Co-extrusion type annular fuel rod

A fuel rod and co-extrusion technology, which is applied to fuel elements, greenhouse gas reduction, nuclear power generation, etc., can solve the problems of narrow and long coolant flow areas, affecting structural stability, heat conduction obstacles, etc., to simplify the assembly and manufacturing process, Effect of increasing stability and lowering core temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

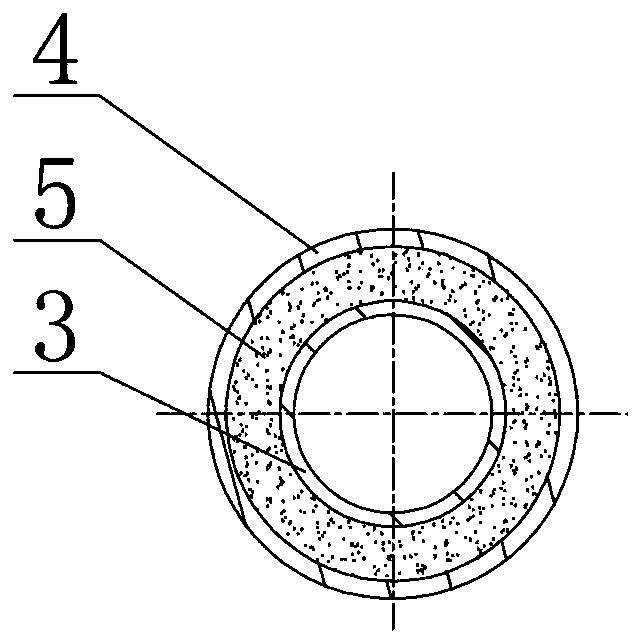

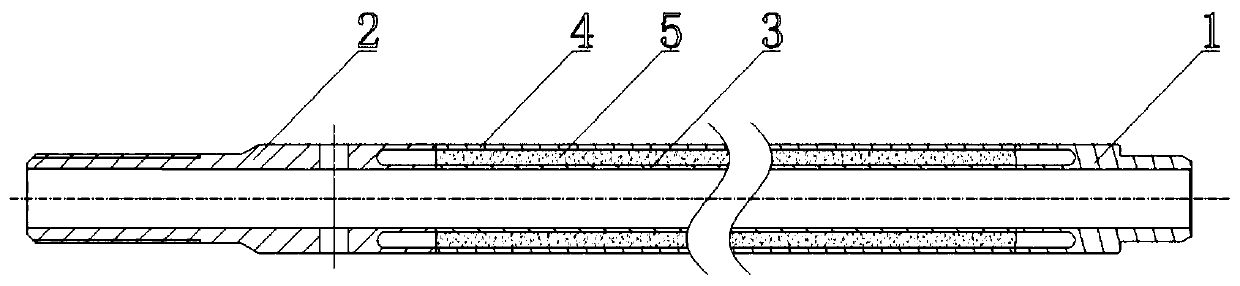

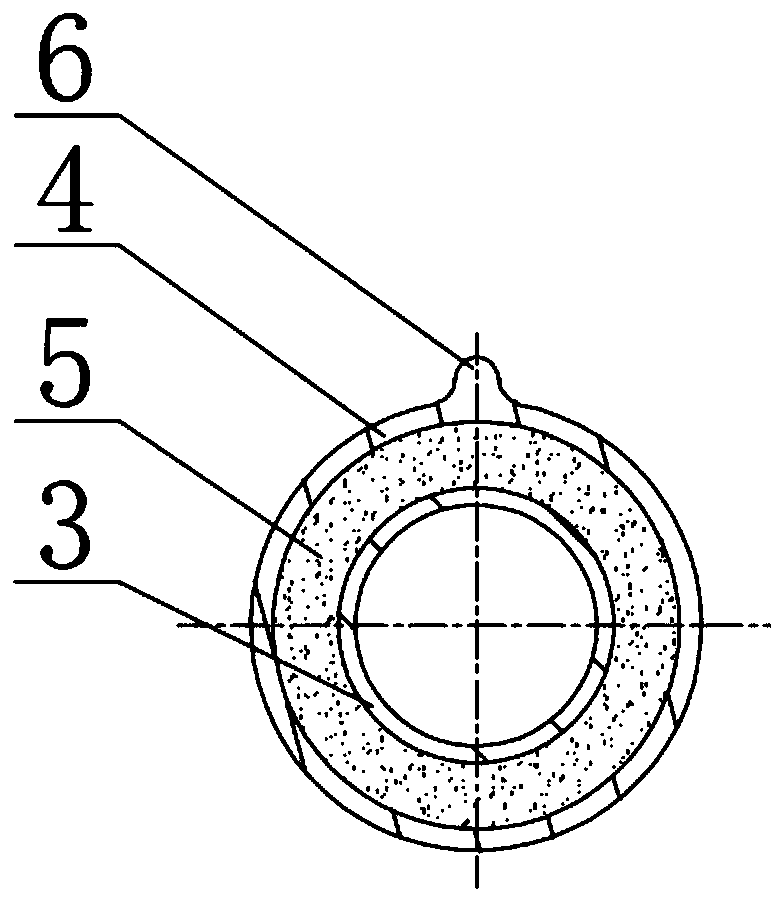

[0034] Such as figure 1 , 2 A co-extruded annular fuel rod shown includes an upper end plug 1 , a lower end plug 2 , an inner cladding 3 , an outer cladding 4 , and an annular fuel core 5 .

[0035] The annular fuel core body 5, the inner cladding 3 and the outer cladding 4 are processed by co-extrusion, and there is no gap between them, which enhances heat conduction and reduces the core temperature of the fuel pellet.

[0036] The upper end plug 1 is connected above the inner shell 3 and the outer shell 4, and the lower end plug 2 is connected below.

[0037] The annular fuel core 5 is a dispersion or metal fuel.

[0038] The traditional co-extrusion processing method is easy to produce uneven distribution of cores at both ends of the co-extrusion, so the co-extruded annular fuel rod of the present application cuts off the uneven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com