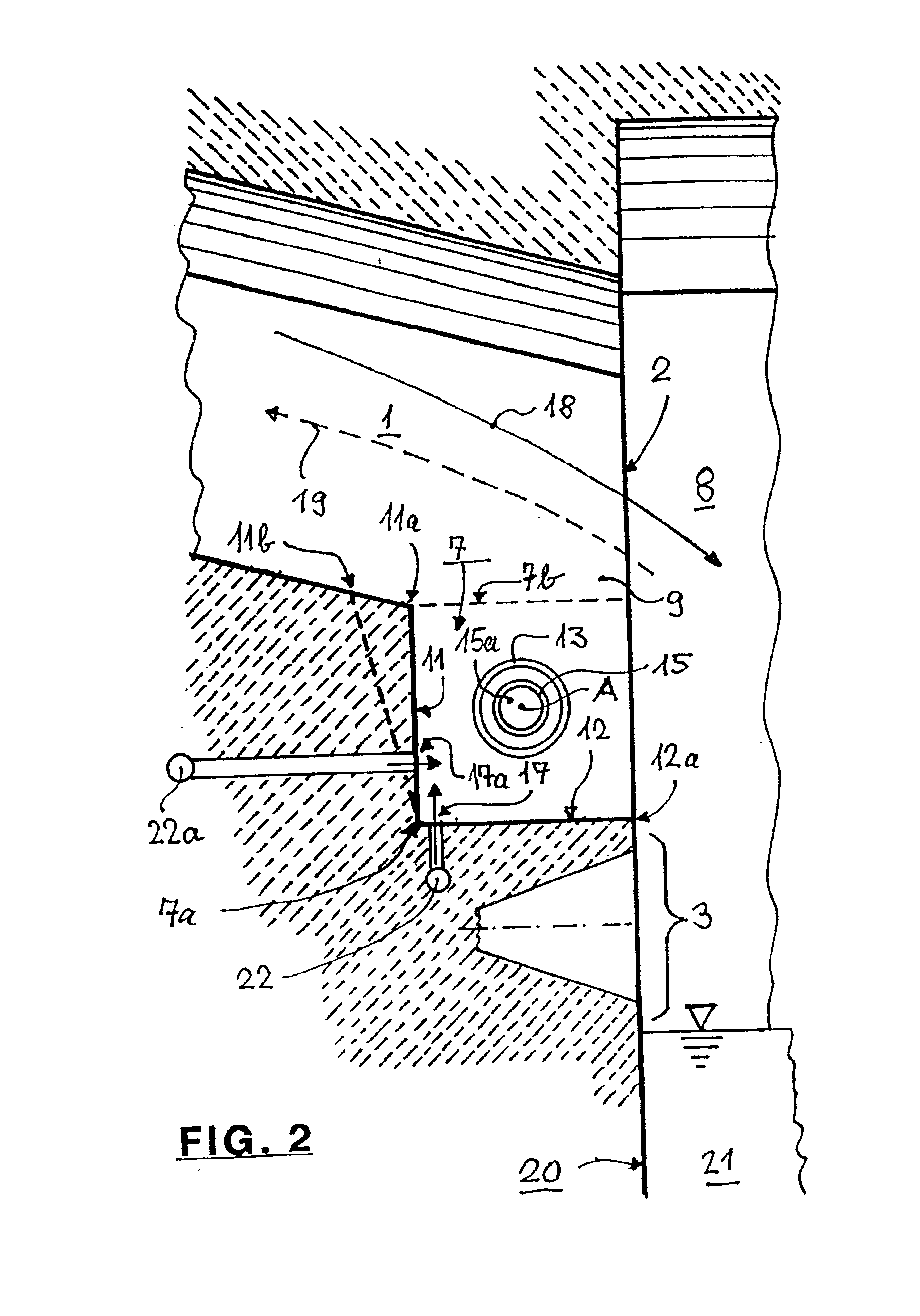

Magnet generator

ActiveUS8354763B2Avoid temperature riseIncrease heatMagnetic circuit rotating partsSynchronous machinesEngineeringCooling pipe

In a flywheel-type magnet generator, a heat dissipation member which has no relation with a magnetic circuit is fitted into a space formed by cutting a bulk of a laminated core used for configuring the magnetic circuit, a cooling tube installed to be inserted into or penetrate the heat dissipation member is provided, and by supplying a cooling medium to the cooling tube, cooling performance of the stator is enhanced.

Owner:MITSUBISHI ELECTRIC CORP

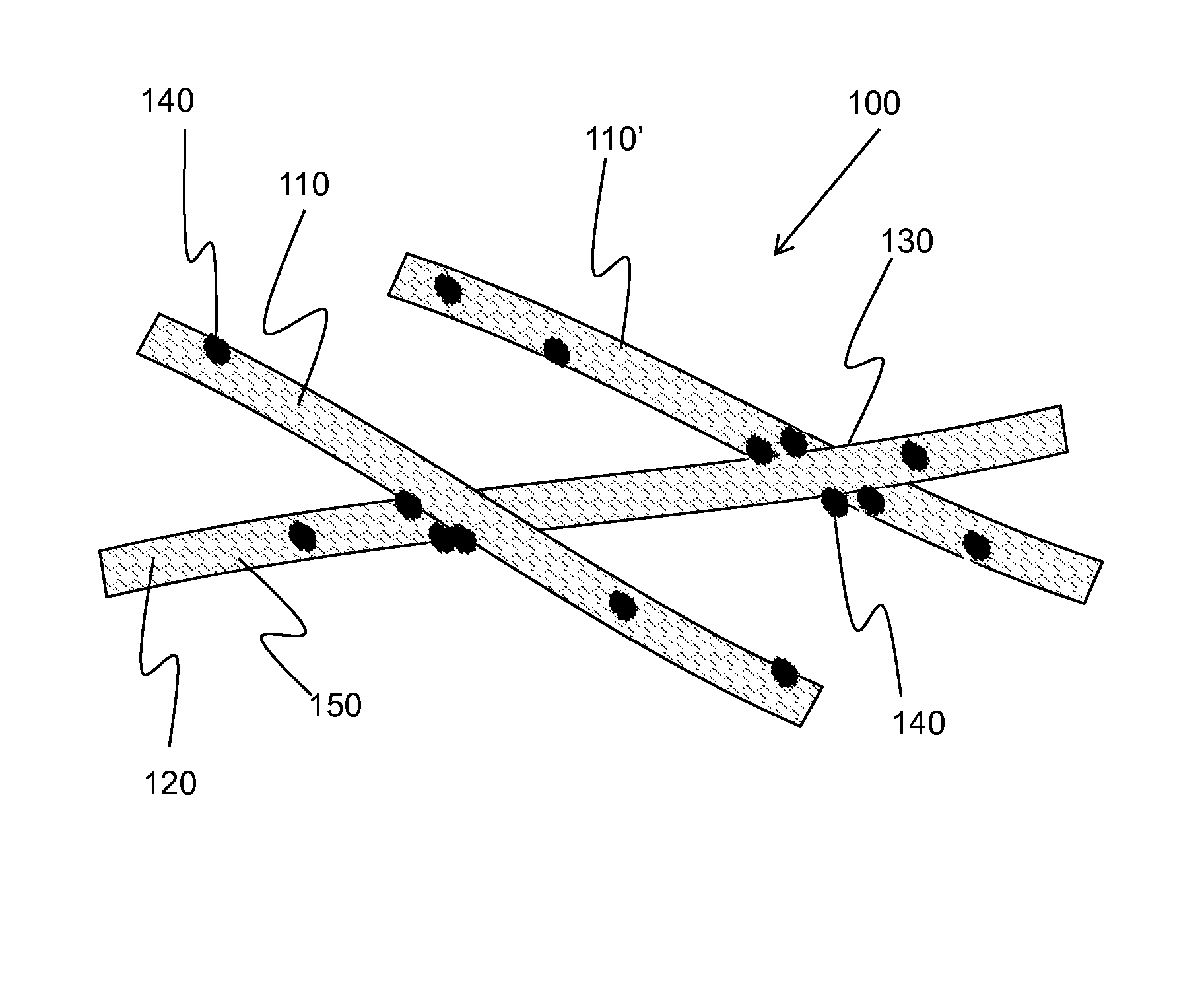

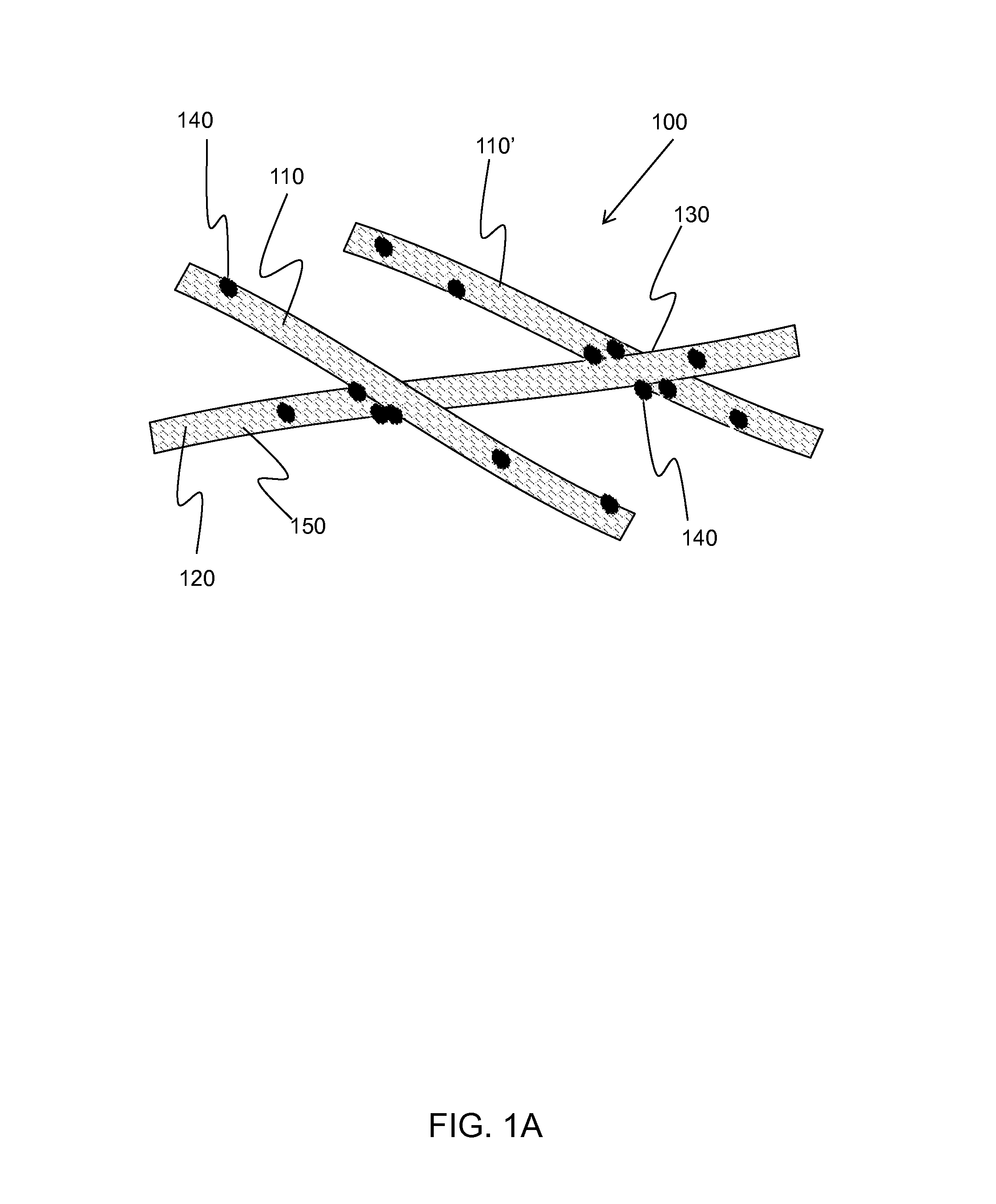

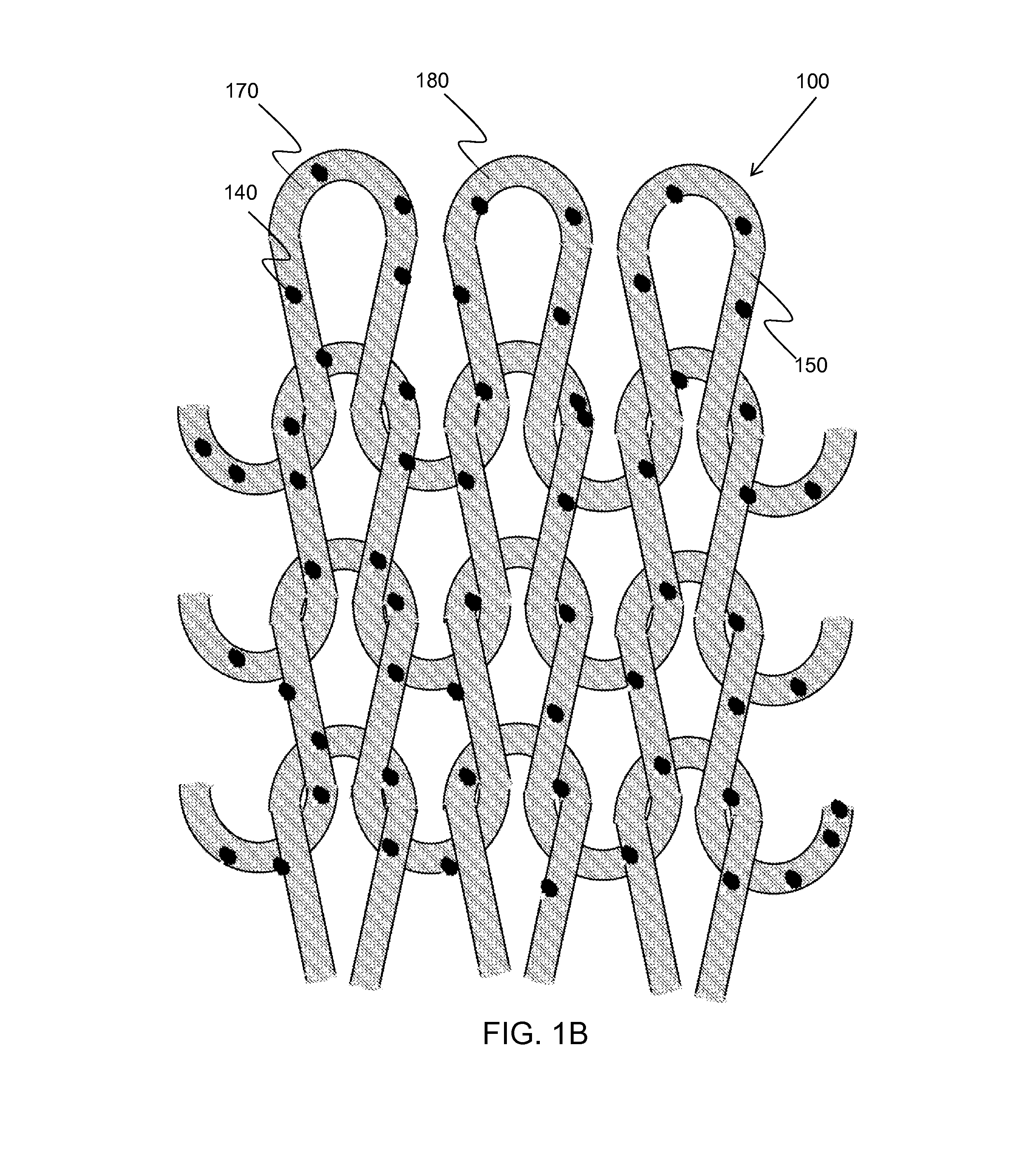

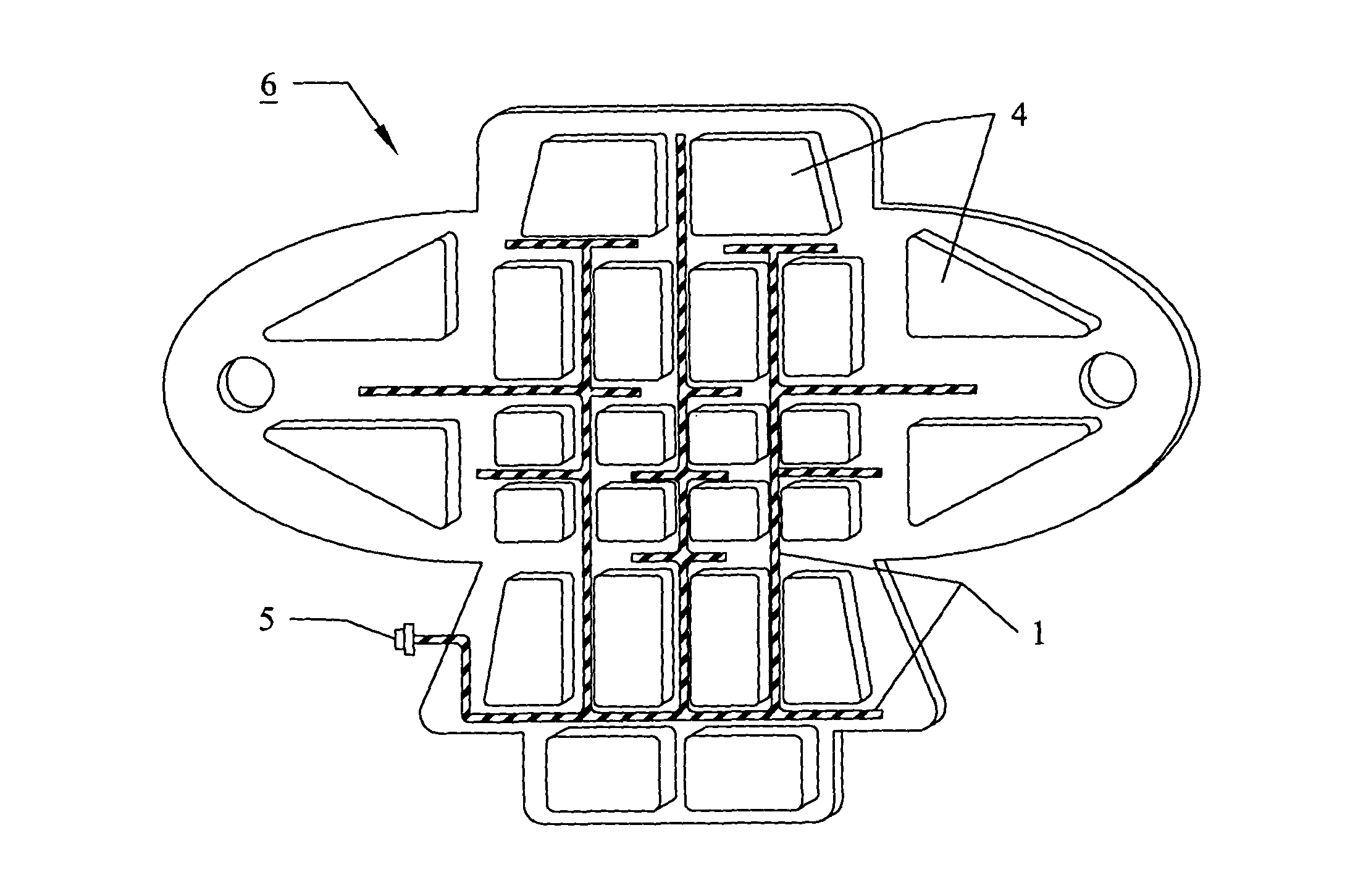

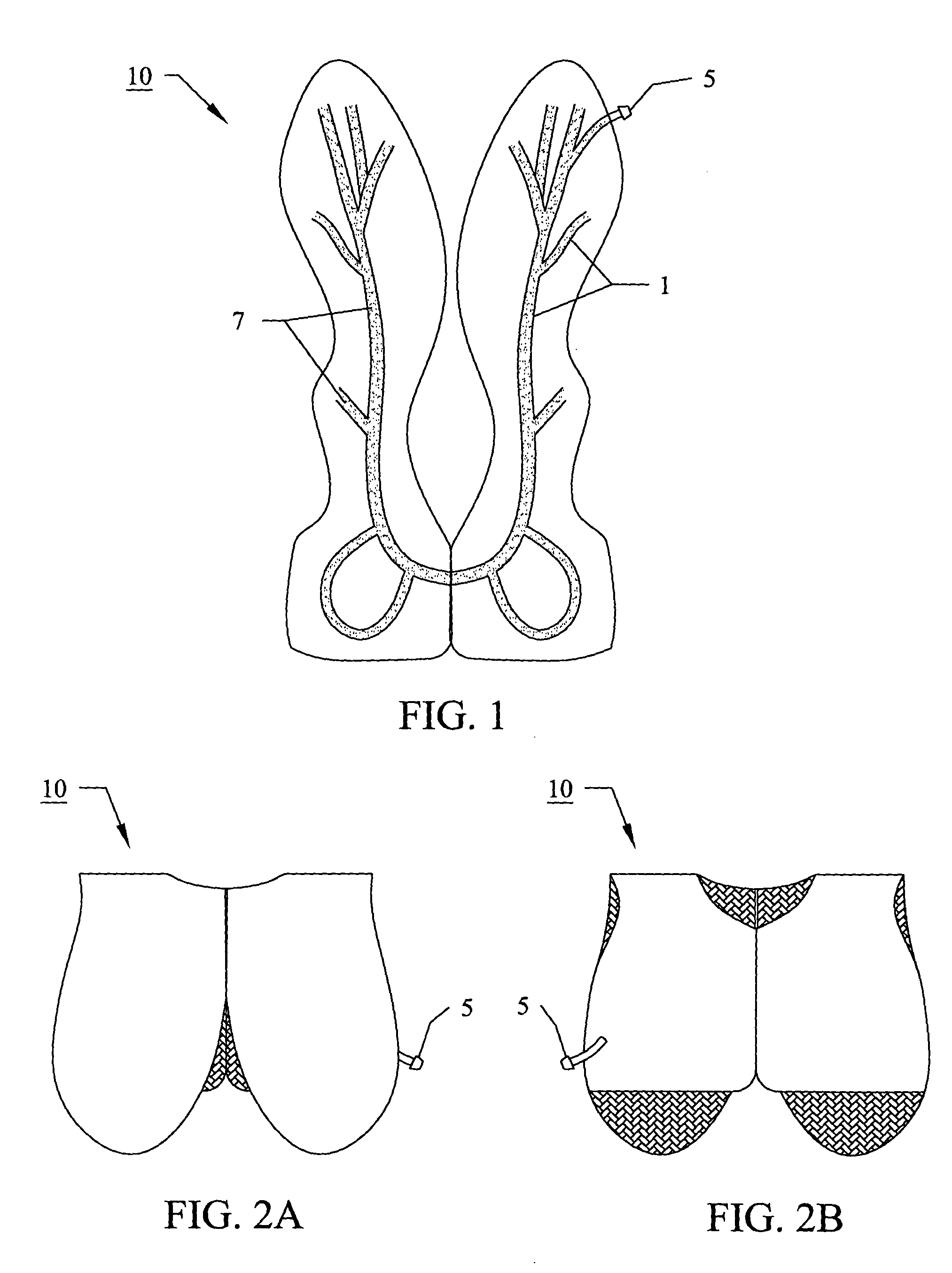

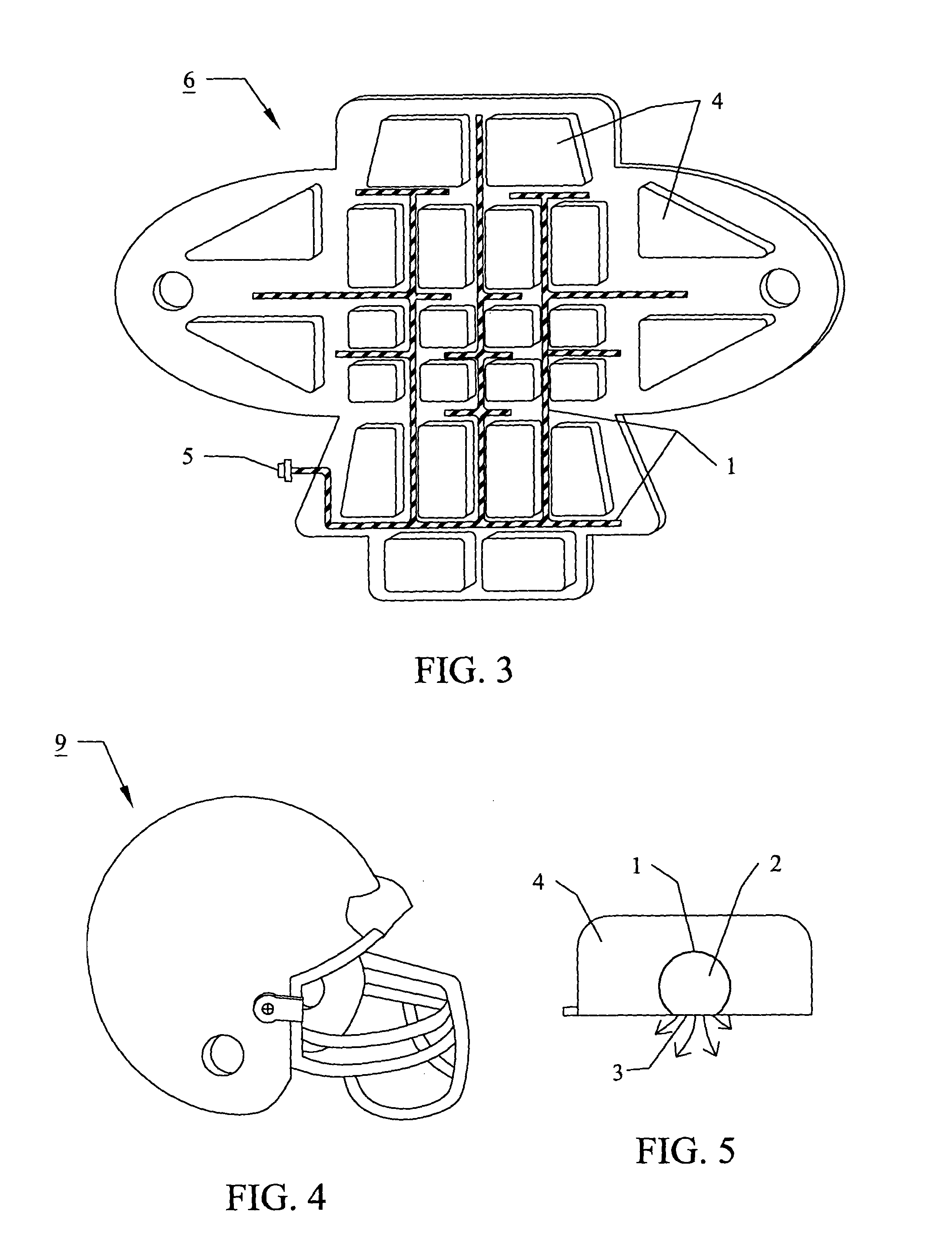

Materials and methods for maintaining proper body temperature

ActiveUS8544115B1Decrease in elevated body core temperatureComfortable and goodChemical protectionHeat protectionProviding materialCold weather

The subject invention provides materials and methods for convective and / or conductive and / or evaporative cooling of individuals, such as athletes and contestants, for safety, comfort, and enhanced performance. The materials and methods of the subject invention can, advantageously, be used to modify body core temperature or rate of change of temperature. Other uses include heating players or player parts (e.g., a kicker's leg, a pitcher's arm) in cold weather conditions.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

Preparation method for quick-frozen okra

InactiveCN105192052AConsistent colorUniform sizeFruits/vegetable preservation by freezing/coolingQuick FreezeFluidized bed

The invention discloses a preparation method for quick-frozen okra. The preparation method is characterized by comprising the following steps: blanching: blanching cleaned okra for deactivation; cooling; quickly spraying water on the blanched okra for cooling; draining: draining the cooled okra by mechanical vibration and blowing; quick freezing: flatly spreading the drained okra in a fluidized bed individual quick-freezing machine for individual quick freezing. The okra prepared by adopting the preparation method for the quick-frozen okra is dark green, consistent in colour and lustre, free of individual adhesion and uniform in size, and has a bacterial clump amount (per gram) being not more than 10000, and an excrement colon bacillus amount (per 100gram) being less than 3. According to the preparation method for the quick-frozen okra, the colour and lustre as well as mouthfeel of the okra are better kept in the preparation process of the quick-frozen okra, the loss of beneficial components is reduced to minimum, and hygienic indexes reach national standards.

Owner:宁夏天瑞产业集团现代农业有限公司

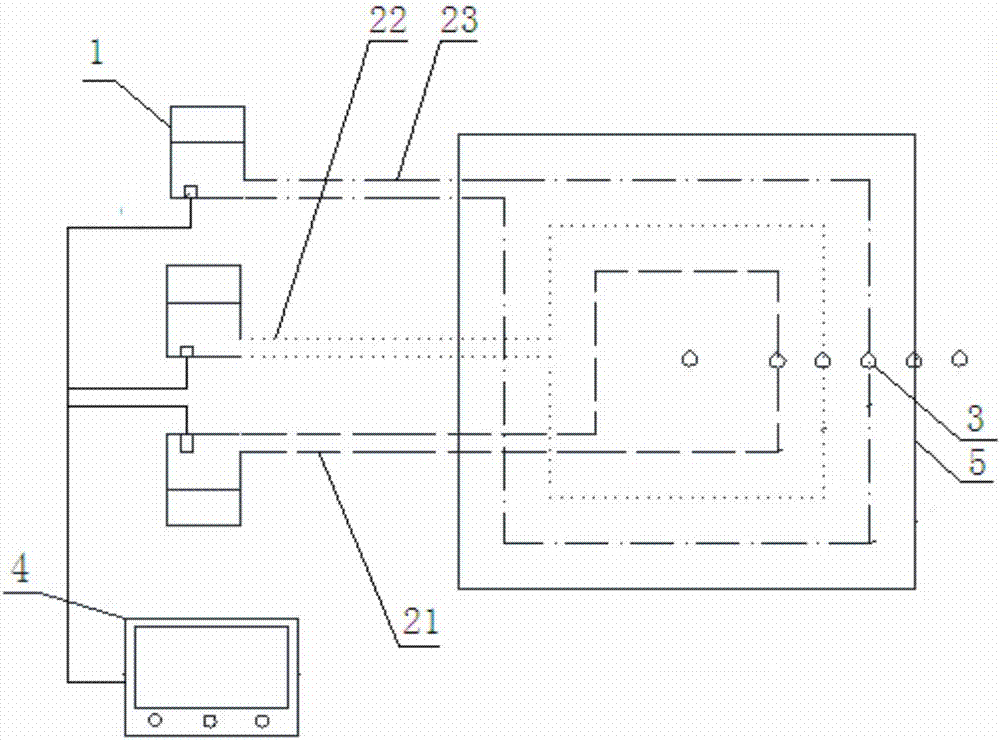

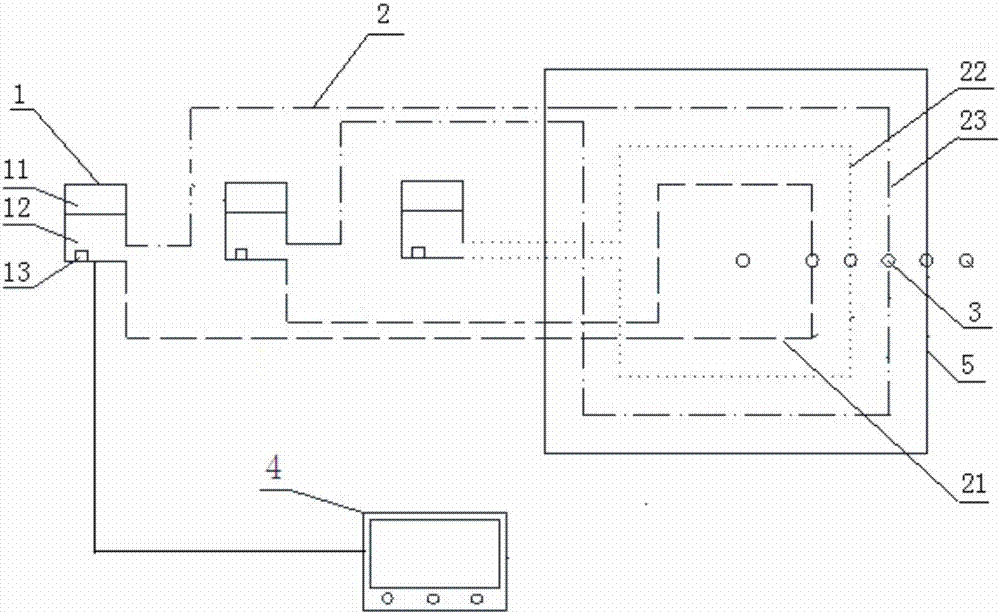

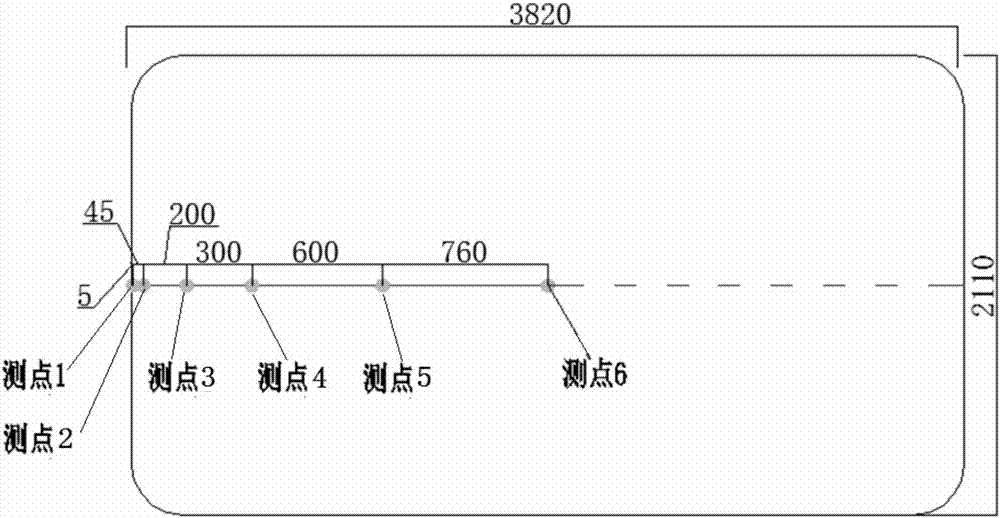

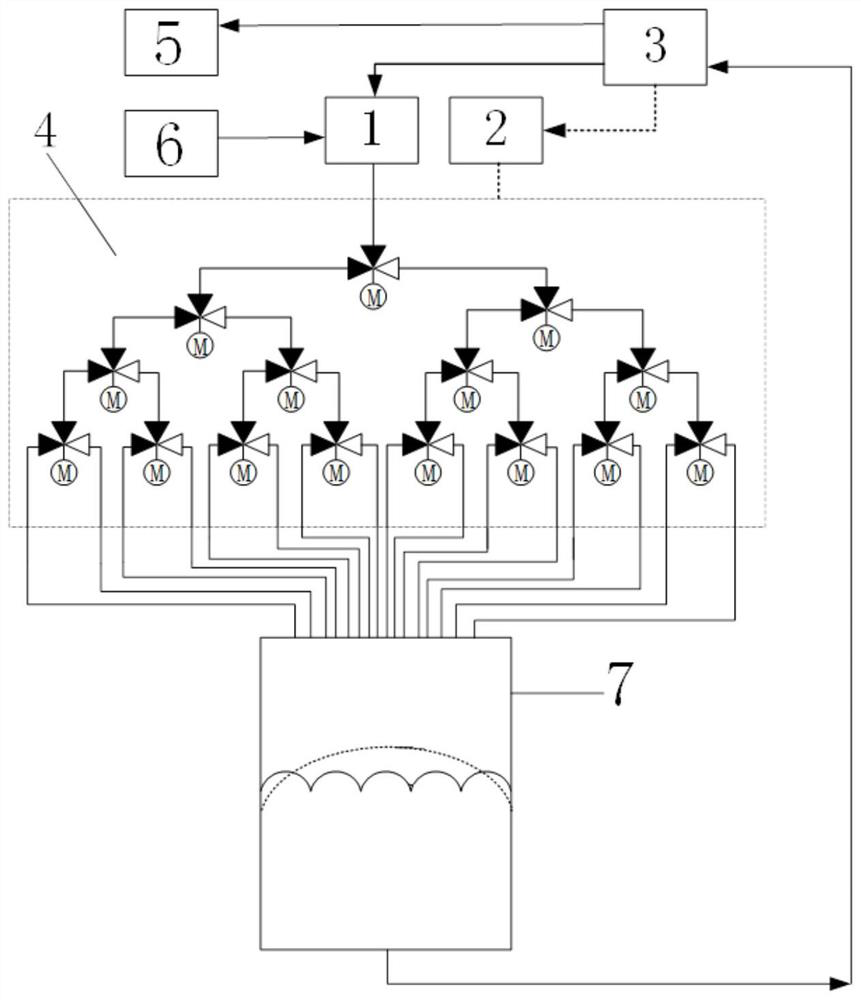

Gradient type concrete water pipe control system and control method

ActiveCN107013047ALower core temperatureReduce adiabatic temperature riseDomestic cooling apparatusLighting and heating apparatusInlet temperatureWater pipe

The invention relates to the field of civil engineering, in particular to a gradient type concrete water pipe control system and control method. According to the gradient type concrete water pipe control system and control method, in the temperature rising period of concrete, the center temperature of the concrete can be reduced as quick as possible with the highest efficiency, the temperature can be reduced by 20-25 DEG C at maximum, adiabatic temperature rising of the concrete is equivalently reduced, and the cracking risk is reduced; in the temperature decreasing period of the concrete, the temperature decreasing speed of the concrete can be reduced by adjusting the water temperatures of water pipes in different positions of the concrete, the temperature decreasing speed of the concrete is smaller than or equal to 3.0 DEG / day, impact of contraction deformation is reduced, and the cracking risk is reduced; and meanwhile the concrete water pipe control system can automatically read the temperatures of temperature measuring points inside the concrete and adjust the water inlet temperatures of the water pipes according to the actual temperatures of the parts inside the concrete, the temperature gradient among the interior, middle and exterior of the concrete and air is reduced to the maximum extent, and the cracking risk is reduced.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

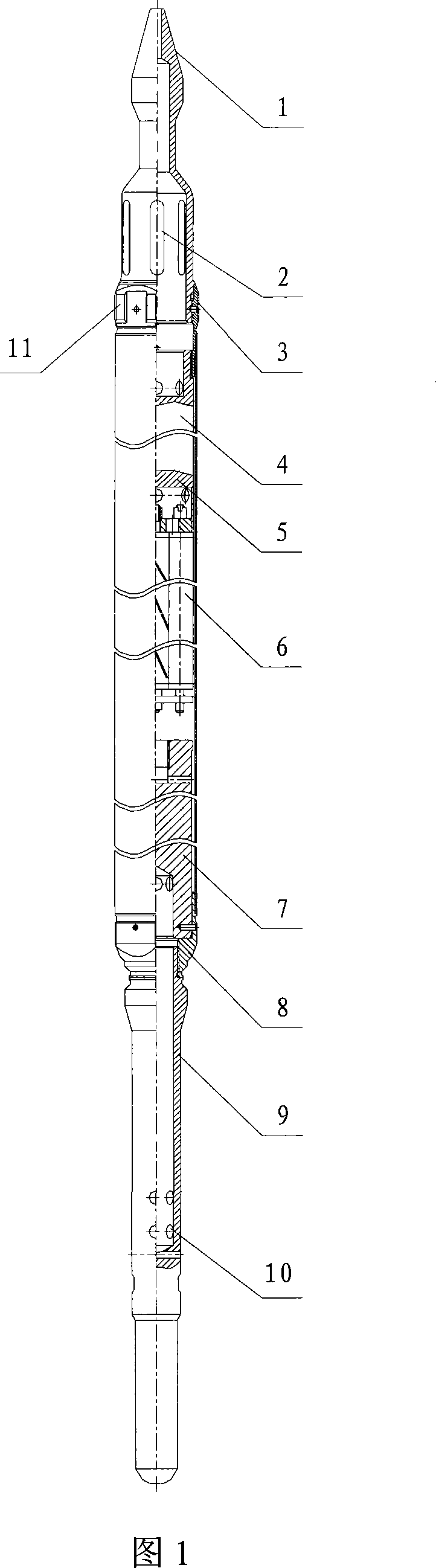

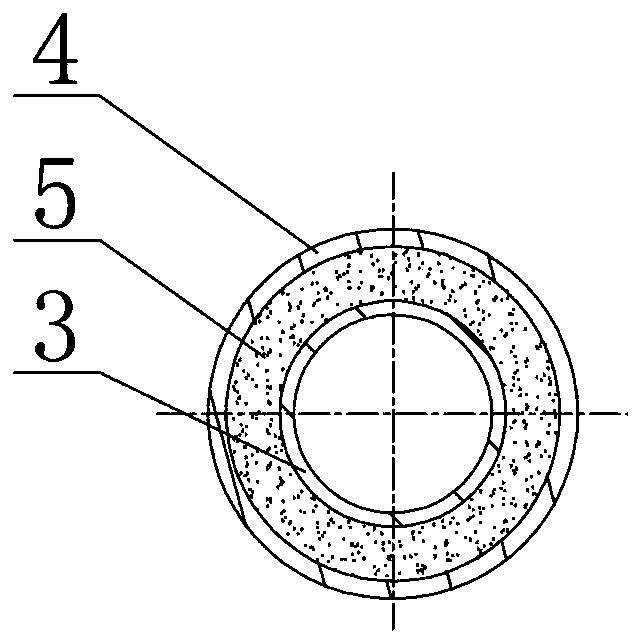

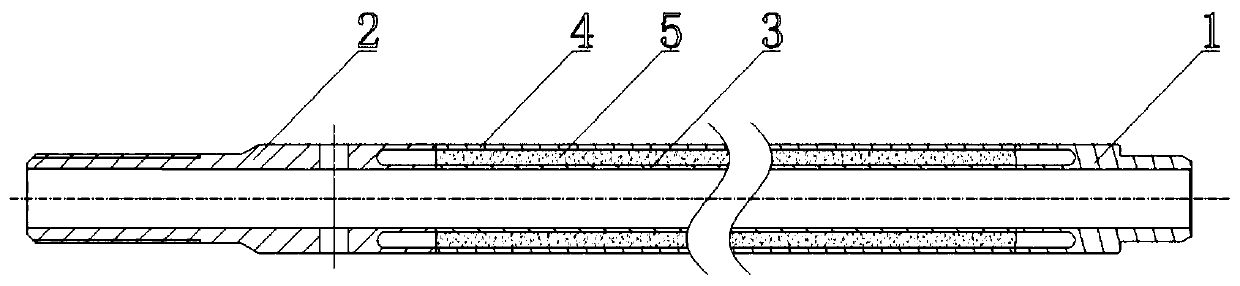

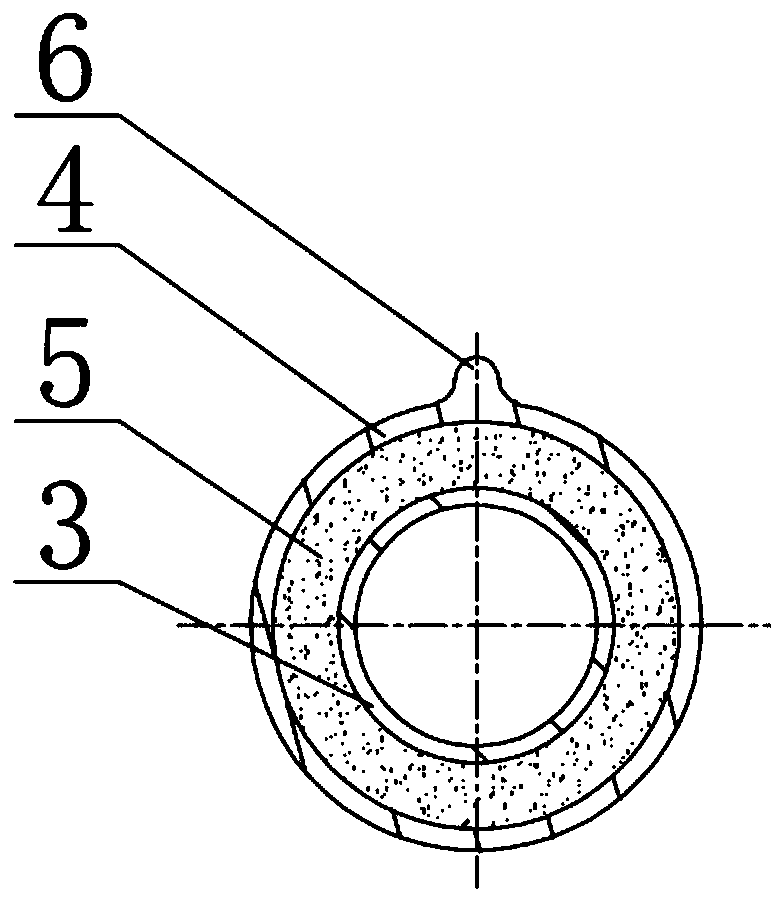

Co-extrusion type annular fuel rod

PendingCN111477354ALower core temperatureImprove thermal conductivityFuel elementsNuclear energy generationThermodynamicsManufacturing technology

The invention relates to the technical field of nuclear fuel, and particularly discloses a co-extrusion type annular fuel rod. No gap exists between a fuel pellet and a cladding, so that heat conduction is enhanced, the center temperature of the fuel pellet is reduced, a traditional pressure spring structure is not needed any more, operation stability is improved, and radioactive waste is reduced.According to the fuel rod structure, the assembling and manufacturing process of the fuel rod is simplified, helium does not need to be filled into the fuel rod during manufacturing, and the cost isreduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Processing method of preserved braised beef

InactiveCN108887606ATaste goodThree-dimensional and soft tasteNatural extract food ingredientsMeat/fish preservation using chemicalsCooling temperatureFlavor

The invention discloses a processing method of preserved braised beef. The processing method comprises the following steps: carrying out unfreezing and cleaning, mixing, pickling, baking, preparing braising soup bases, carrying out braising by virtue of a cold-hot conversion method, selecting, removing impurities, carrying out step cooling, slicing, carrying out packaging, and the like. Accordingto the processing method, braising is carried out by virtue of the cold-hot conversion method, so that the braised beef has relatively good tasty effect; the cooling temperature during the braising through the cold-hot conversion method is controlled in a step manner, so that relatively good quality of the braised beef is well obtained; and the prepared braised beef has two flavors of braised products and baked foods, the flavors are stereoscopic and gentle, the taste is specific. Two specific compound mixtures can penetrate into beef, so that the tissue structure of the beef can be improved,and the synchronous antibacterial effect can be achieved.

Owner:江苏你好鸭食品有限公司

Method and apparatus for heating glass melting furnaces with fossil fuels

InactiveUS6862899B2Reduce soot formationReduce formationTank furnacesGlass furnace apparatusGlass meltingFossil fuel

During the heating of glass melting furnaces having a combustion chamber with regenerators for preheating oxidation gases, with port necks that open into the combustion chamber, with primary burners and with secondary burners that are installed in a cascade arrangement relative to the primary burners, the secondary burners are operated as cascade burners with a relatively low proportion of the fuel, the secondary fuel. Flames are thereby created in over- and sub-stoichiometric conditions and the flame gases formed are mixed with one another so that the complete combustion process in the combustion chamber is more or less stoichiometric. The secondary fuel is supplied by the secondary burners to a step, installed in the port neck. In order to prevent or reduce soot and graphite deposits in the step without increasing the nitrogen oxide content in the furnace waste gases, a secondary oxidation gas is blown into step during the firing phase of each port neck in addition to the primary oxidation gas preheated in the regenerators that flows over the step. If significant deposits of carbon material and / or temperature problems occur, then in a similar way an oxidation gas can be blown in during the exhaust phase for the furnace waste gases of each port neck when the secondary burner is switched off.

Owner:BETEILIGUNGEN SORG

Low-melting-point optical glass forming device

ActiveCN111620550AIncrease surface areaImprove cooling efficiencyGlass pressing apparatusRetention timeBand shape

The invention provides a low-melting-point optical glass forming device, and belongs to the technical field of optical glass forming. The problem that stripes are formed on the surface of a low-melting-point optical glass strip is mainly solved. According to the main scheme, the device is characterized in that a striker plate and a striker plate fixing frame are additionally arranged on a mold rear baffle; a leaking groove with a triangular section is formed by the striker plate and the mold rear baffle; under the action of the leaking groove, molten glass flowing out of a material pipe is changed into a strip shape from a columnar shape, the superficial area of the molten glass is increased, the cooling efficiency of a mold on the molten glass is improved, meanwhile, the temperature difference between the center and the edge of the molten glass is reduced, the viscosity difference is reduced, and convection stripes caused by large viscosity difference between the center and the edge during columnar molten glass forming can be prevented; and meanwhile, the arc-shaped structure of the working surface of the rear baffle is formed, so that the molten glass directly flows onto the rearbaffle to be cooled, the stroke and retention time of the molten glass on the mold are prolonged, the molten glass is cooled in a shaping area range on the rear baffle, and convection stripes causedby high molding temperature and low viscosity are prevented.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

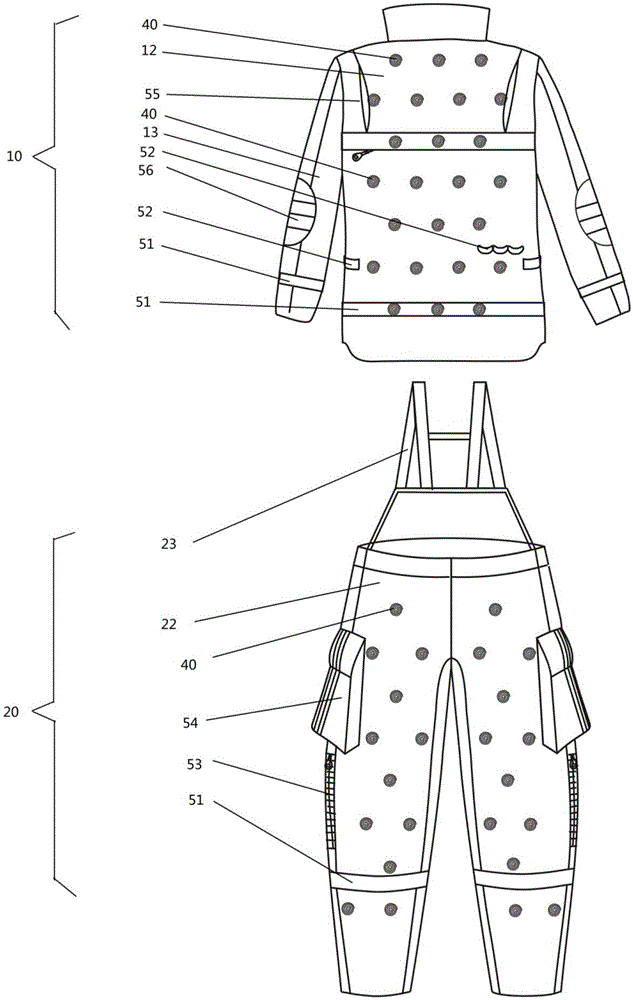

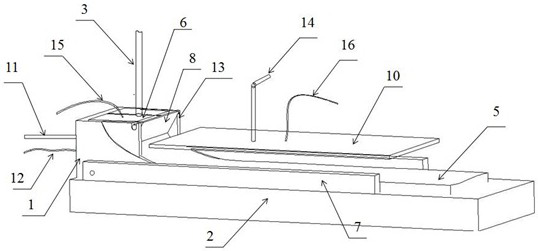

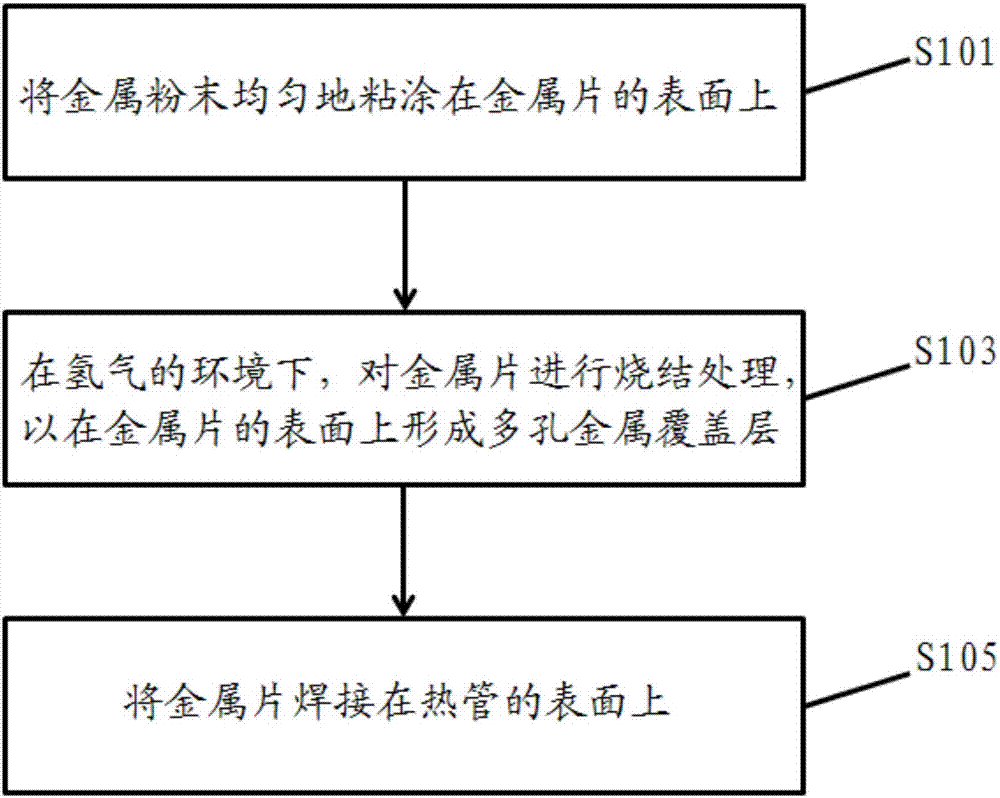

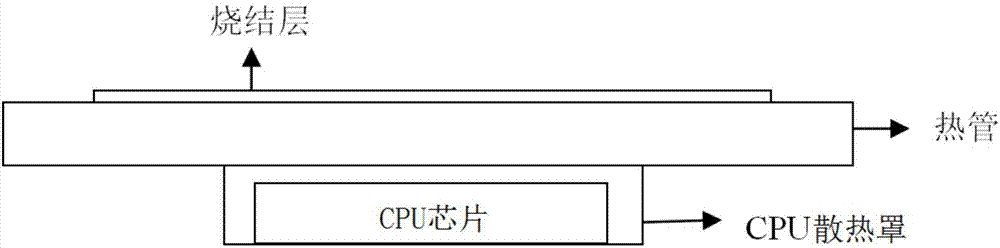

CPU cooling method and apparatus

InactiveCN107168493AUniform temperature fieldLower core temperatureDigital data processing detailsModifications by conduction heat transferHydrogenEvaporation

The invention discloses a CPU cooling method and apparatus. The CPU cooling method comprises the steps of uniformly adhering metal powder to the surface of a metal sheet; in a hydrogen environment, performing sintering processing on the metal sheet to form a porous metal coverage layer on the surface of the metal sheet; and welding the metal sheet on the surface of a heat pipe. According to the method and the apparatus, the metal powder is uniformly adhered to the surface of the metal sheet, then in the hydrogen environment, the metal sheet is subjected to the sintering processing to form the porous metal coverage layer on the surface of the metal sheet, and the metal sheet is welded on the surface of the heat pipe; the heat pipe is mounted on the surface of a CPU chip, and the surface of heat pipe is subjected to sintering and enhanced boiling processing, so that a temperature field of the boiling surface is uniform, and the boiling area and the evaporation core are enlarged; and enhanced boiling heat transfer is performed, so that the core temperature of the chip is reduced.

Owner:SUGON DATAENERGYBEIJING CO LTD

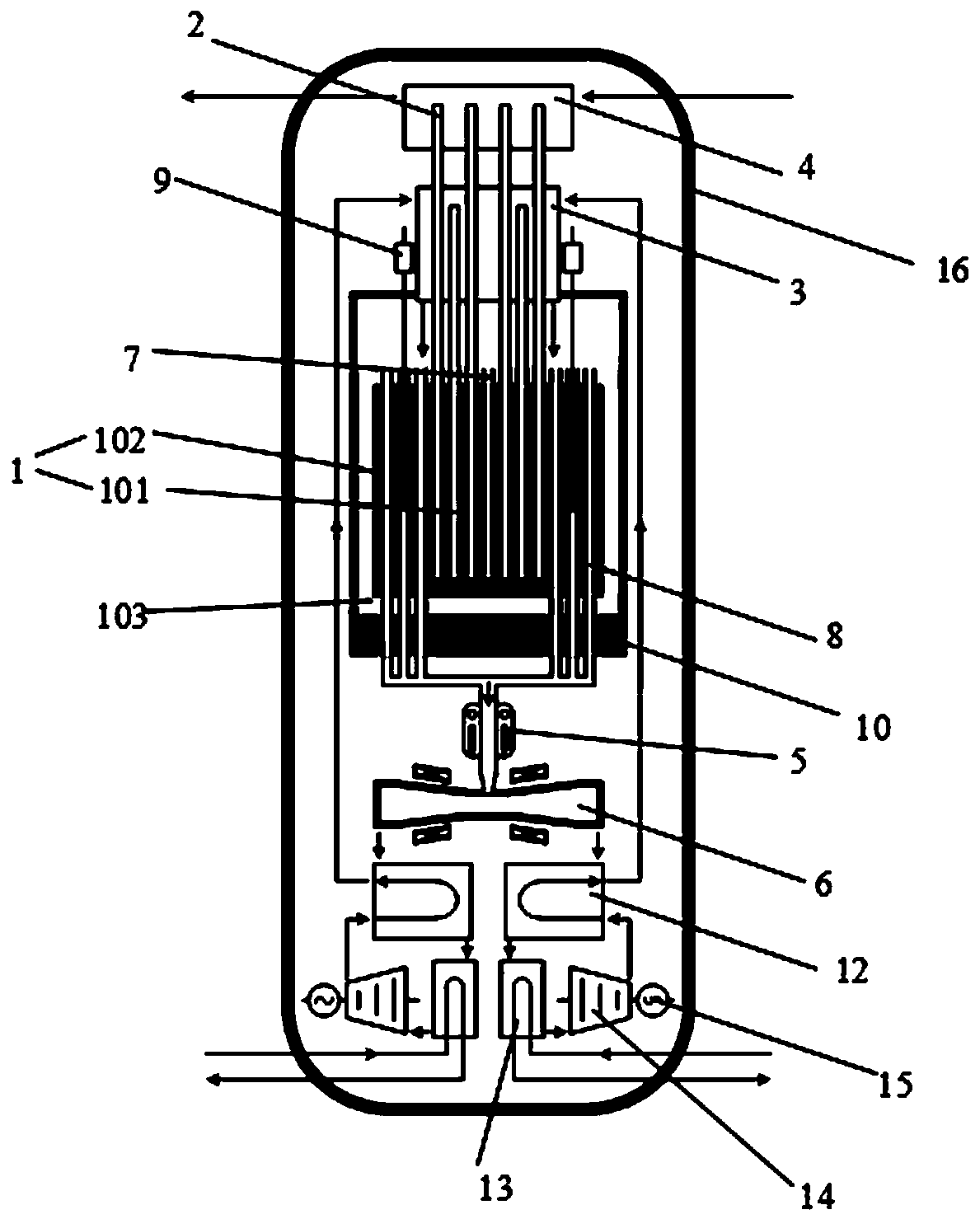

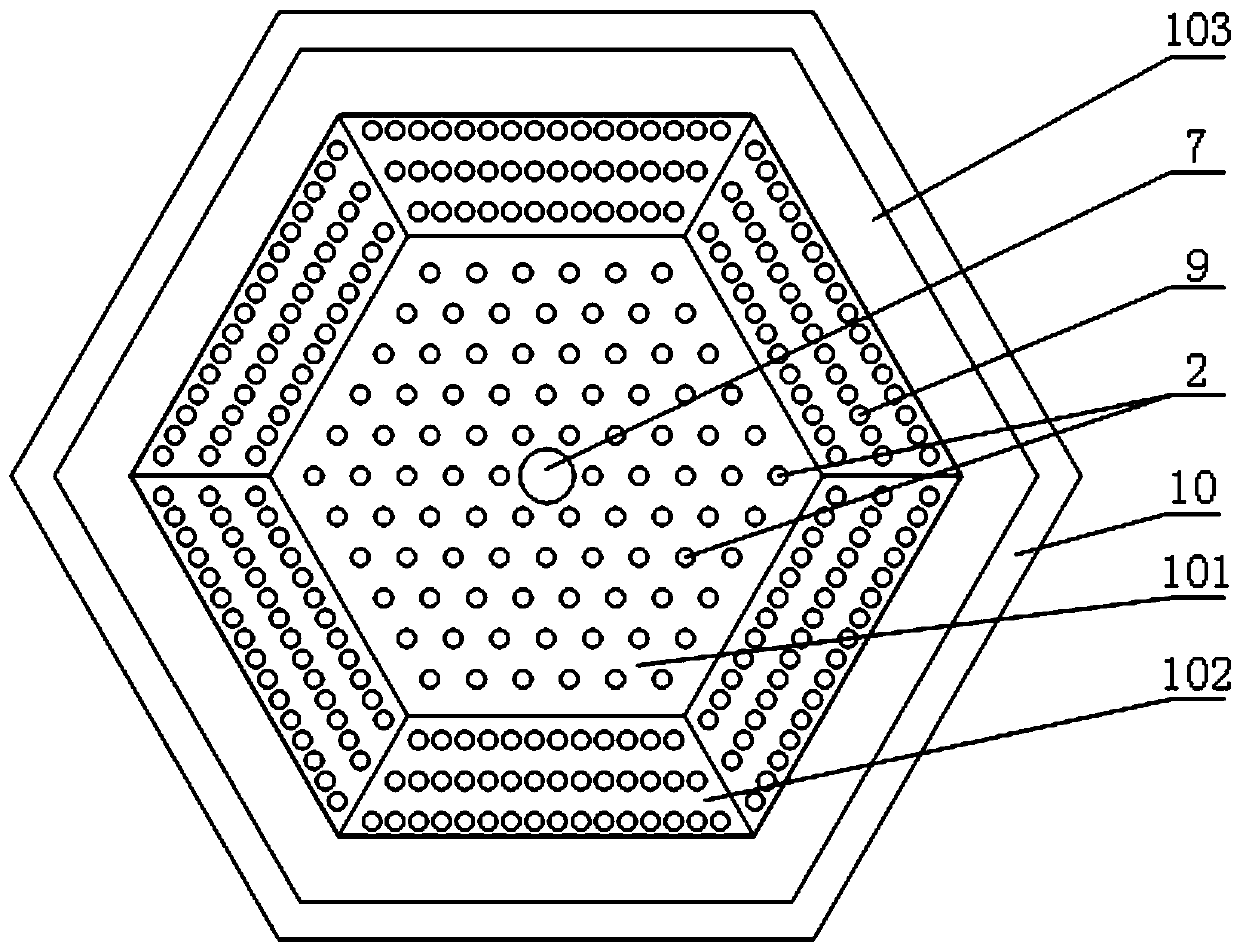

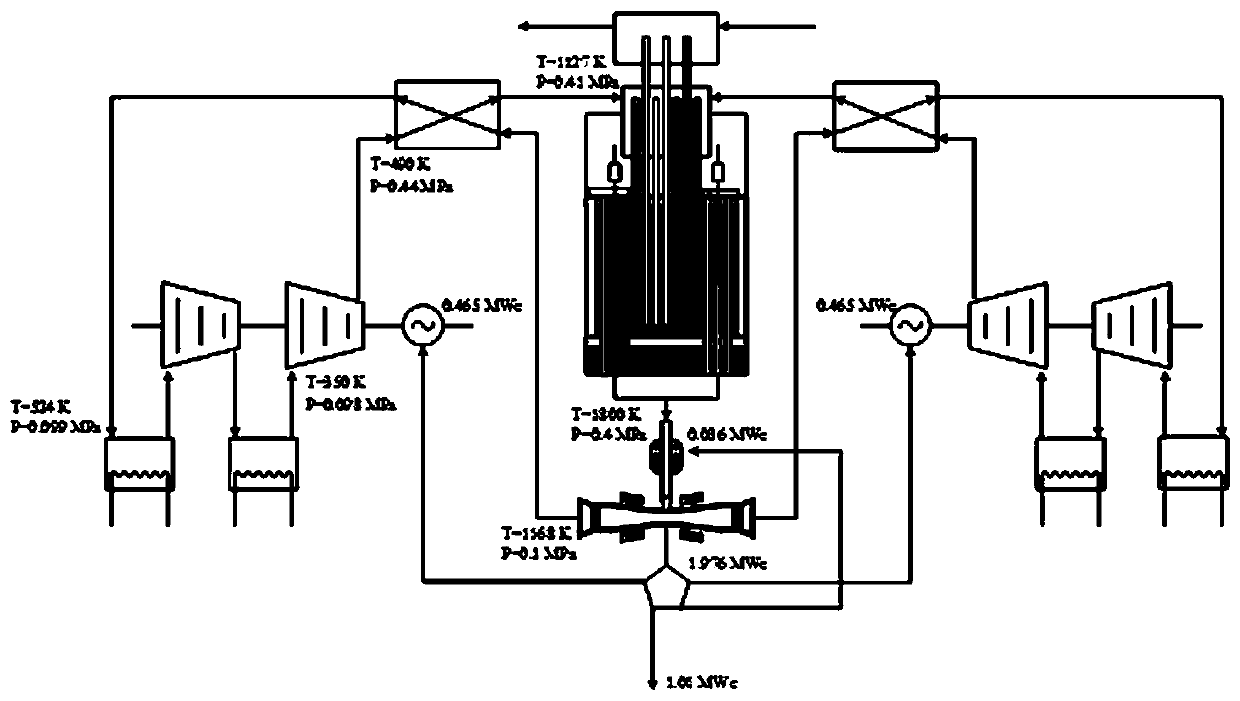

Double-layer cooling reactor core power generation system

ActiveCN110491533AIncrease the heat exchange areaAchieve compactnessNuclear energy generationCooling arrangementNuclear reactor coreReflective layer

The invention discloses a double-layer cooling reactor core power generation system, which comprises: a reactor core, which comprises an inner-layer reactor core and an outer-layer reactor core, wherein the inner-layer reactor core is arranged inside the outer-layer reactor core, and a reflecting layer is arranged outside the outer-layer reactor core; a plurality of heat pipes, which are arrangedin the inner-layer reactor core, wherein a preheater and a heat exchanger are arranged on the heat pipes; a pre-ionization module that is connected with the outer-layer reactor core; and a power generation module which is electrically connected with the pre-ionization module. According to the invention, the compactness of the reactor core is achieved, and the outlet temperature of the reactor coreis increased by utilizing the characteristics of the gas cooled reactor, so that the helium-xenon working medium at the outlet can reach an unbalanced ionization state through pre-ionization.

Owner:HARBIN ENG UNIV

Preparation method of quick-frozen Lycium barbarum

The invention discloses a preparation method of quick-frozen Lycium barbarum. The method is characterized by comprising the following steps: cooling ice water; draining; quick-freezing. The prepared quick-frozen Lycium barbarum has bright red color, color consistency, no individual adhesion and uniform size; the preparation method effectively maintains the color and flavor of Lycium barbarum, and extends the storage period; and the bacterial colony count / g is less than or equal to 10000, and fecal coliform (MPN / 100 g) is less than 3. The preparation method of quick-frozen Lycium barbarum effectively solves the problem of serious effective component loss in storage process, retains the nutritional ingredients to the maximum and keeps the appearance and quality of the quick-frozen Lycium barbarum the same to the fresh ones, so as to ensure that people can always eat fresh Lycium barbarum.

Owner:宁夏天瑞产业集团现代农业有限公司

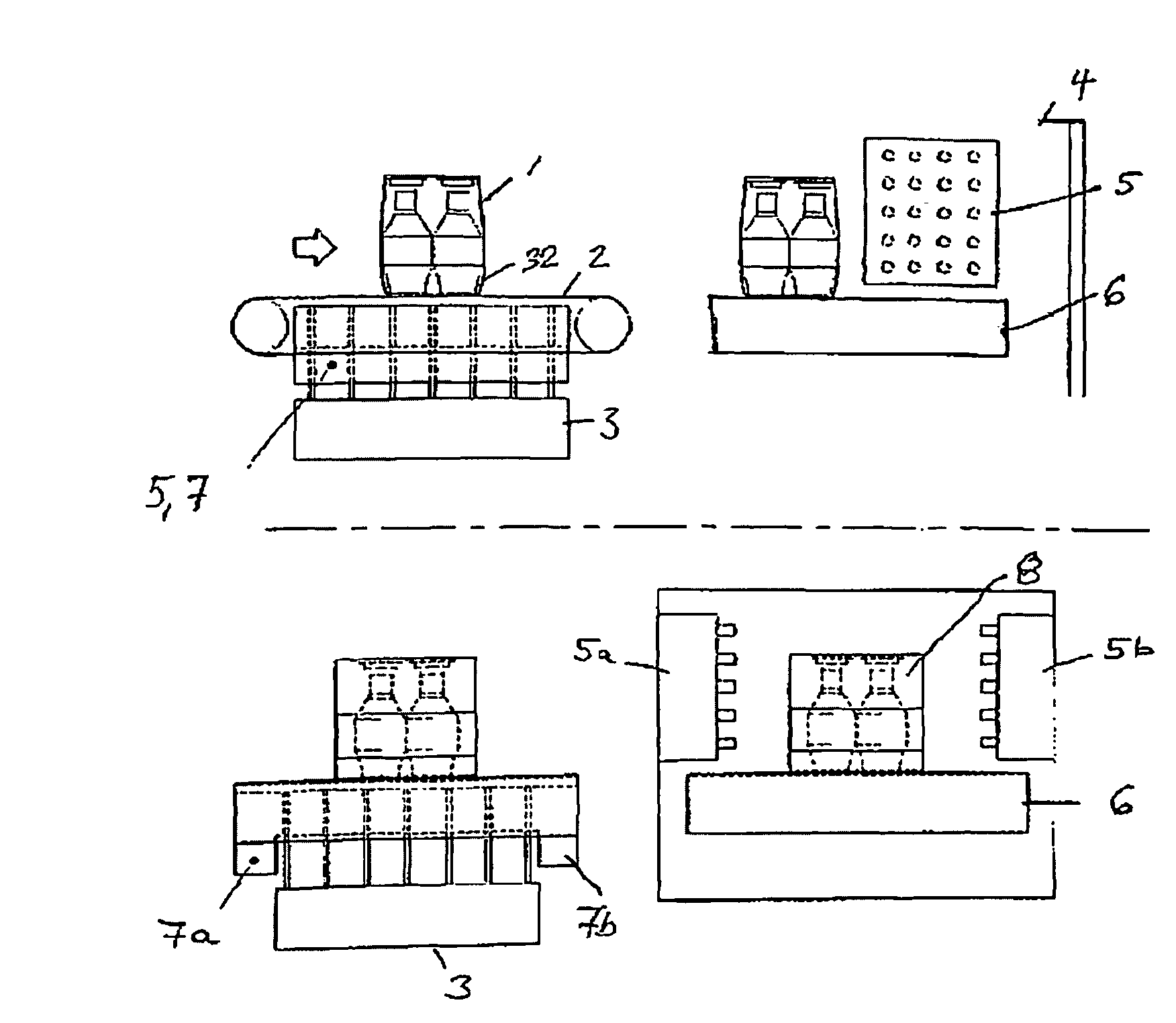

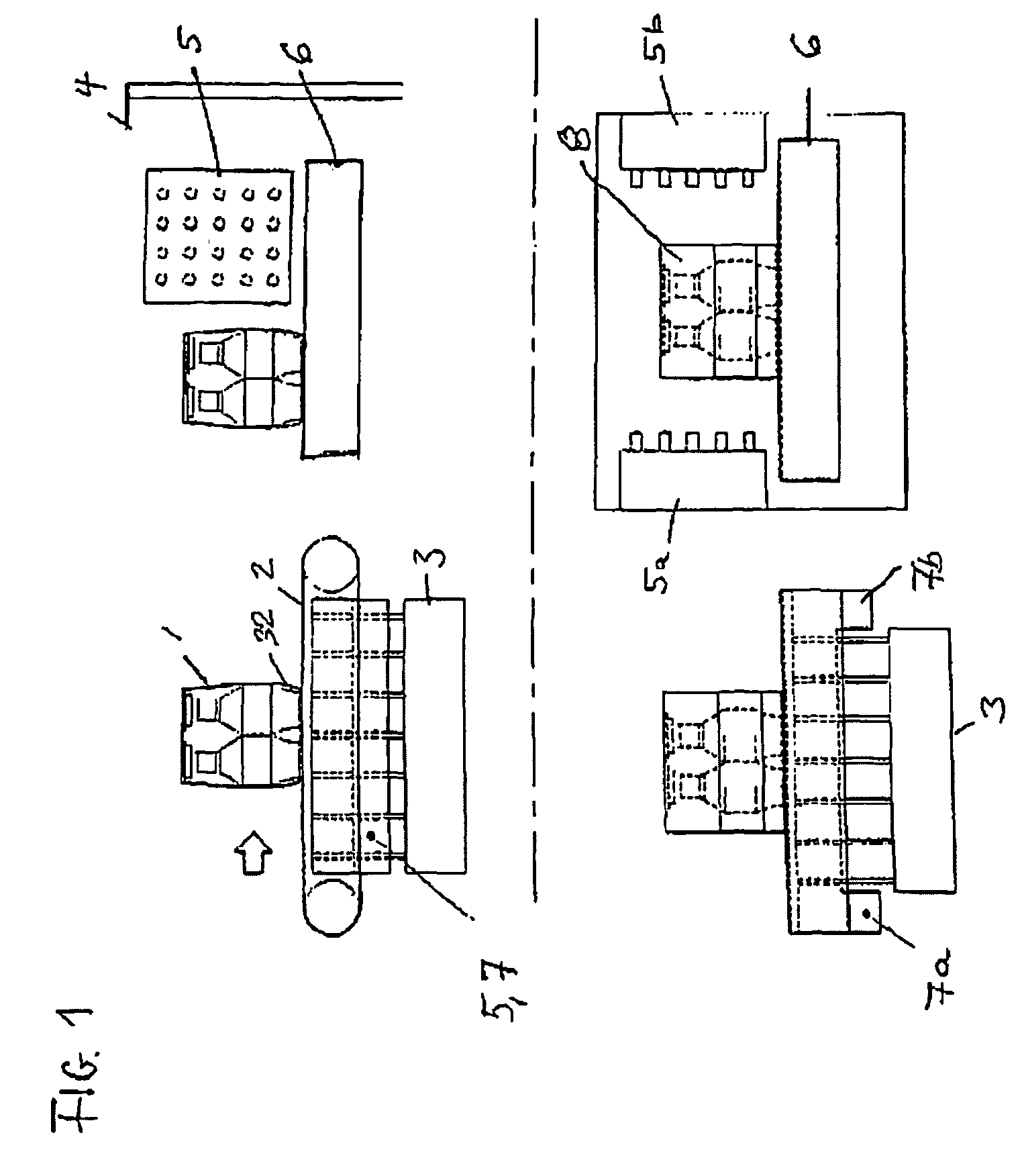

Shrinking process for producing solid, transportable and printable containers and a device for carrying out a shrinking process of this type

ActiveUS7946100B2Efficient transfer of energyReduced energy outputWrappers shrinkageContainers with multiple articlesEngineeringBottle

The invention relates to a shrinking process for producing solid, transportable and printable containers by wrapping the articles to be packaged with a film in such a manner as to produce an overlapping section of the film ends on the base area, heating by heat exchange or convection in order to seal the free ends in the area of overlap, and finally heating in a shrinking oven, the container so produced being stabilized by the shrinking process. The method comprises first locally limiting the incoming hot air to the base area of the container to form a peripheral shell in the area of the bottle bottoms, the shape of the container being stabilized thereby, while the container is continuously transported during stabilization and the hot air directed onto the base area of the container in a bundle of discretely distributed gas jets is thereby discharged and guided back after a locally limited heat transfer with the film, and more hot gas is directed laterally against the continuously transported container at an increased lateral blow speed in order to complete the shrinking process. The invention further relates to a device for carrying out the shrinking process.

Owner:KHS GMBH

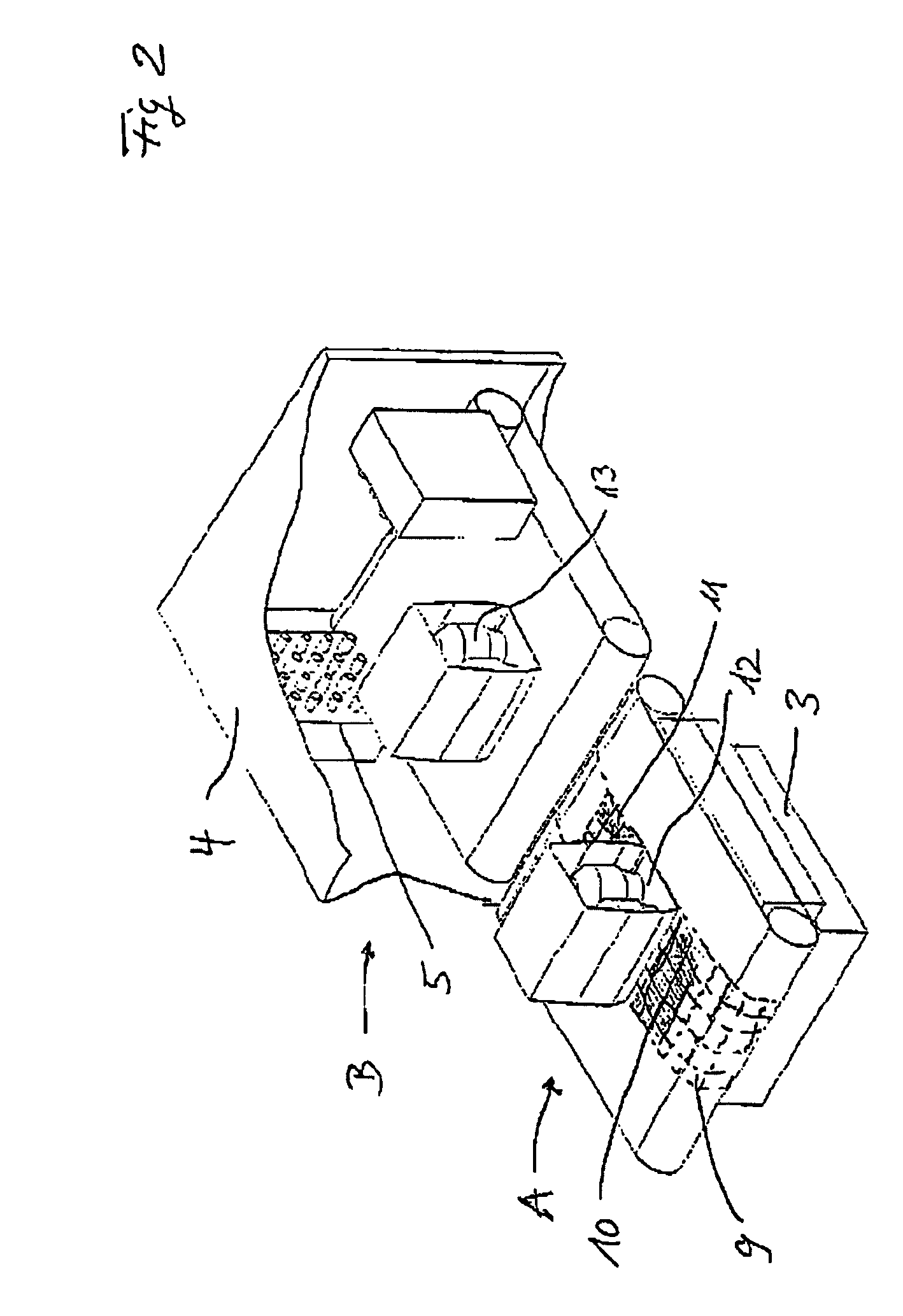

Device and method for partitioned loading of high-temperature gas cooled reactor core

ActiveCN112309595AReduce peak powerLower core temperatureNuclear energy generationNuclear monitoringReactor pressure vesselBurnup

The invention discloses a device and a method for partitioned loading of high-temperature gas cooled reactor cores. The device comprises a reactor pressure vessel, a burnup measuring system, a spent fuel system, a fuel loading and unloading system, a new fuel system and a three-way valve group; and a high-temperature gas cooled reactor fuel ball is loaded in the reactor pressure vessel, an outletin the bottom of the reactor pressure vessel is communicated with an inlet of the burnup measuring system, an outlet of the burnup measuring system is communicated with an inlet of the spent fuel system and an inlet of the fuel loading and unloading system, an outlet of the new fuel system is communicated with an inlet of the fuel loading and unloading system, an outlet of the fuel loading and unloading system is communicated with N feeding ports in the top of the reactor pressure vessel through the three-way valve group, a reactor core loading subarea in the reactor pressure vessel is dividedinto N loading subareas, one loading subarea corresponds to one feeding port, and each feeding port is communicated with the corresponding loading subarea. The device and the method can effectively solve the problems of non-uniform burnup and higher power peak factor of the reactor cores.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com