Patents

Literature

69results about How to "Reduced energy output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

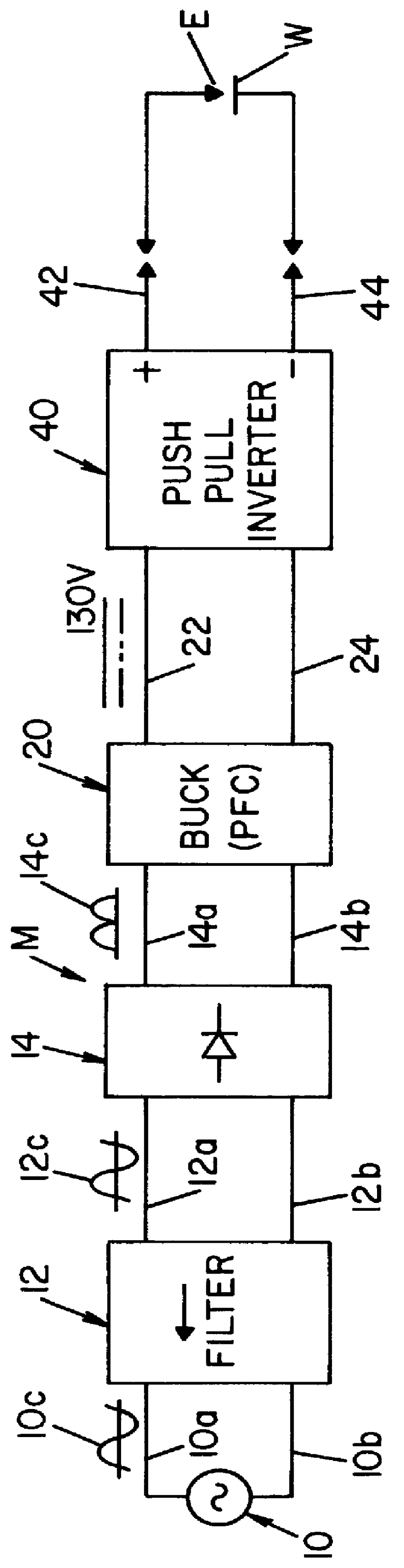

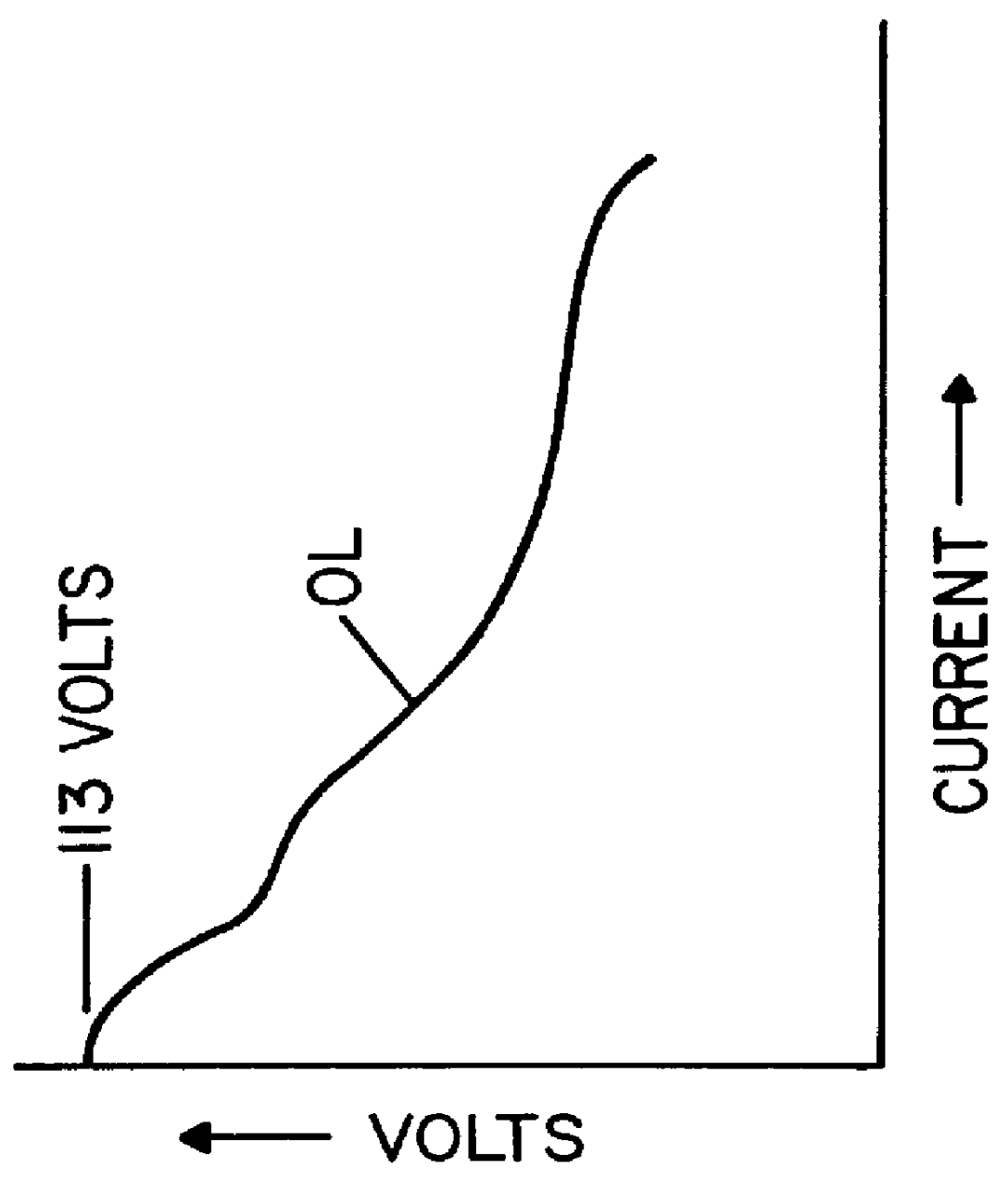

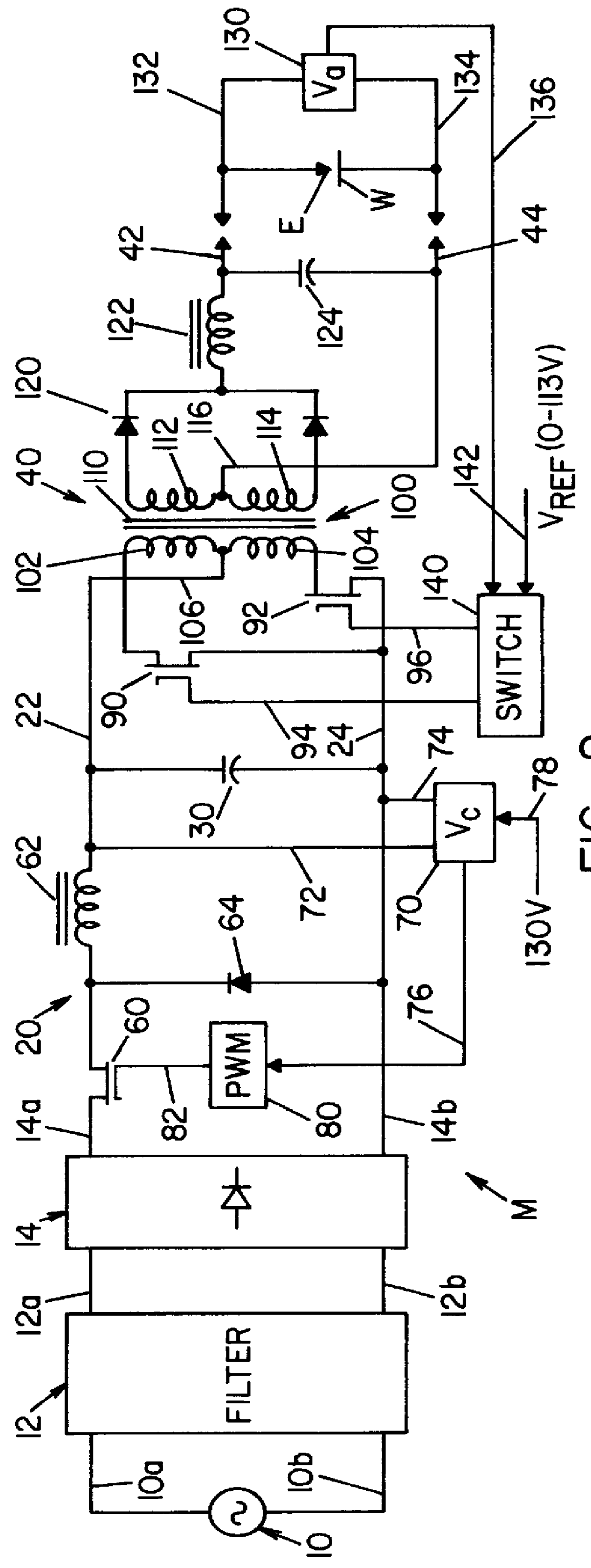

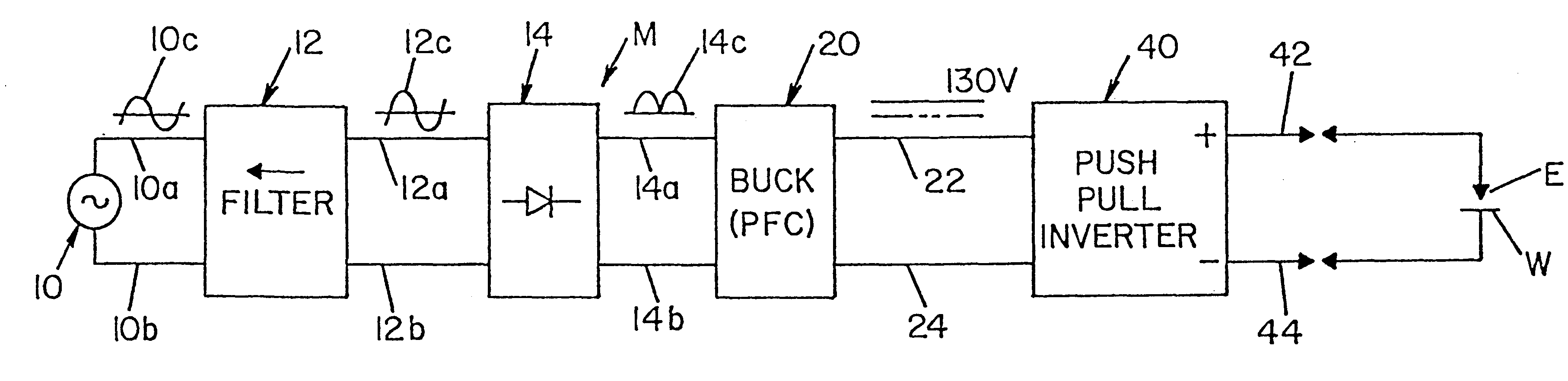

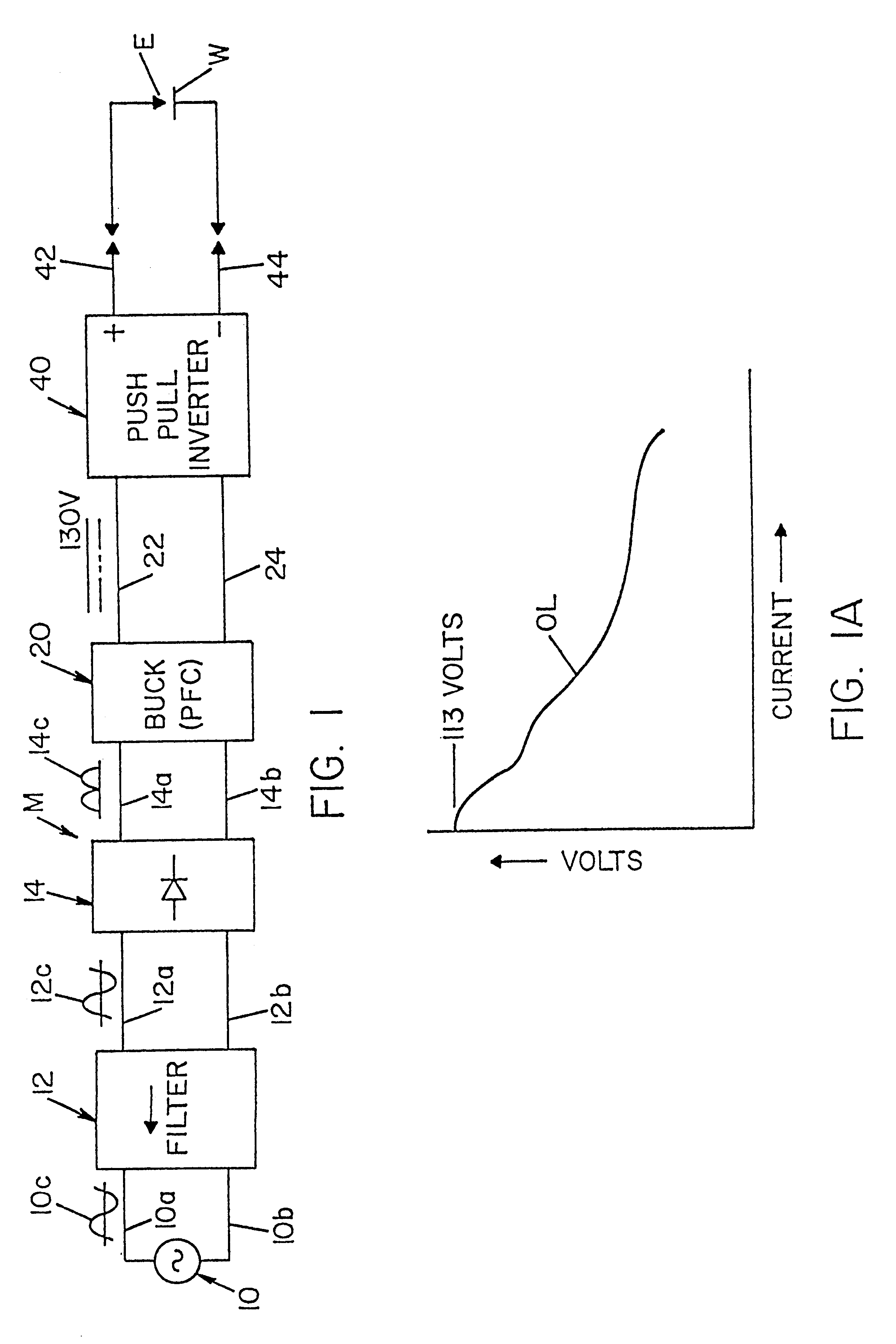

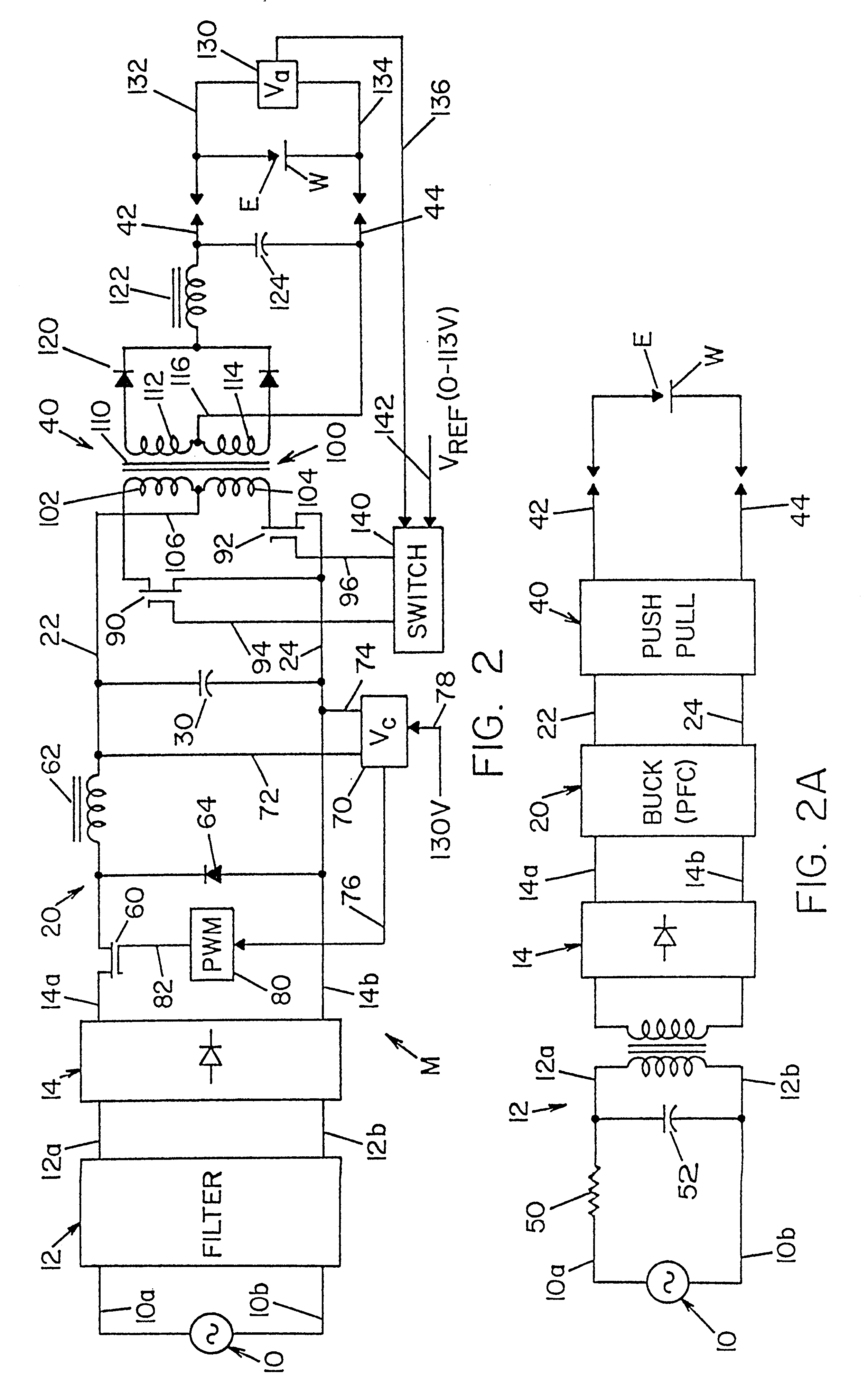

Electric ARC welder and plasma cutter

InactiveUS6023037AReduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveTransformer coupling

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

Electric arc welder and plasma cutter

InactiveUS6177645B1Reduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveEngineering

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

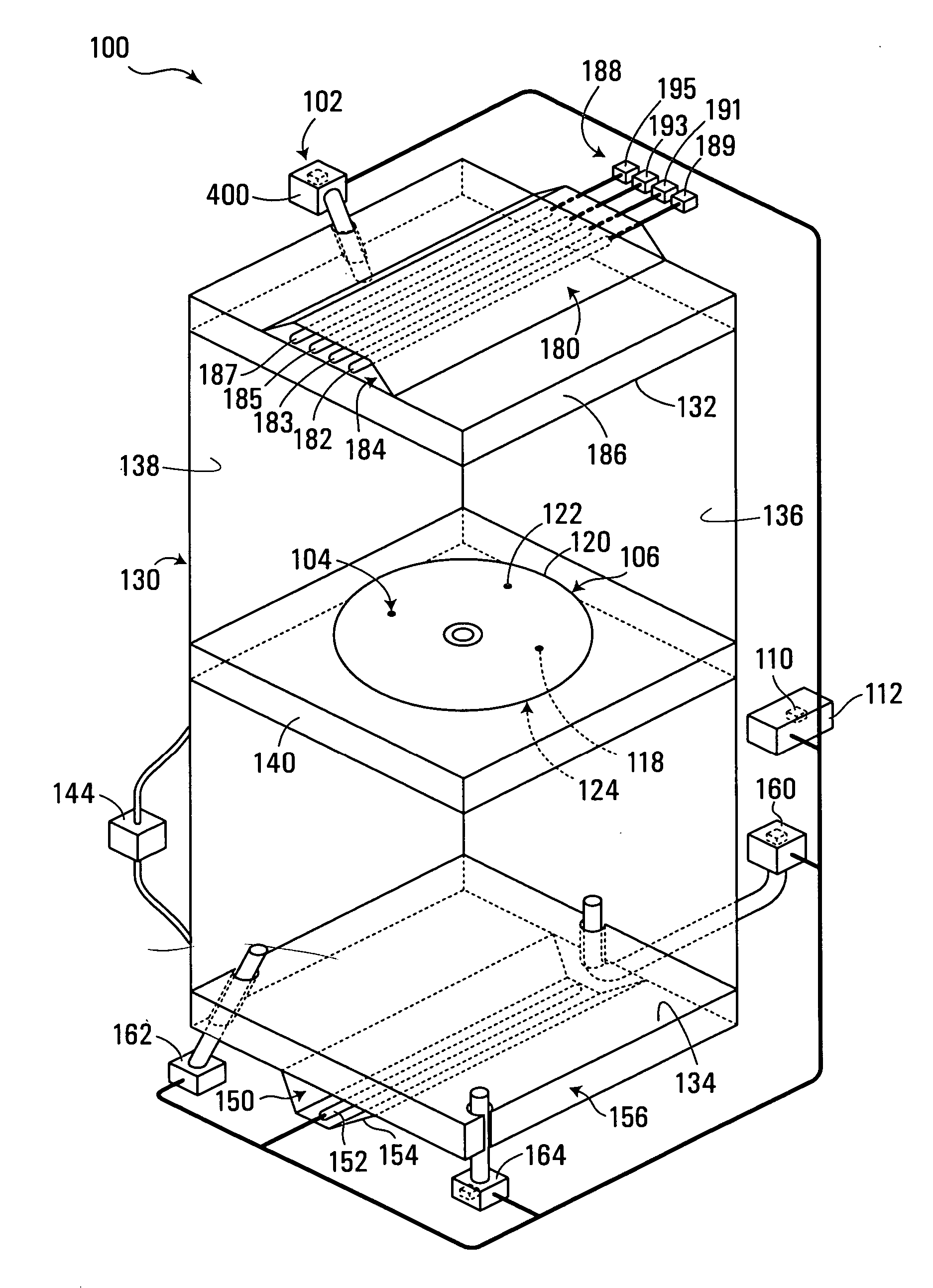

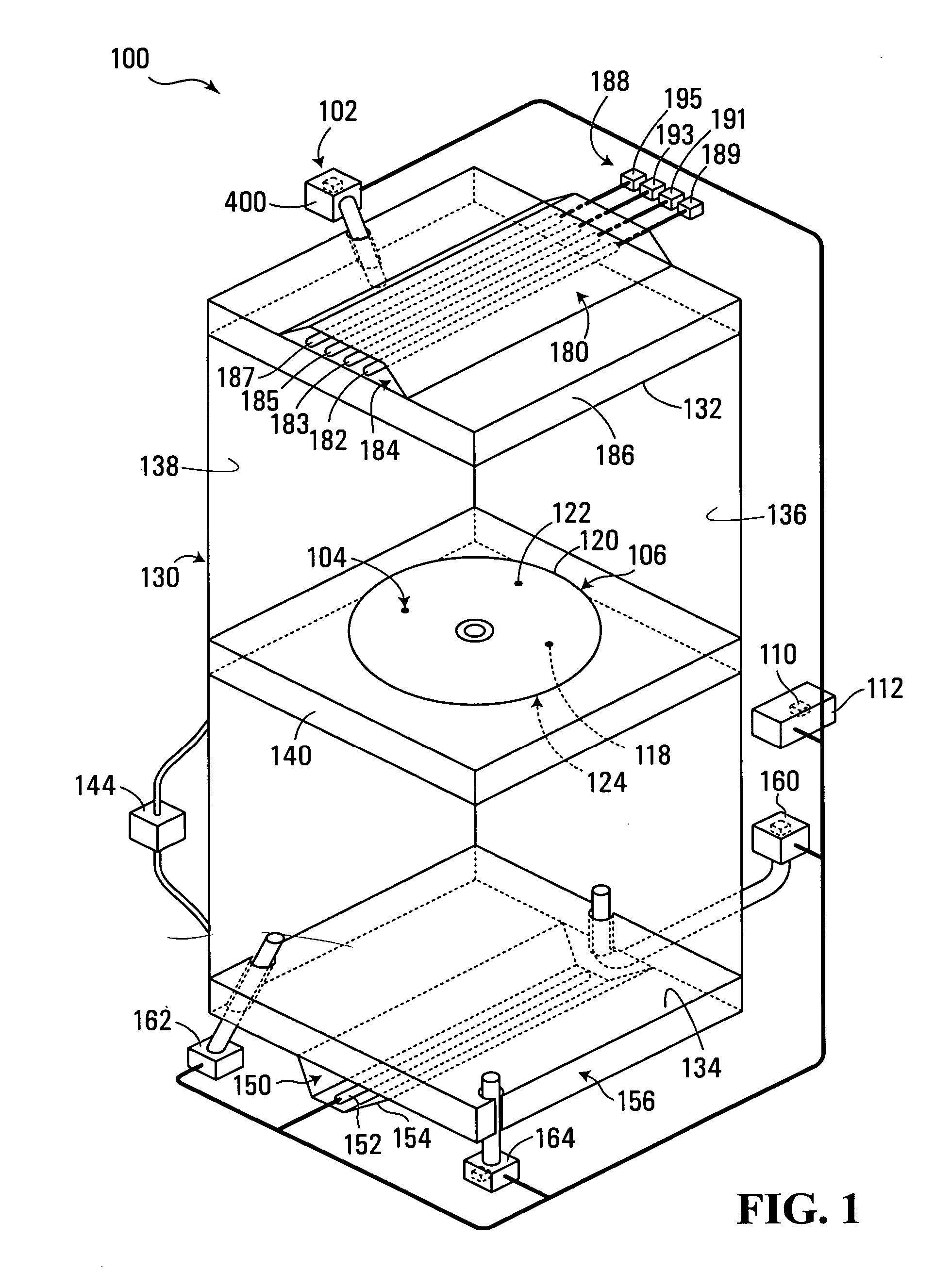

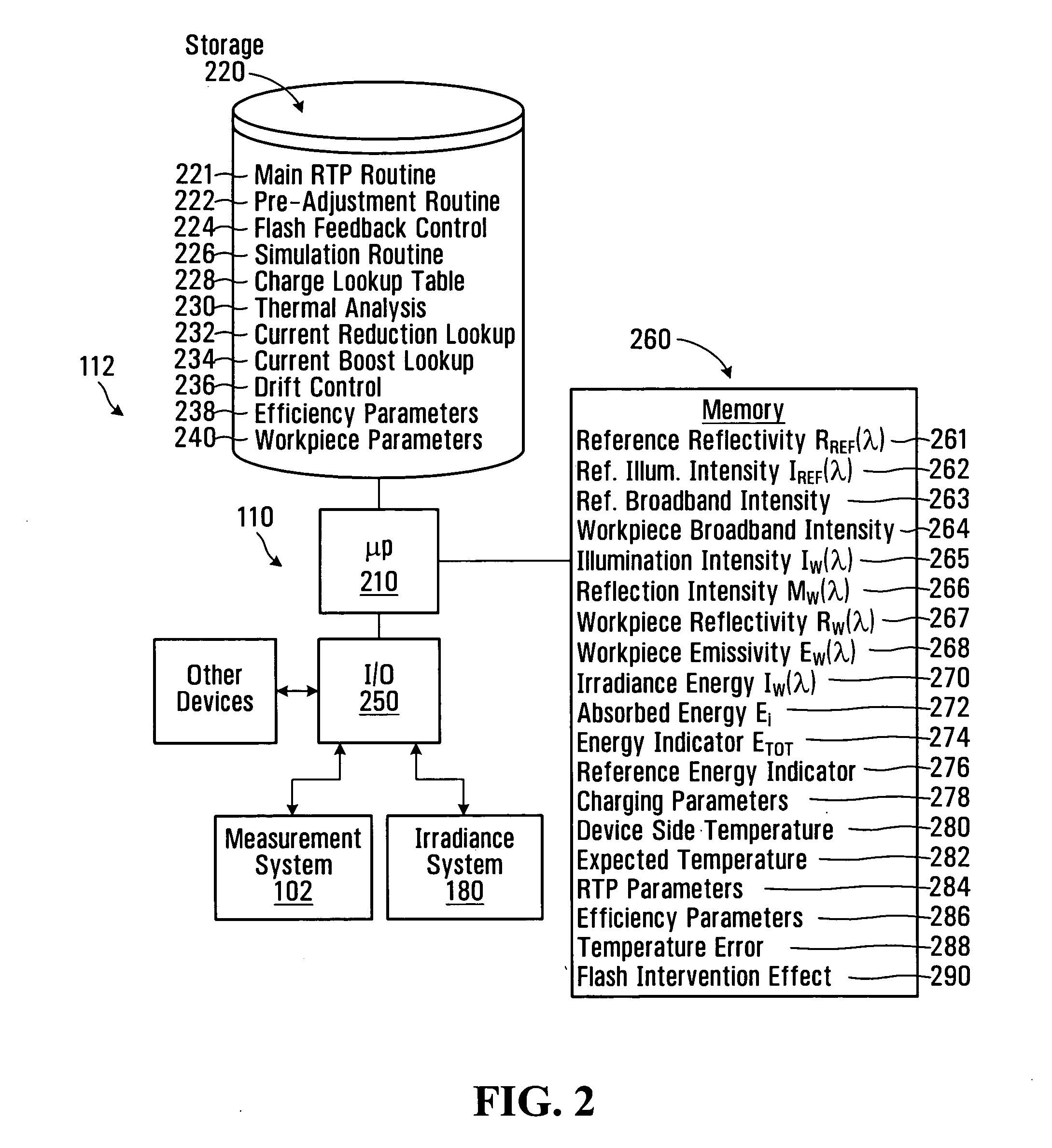

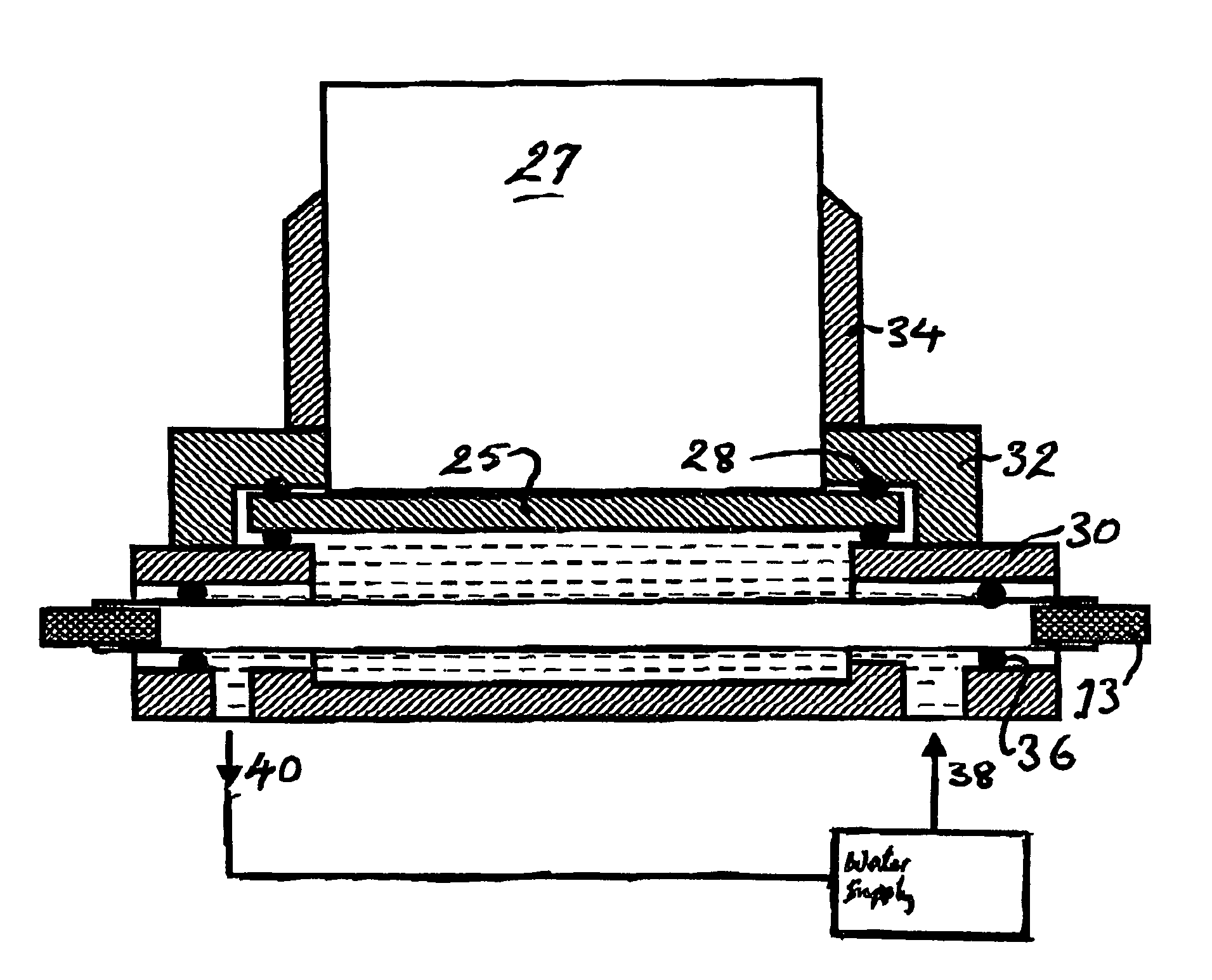

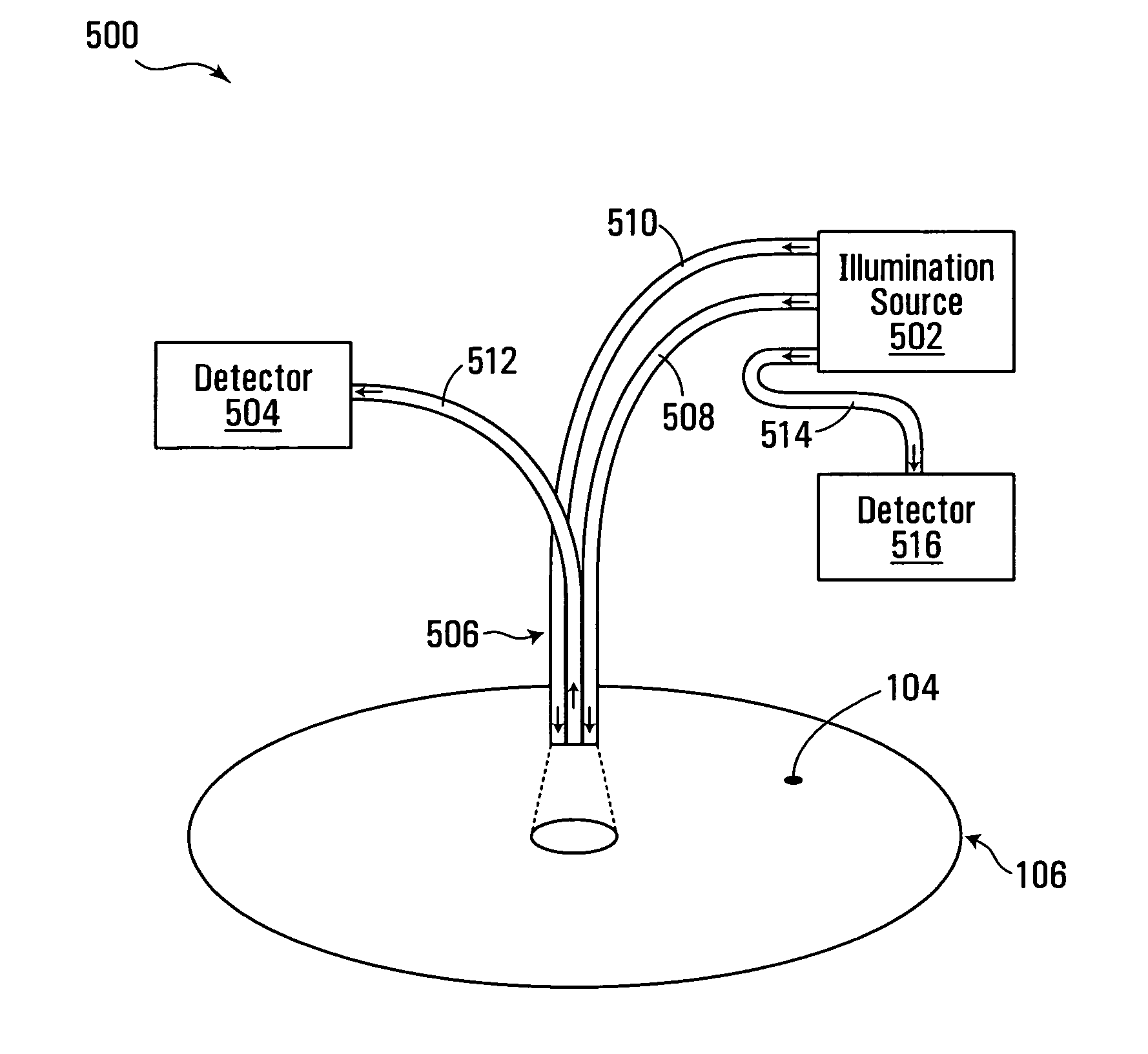

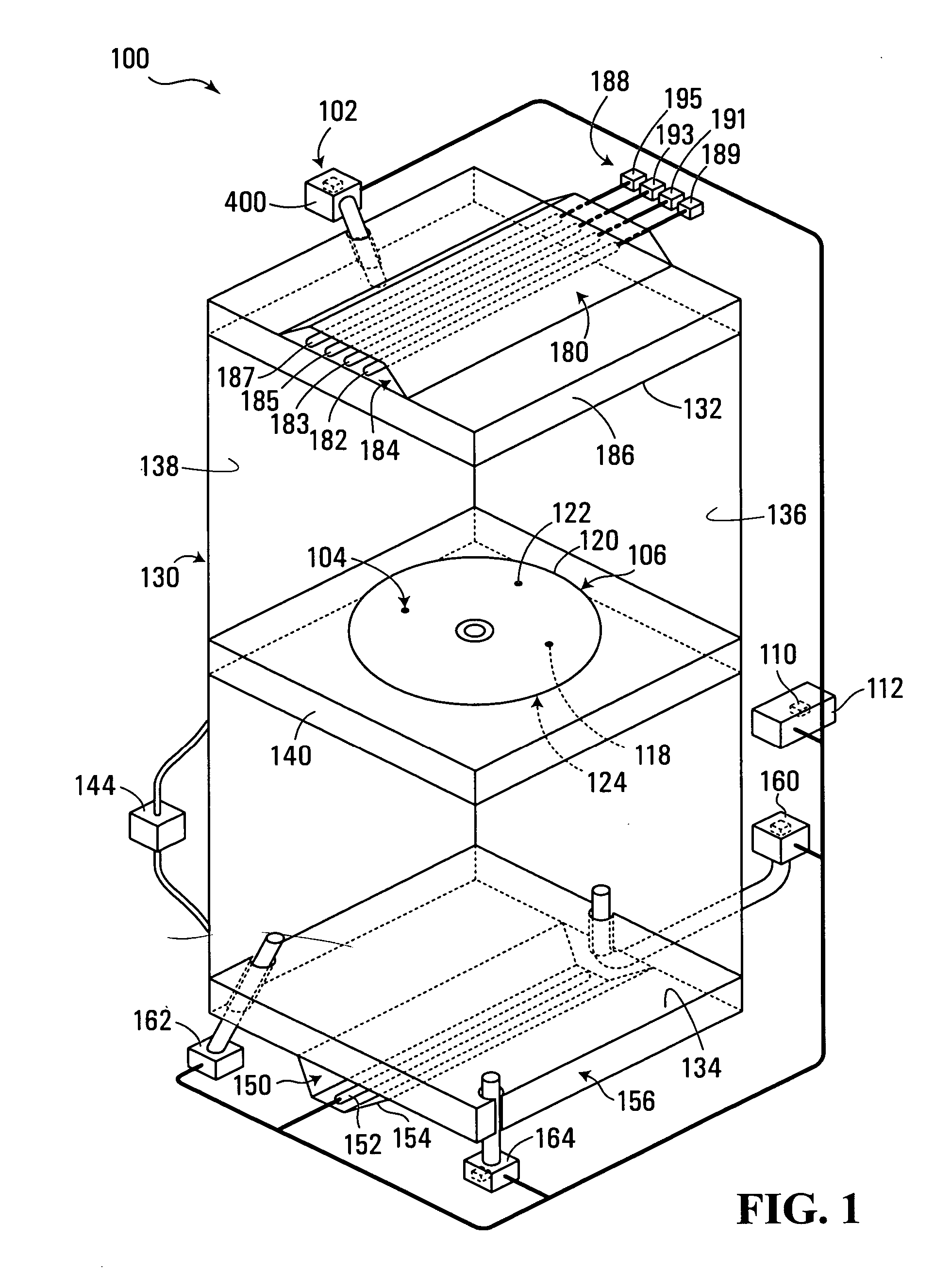

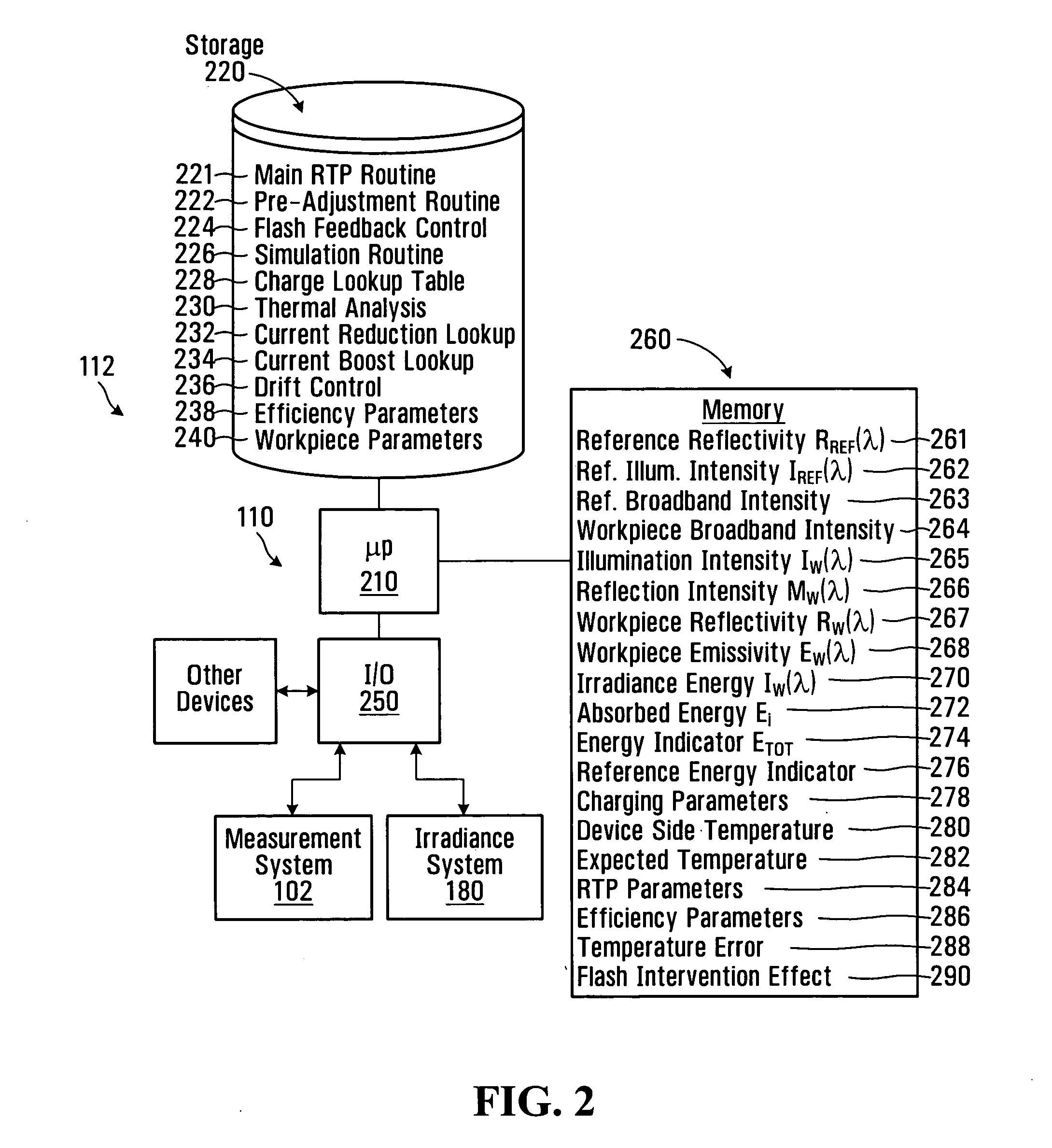

Repeatable heat-treating methods and apparatus

ActiveUS20070069161A1Weakening rangeChange efficiencyRadiation pyrometrySemiconductor/solid-state device testing/measurementTemperature controlHeating effect

A first heat-treating method involves monitoring at least one thermal efficiency parameter associated with an irradiance system configured to produce an irradiance flash incident on a surface of a workpiece, and automatically updating control information used by the irradiance system to produce the irradiance flash, in response to the monitoring of the thermal efficiency parameter. A second method involves predicting a heating effect of an irradiance flash to be incident upon a surface of a workpiece, in response to a measurement of a heating parameter of the surface, and pre-adjusting the irradiance flash, in response to the predicted heating effect. A third method involves measuring a temperature of a surface of a workpiece during an initial portion of an irradiance flash incident on the surface, and controlling a power of a remaining portion of the irradiance flash, in response to the temperature.

Owner:MATTSON TECHNOLOGY +1

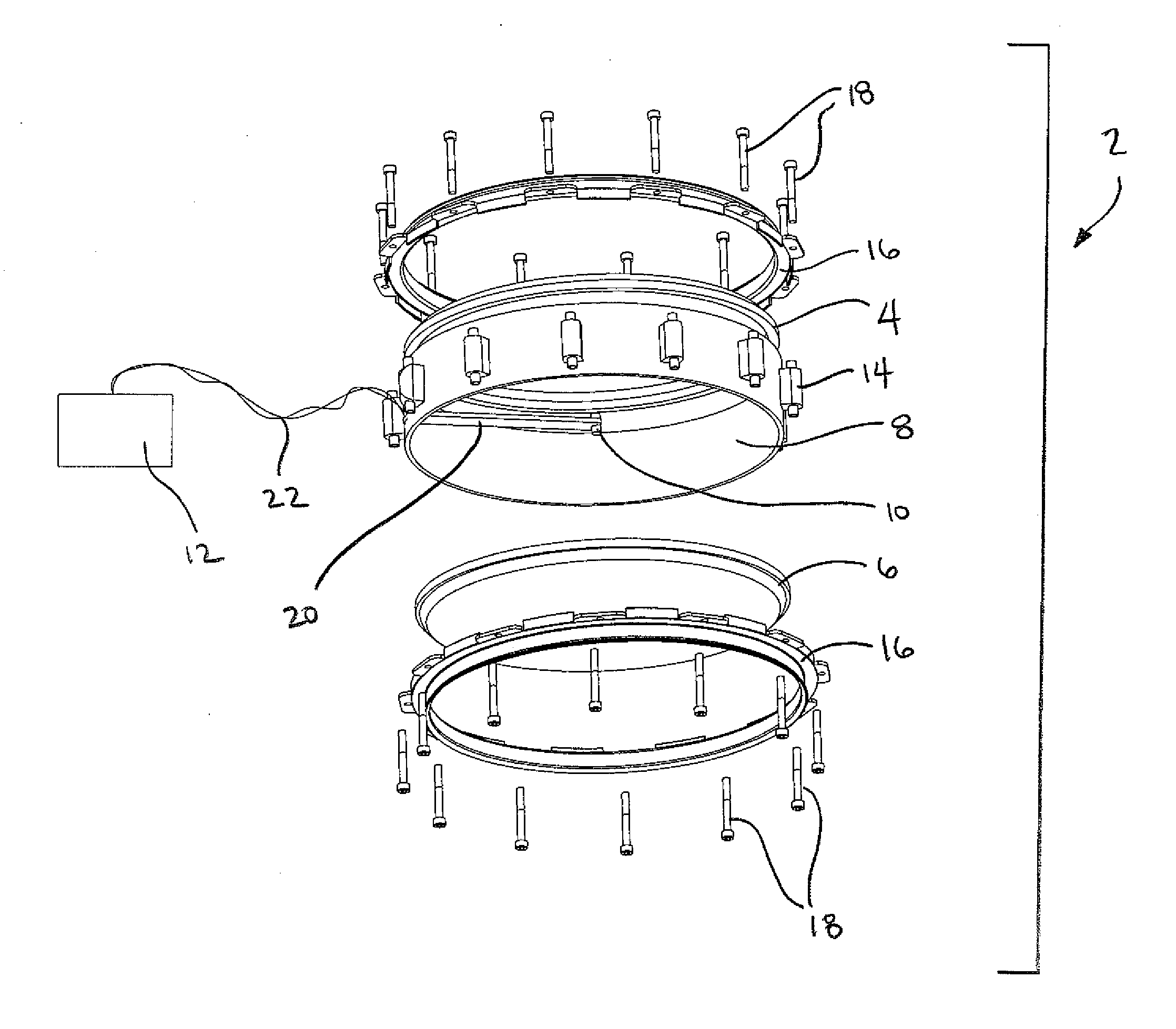

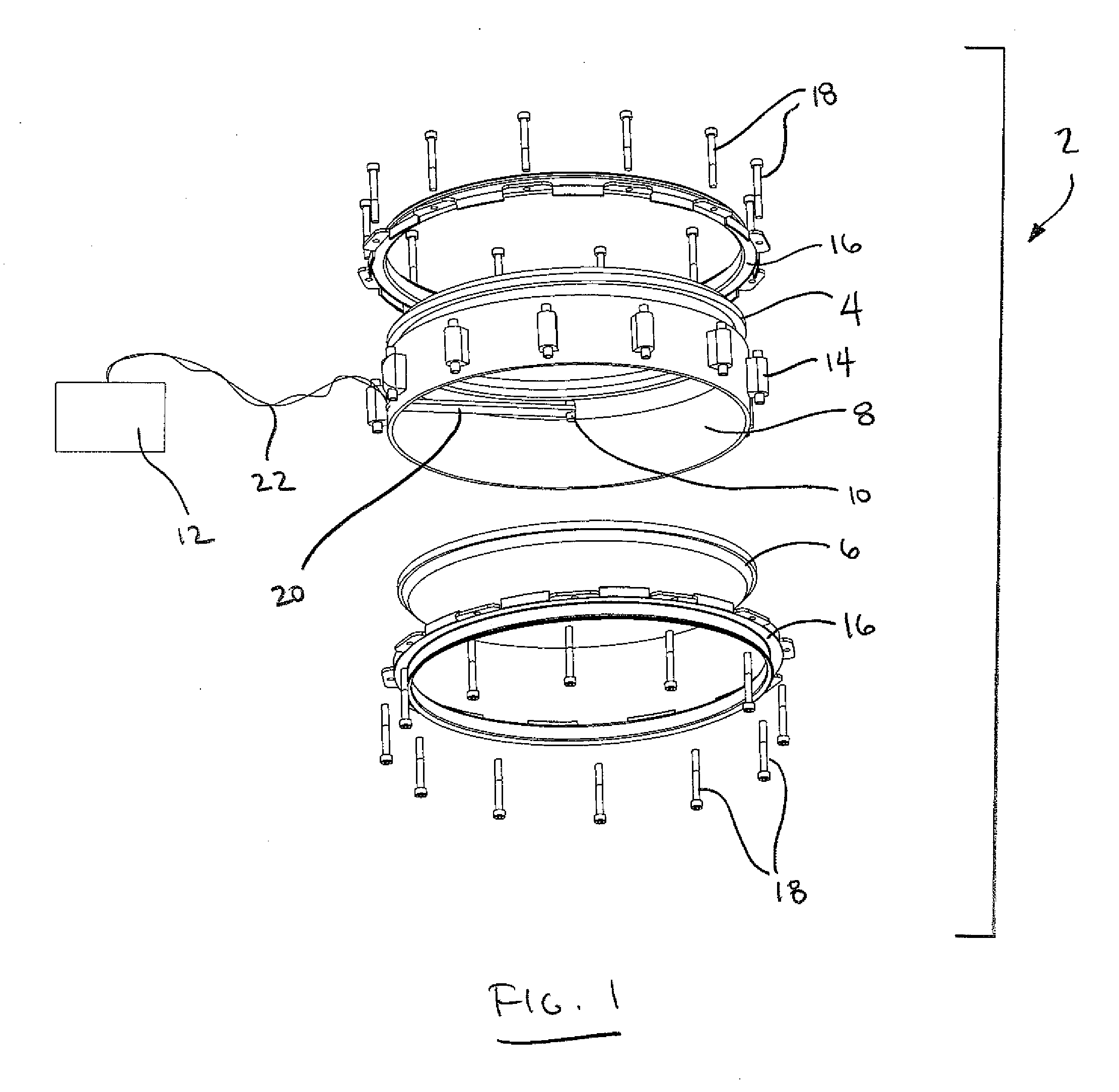

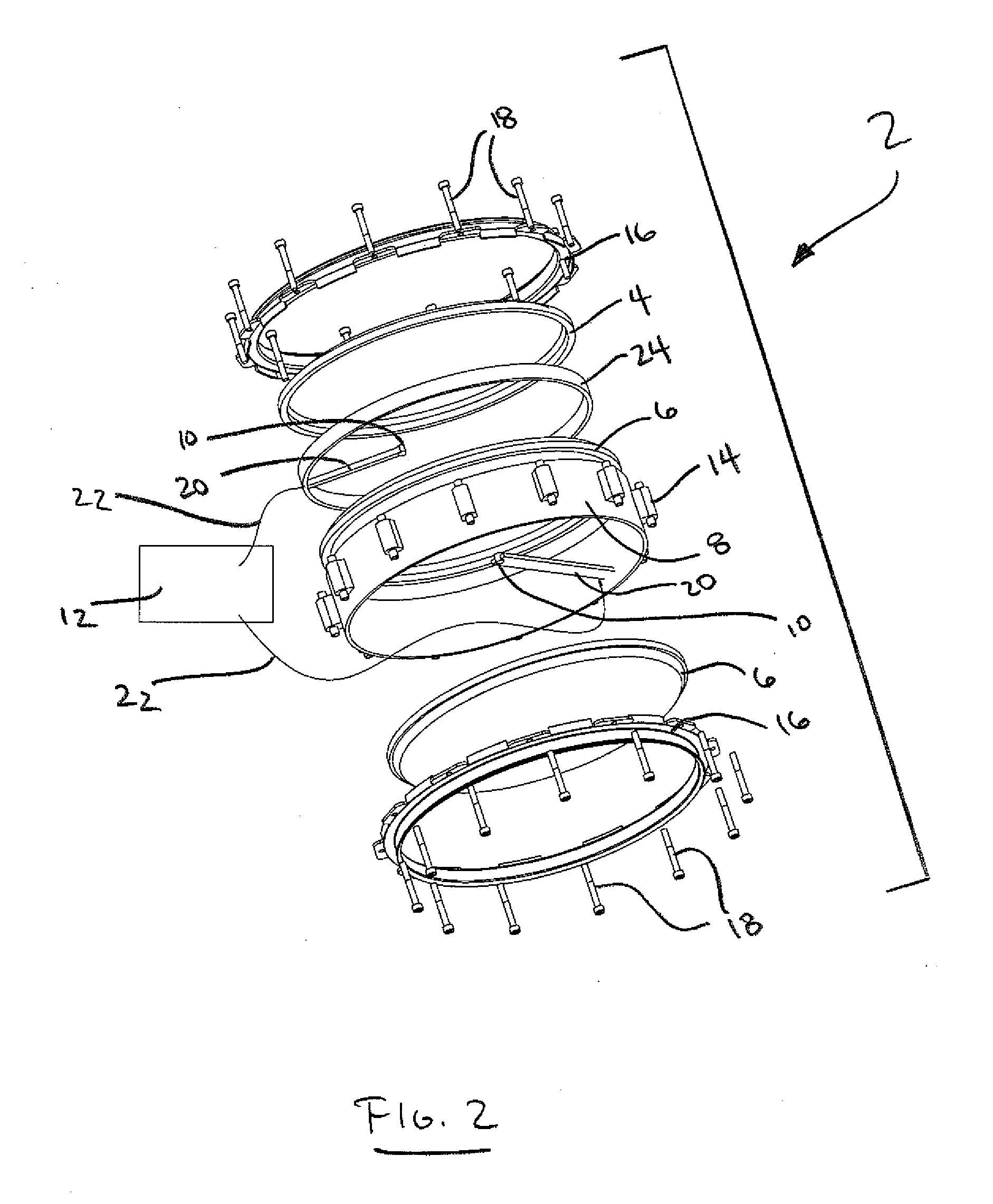

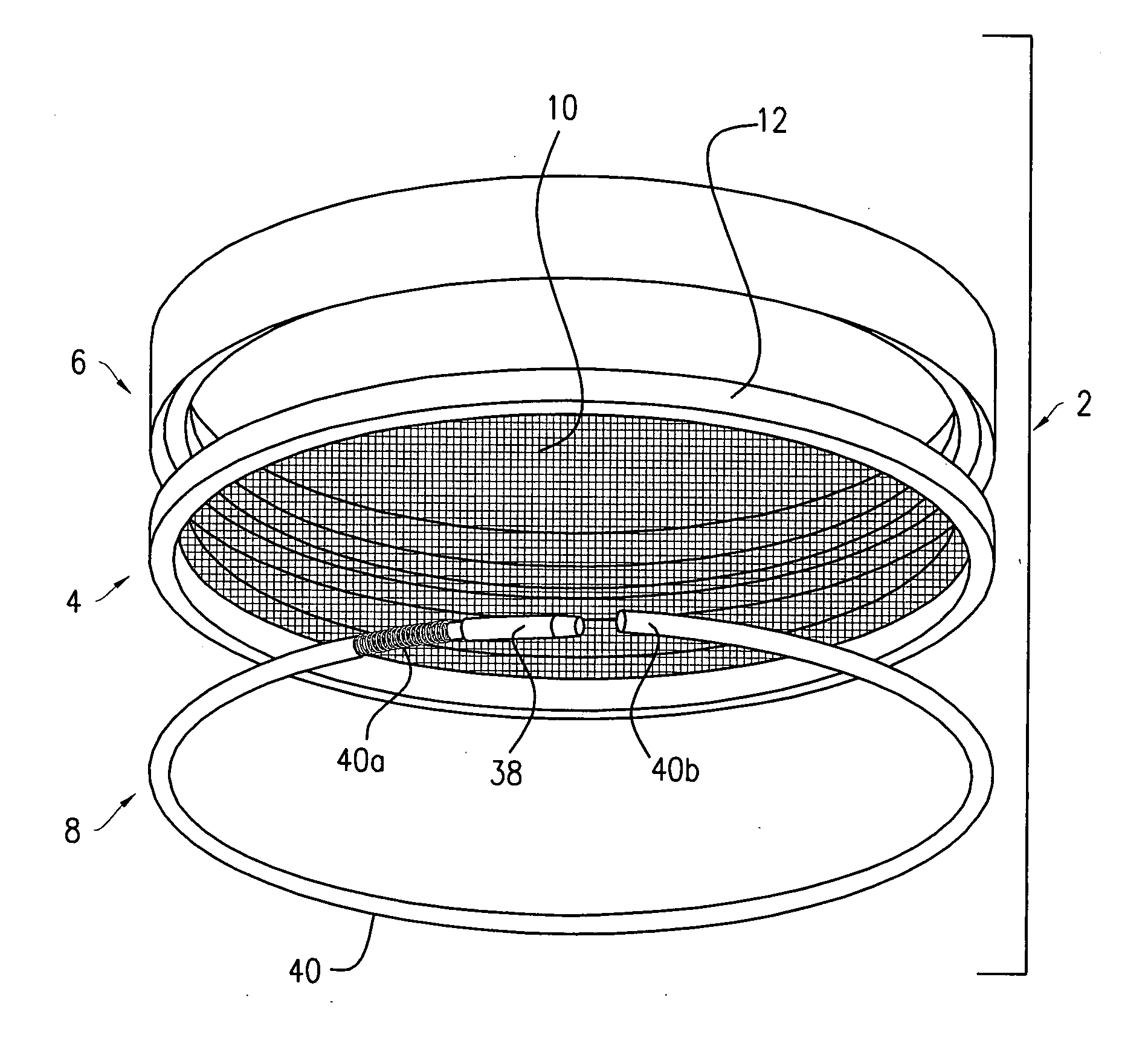

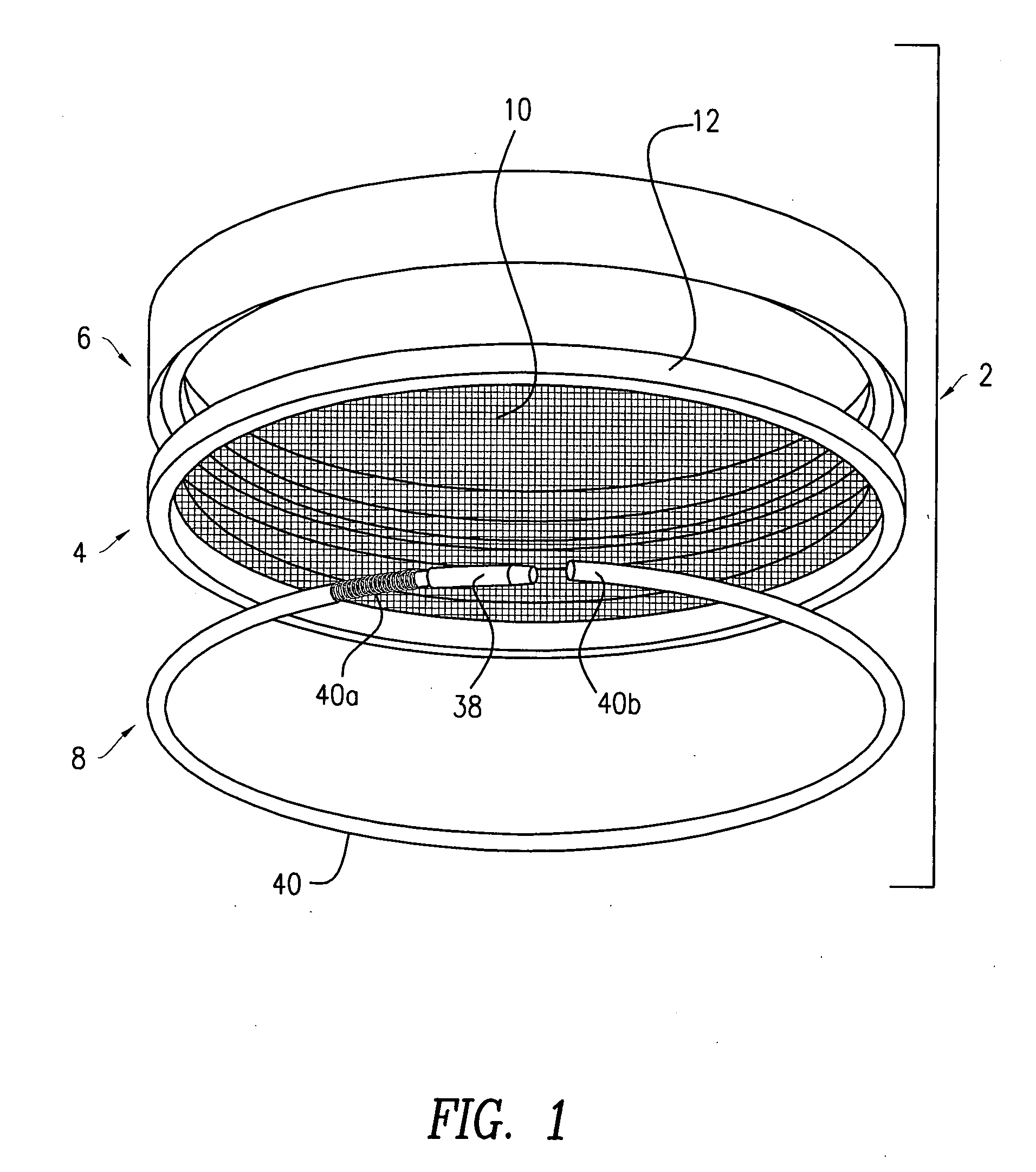

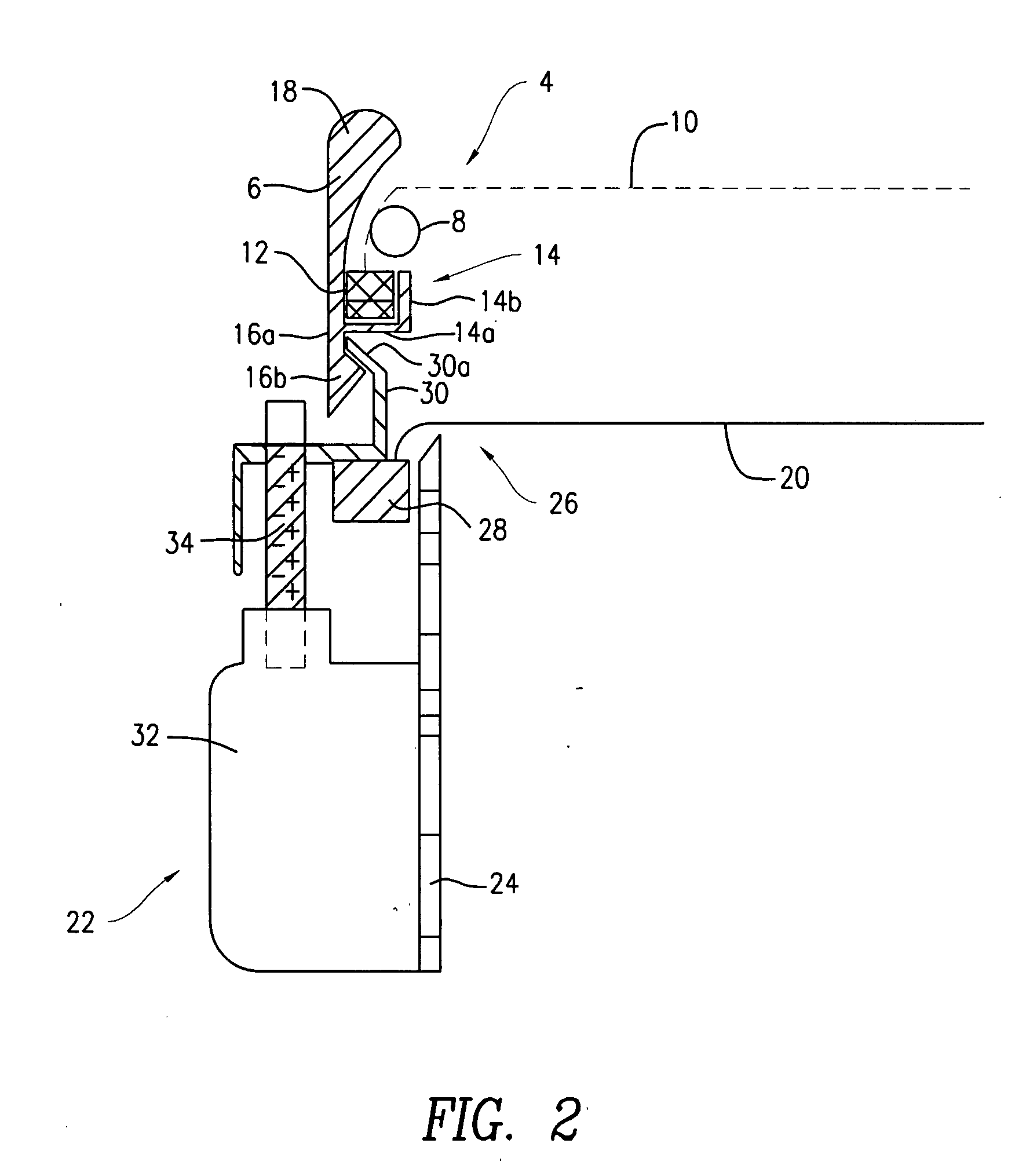

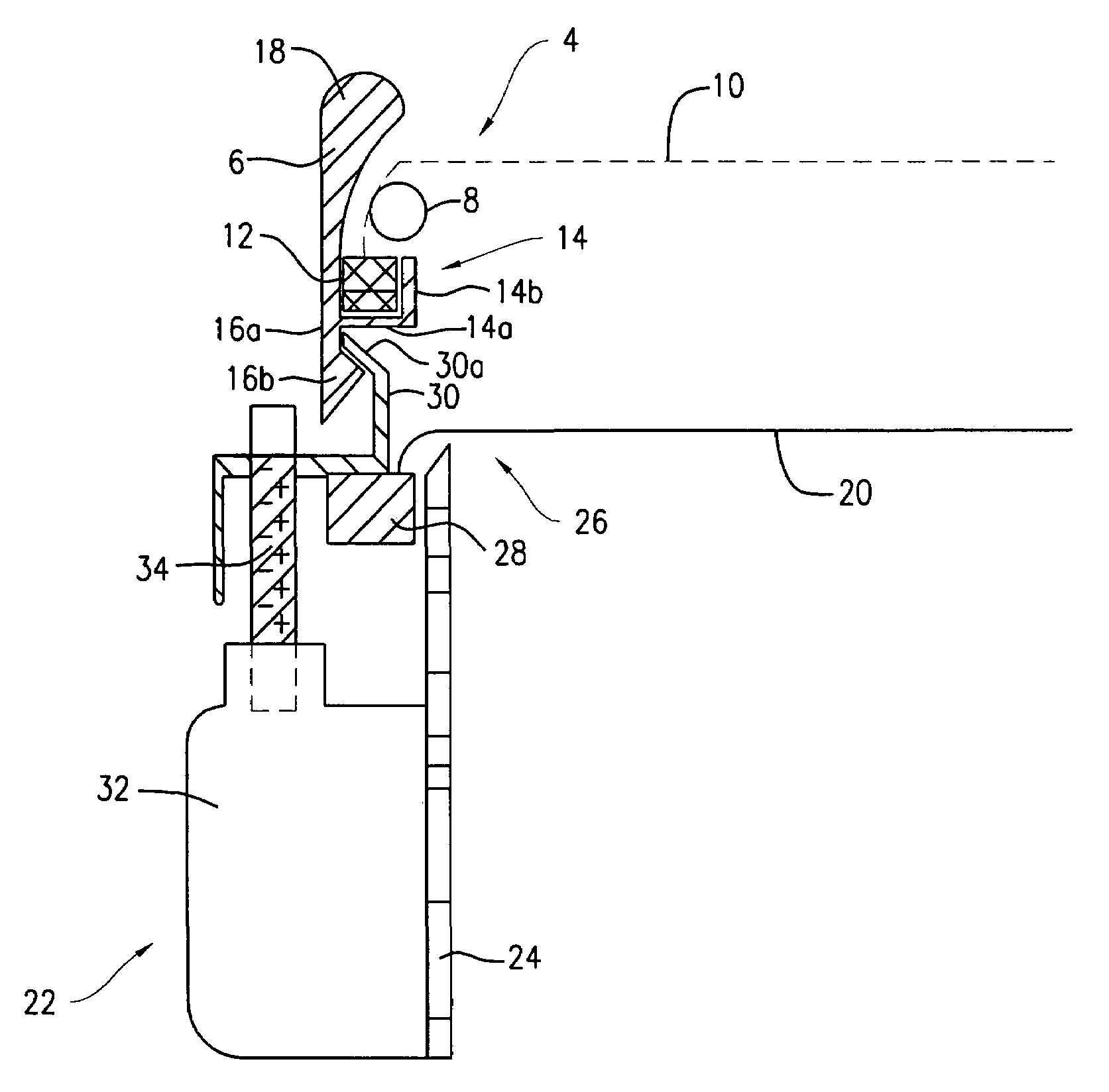

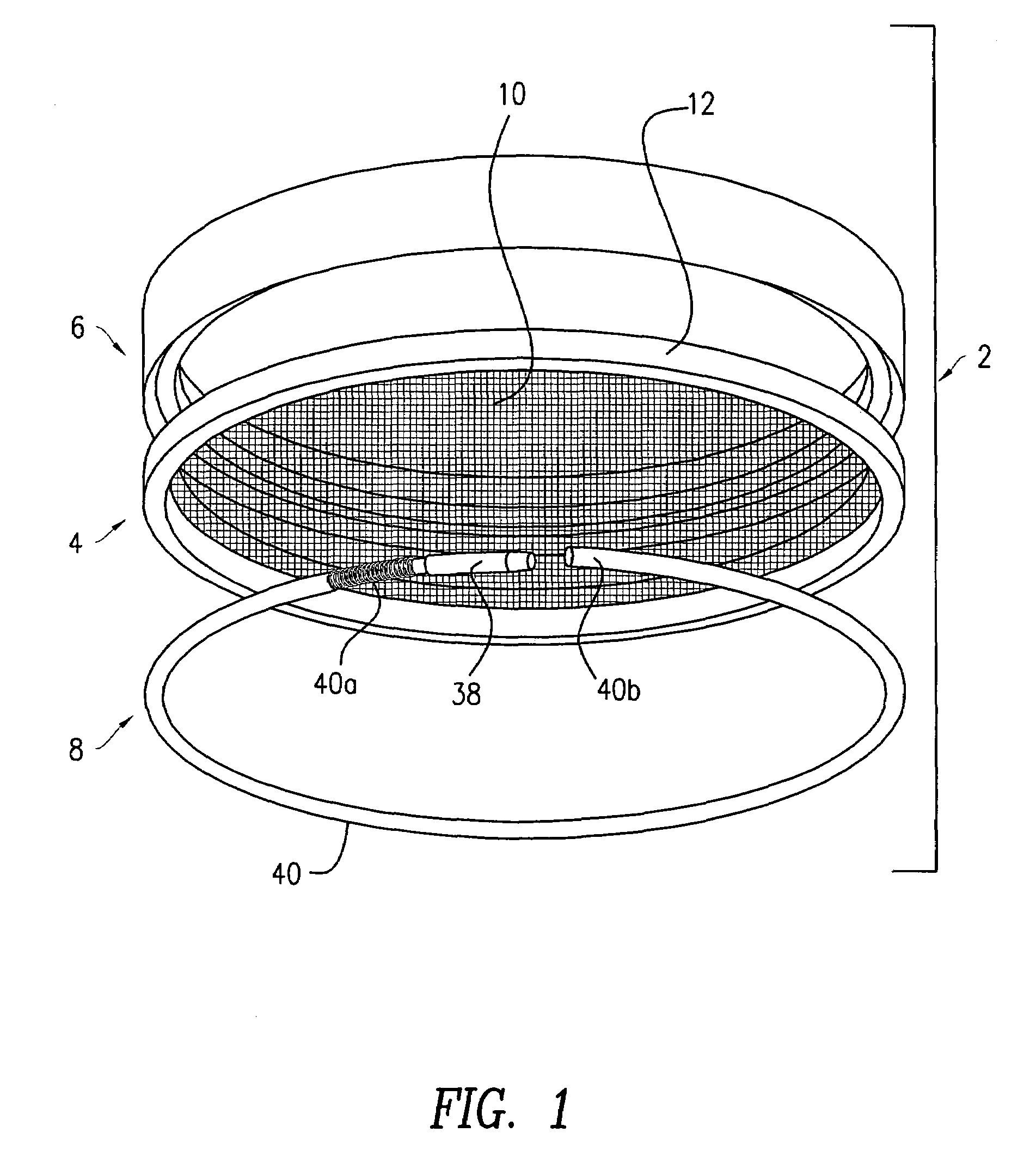

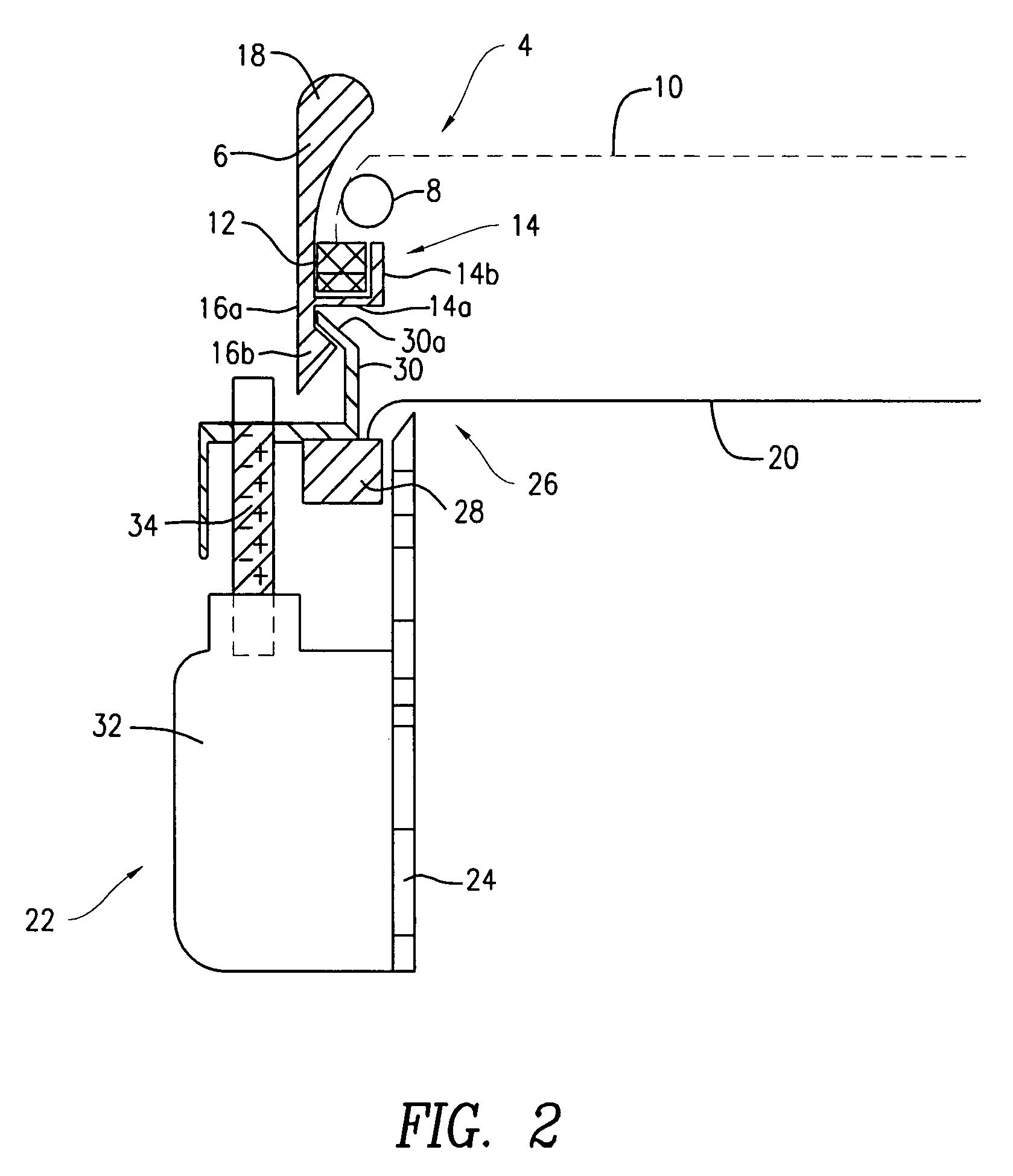

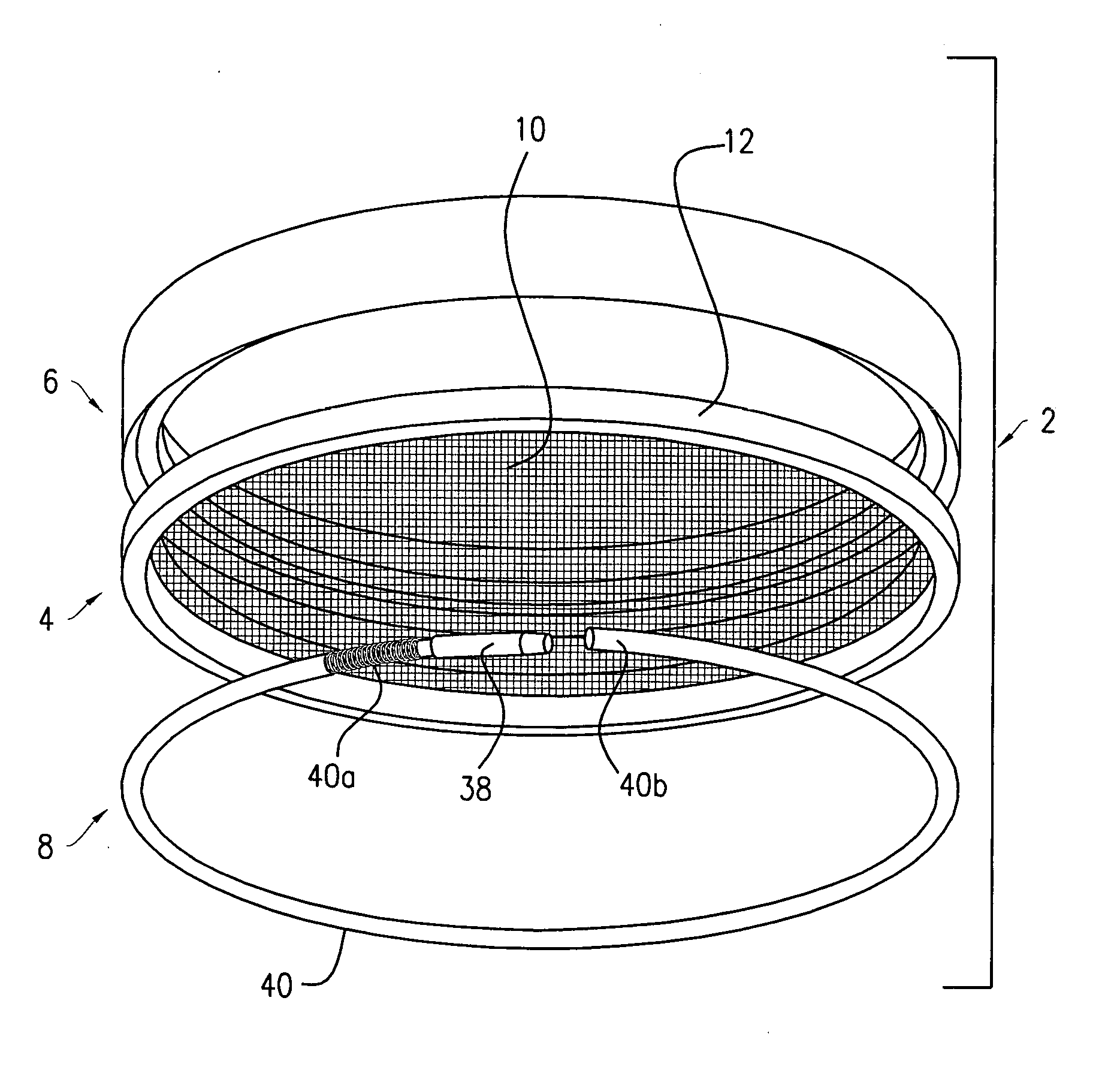

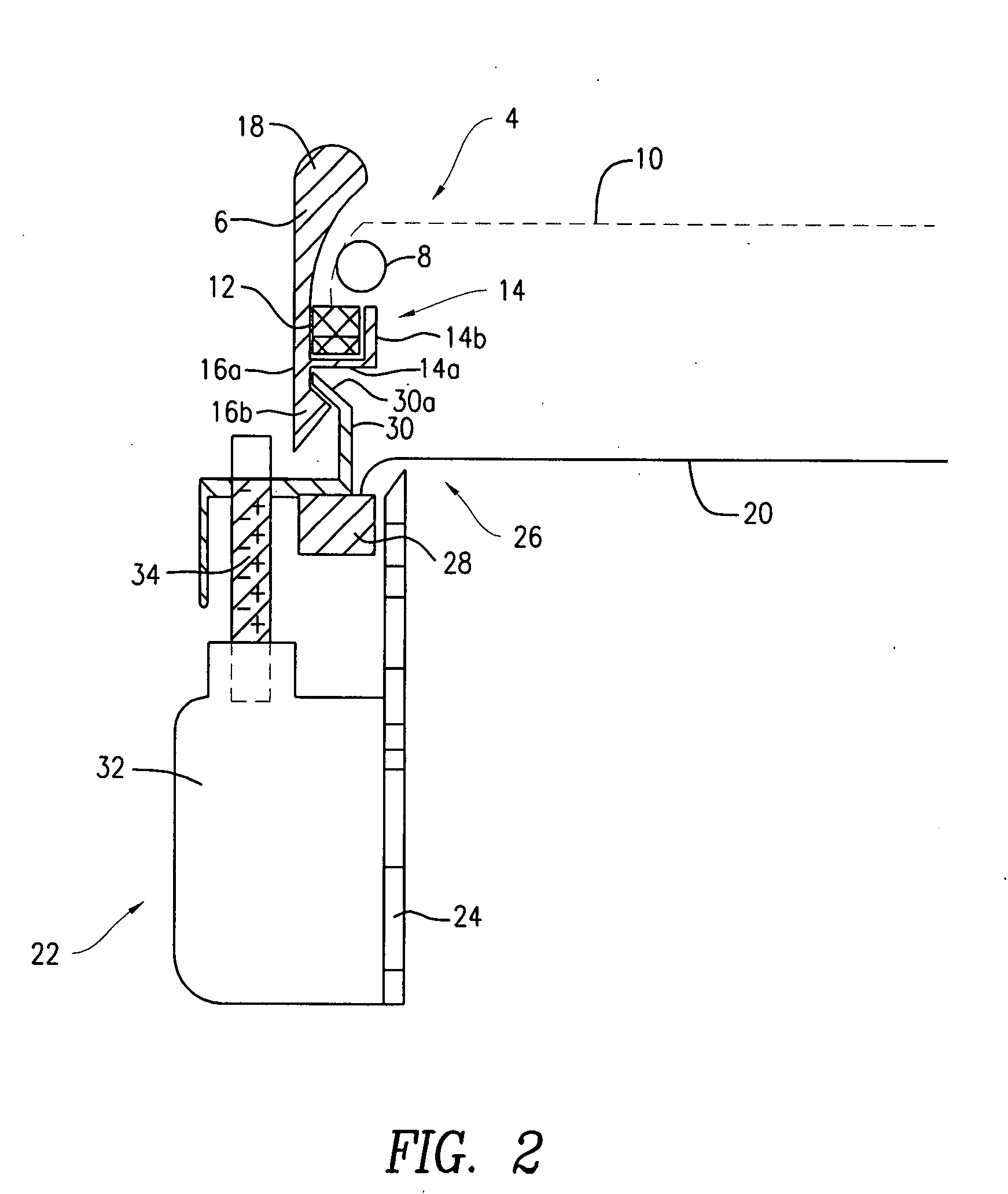

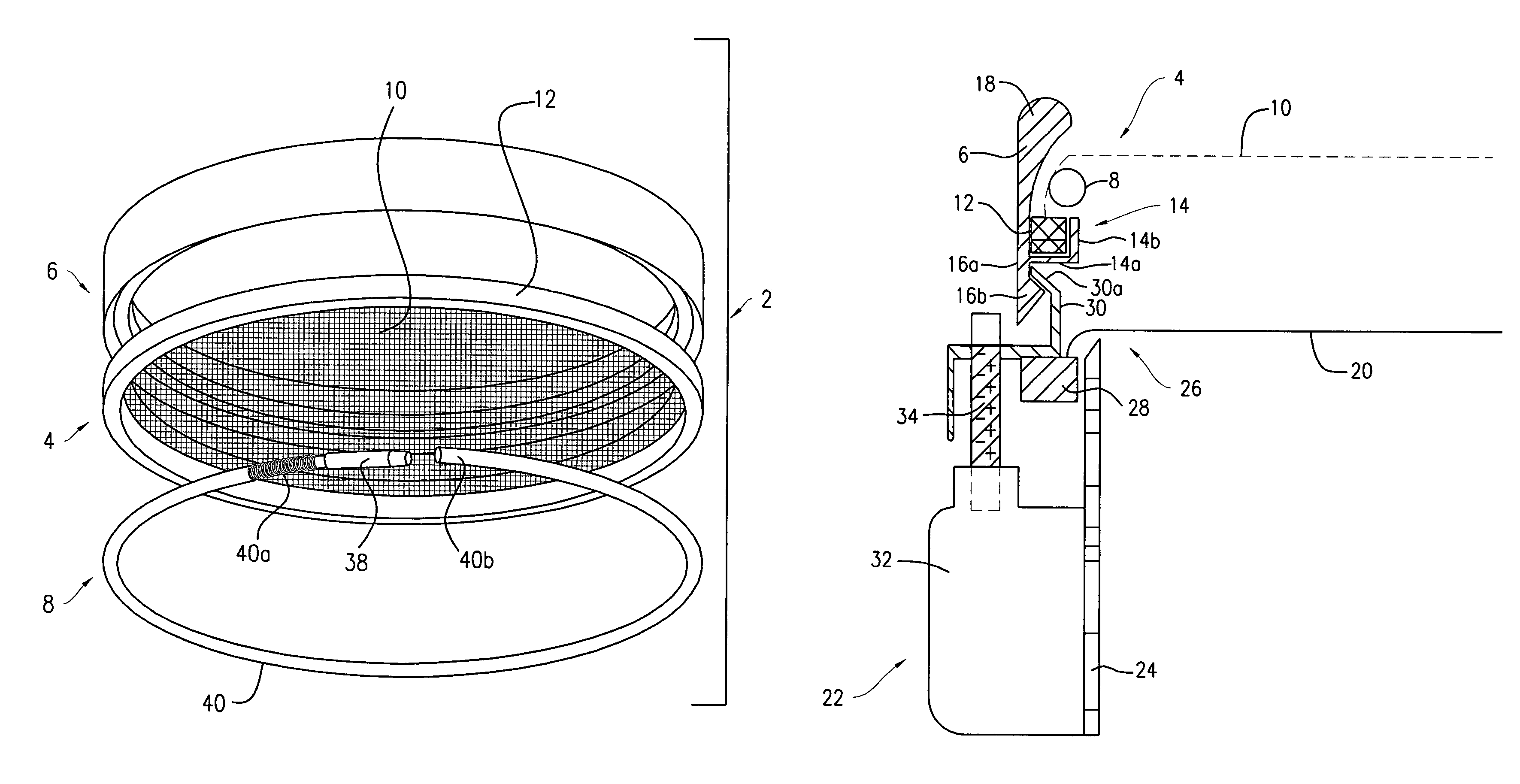

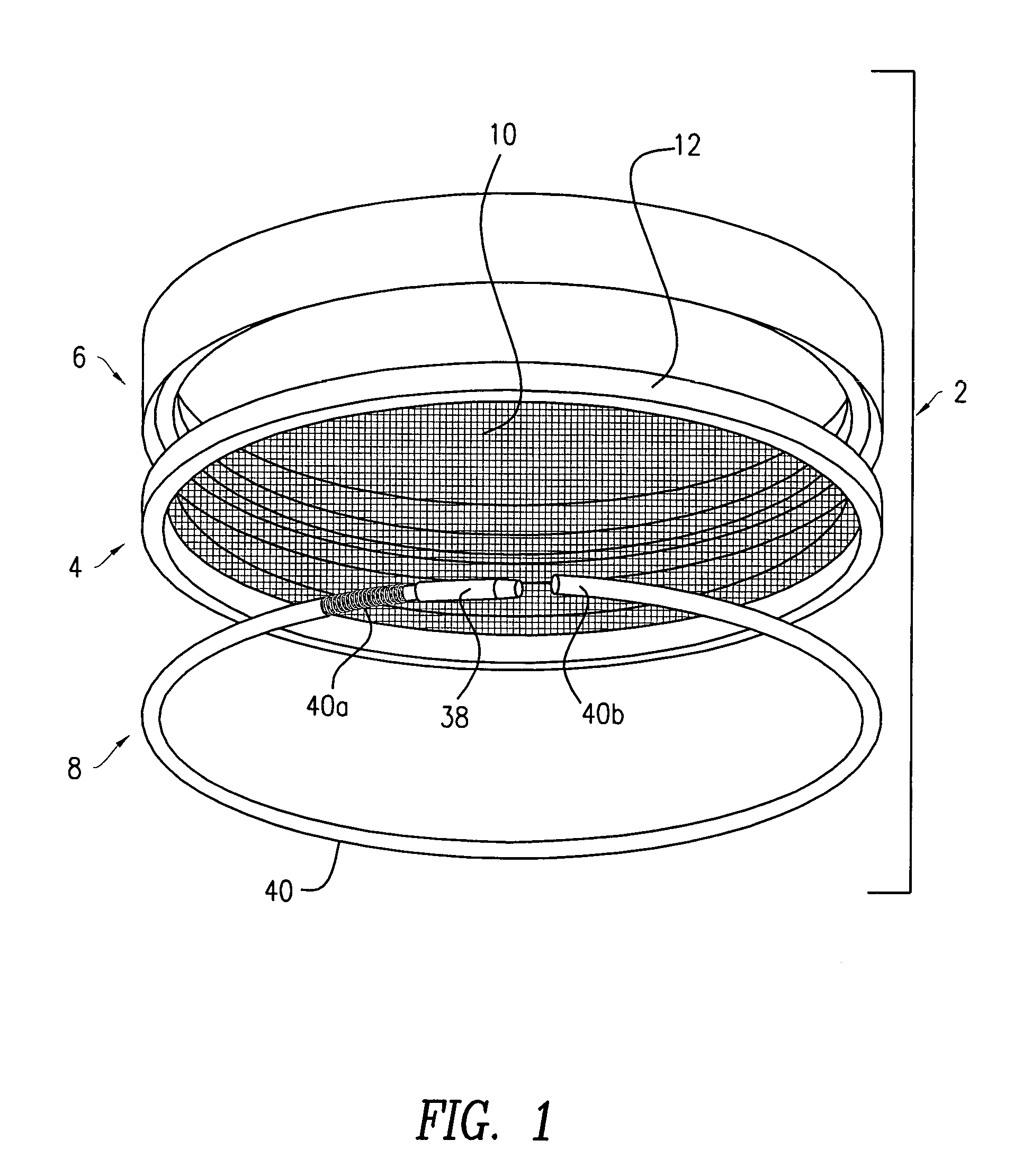

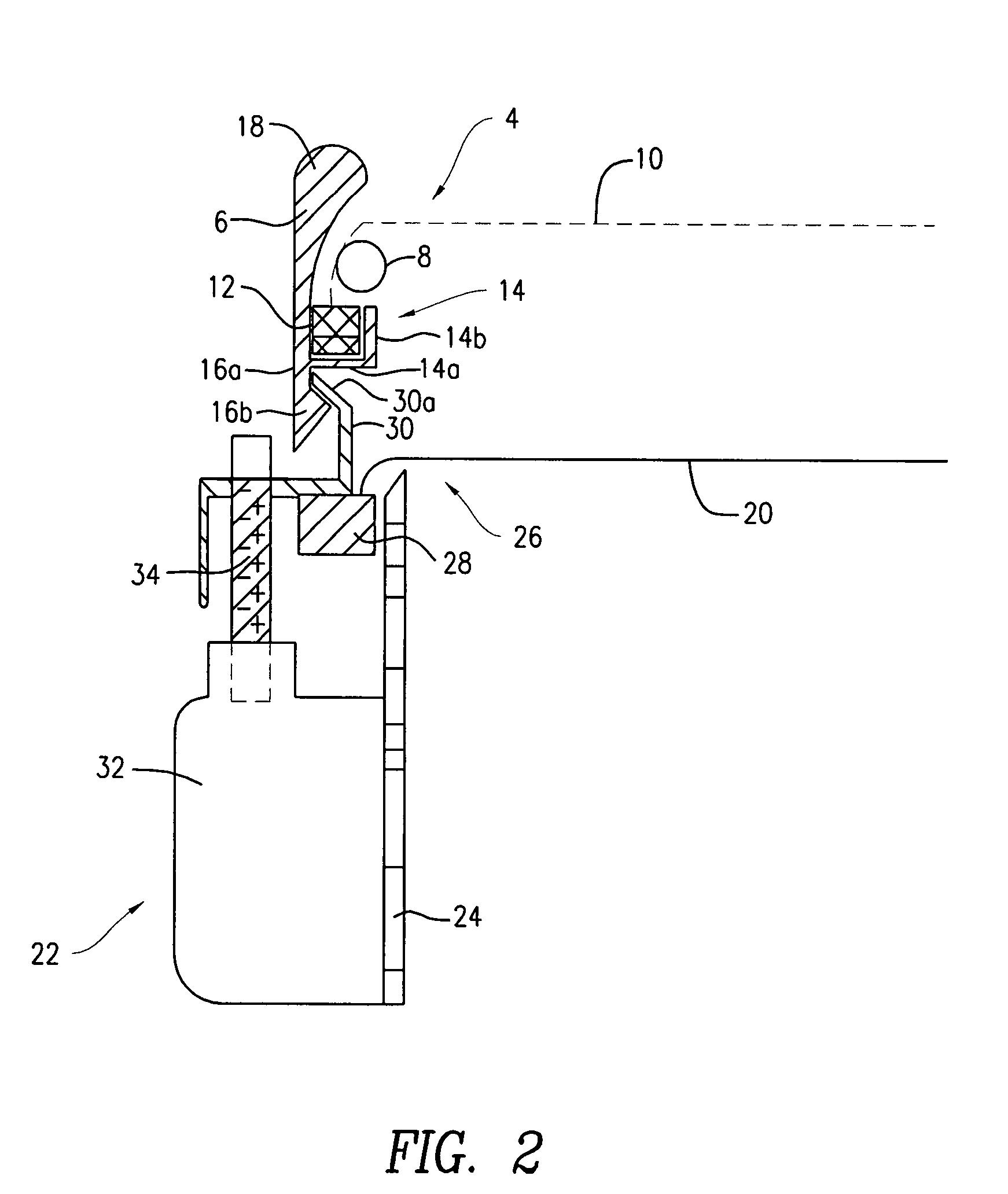

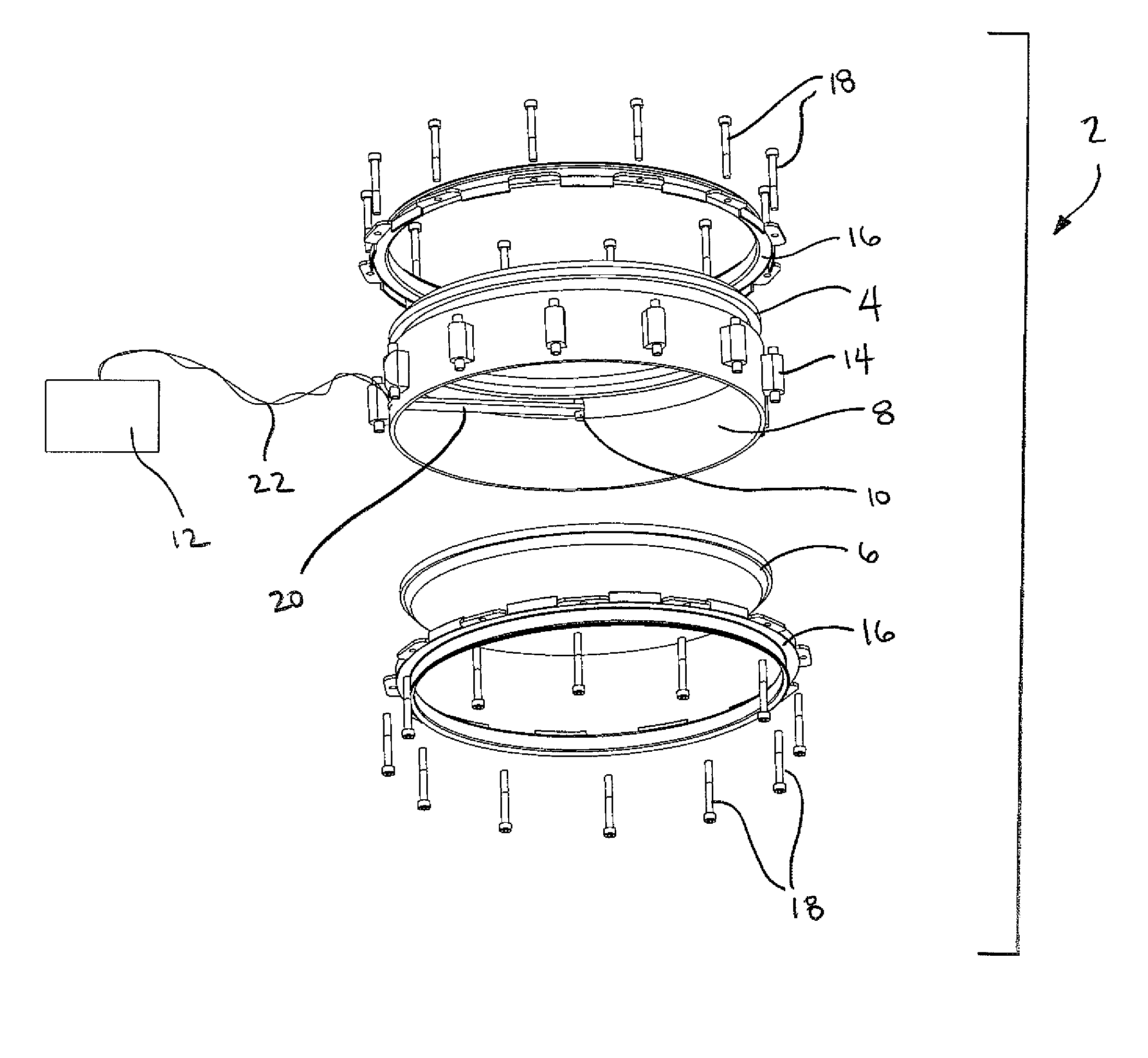

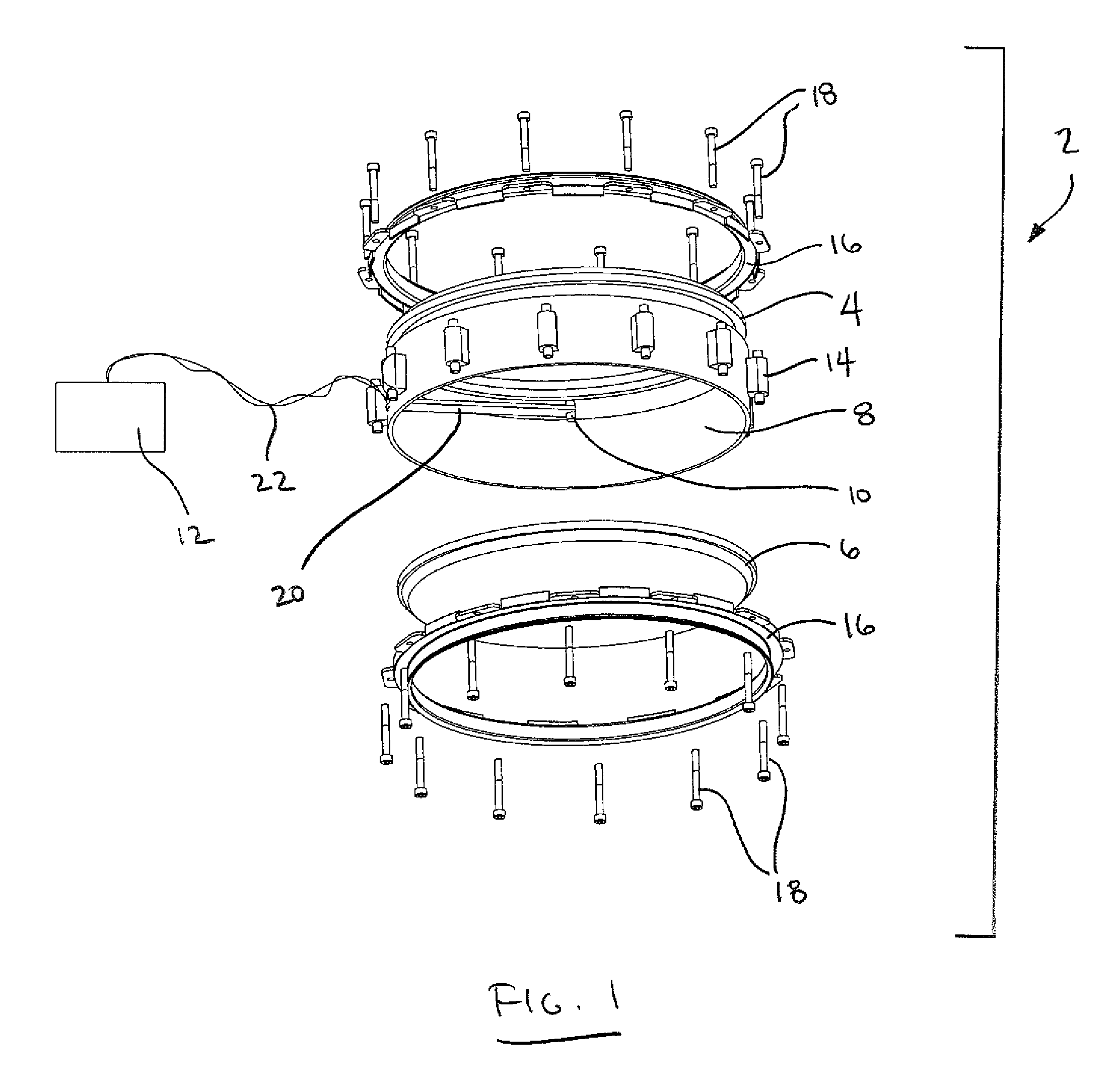

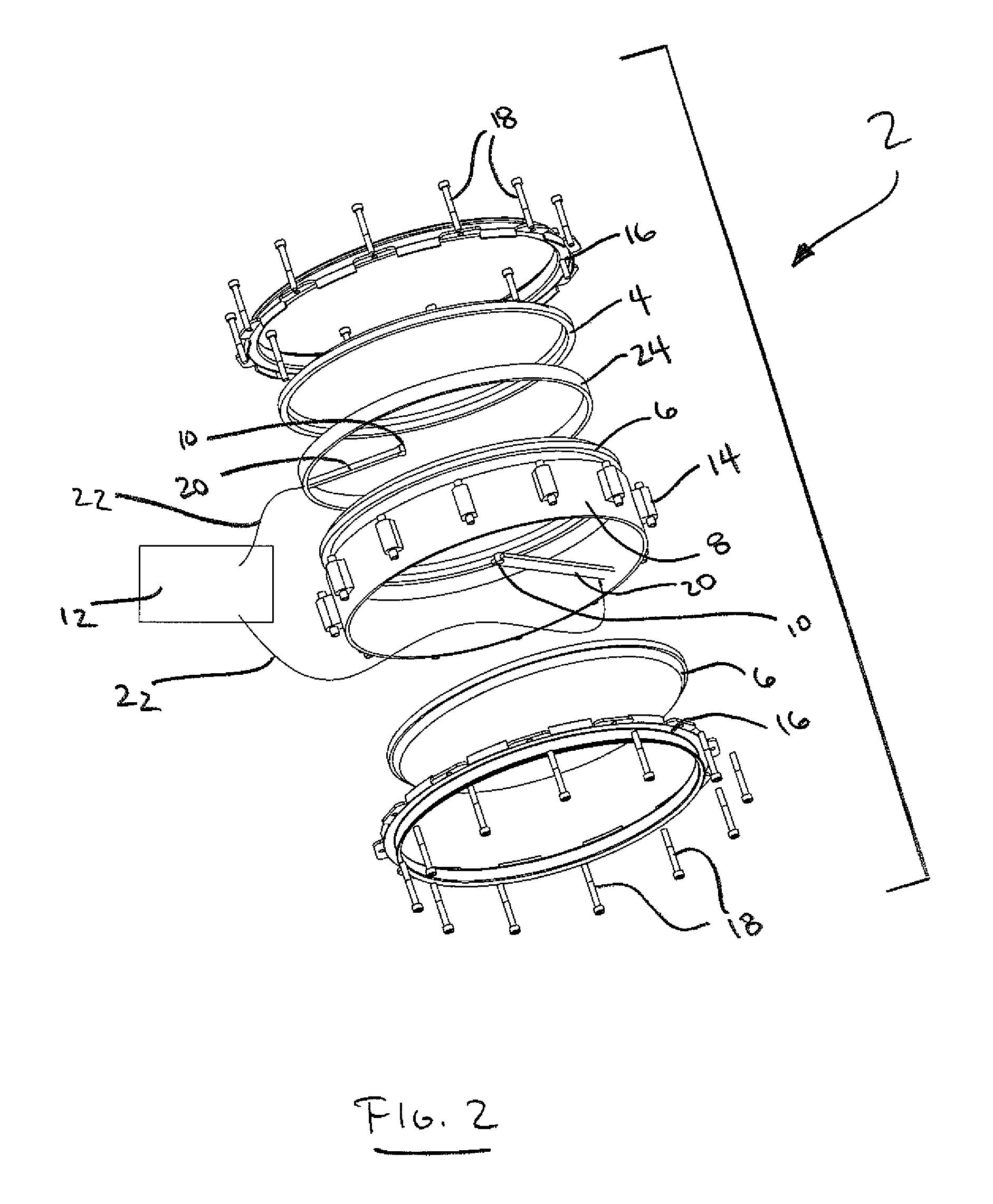

Acoustic/electronic drum assembly

InactiveUS20130112068A1Maintenance characteristicMaintain dynamic rangeElectrophonic musical instrumentsPercussion musical instrumentsEngineeringAcoustic membrane

An acoustic / electronic drum assembly comprising a mesh batter drumhead comprising a mesh membrane and an annular ring, a resonant drumhead comprising an acoustic membrane and an annular ring, the acoustic membrane capable of creating acoustic sound in response to a force applied to the mesh batter drumhead, an annular shell member for maintaining the mesh batter drumhead in fixed relation to the resonant drumhead, and a pick-up acoustically coupled to at least the resonant drumhead for picking up the acoustic sound and creating an electrical signal.

Owner:RTOM CORP CORP

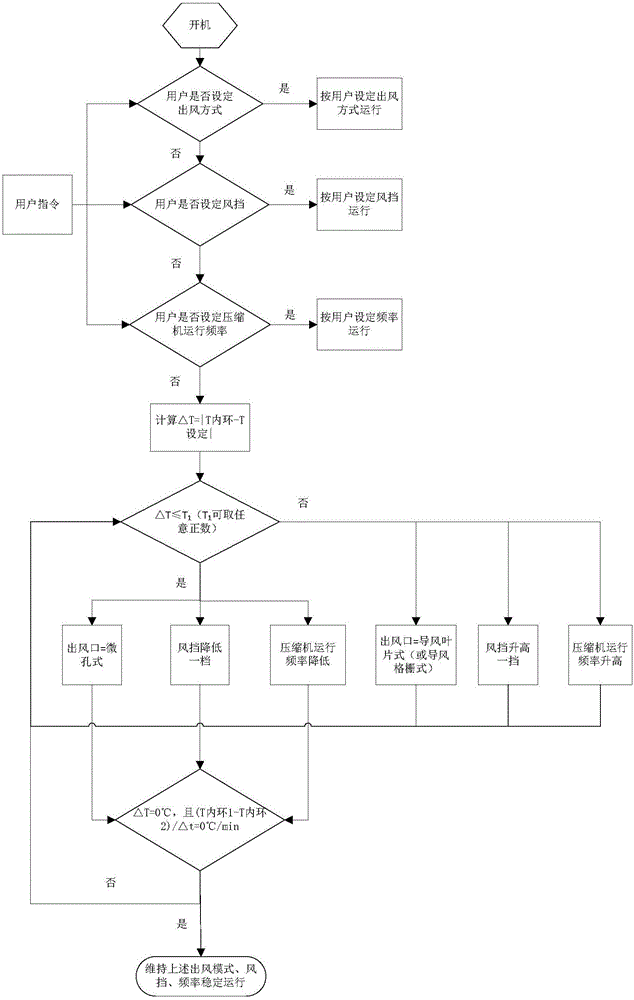

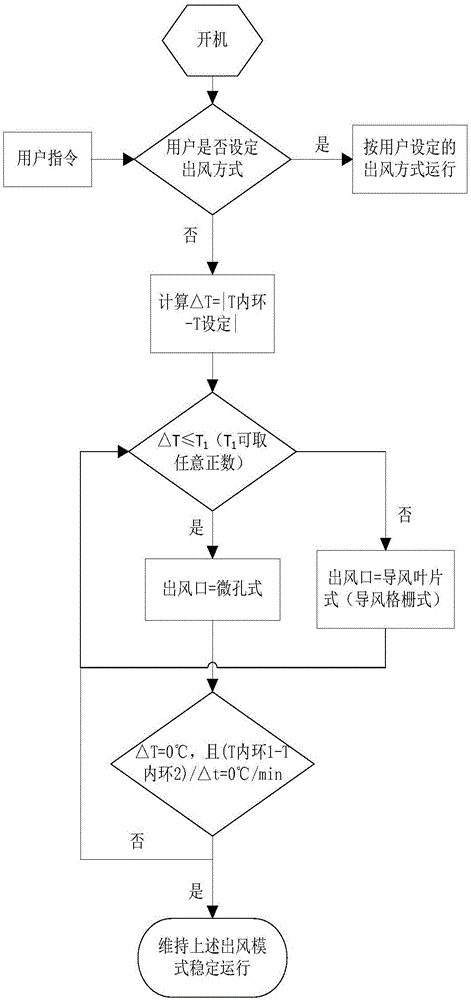

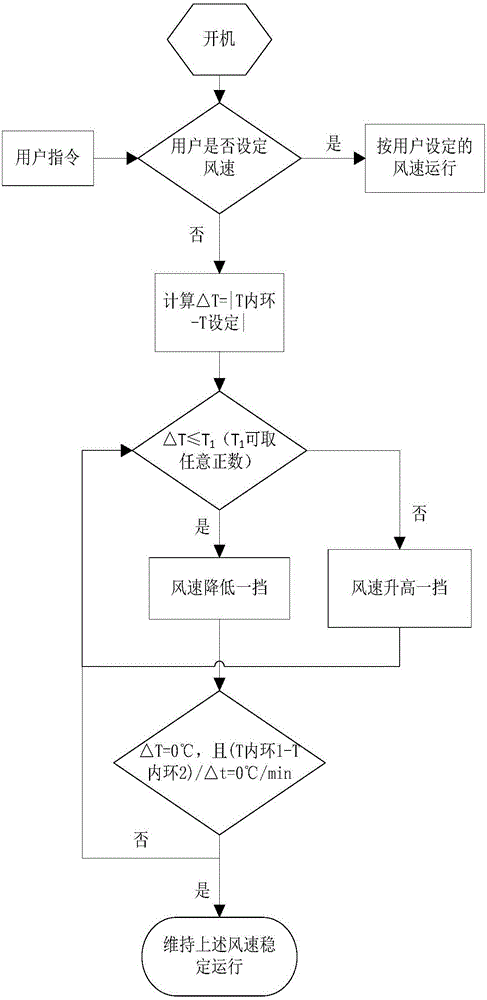

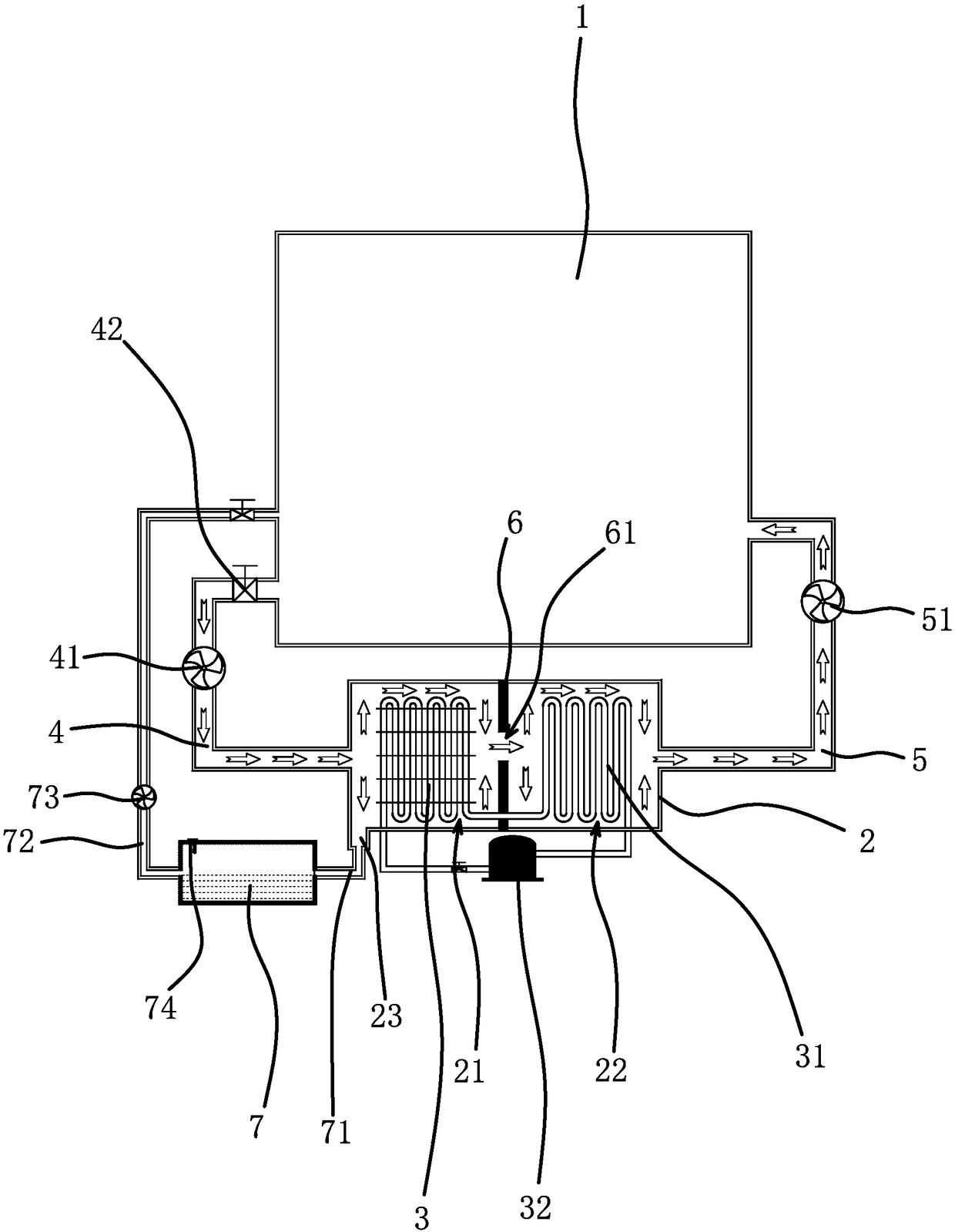

Air-conditioner control system and control method thereof

ActiveCN106839352ALow powerReduced indoor cooling or heating horsepowerMechanical apparatusSpace heating and ventilation safety systemsEngineeringComfort levels

The invention provides an air-conditioner control system and a control method thereof; the air-conditioner comprises a low output running mode with relatively low output energy and a high output running mode with relatively high output energy; the air conditioner can be mutually switched between two running modes, and the control system comprises a detecting unit, a judging unit, and a control unit. The detecting unit is used for detecting an inner ring of indoor environment temperature T; the judging unit is used for calculating the inner ring-T setting I of delta T=IT, and judging if delta T is not more than T1, wherein T is set as the indoor setting temperature of the air conditioner, T 1 is setting value and any positive number; the control unit can run the air condition in low output running mode or high output running mode according to the judging result of the judging unit. Through the invention, the room temperature can slowly change when closing to the T setting scale, prevent exceeding the setting temperature for too fast drop or rise of room temperature, avoid frequent startup of compressor, effectively prevent fluctuation of indoor environment temperature, and improve the comfort level of the indoor environment.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

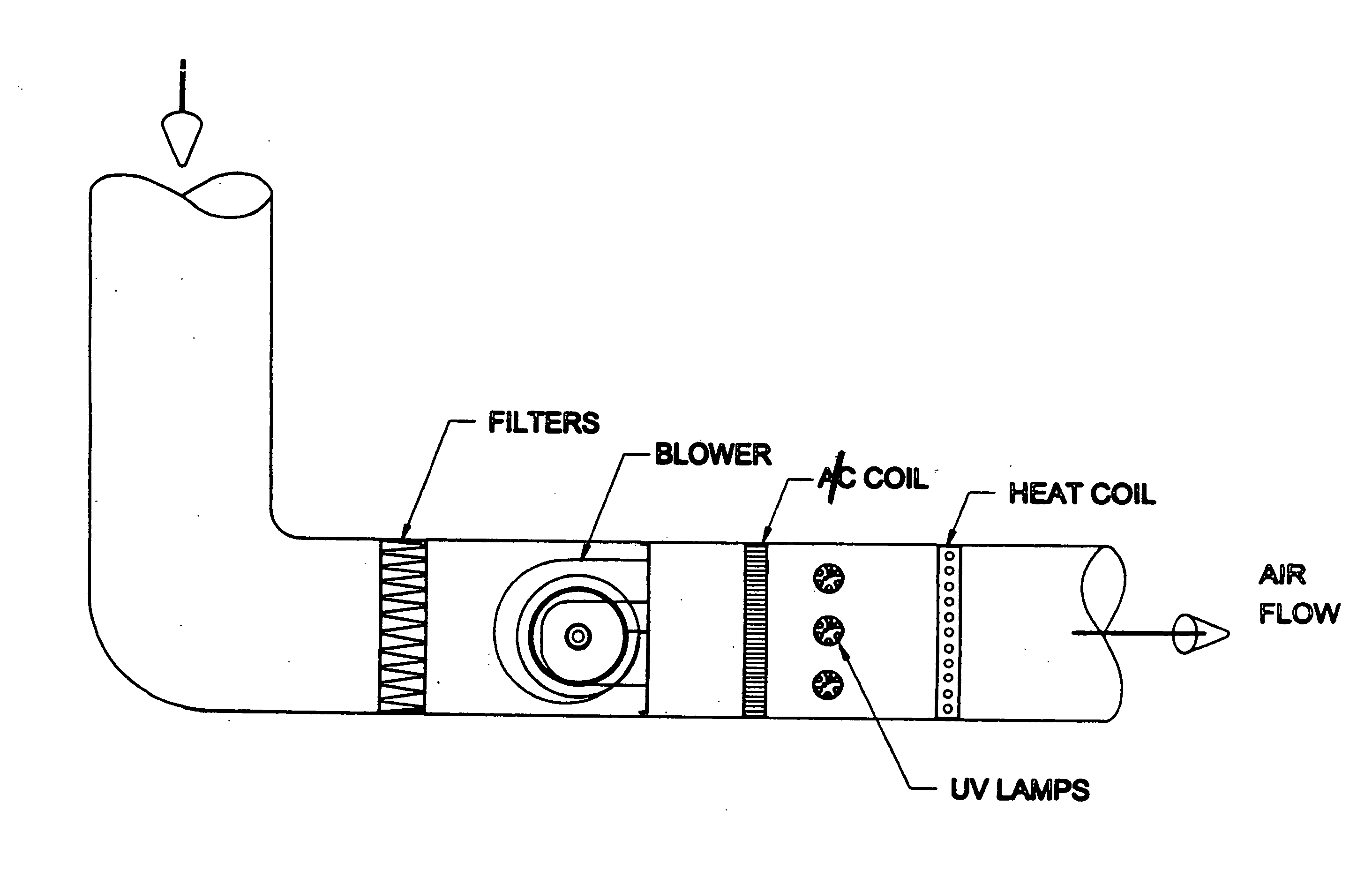

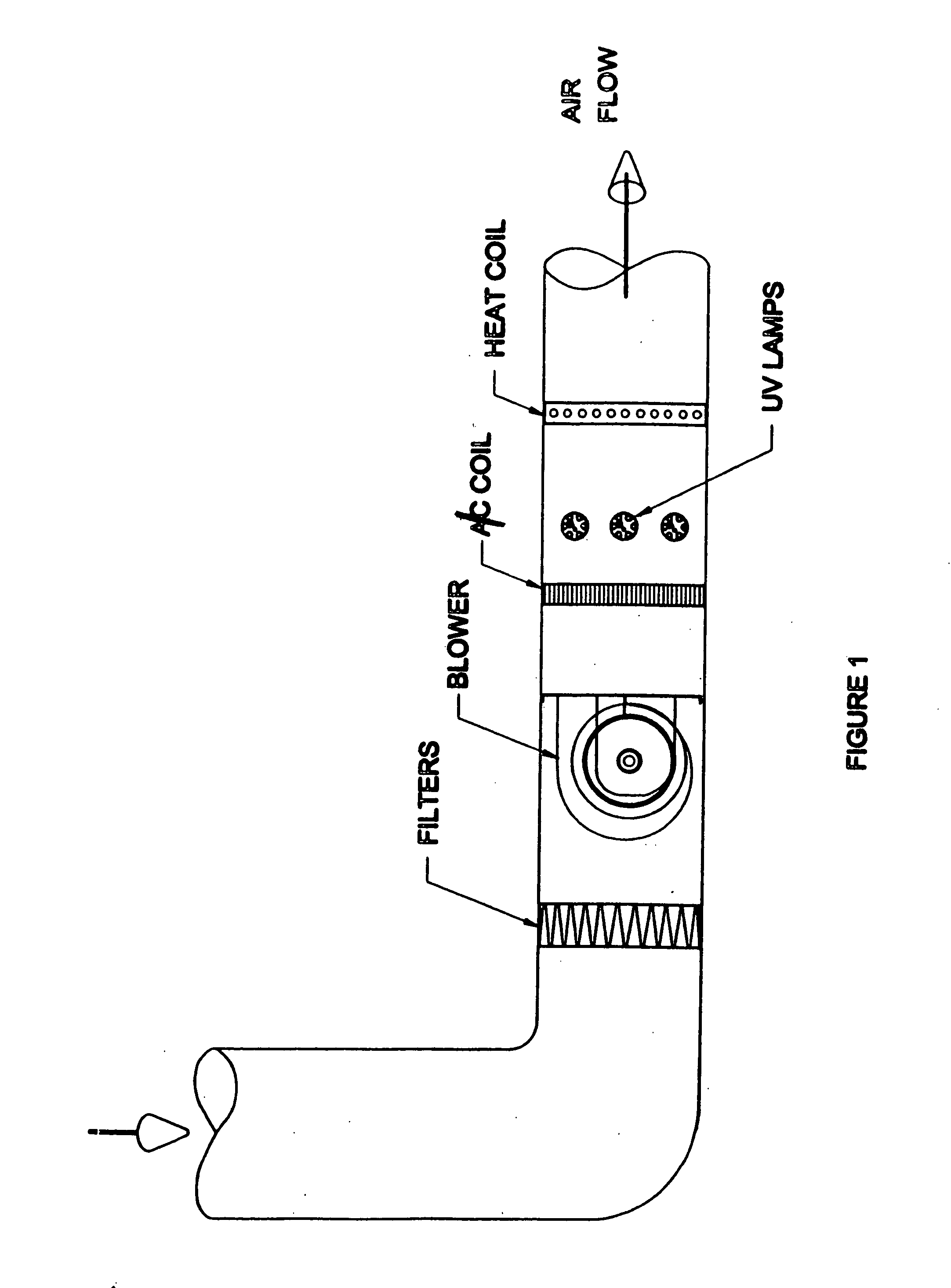

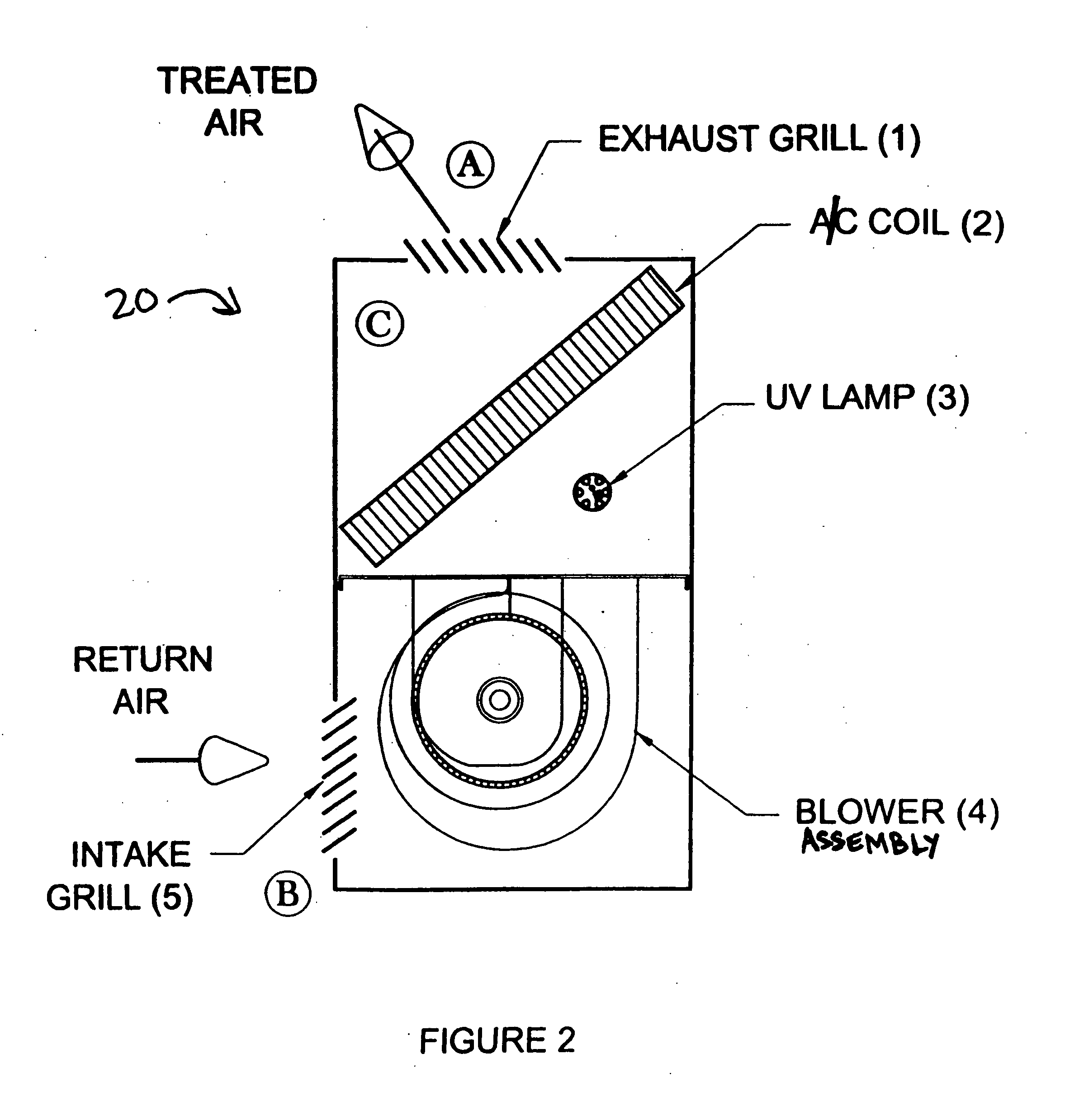

Low level ultraviolet disinfecting system

InactiveUS20050163652A1Safe exposure levelAdequate levelMechanical apparatusLighting and heating apparatusFluid intakeHuman exposure

A disinfecting system comprises a light source having output suitable for use as a germicidal agent, and a power supply for the light source that is adapted to limit the output of the light source to levels adequate for microbial growth control. The light source is operatively housed in fluid-conveying equipment for disinfecting fluids and surfaces therein. The limited output is attenuated by fluid-conveying equipment components disposed within the output range of the light source. The attenuated output provides safe human exposure levels in the vicinity of fluid intake and exhaust portions of the fluid-conveying equipment. The limited output inhibits the degradation of fluid-conveying equipment components disposed within the output range of the light source. The light source may be covered with a thin film or sleeve of material being semi-transparent to germicidal UV wavelengths to control the output of the light source.

Owner:ULTRAVIOLET DEVICES

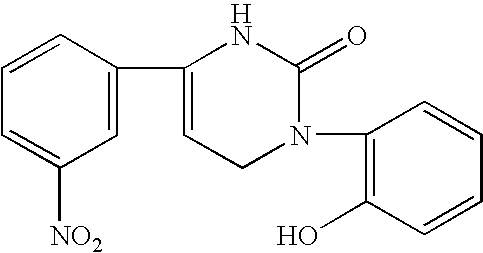

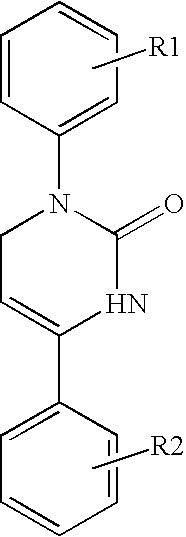

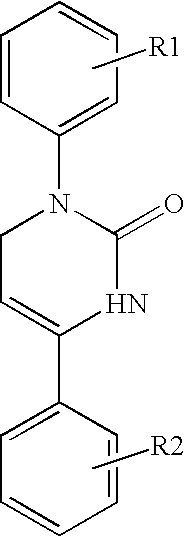

Reduction of hair growth

A method of reducing hair growth includes topical application of a TRPM8 and / or a TRPA1 agonist, alone or in conjunction with heat.

Owner:PROCTER & GAMBLE CO

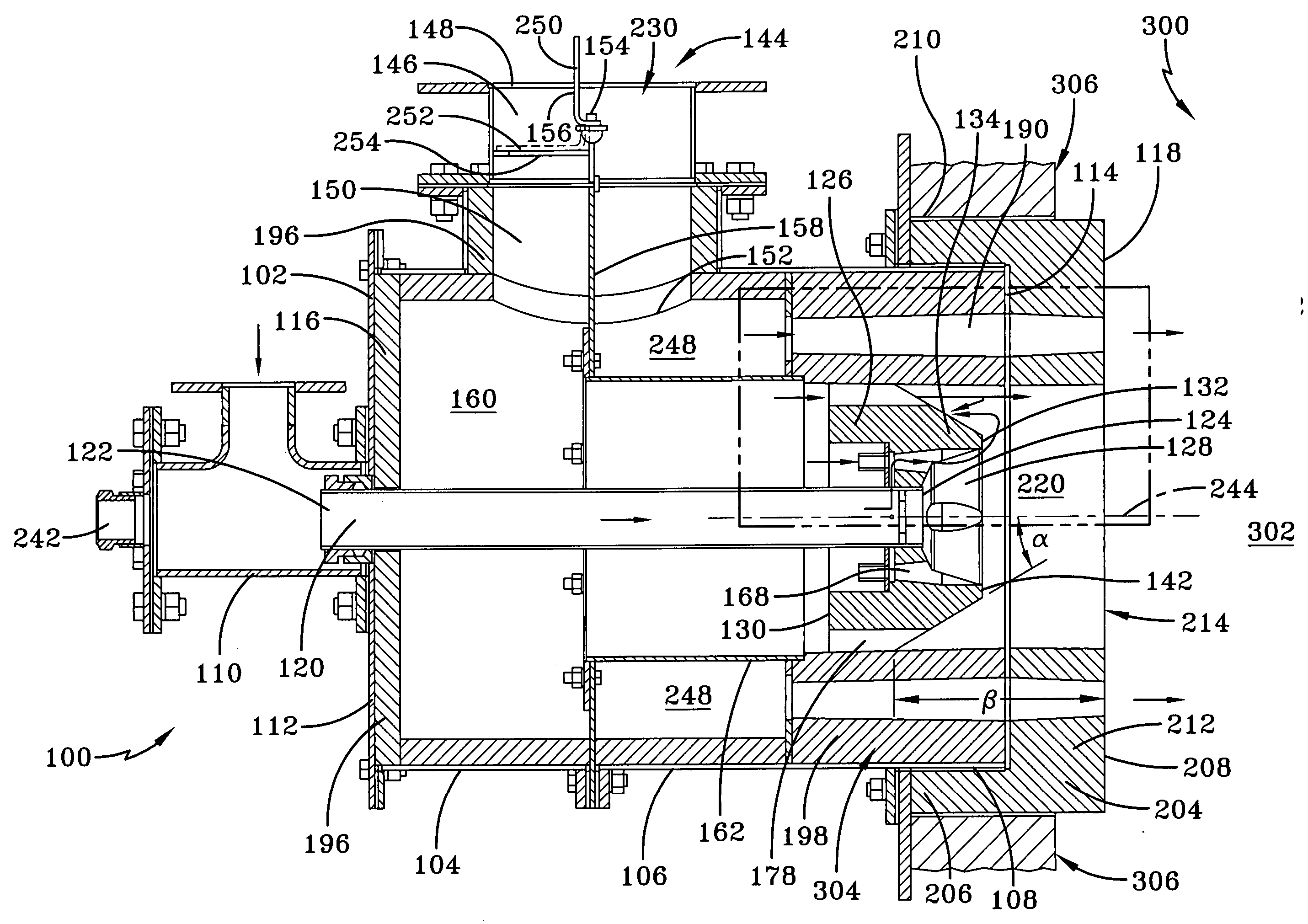

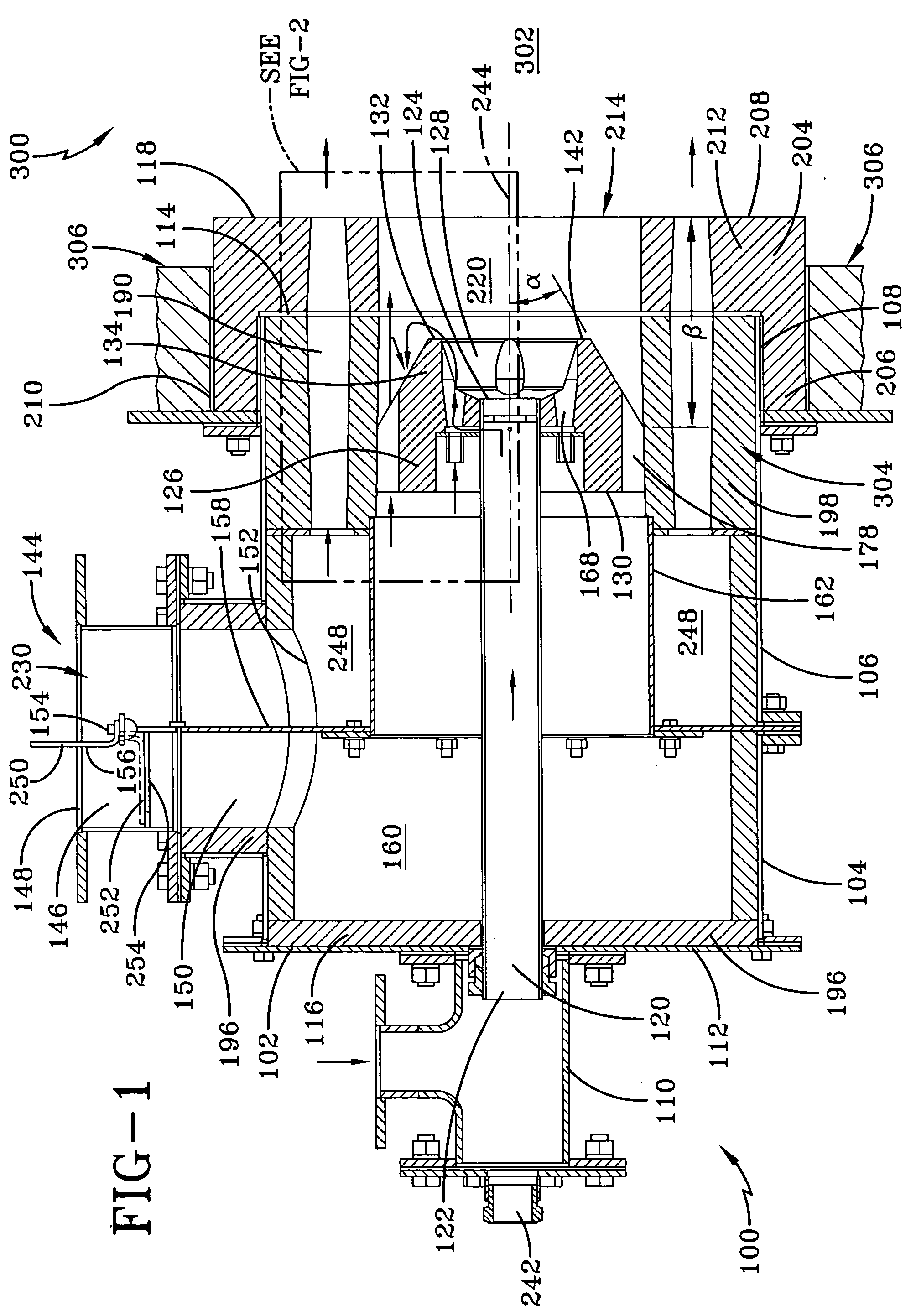

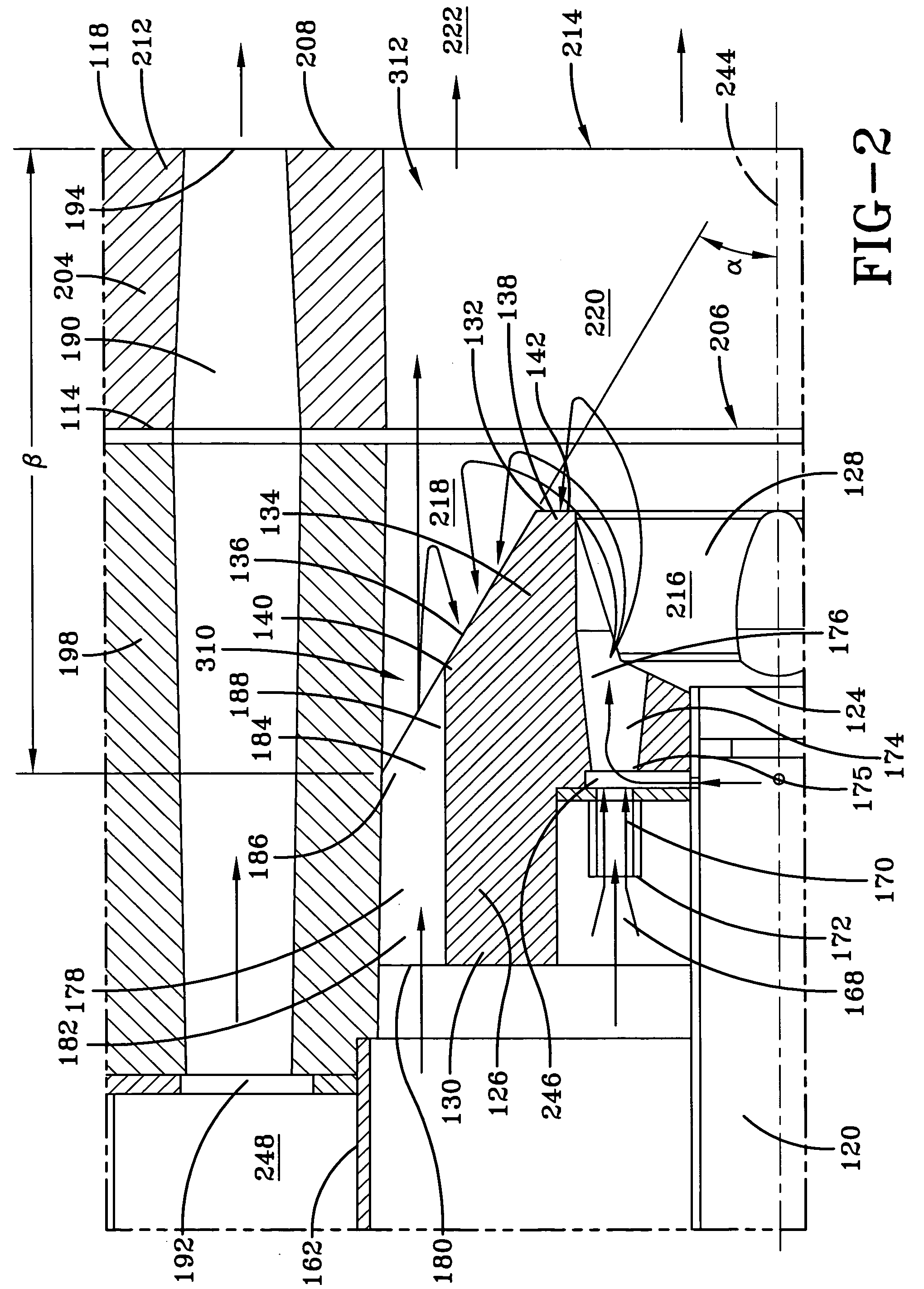

Three stage low NOx burner and method

ActiveUS20050053877A1Reduce nitrogen oxide emissionsEmission reductionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorMarine engineering

Owner:HAUKE MFG

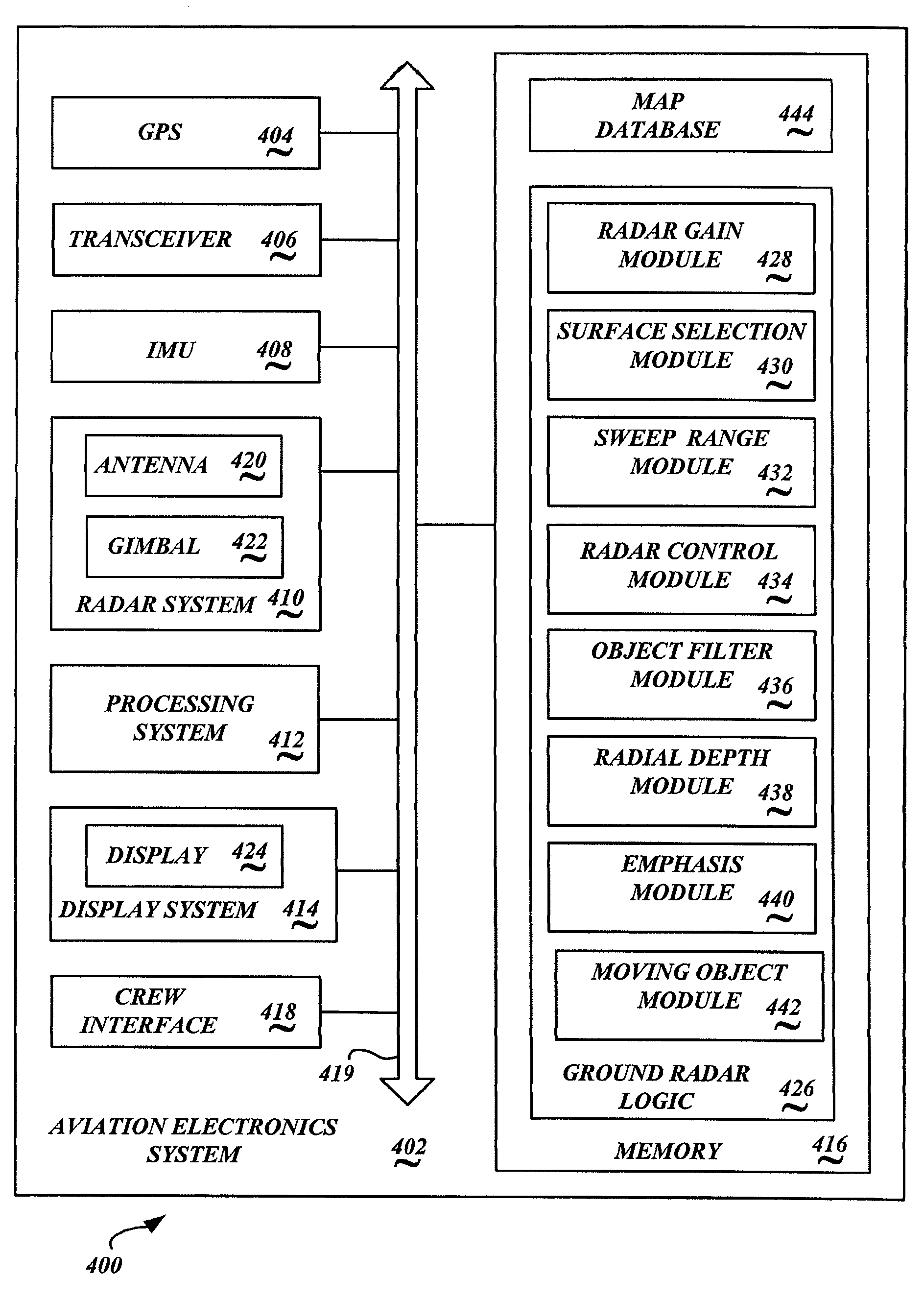

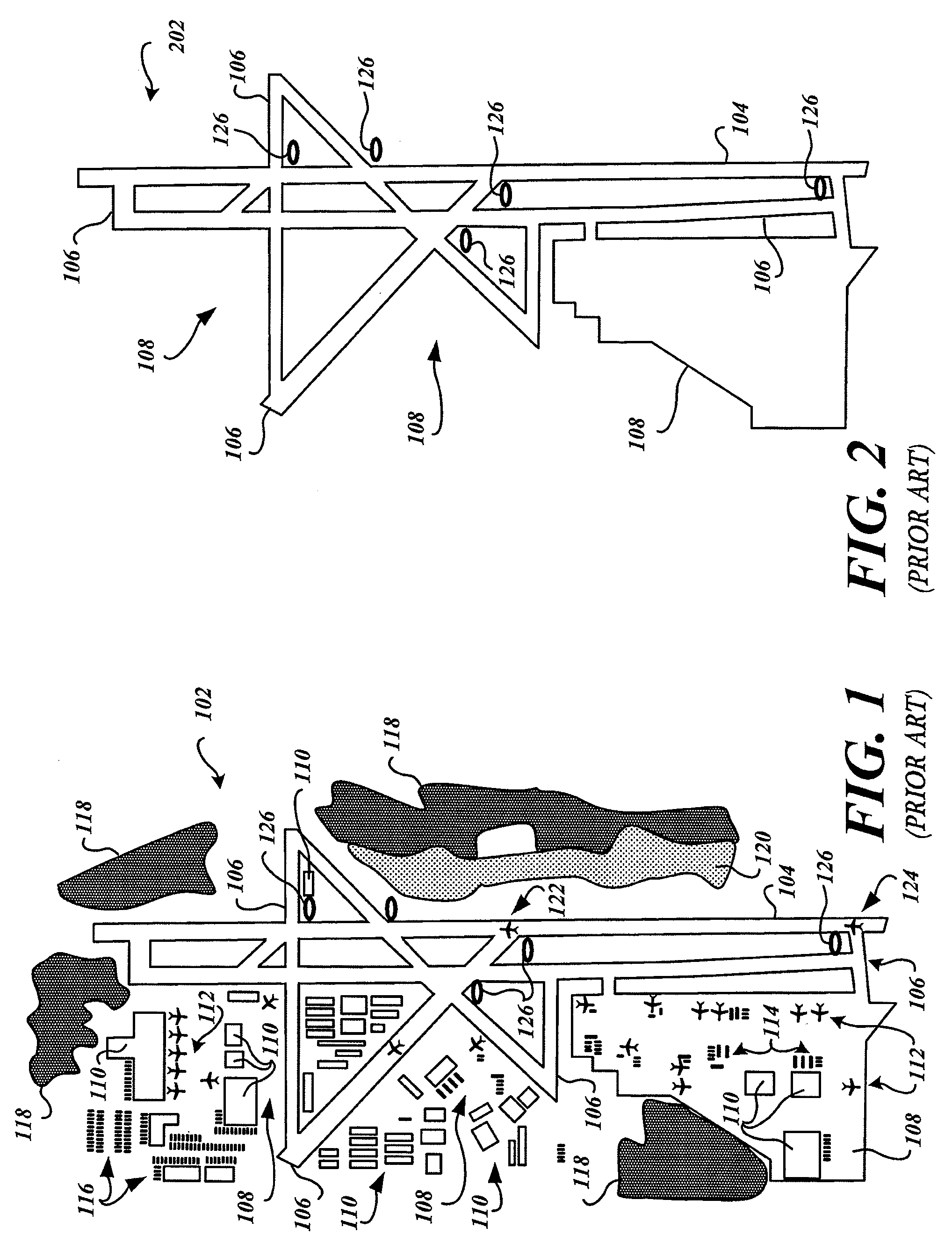

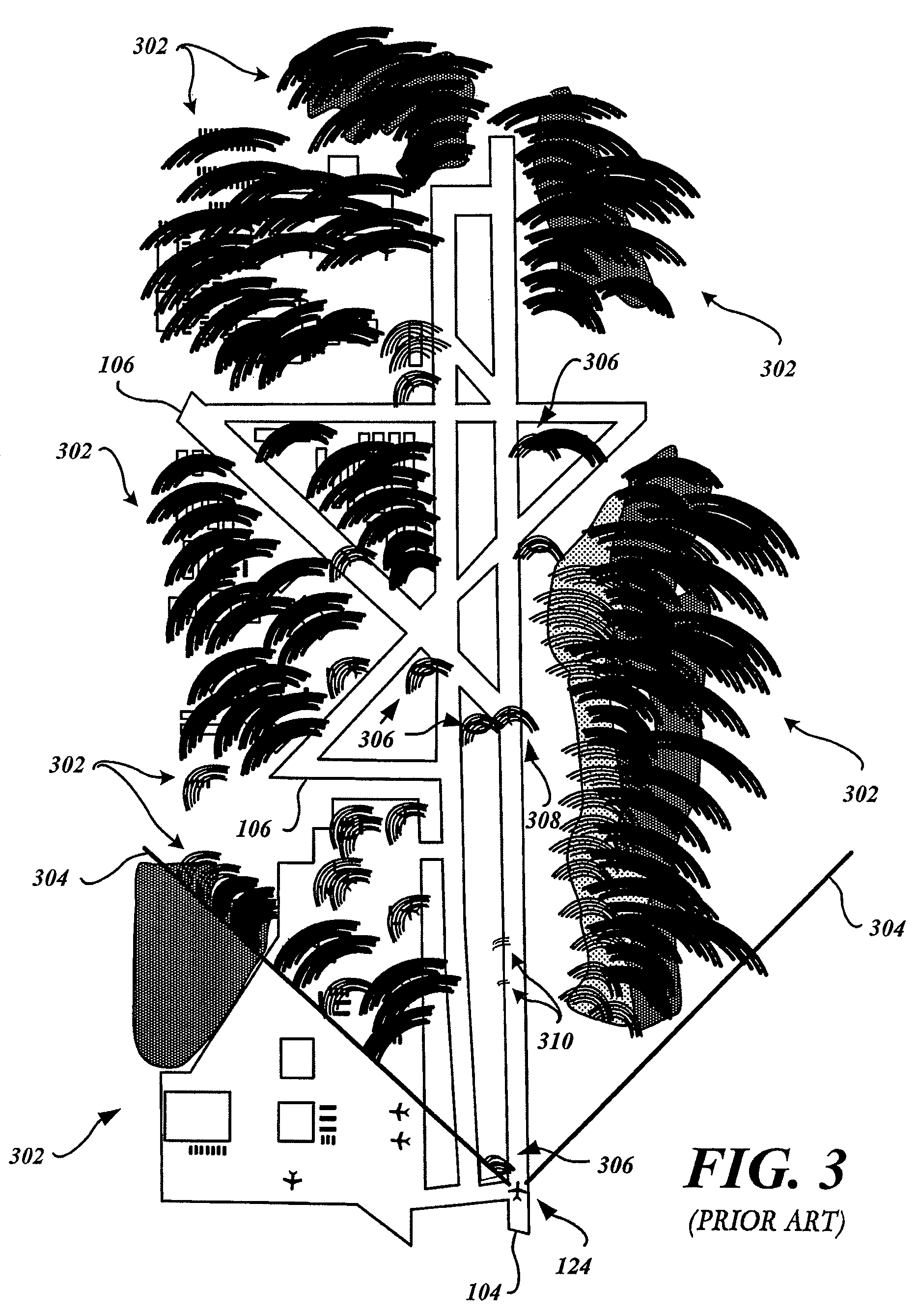

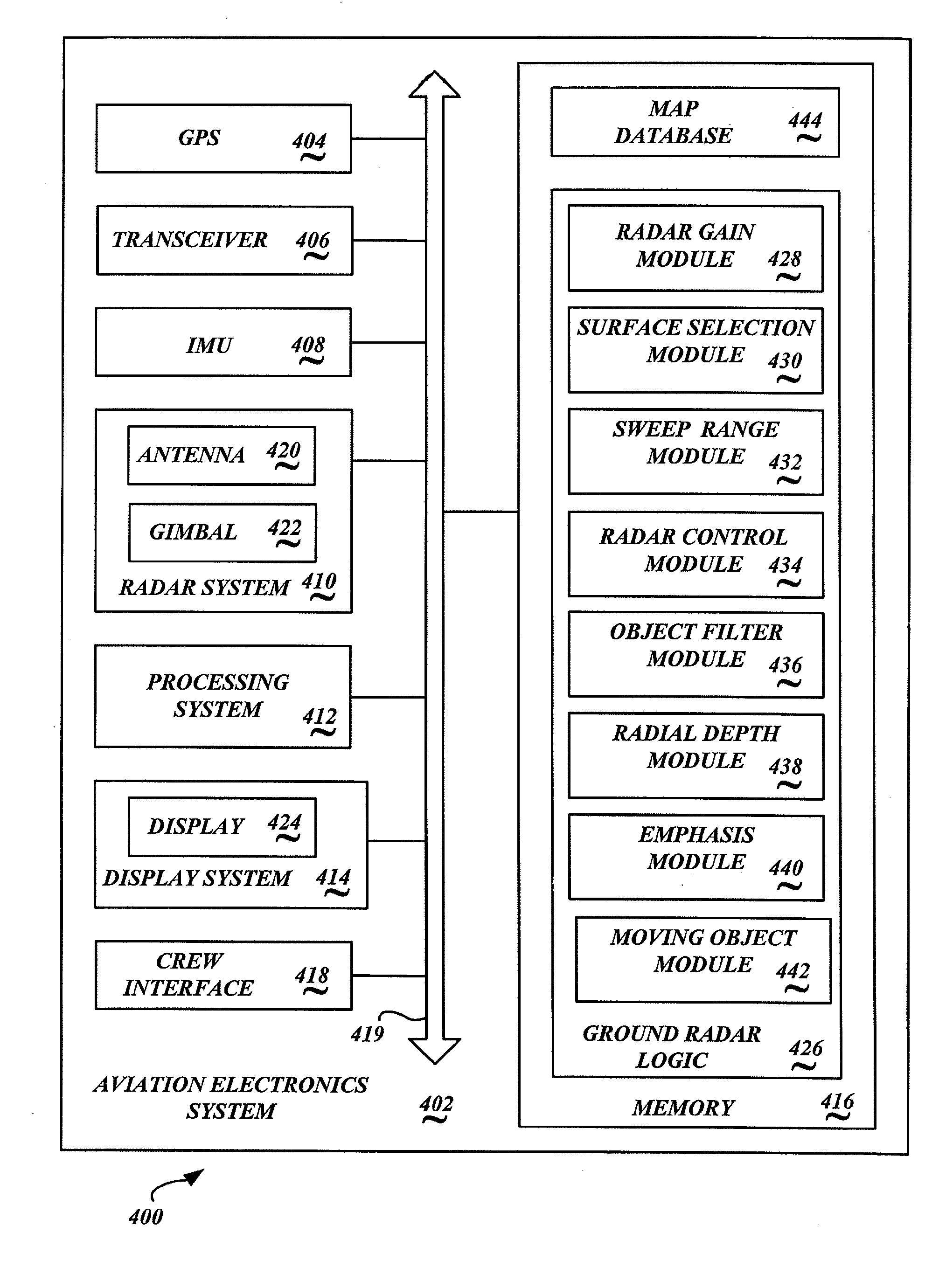

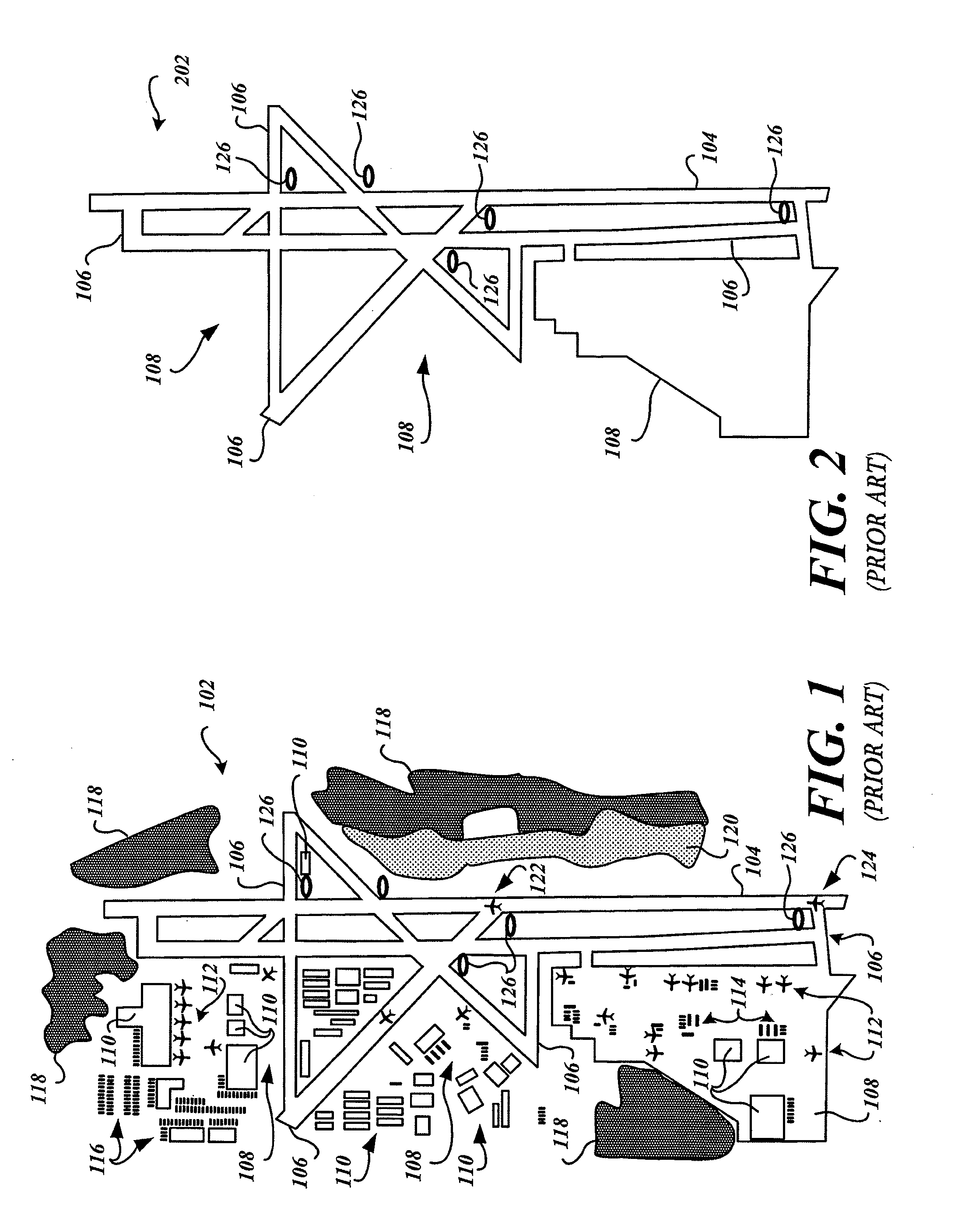

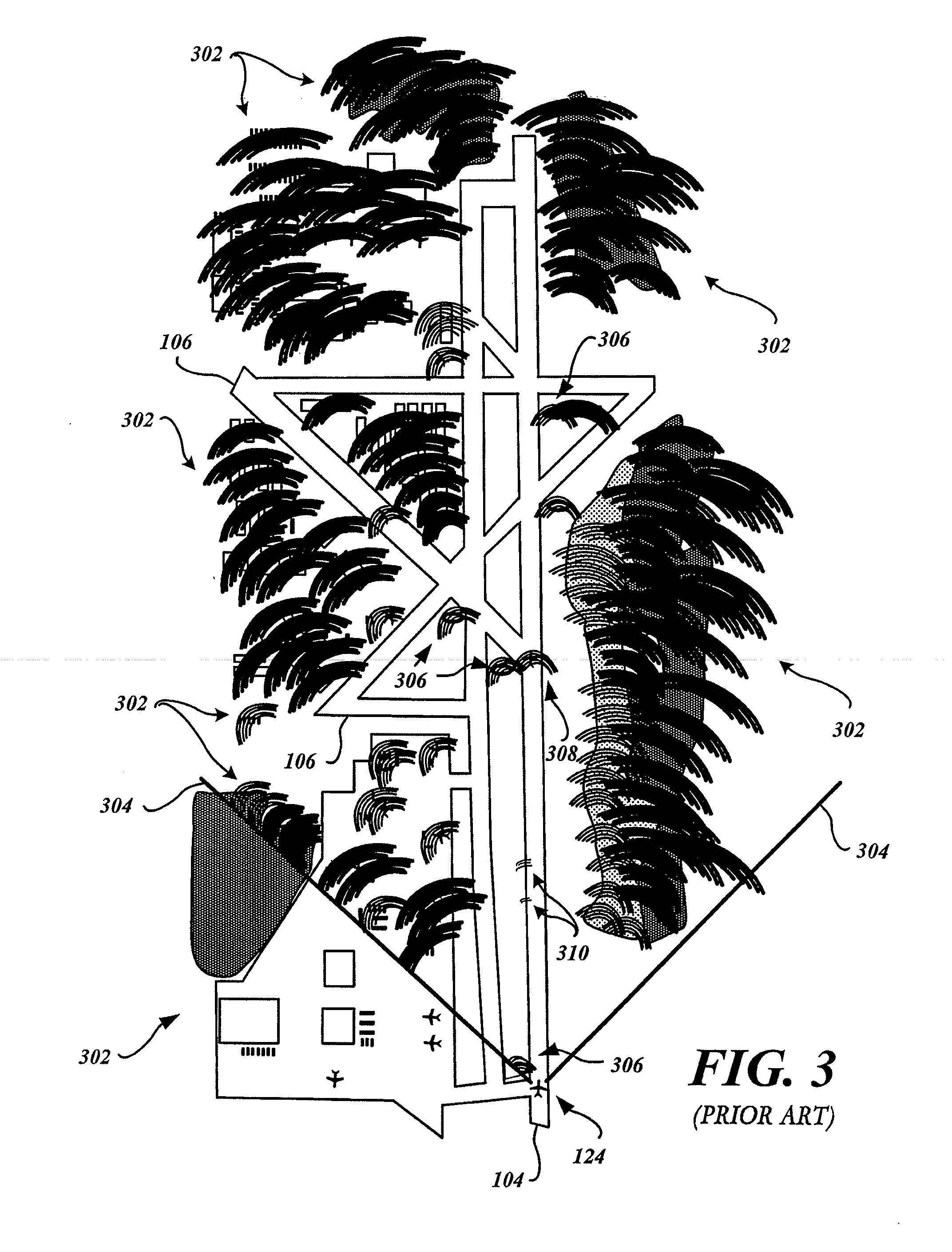

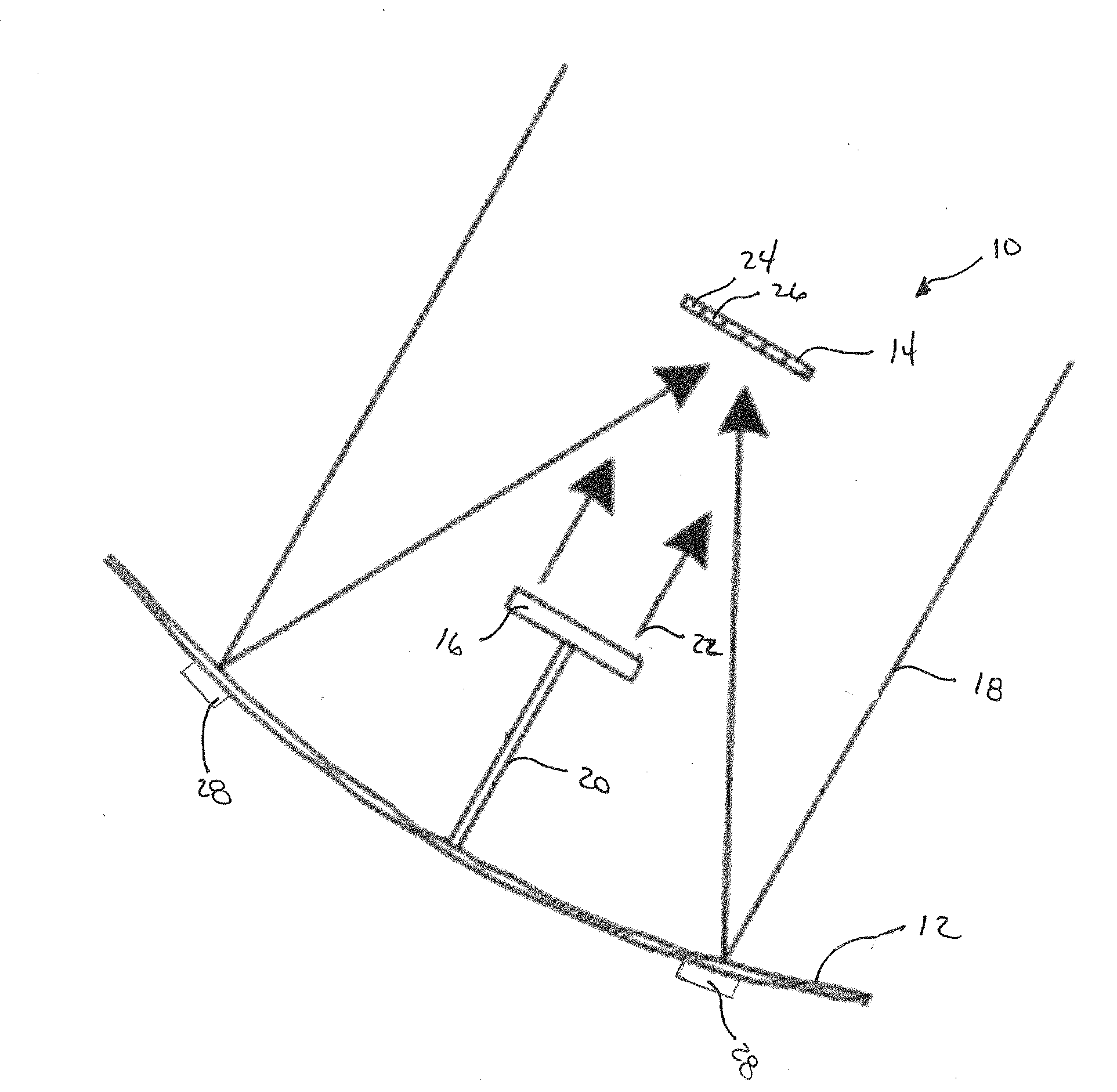

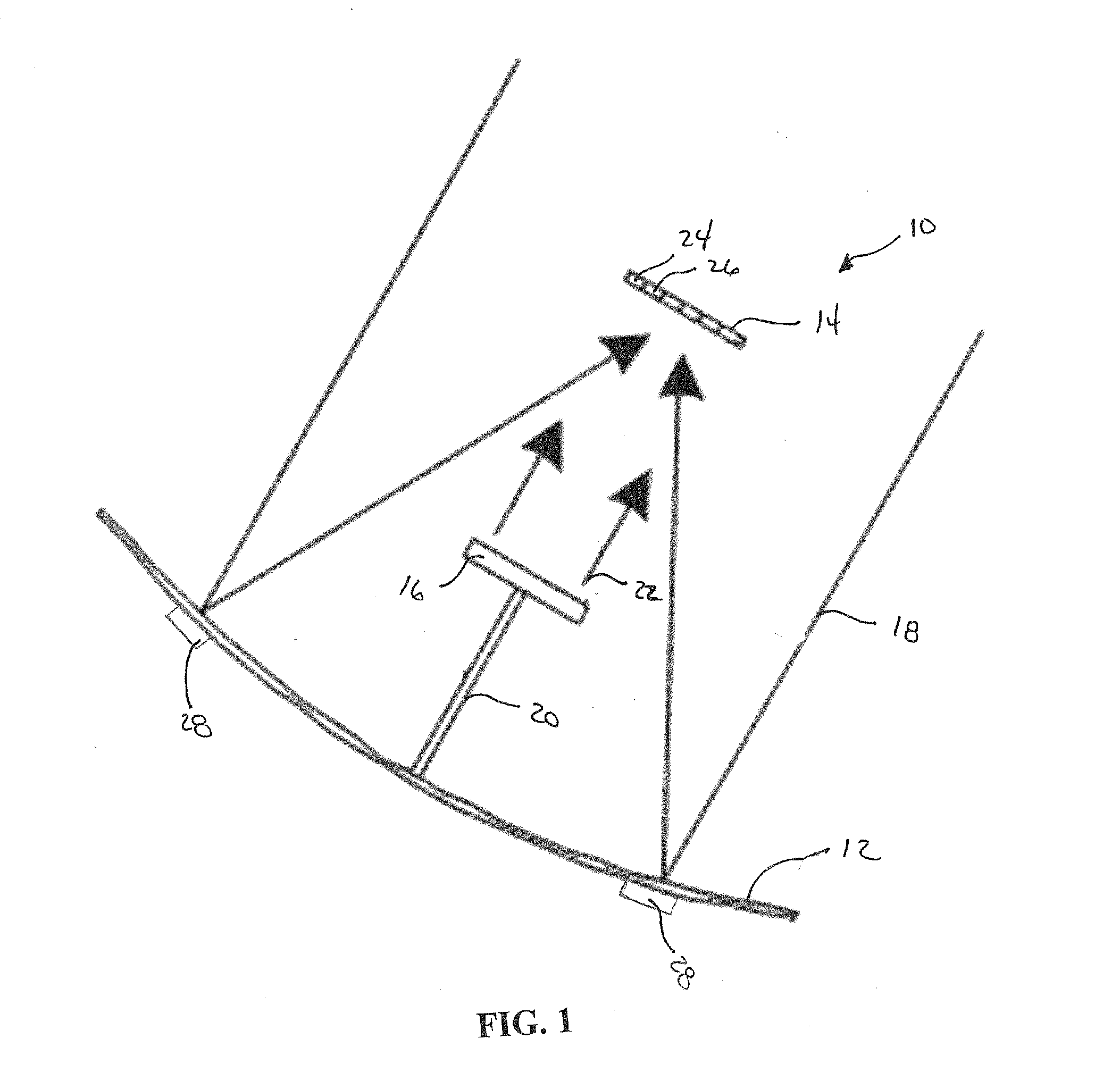

Ground collision instrument for aircraft and marine vehicles

ActiveUS8077081B2Reduce output energyNarrow down the scan rangeAnti-collision systemsPosition fixationRadarHandling system

Radar return processing systems and methods are operable to process radar information when an installation vehicle is operating in proximity to a surface area of interest. An exemplary embodiment reduces energy of an output pulse emitted from a radar system; receives a plurality of radar returns from a plurality of objects that reflect the reduced energy output pulses emitted from the radar system; determines a surface area of interest based upon at least a current location of the installation vehicle; and filters the radar returns generated by objects that are located outside of the surface area of interest. Optionally, some systems and methods may reduce a sweep range of an antenna from which the reduced energy output pulses are emitted.

Owner:HONEYWELL INT INC

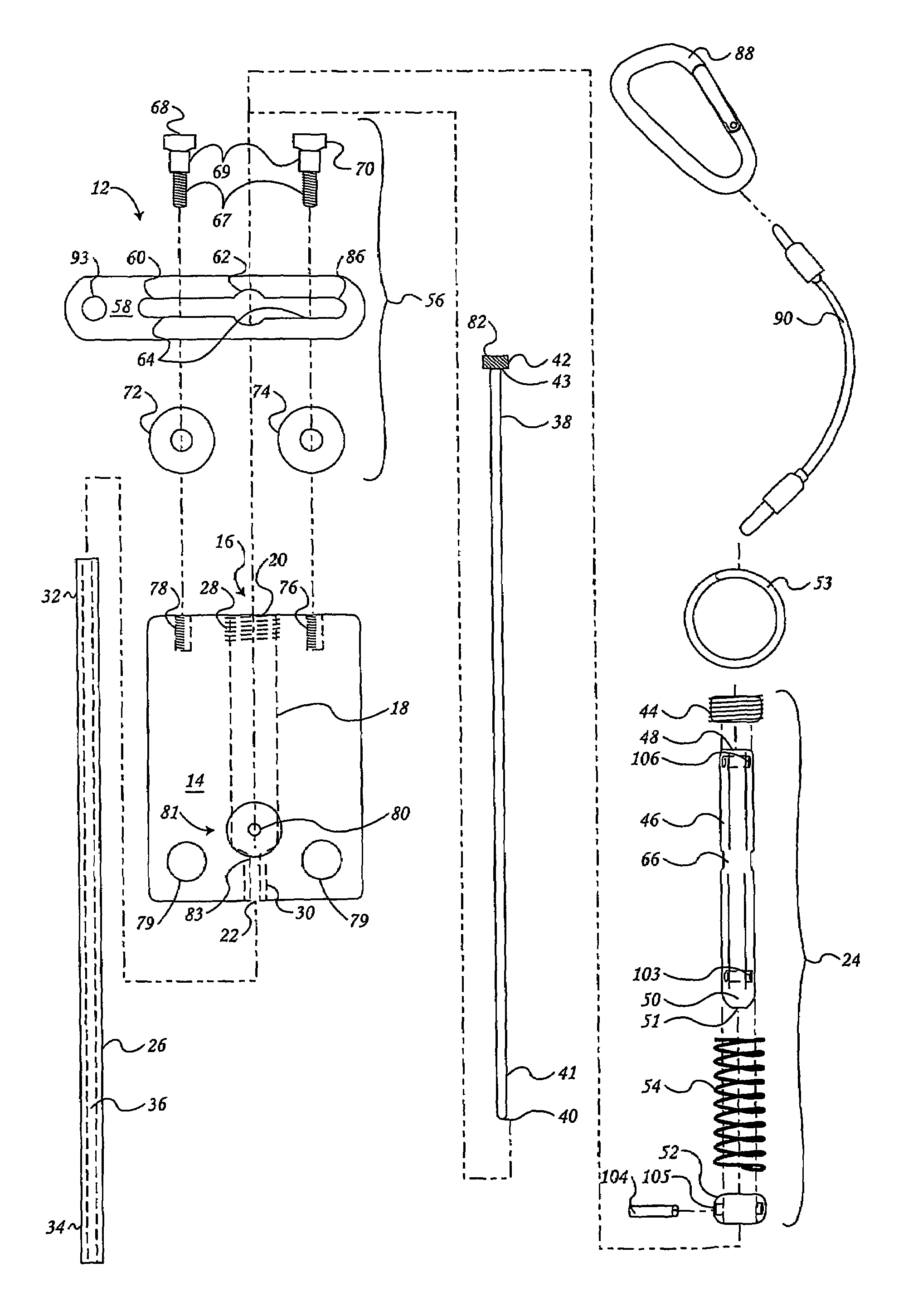

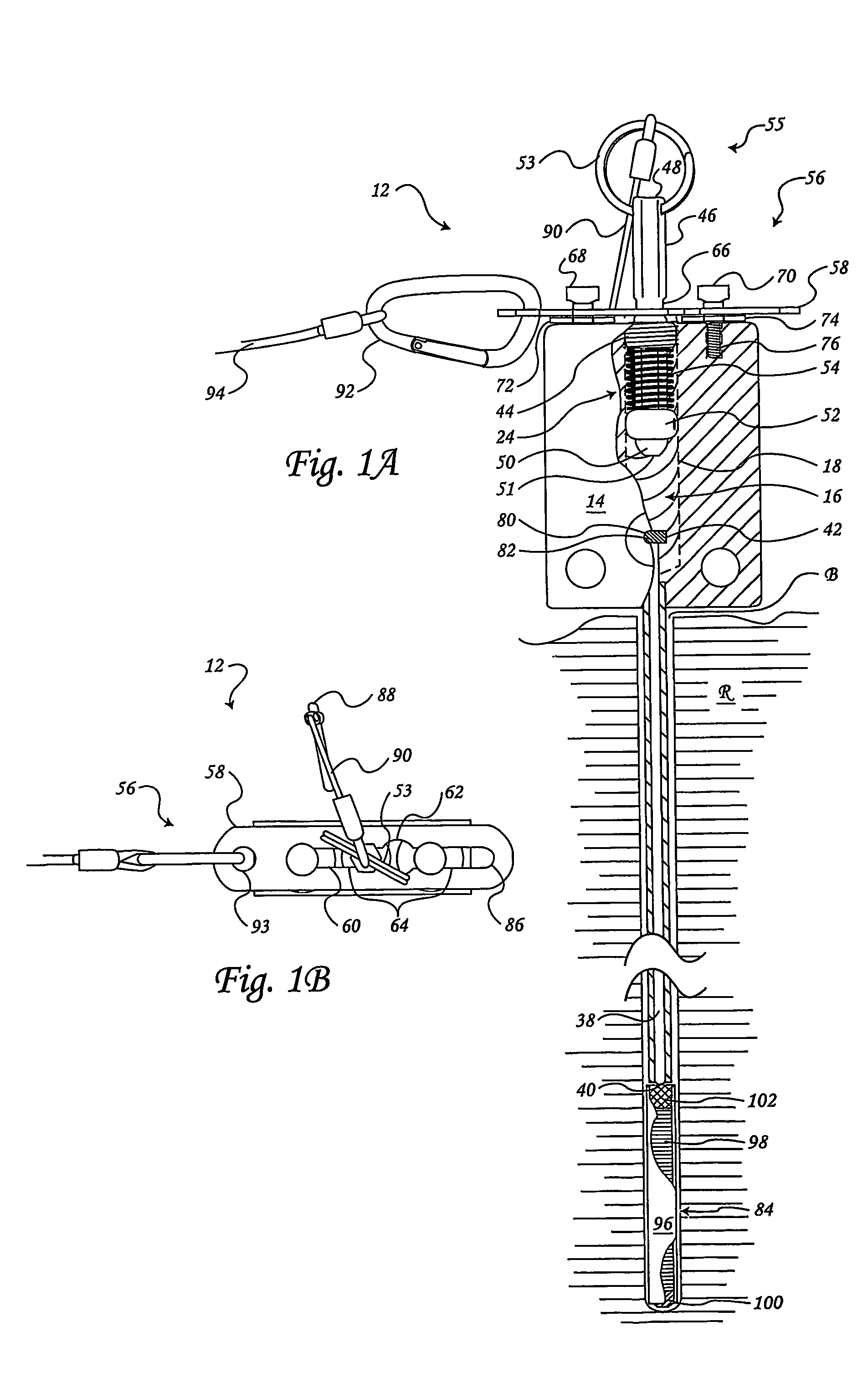

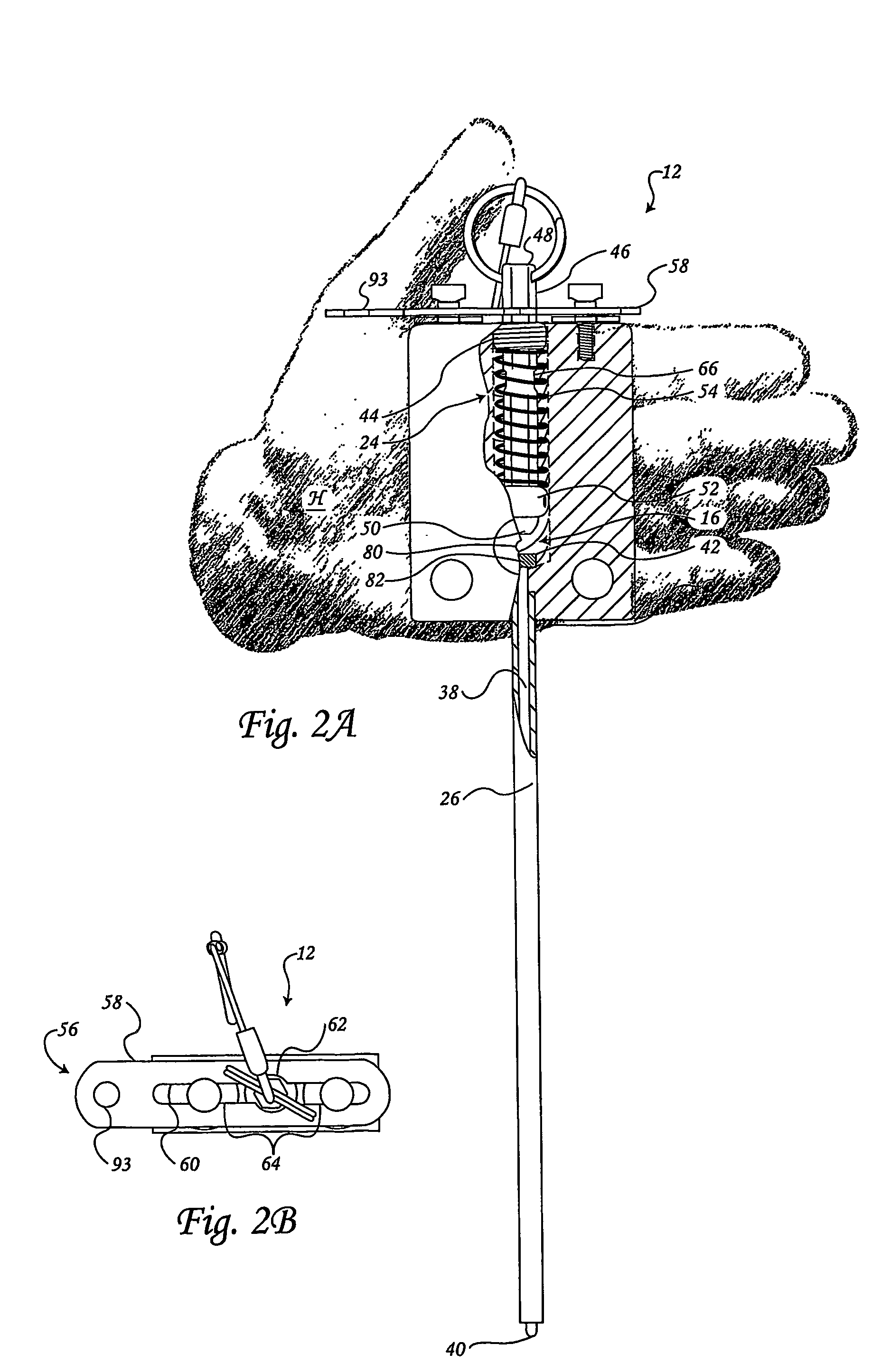

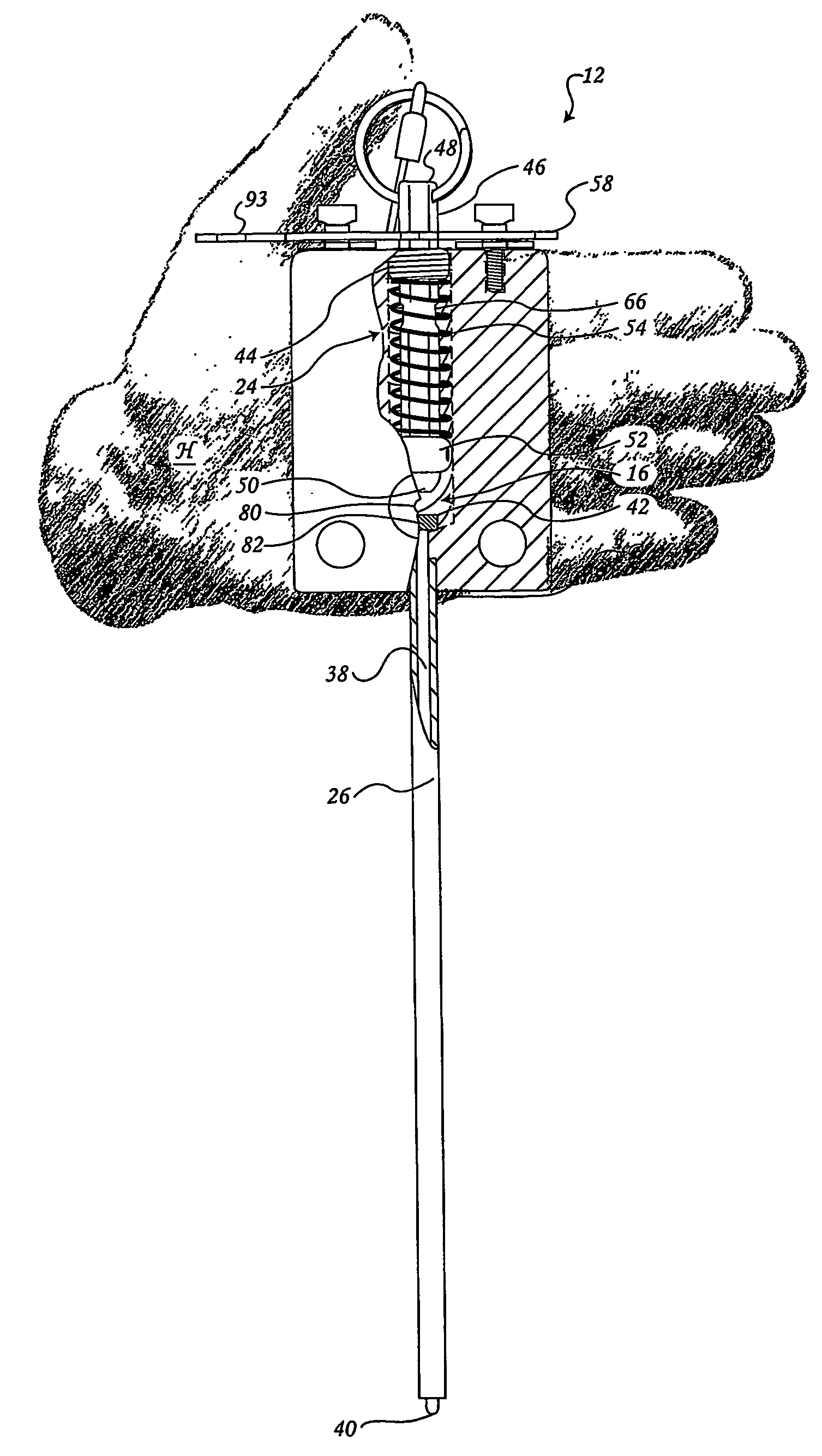

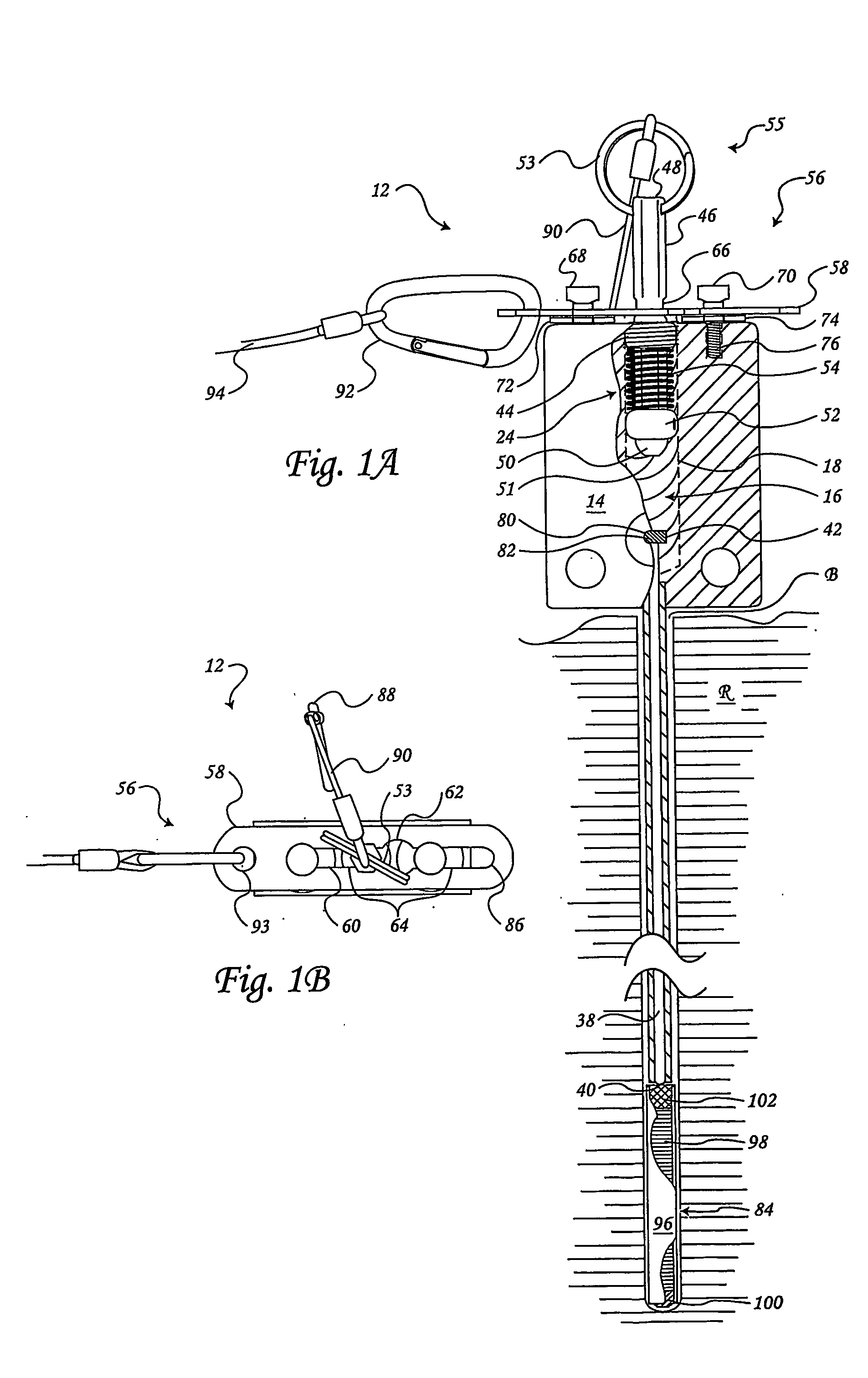

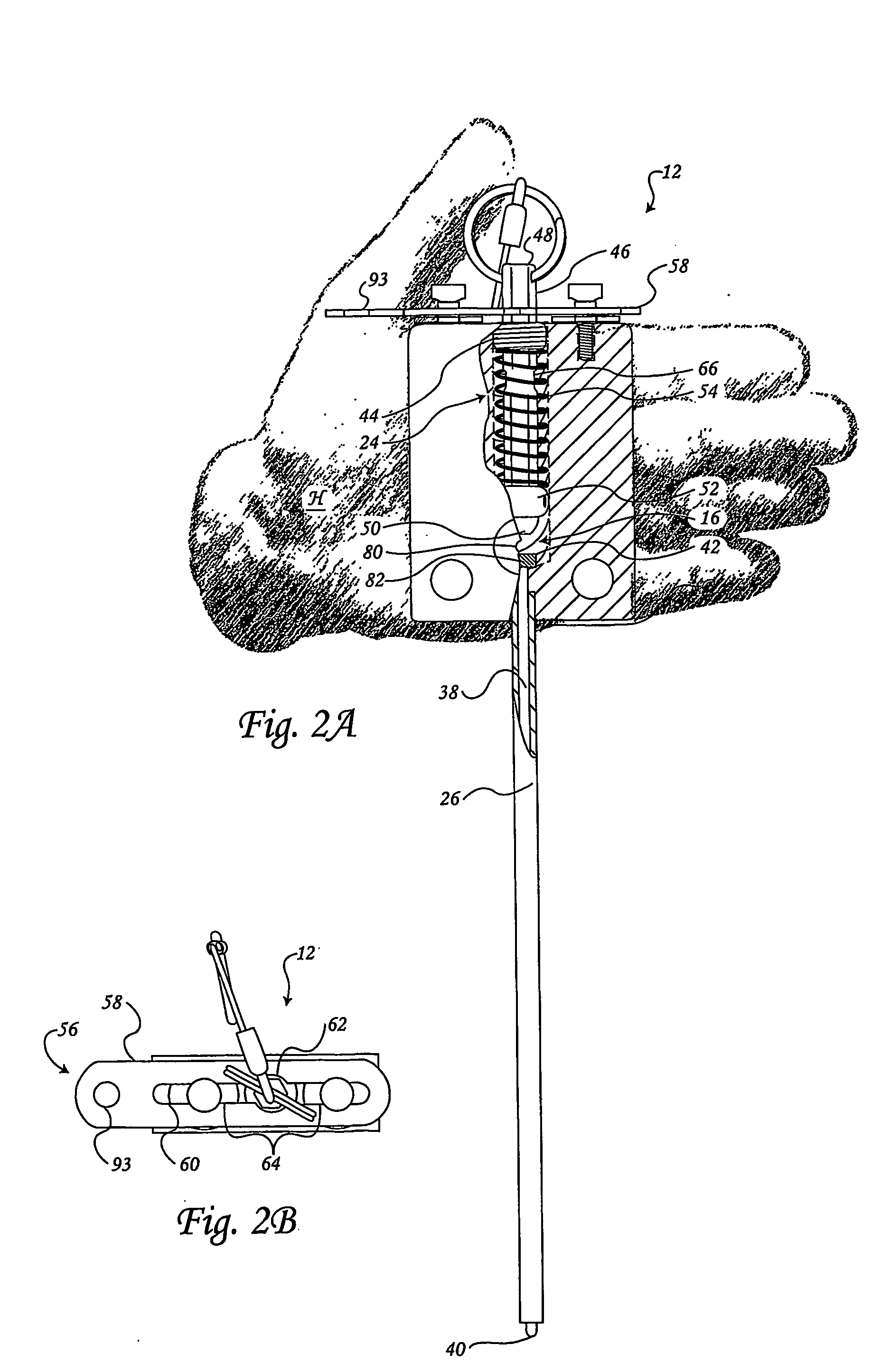

Handheld tool for breaking up rock

InactiveUS7069862B2Easy to drillHigh levelDrilling using explosivesDisloding machinesEngineeringActuator

A tool (12) has a body (14) with a barrel (18) having opposing threaded and fitted openings (30 and 28). An actuator pin tube (26), for slidably engaging an actuator pin (38) having a tip (40) opposing a retention head (42), extending from the fitted opening (30). A spring assembly (24), disposed in the barrel (18), has a hammer guide (44) engaged in the threaded opening (28) with a hammer (46) slidably engaged therein, a handle mechanism (55) disposed at one end and a spring retainer (52) disposed adjacent the other end of the hammer (46) before a hammerhead (51), and a spring (54) engaged between the hammer guide (44) and the spring retainer (52). A release mechanism (56) engages the hammer (46). A kit (108) containing the tool (12) and a method of operating the tool (12) involving drilling and cleaning a borehole, inserting a cartridge and tool therein, and detonating the load remotely using a pull cord.

Owner:BASSETT CARROLL

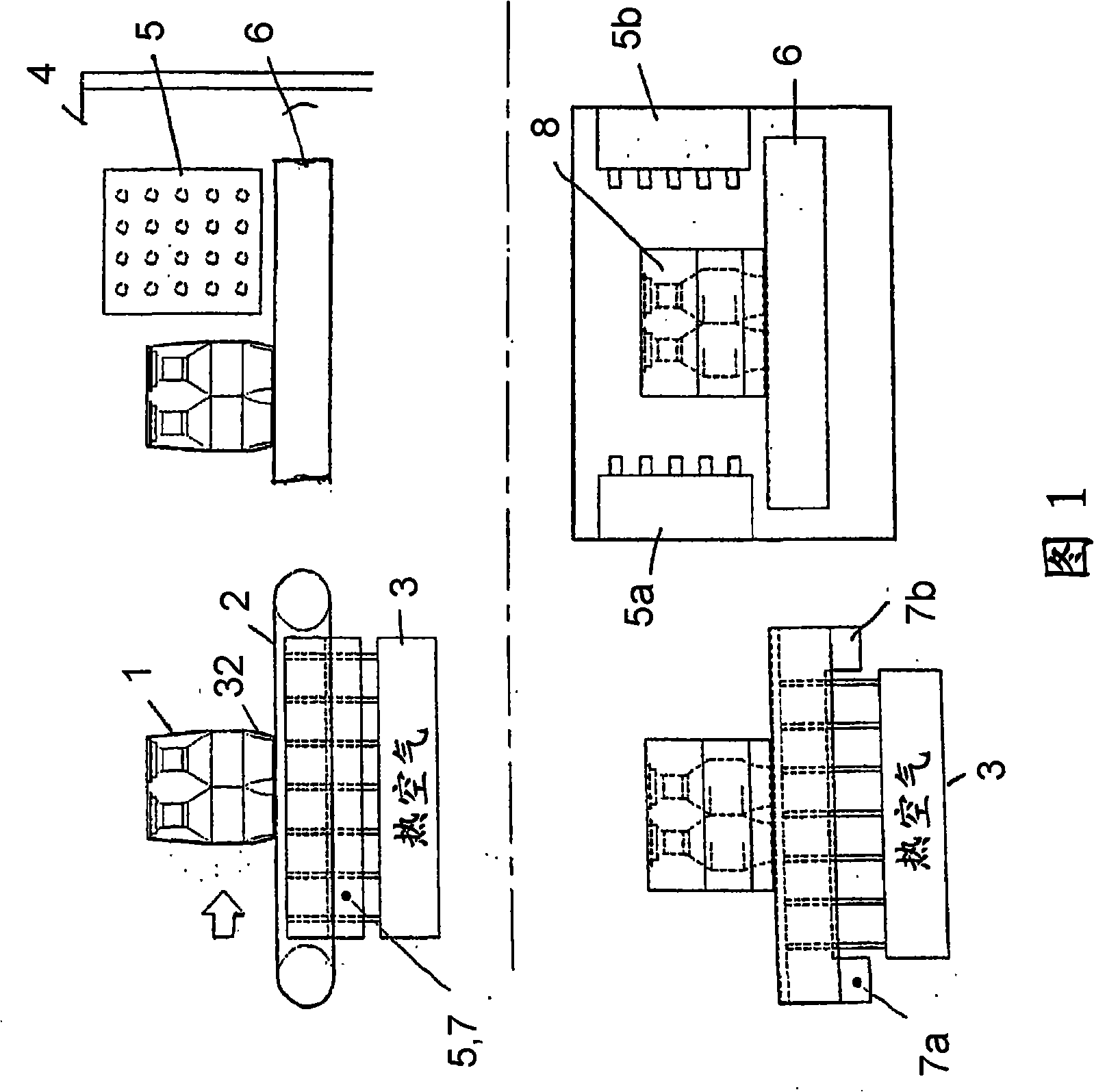

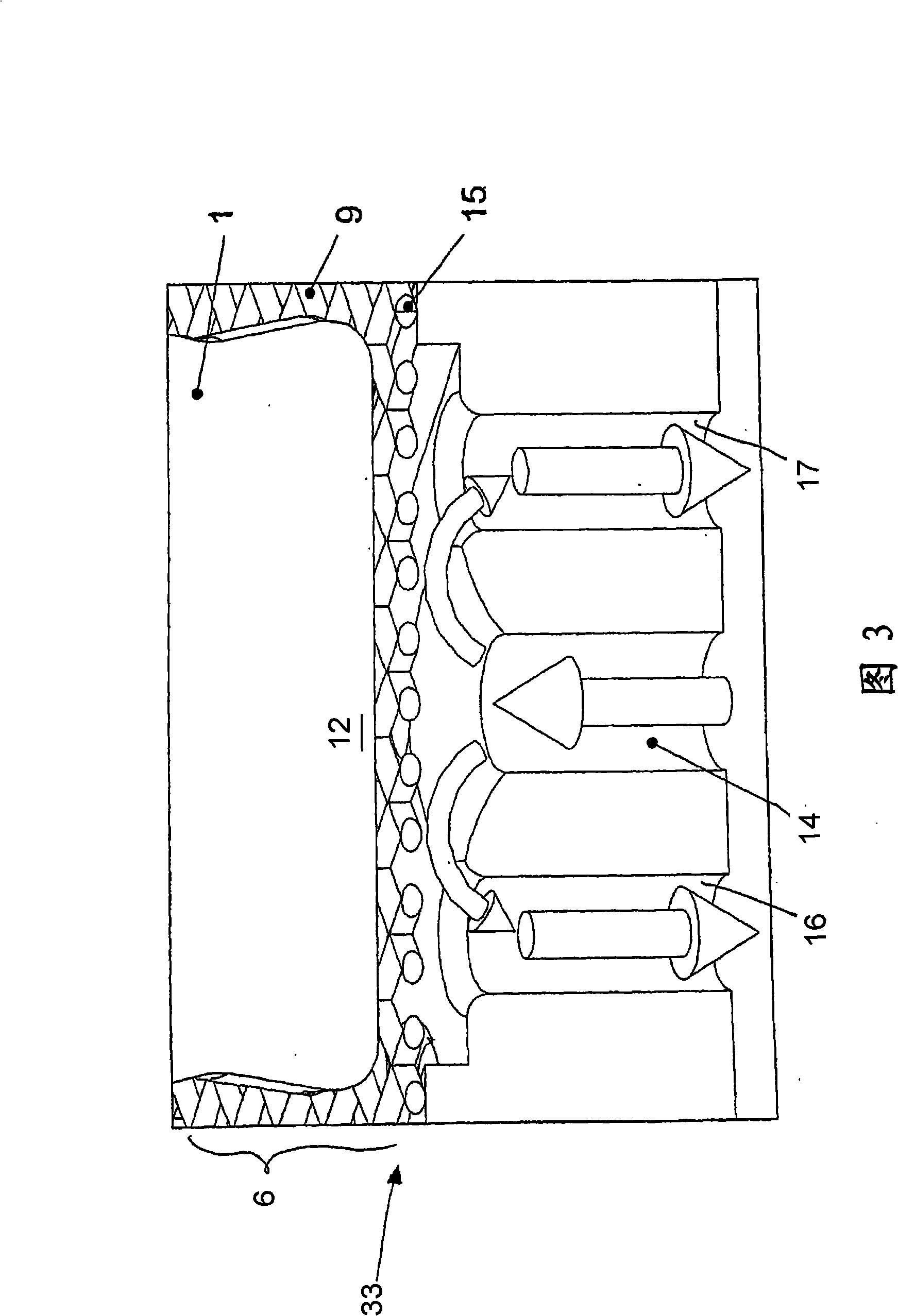

Shrinking process for producing solid, transportable and printable containers and device for carrying out said shrinking process

ActiveCN101356094AReduced energy outputFast shapingWrappers shrinkageContainers with multiple articlesWaddingProduct gas

The invention relates to a shrinking process for producing solid, transportable and printable containers, especially bottle containers with a height / width ratio of > 1 and containing heat-sensitive filling substances. The shrinking process comprises the steps of covering the containers to be packaged with a film in such a manner as to produce an overlapping section of the film ends on the bottom surface, heating them by heat transfer or convection, thereby fusing together the free ends in the area of overlap, and then finally heating the containers in a shrinking oven, the container so produced being stabilized by the shrinking process. The incoming hot air is first locally limited to the bottom surface of the container in order to form a peripheral shell in the area of the bottle bottoms and the shape of the container is stabilized while the container is continuously transported during stabilization. The hot air directed onto the bottom area of the container in a bundle of discretely distributed gas jets is discharged and returned after a locally limited heat transfer with the film. More hot gas is directed laterally onto the continuously transported container at an increased lateral blow speed in order to complete the shrinking process.

Owner:KHS GMBH

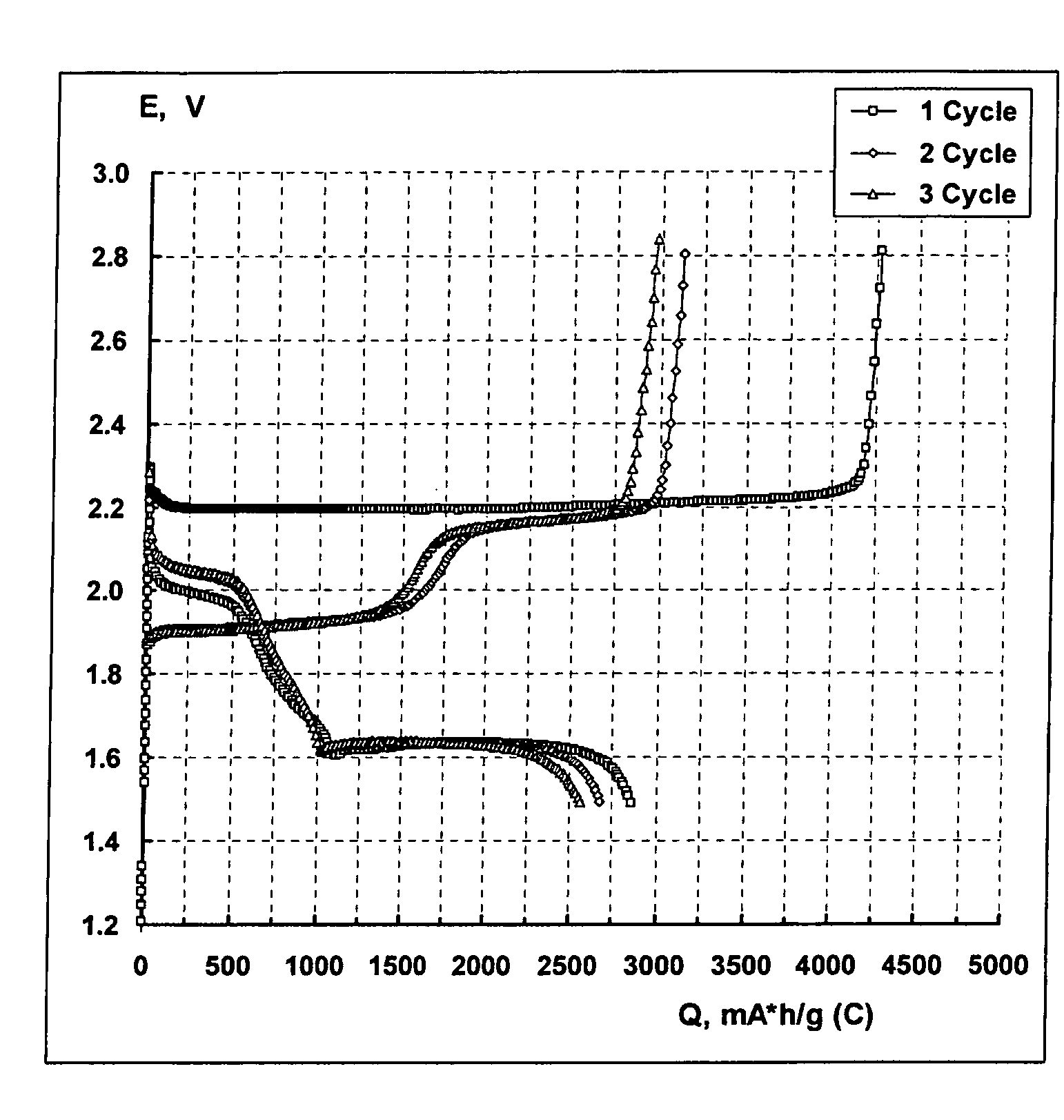

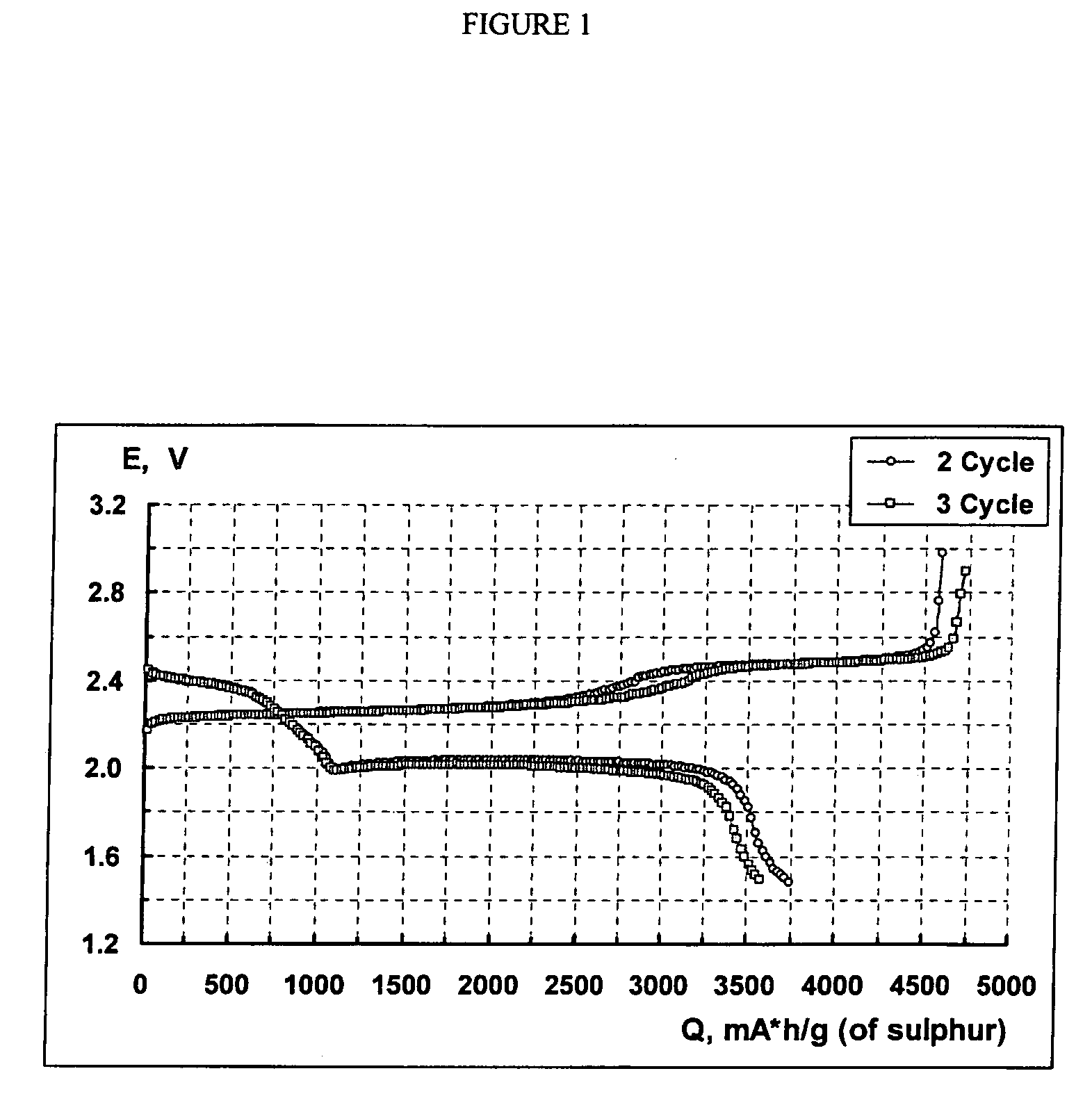

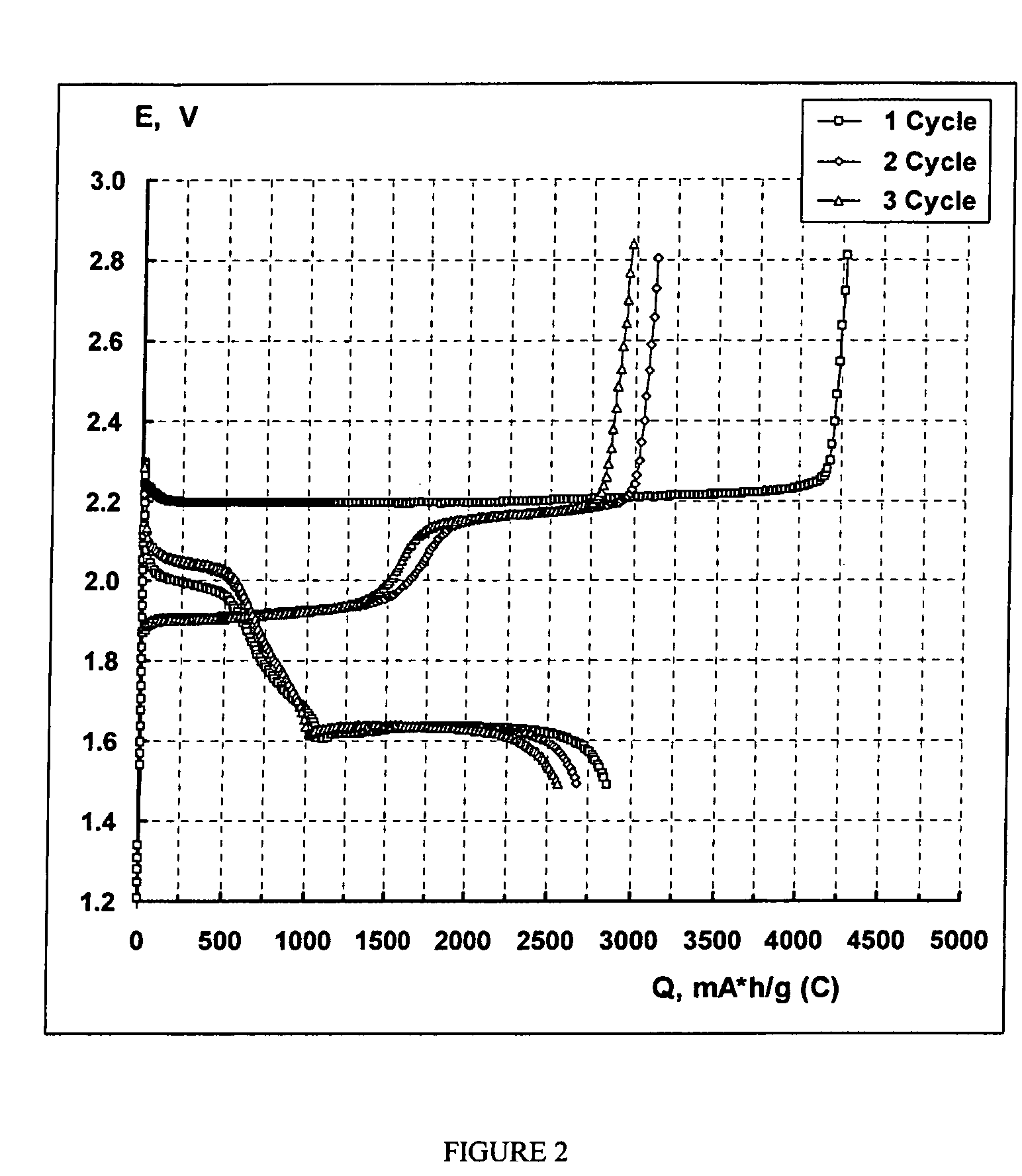

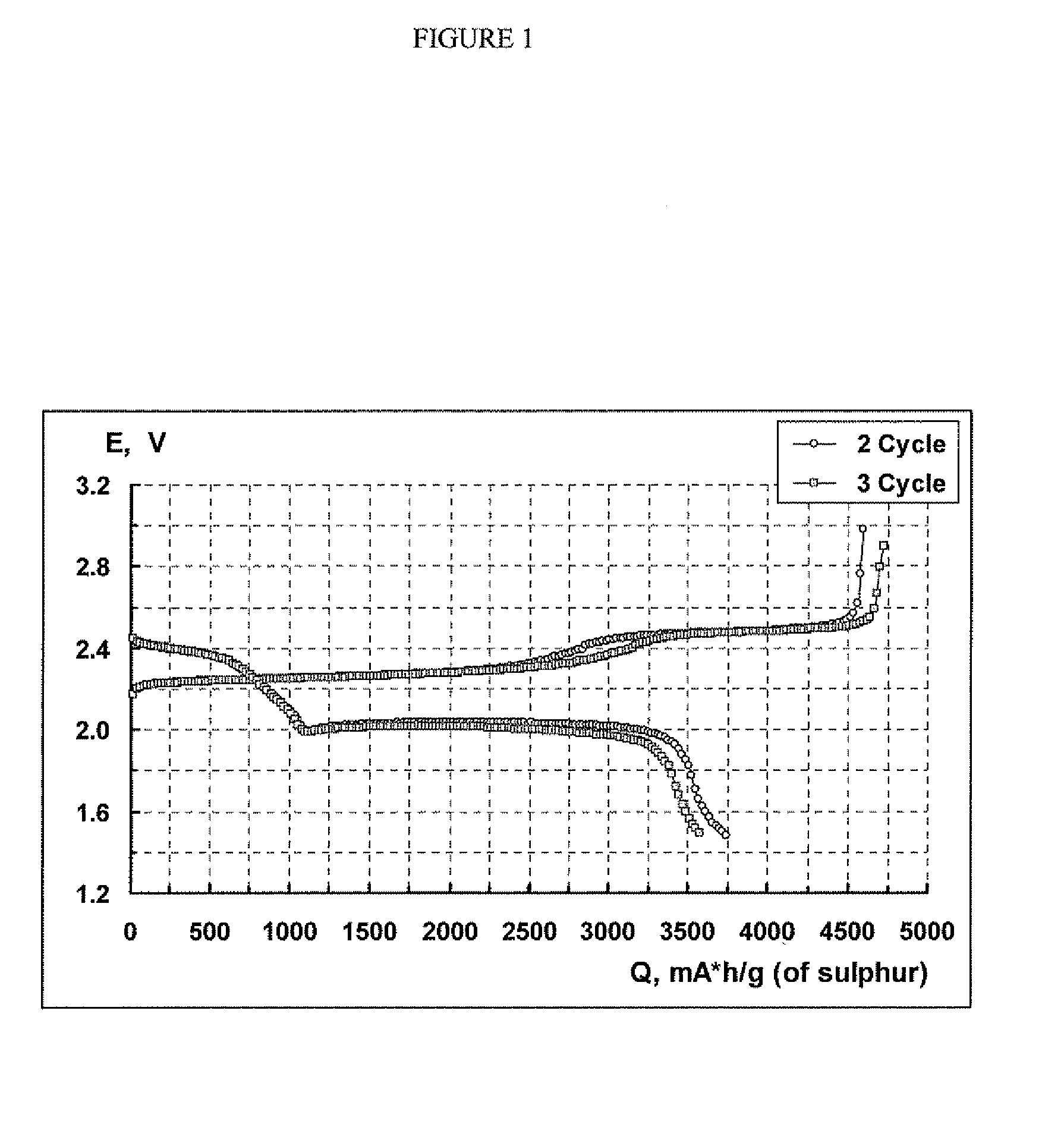

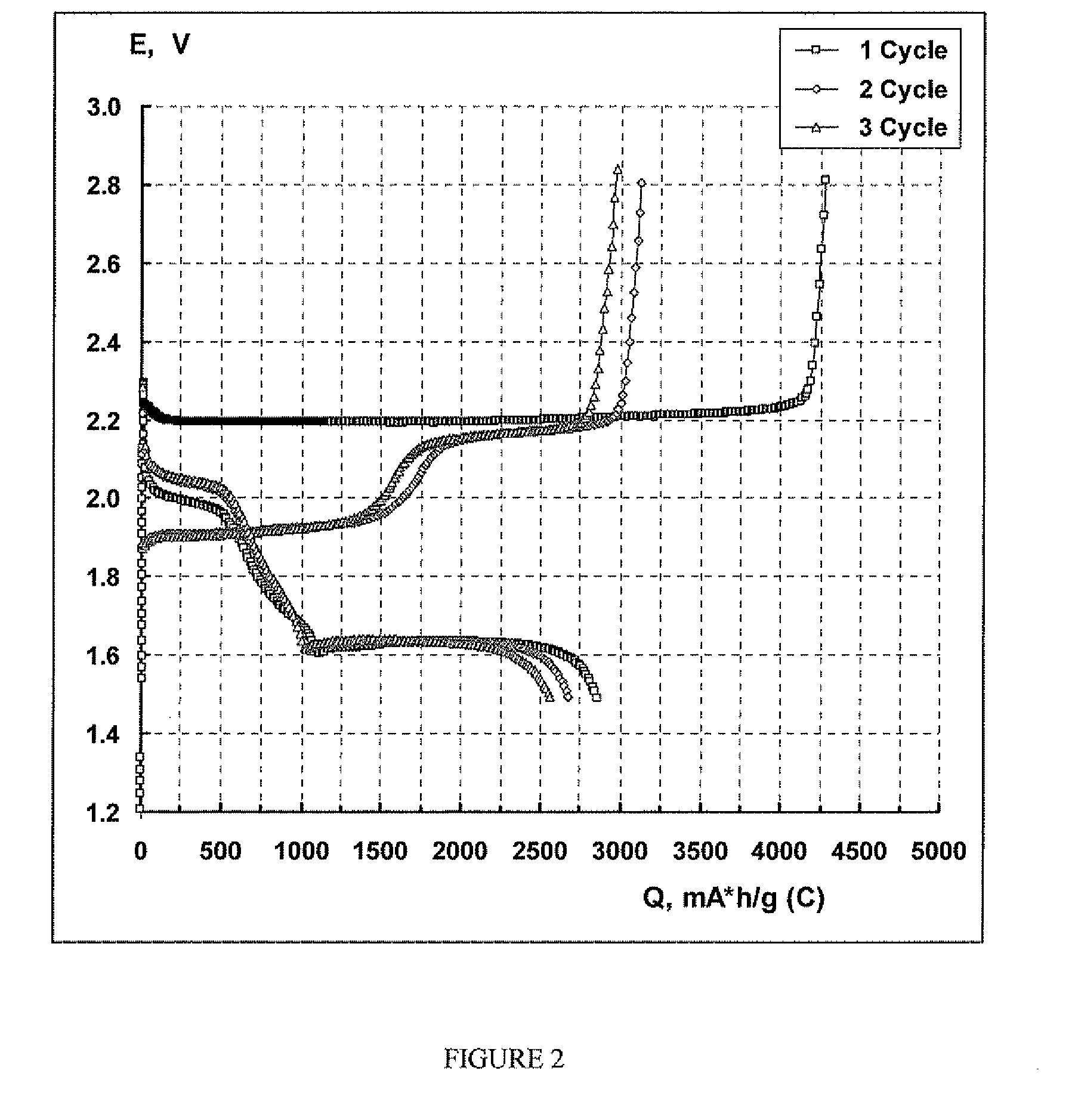

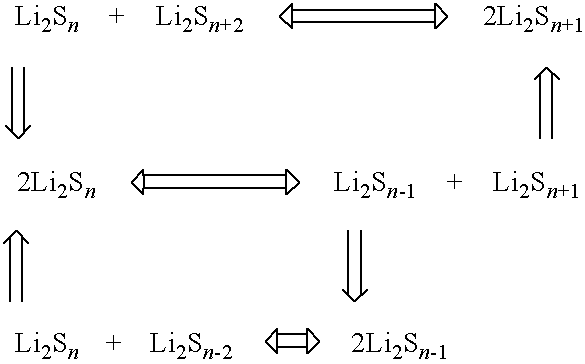

Lithium sulphide battery and method of producing the same

ActiveUS7695861B2Add depthShorten the lengthFinal product manufactureElectrode carriers/collectorsLithiumSulfur

A chemical source of electrical energy may include a positive electrode (cathode) made of an electrically conductive material, a mixture of lithium sulphide and sulphur, a permeable separator or membrane, and a negative electrode (anode) made of an electrically conductive material or a material that is able reversibly to intercalate lithium ions, wherein an aprotic electrolyte comprising at least one lithium salt in at least one solvent is provided between the electrodes.

Owner:INTELLIKAFT LTD +1

Practice drumhead assembly

ActiveUS20070163422A1Easy to disassembleReduce outputPercussion musical instrumentsFriction grip releasable fasteningsDrumheadEngineering

A practice drumhead assembly including a mesh membrane held in substantially fixed relation to an acoustic membrane. The assembly preferably includes an annular tensioning ring for tensioning the mesh membrane, and an engagement member for substantially fixing the mesh membrane relative to the acoustic membrane. The tensioning ring includes a cylindrical rod with a turnbuckle that is rotated to increase the diameter of the tensioning ring.

Owner:RTOM CORP CORP

Practice drumhead assembly

ActiveUS7514617B2Easy to disassembleReduce outputPercussion musical instrumentsFriction grip releasable fasteningsDrumheadEngineering

A practice drumhead assembly including a mesh membrane held in substantially fixed relation to an acoustic membrane. The assembly preferably includes an annular tensioning ring for tensioning the mesh membrane, and an engagement member for substantially fixing the mesh membrane relative to the acoustic membrane. The tensioning ring includes a cylindrical rod with a turnbuckle that is rotated to increase the diameter of the tensioning ring.

Owner:RTOM CORP CORP

Drumhead assembly with improved rebound

ActiveUS20070163423A1Easy to disassembleReduce outputPercussion musical instrumentsFriction grip releasable fasteningsDrumheadEngineering

A drumhead comprising a mesh membrane having a bottom surface and a damper contacting at least a portion of the bottom surface for improved rebound. Also, a practice drumhead assembly including the mesh membrane with a damper in contact with at least a portion of the bottom surface, held in substantially fixed relation to an acoustic membrane. The assembly preferably includes an annular tensioning ring for tensioning the mesh membrane, and an engagement member for substantially fixing the mesh membrane relative to the acoustic membrane. The tensioning ring includes a cylindrical rod with a turnbuckle that is rotated to increase the diameter of the tensioning ring.

Owner:RTOM CORP CORP

Drumhead assembly with improved rebound

ActiveUS7498500B2Easy to disassembleReduce outputPercussion musical instrumentsFriction grip releasable fasteningsDrumheadEngineering

Owner:RTOM CORP CORP

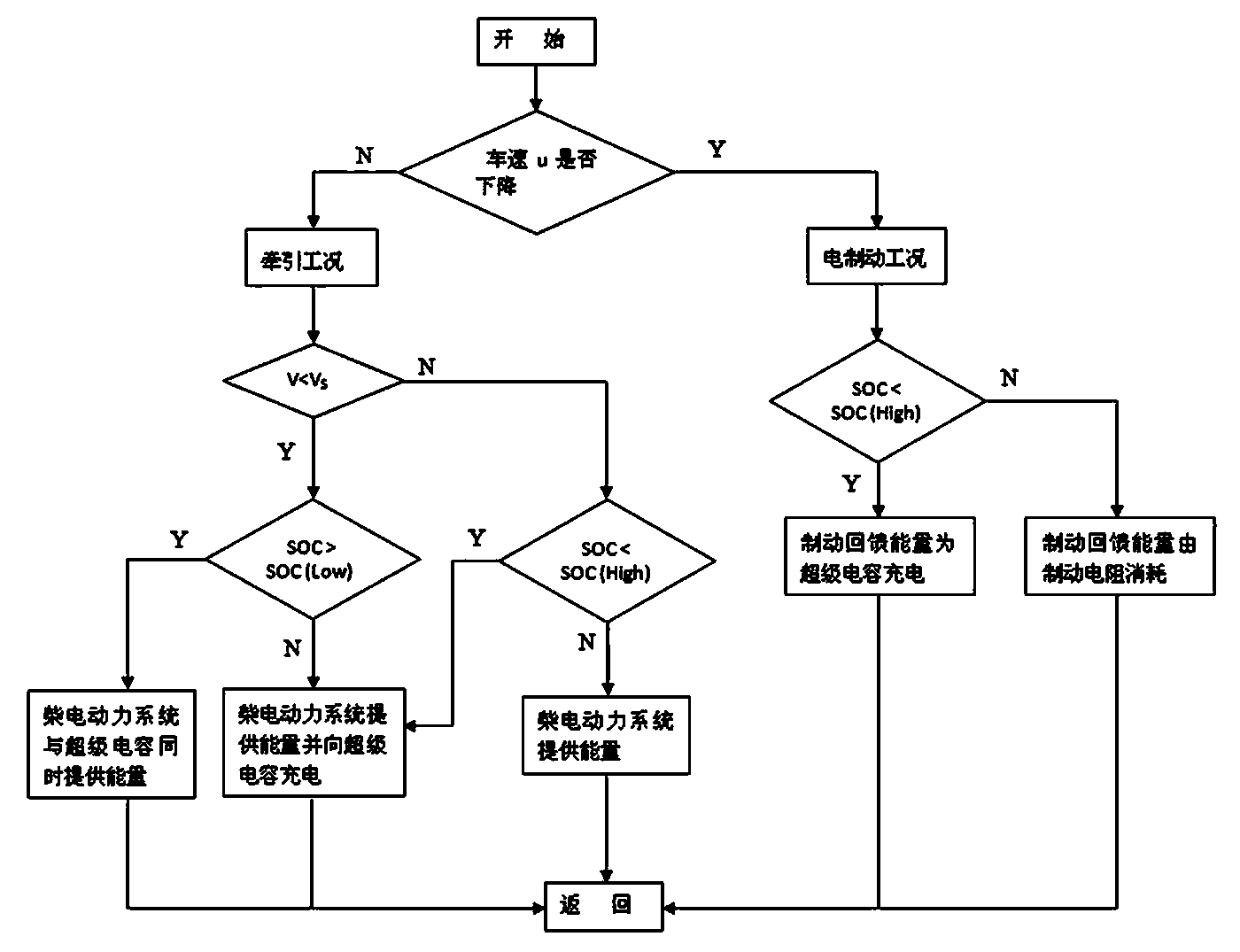

Energy control method for hybrid power mining electric wheel dumper

ActiveCN103832286AReduced energy outputImprove powerElectrodynamic brake systemsCapacitanceWheel speed sensor

The invention relates to an energy control method for a hybrid power mining electric wheel dumper. The energy control method comprises the following steps that firstly, after the dumper is started, a wheel speed sensor of an electric wheel starts to work and inputs a wheel speed signal to an electric transmission control system to be judged; secondly, the electric transmission control system monitors the voltage of a direct current bus in real time; thirdly, an energy managing unit monitors the SOC of a super-capacitor auxiliary power source; fourthly, the energy managing unit monitors the SOC of the super-capacitor auxiliary power source again; fifthly, if the monitored SOC value of the super-capacitor auxiliary power source is no less than the set SOC maximum value, electric braking feedback energy of the electric wheel is consumed through a braking resistor, and if the monitored SOC value is smaller than the set SOC maximum value, the redundant electric braking feedback energy of the electric wheel is consumed by the braking resistor. The energy control method plays a peak clipping and valley filling role to enable a diesel engine to often work in a high efficiency zone, and meanwhile, the electric braking energy of the dumper can be recycled.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Ground collision instrument for aircraft and marine vehicles

ActiveUS20090219189A1Reduce output energyNarrow down the scan rangeRadio wave reradiation/reflectionICT adaptationRadarHandling system

Radar return processing systems and methods are operable to process radar information when an installation vehicle is operating in proximity to a surface area of interest. An exemplary embodiment reduces energy of an output pulse emitted from a radar system; receives a plurality of radar returns from a plurality of objects that reflect the reduced energy output pulses emitted from the radar system; determines a surface area of interest based upon at least a current location of the installation vehicle; and filters the radar returns generated by objects that are located outside of the surface area of interest. Optionally, some systems and methods may reduce a sweep range of an antenna from which the reduced energy output pulses are emitted.

Owner:HONEYWELL INT INC

Acoustic/electronic drum assembly

InactiveUS8933310B2Reduced energy outputLower the volumeElectrophonic musical instrumentsPercussion musical instrumentsDrumheadEngineering

Owner:RTOM CORP CORP

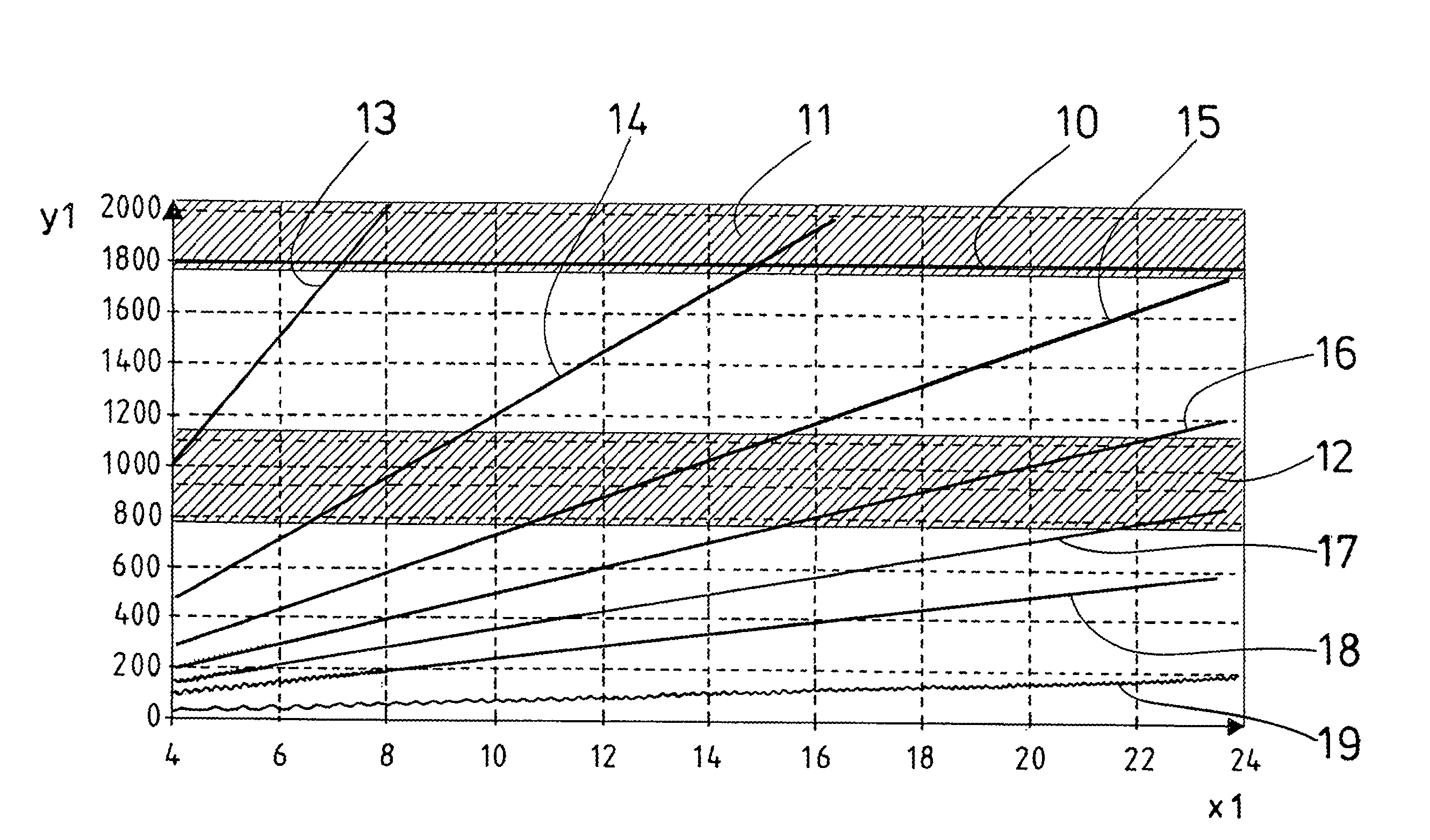

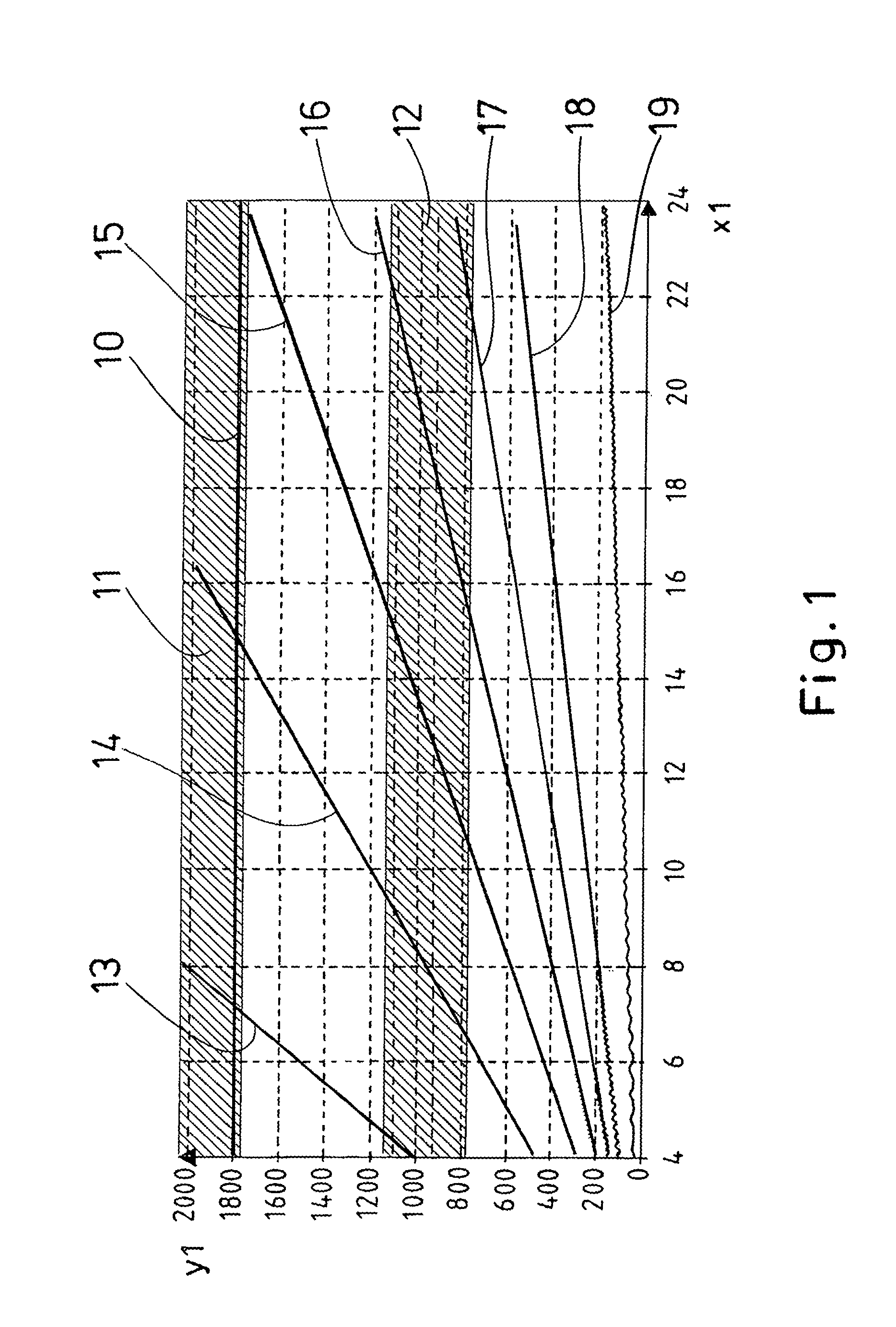

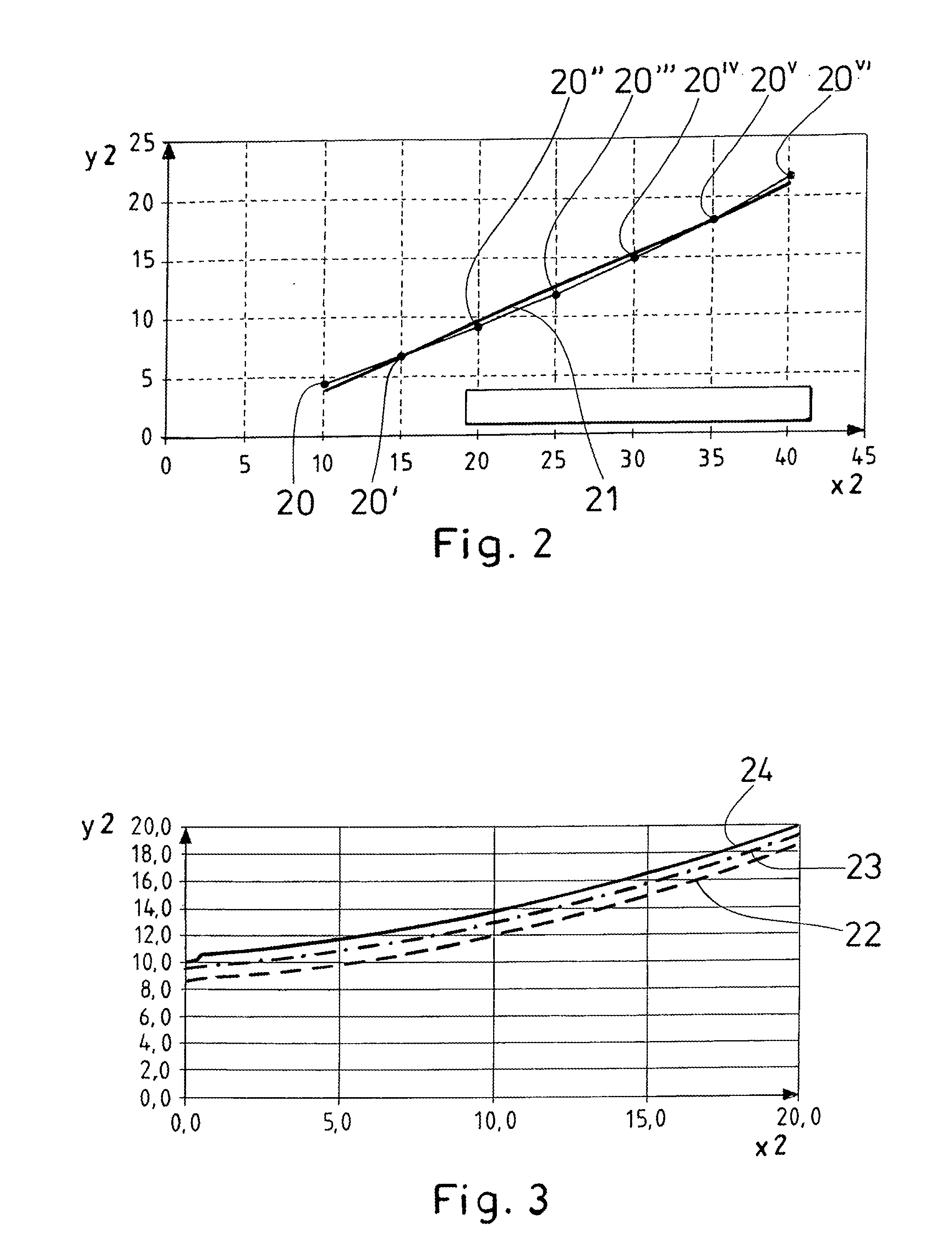

Method for operating a wind power plant

ActiveUS20140186177A1Weaken energyEliminate disadvantagesPropellersWind motor controlPeaking power plantPower station

A method for operating a wind power plant having at least one rotor blade, the blade angle of which can be adjusted. The wind power plant is operated with a predefinable reduced energy output set point. To determine the potential output, at least one predefinable operating parameter of the wind power plant is measured and is applied to at least one stored characteristic curve for the reduced energy output set point. The actual energy output is determined and the loss in the output is formed from the difference between the potential output and the actual energy output.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

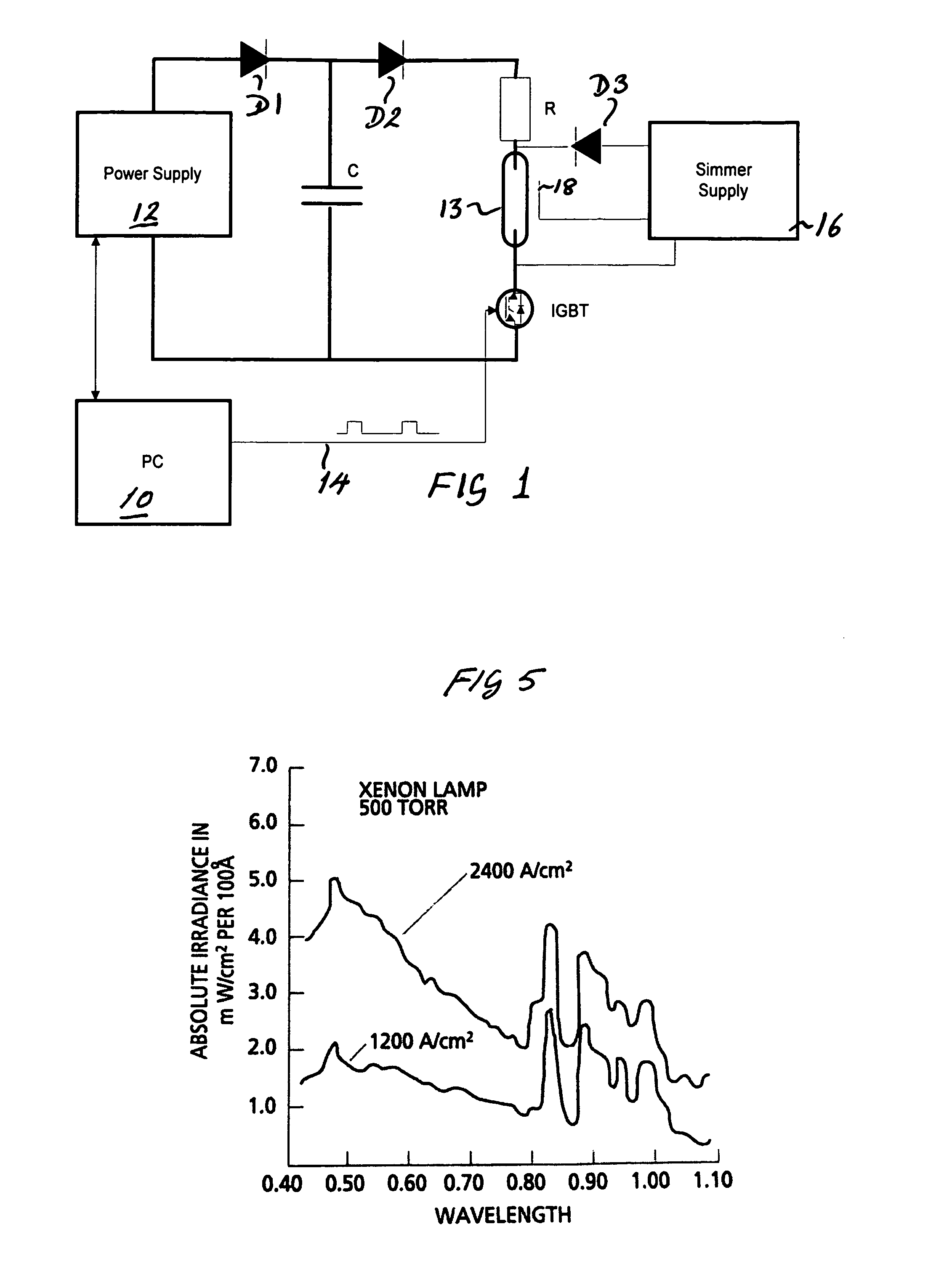

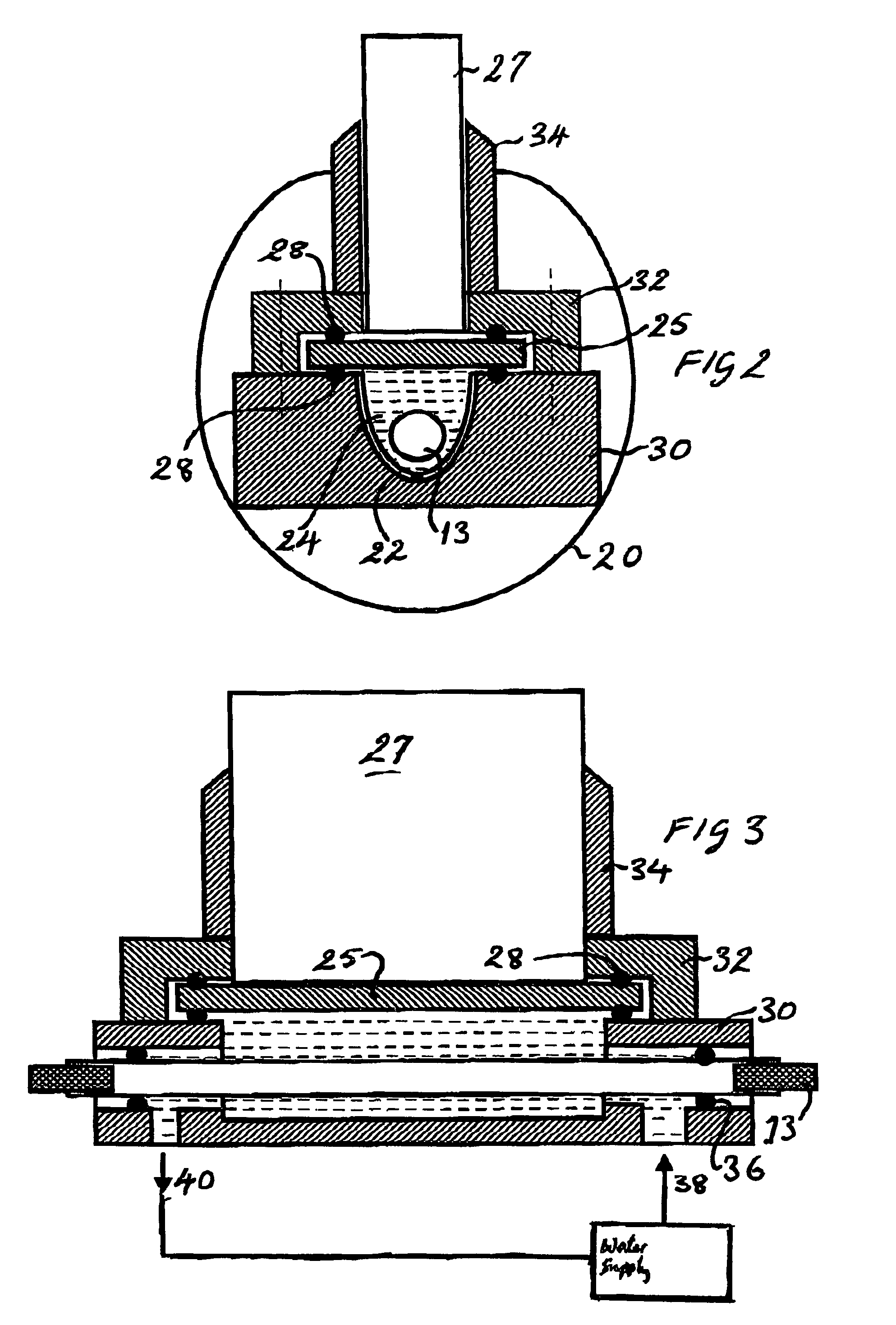

Light pulse generating apparatus and cosmetic and therapeutic phototreatment

InactiveUS8226696B1High intrinsic power lossIncreased power lossSurgical instrument detailsLight therapyLight guideSkin surface

Apparatus for therapeutic or cosmetic photo-treatment comprises a flash lamp and a lamp operating circuit. The lamp is cooled by water in contact with the lamp which acts as an infra-red filter to reduce skin burning. Light from the lamp reaches the skin through a light guide which has a convex curved end to focus the light and to press away haemoglobin in the target area or has a concave end to reduce pressure on the skin depending on the desired treatment. Relatively long and low power square shaped power pulses drive the lamp to produce light output pulses adapted to the relaxation time of the target structure to maximize the heating of the target while minimizing heating of the skin surface. Target structures may be blood vessels or hair follicles. Automatic detection of a glass filter may be provided.

Owner:FOARD GEYSEN +1

Repeatable heat-treating methods and apparatus

ActiveUS9482468B2Change efficiencyAvoid the needRadiation pyrometrySemiconductor/solid-state device testing/measurementTemperature controlHeating effect

A first heat-treating method involves monitoring at least one thermal efficiency parameter associated with an irradiance system configured to produce an irradiance flash incident on a surface of a workpiece, and automatically updating control information used by the irradiance system to produce the irradiance flash, in response to the monitoring of the thermal efficiency parameter. A second method involves predicting a heating effect of an irradiance flash to be incident upon a surface of a workpiece, in response to a measurement of a heating parameter of the surface, and pre-adjusting the irradiance flash, in response to the predicted heating effect. A third method involves measuring a temperature of a surface of a workpiece during an initial portion of an irradiance flash incident on the surface, and controlling a power of a remaining portion of the irradiance flash, in response to the temperature.

Owner:MATTSON TECHNOLOGY +1

Handheld tool for breaking up rock

InactiveUS20050257675A1Easy to drillHigh level of skillCartridge extractorsUnderground miningClassical mechanicsRetainer

A tool (12) has a body (14) with a barrel (18) having opposing threaded and fitted openings (30 and 28). An actuator pin tube (26), for slidably engaging an actuator pin (38) having a tip (40) opposing a retention head (42), extending from the fitted opening (30). A spring assembly (24), disposed in the barrel (18), has a hammer guide (44) engaged in the threaded opening (28) with a hammer (46) slidably engaged therein, a handle mechanism (55) disposed at one end and a spring retainer (52) disposed adjacent the other end of the hammer (46) before a hammerhead (51), and a spring (54) engaged between the hammer guide (44) and the spring retainer (52). A release mechanism (56) engages the hammer (46). A kit (108) containing the tool (12) and a method of operating the tool (12) involving drilling and cleaning a borehole, inserting a cartridge and tool therein, and detonating the load remotely using a pull cord.

Owner:BASSETT CARROLL

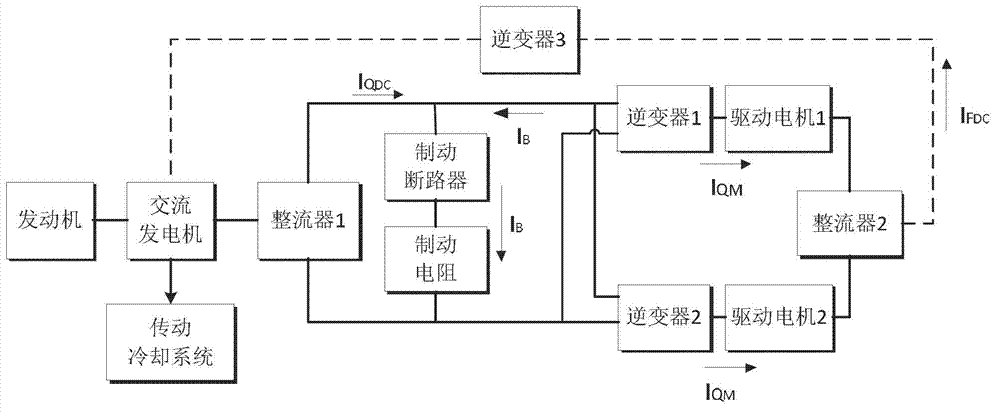

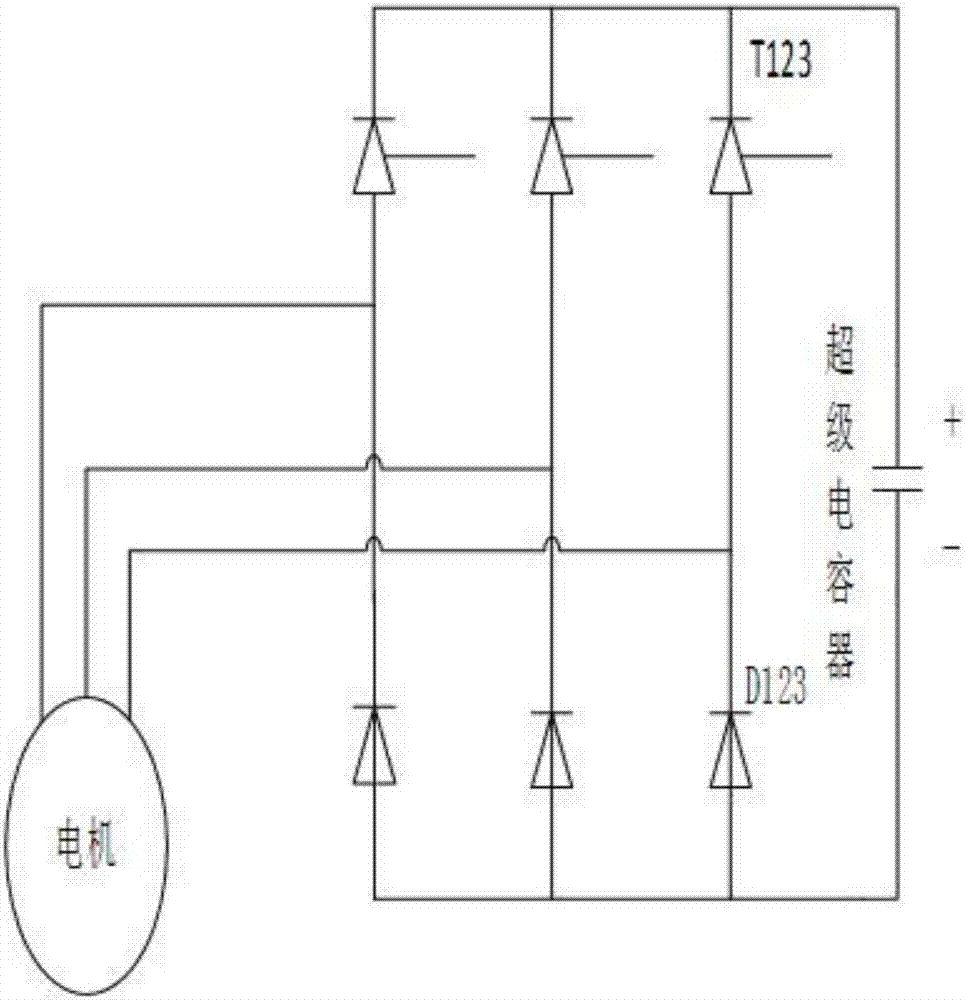

Energy-saving control system for braking process of electrically-driven mining automobile

InactiveCN102963268AReduced energy outputAchieve energy saving effectSpeed controllerElectrodynamic brake systemsControl mannerEngineering

The invention provides an energy-saving control system for braking process of an electrically-driven mining automobile, which comprises an engine, an alternator, a rectifier I, an inverter I, an inverter II, a driving motor I, a driving motor II, a brake circuit breaker, a braking resistor and a transmission cooling system. The control system further comprises a control loop for braking process; the control loop for braking process comprises a rectifier II and an inverter III. The control system provided by the invention saves the energy output of the engine by changing the vehicle energy transfer path and control mode during the braking process, so as to achieve the effect of energy conservation.

Owner:UNIV OF SCI & TECH BEIJING

Lithium sulphide battery and method of producing the same

InactiveUS20100196757A1Add depthShorten the lengthAlkaline accumulatorsFinal product manufactureLithiumSulfur

A chemical source of electrical energy may include a positive electrode (cathode) made of an electrically conductive material, a mixture of lithium sulphide and sulphur, a permeable separator or membrane, and a negative electrode (anode) made of an electrically conductive material or a material that is able reversibly to intercalate lithium ions, wherein an aprotic electrolyte comprising at least one lithium salt in at least one solvent is provided between the electrodes.

Owner:OXIS ENERGY

Internal circulation drying system for household dishwasher

PendingCN108403061ASimple structureReduced energy outputTableware washing/rinsing machine detailsHome appliance efficiency improvementProcess engineeringAir drying

The invention provides an internal circulation drying system for a household dishwasher and belongs to the technical field of dishwashers. The technical problems that drying systems of existing dishwashers have complicated structures and energy cannot be saved are solved. The dishwasher includes an inner container, and the internal circulation drying system includes a circulation pipeline and a drying assembly. Both ends of the circulation pipeline can be communicated with the inner container separately to form an internal circulation passage, and the drying assembly is disposed in the middleof the circulation pipeline and can perform drying treatment on air passing through the internal circulation passage. The internal circulation drying system for the domestic dishwasher has the advantages of achieving efficient drying of bowls and chopsticks, saving energy and not causing secondary pollution to the bowls and the chopsticks.

Owner:MARSSENGER KITCHENWARE CO LTD

Solar-infrared hybrid collector

ActiveUS20150349698A1High power outputLow utilizationPV power plantsPhotovoltaic energy generationEngineeringSolar energy harvesting

A system and method for improving solar collector design to provide thermal and electric output during times of low or no solar intensity. The improved solar collector design includes an infrared heater to supplement energy provided by the sun during time of low or no solar intensity.

Owner:GAS TECH INST

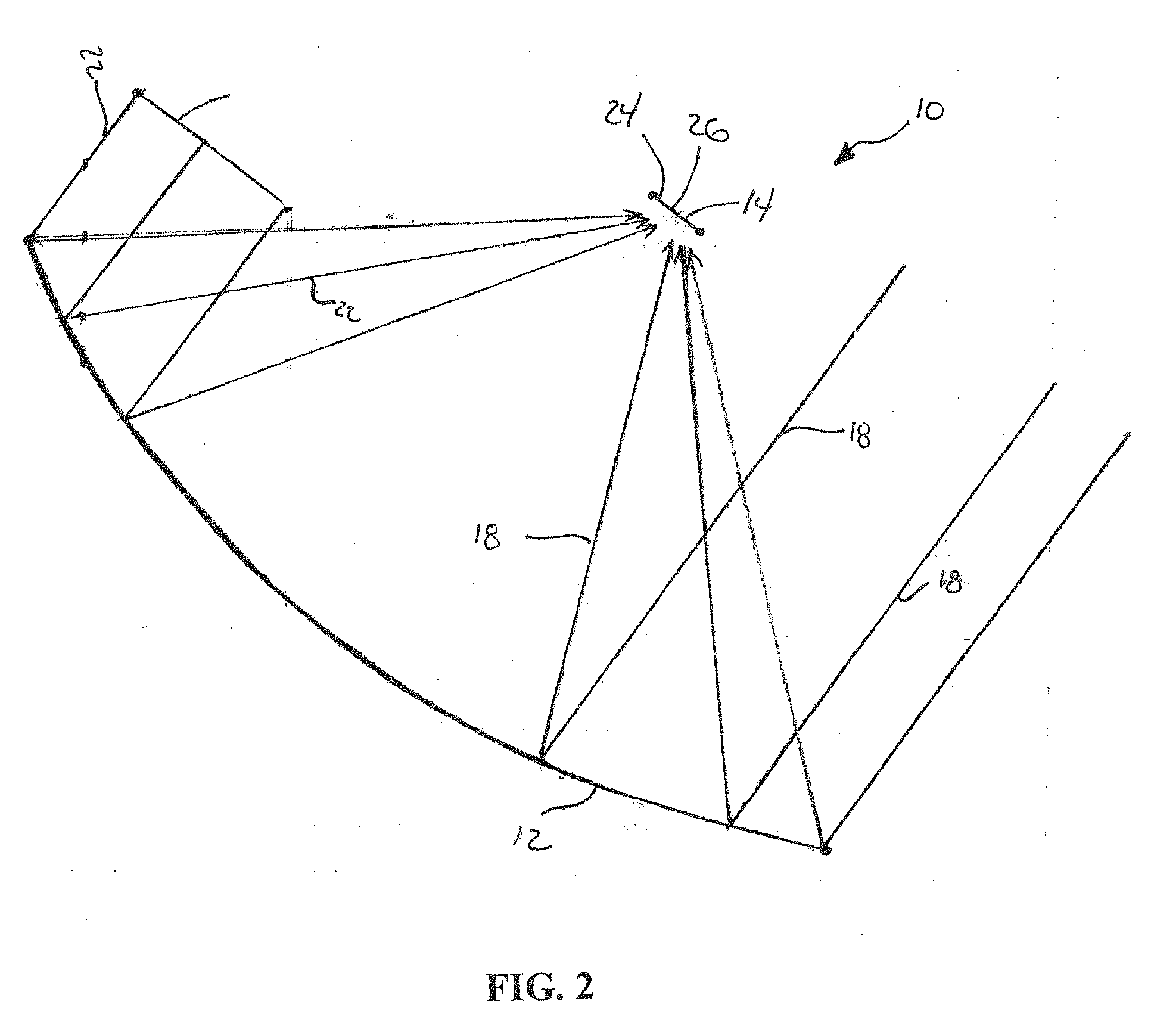

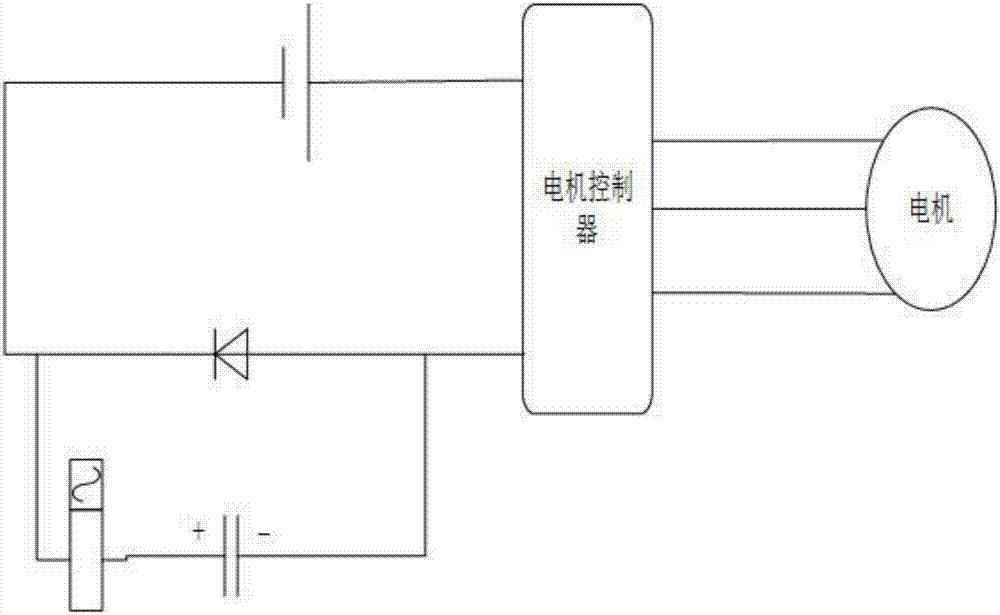

Control device and method for electric car driving and braking system

ActiveCN107117040AReduced energy outputPrevent reverse chargingSpeed controllerElectrodynamic brake systemsThree-phase electric powerCapacitance

The invention discloses a control device and method for an electric car driving and braking system. The device comprises a motor controller, a three-phase motor, a diode, a rectifying circuit, a super capacitor, a power battery, a thyristor triggering circuit, an inductor and a relay. In driving, when the terminal voltage of the super capacitor is higher than the voltage between an audion base electrode and a collector electrode, the relay is switched on, and the super capacitor and the power battery together drive the motor to rotate; when the terminal voltage of the super capacitor is lower than the voltage between the audion base electrode and the collector electrode, the relay is switched off, and at this moment, only the power battery conducts separate drive; and in braking, three-phase power of the motor passes through the inductor and directly charges the super capacitor through the rectifying circuit which is composed of a thyristor and the diode. In driving, the device can reduce energy output of the power battery and prevent discharge of the super capacitor when the voltage is low, and in braking, by adoption of the rectifying circuit with the thyristor, consumption of recovered energy can be reduced.

Owner:JIANGSU UNIV

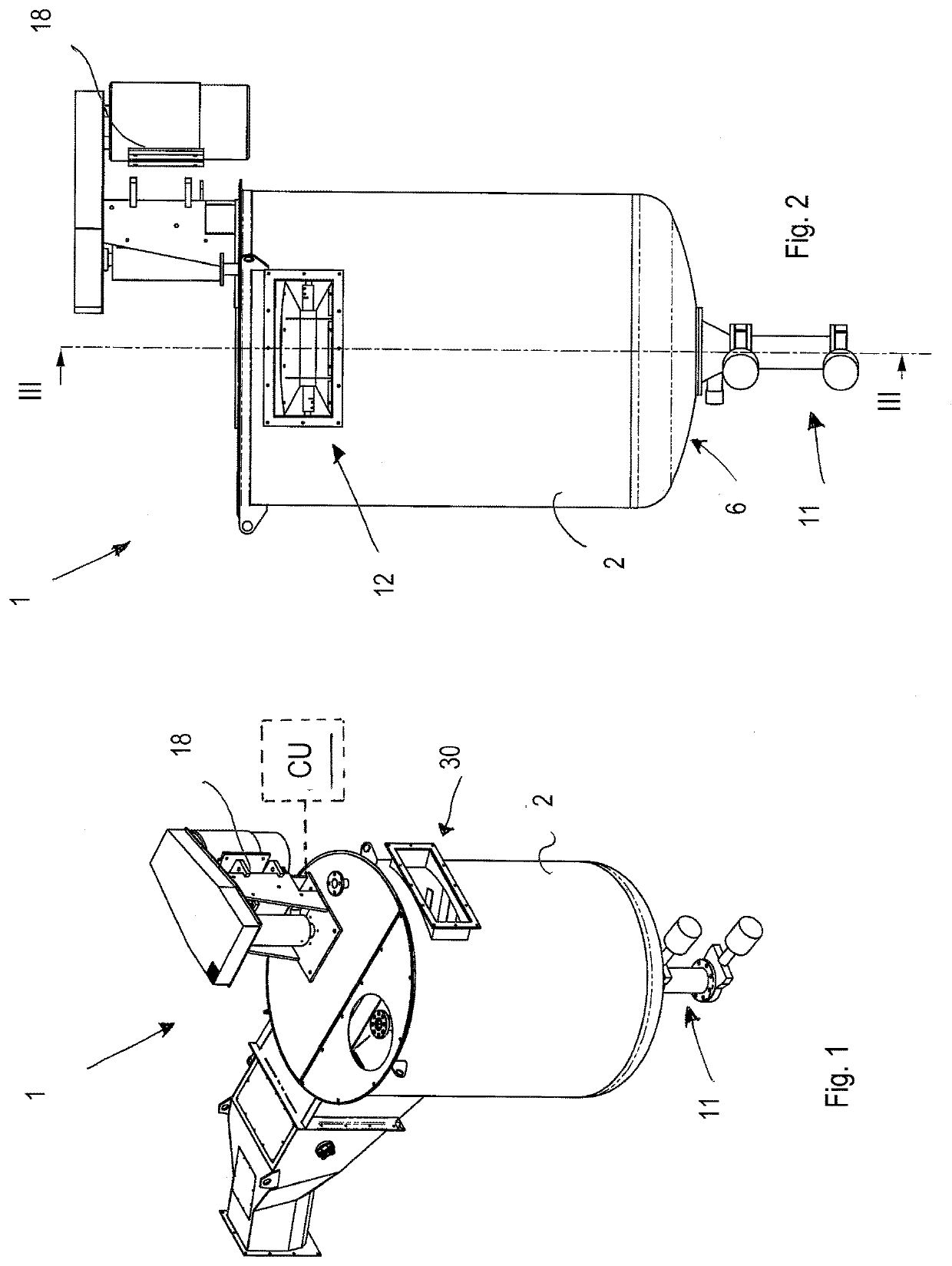

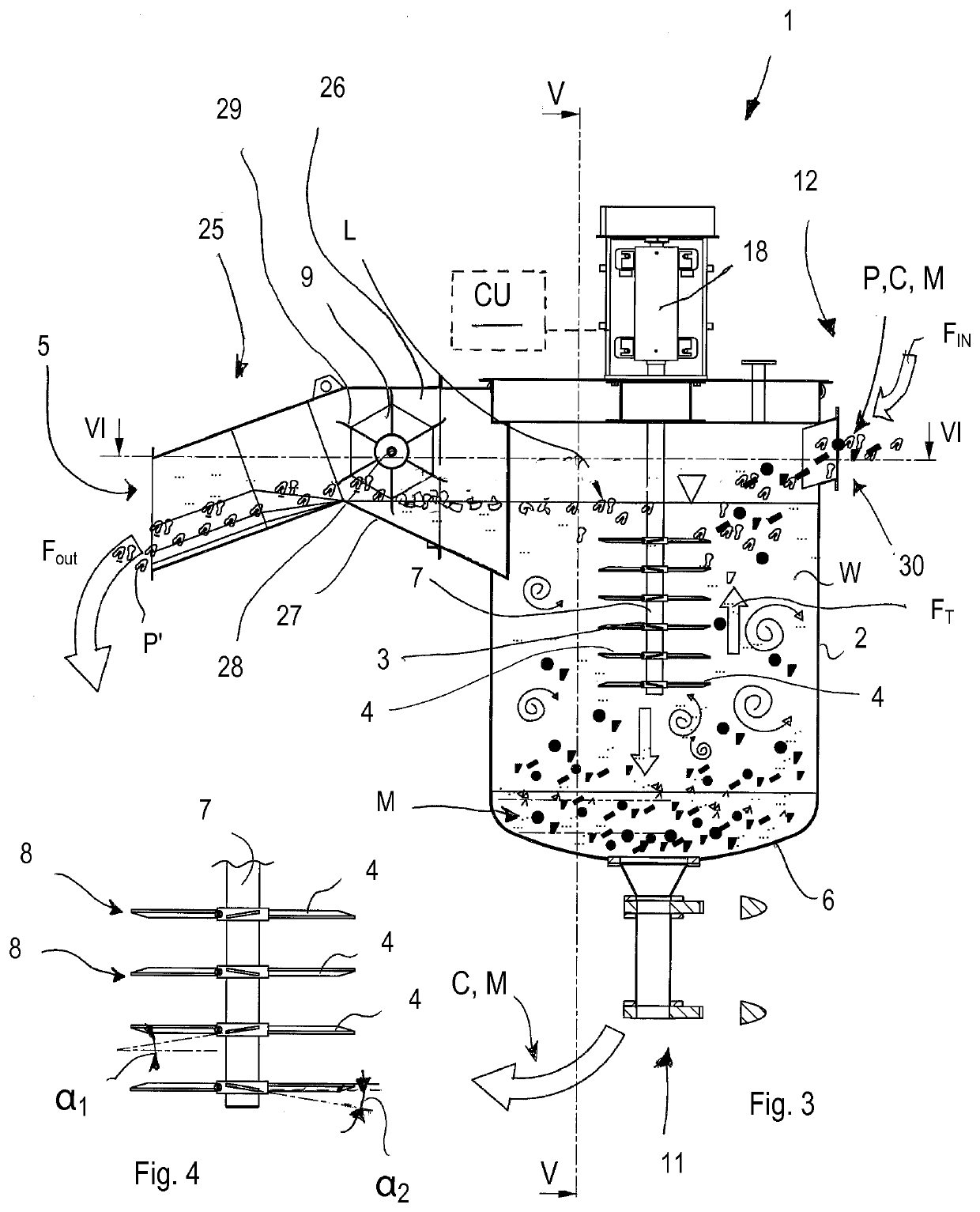

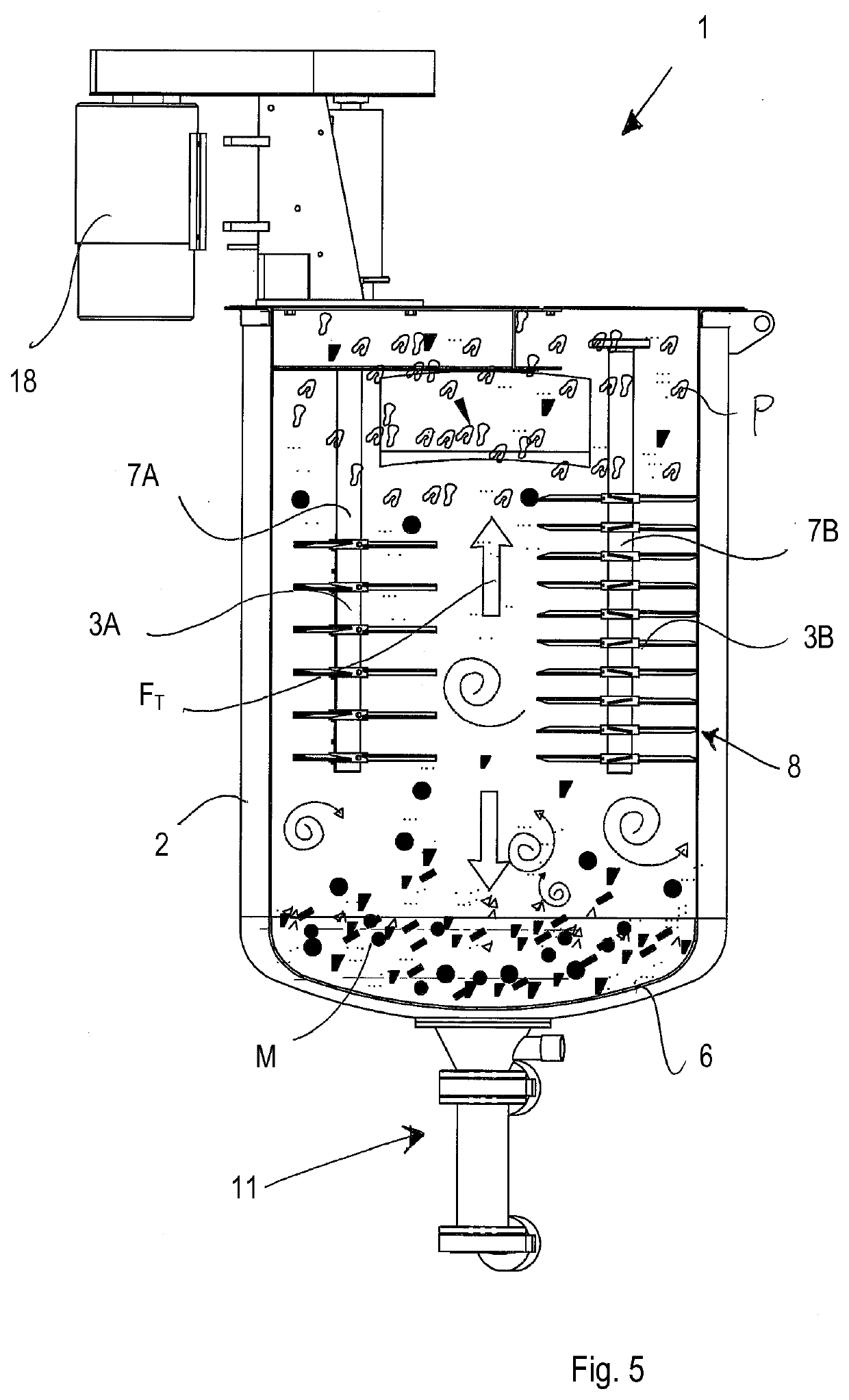

Method and apparatus for washing and separating plastics material

ActiveUS20190351427A1Increase currentHigh level of efficacyPlastic recyclingCleaning using liquidsSufficient timePlastic materials

A method for washing and separating pieces of plastics material from contaminating material that also includes metal elements, comprises the steps of: supplying, to a washing container, a washing fluid, having a first specific weight value , and the pieces of plastics material joined to the contaminating material; driving, in the washing container, a stirring arrangement provided with blades for generating in the washing fluid a turbulent stirring action to remove from the plastics material, through mechanical action, the part of contaminating material adhering thereto. The tilt of the blades and the rotation speed of the stirring arrangement are chosen carefully to generate a thrusting action upwards so as to maintain in a floating condition the plastics material with a specific weight that is greater than the specific weight of the fluid; the force of the thrusting action is limited to a value that is such as not to hinder the downward precipitation of the contaminating metal elements that have a further specific weight value that is greater than the aforesaid second value. The plastics material is retained inside the container for sufficient time to obtain a desired degree of purity and decontamination for the plastics material, after which it is evacuated by controlled overflow. The heavy contaminating material, in particular the metal elements that accumulate on the bottom, are periodically evacuated by a device of valve or pump type. The apparatus for implementing the aforesaid method is also disclosed.

Owner:PREVIERO N

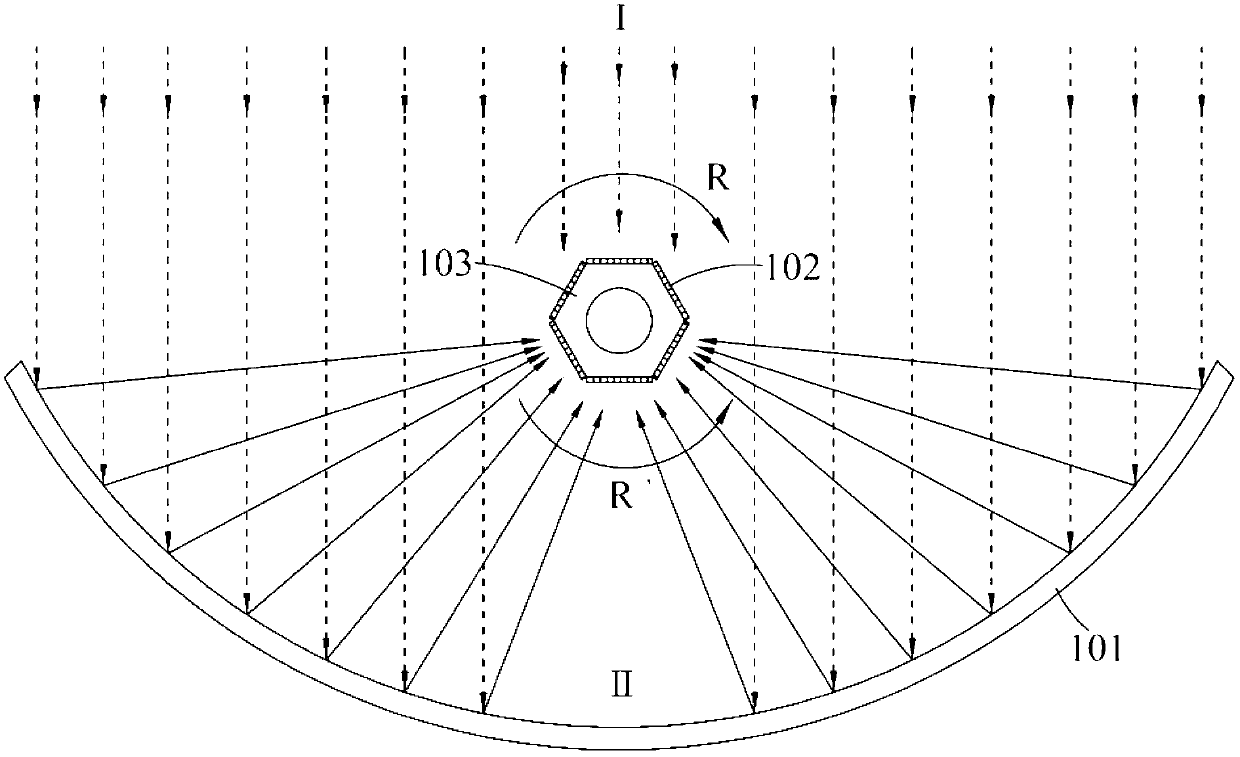

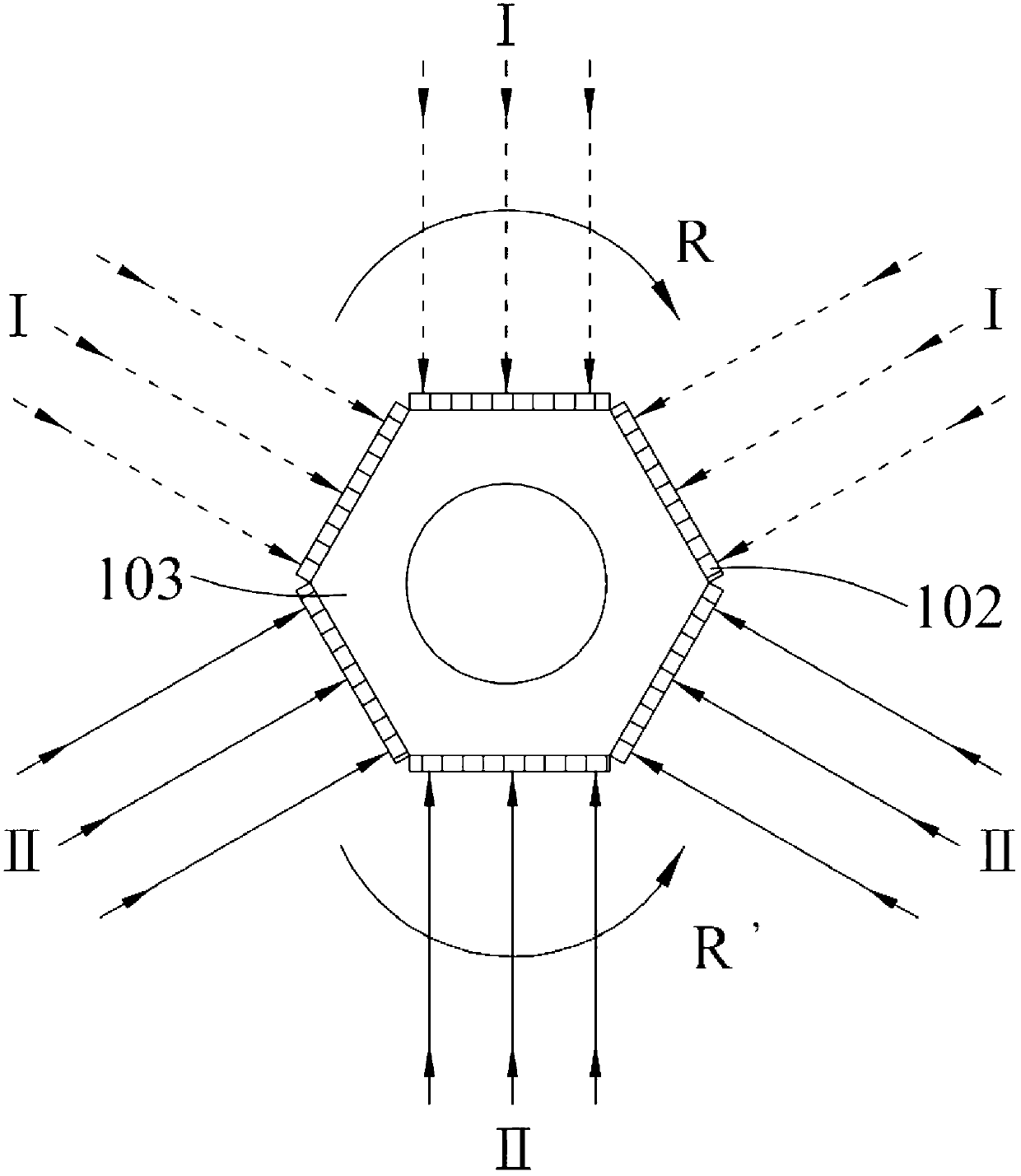

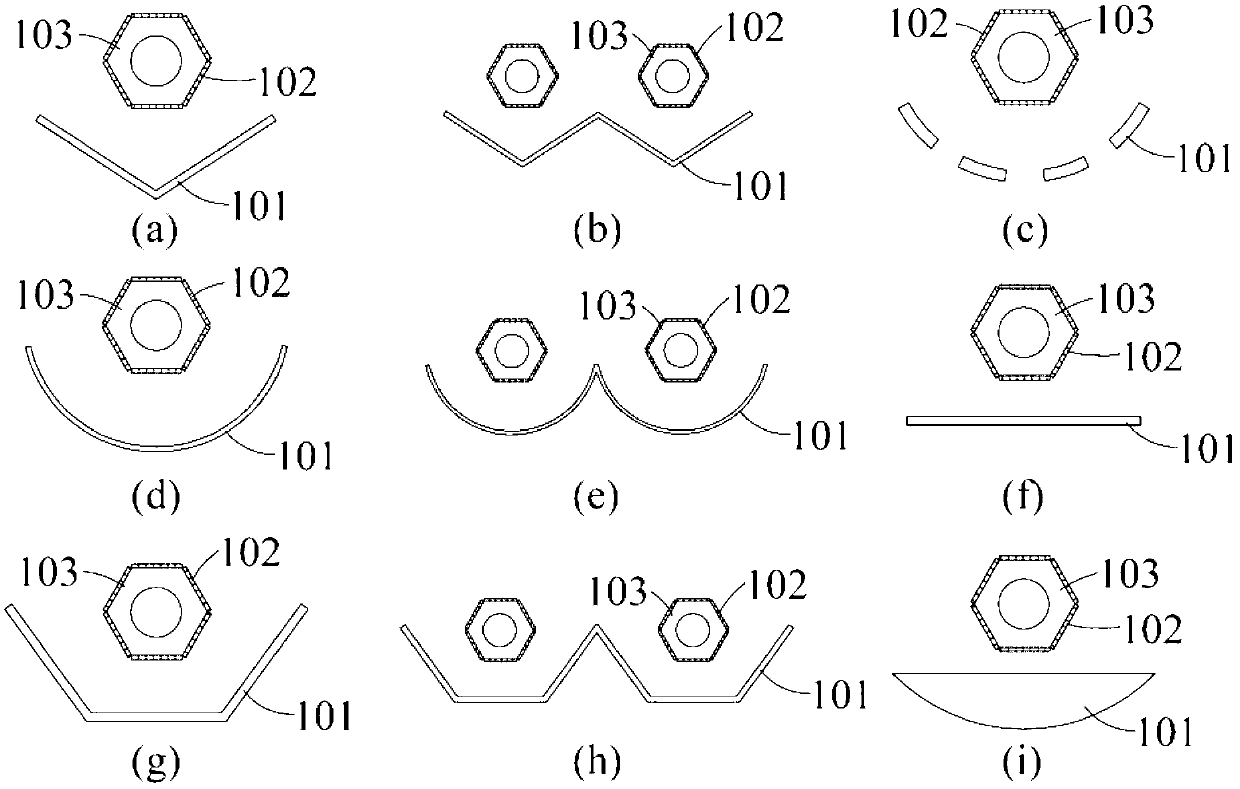

Use of rotating photovoltaic cells and assemblies for concentrated and non-concentrated solar systems

InactiveCN103219409AImprove cooling effectIncrease energy outputPhotovoltaic energy generationThermal-PV hybrid energy generationCell assemblyEngineering

A concentrated and non-concentrated solar photovoltaic (PV) system with rotating PV cells or cell assemblies is provided to enhance cooling, receive both concentrated and non-concentrated sunlight, avoid hot spots and prolong PV cell operation life. The solar PV system comprises: one or more reflectors having a sun-facing side and a non-sun-facing side; and one or more rotating members with attaching PV cells or cell assemblies disposed at the sun-facing side of the reflector, herein the rotating members are able to rotate. The one or more rotating members with PV cells or cell assemblies are placed at predetermined positions at the sun-facing side of the reflector, and, during operation, the PV cells or cell assemblies has at least one light illuminated surface which is able to receive reflected light from different positions of the reflector, the direct solar radiation from the sun or the diffused solar radiation from the surroundings.

Owner:郑佳卿 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com