Patents

Literature

35results about How to "Reduce output energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

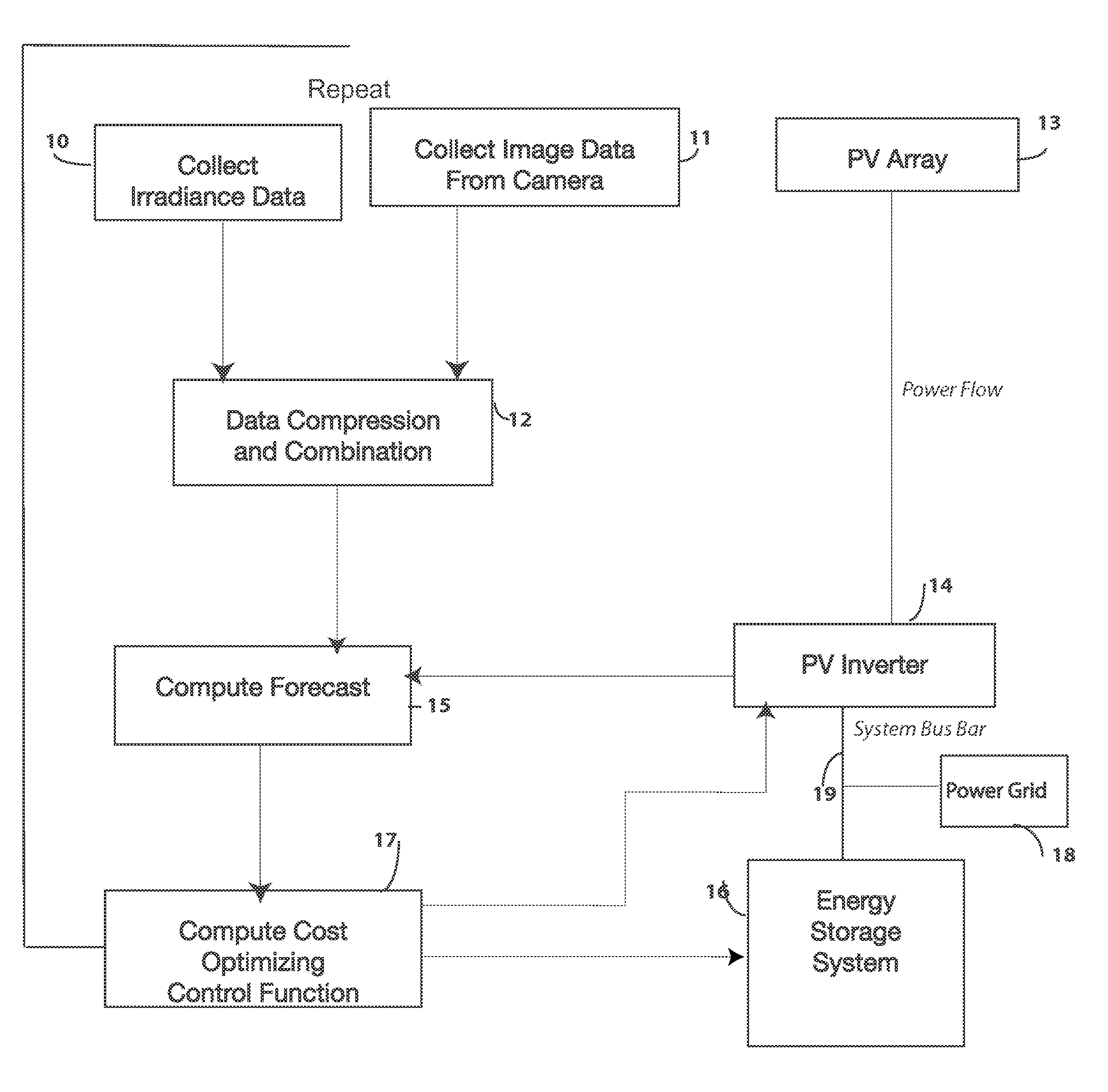

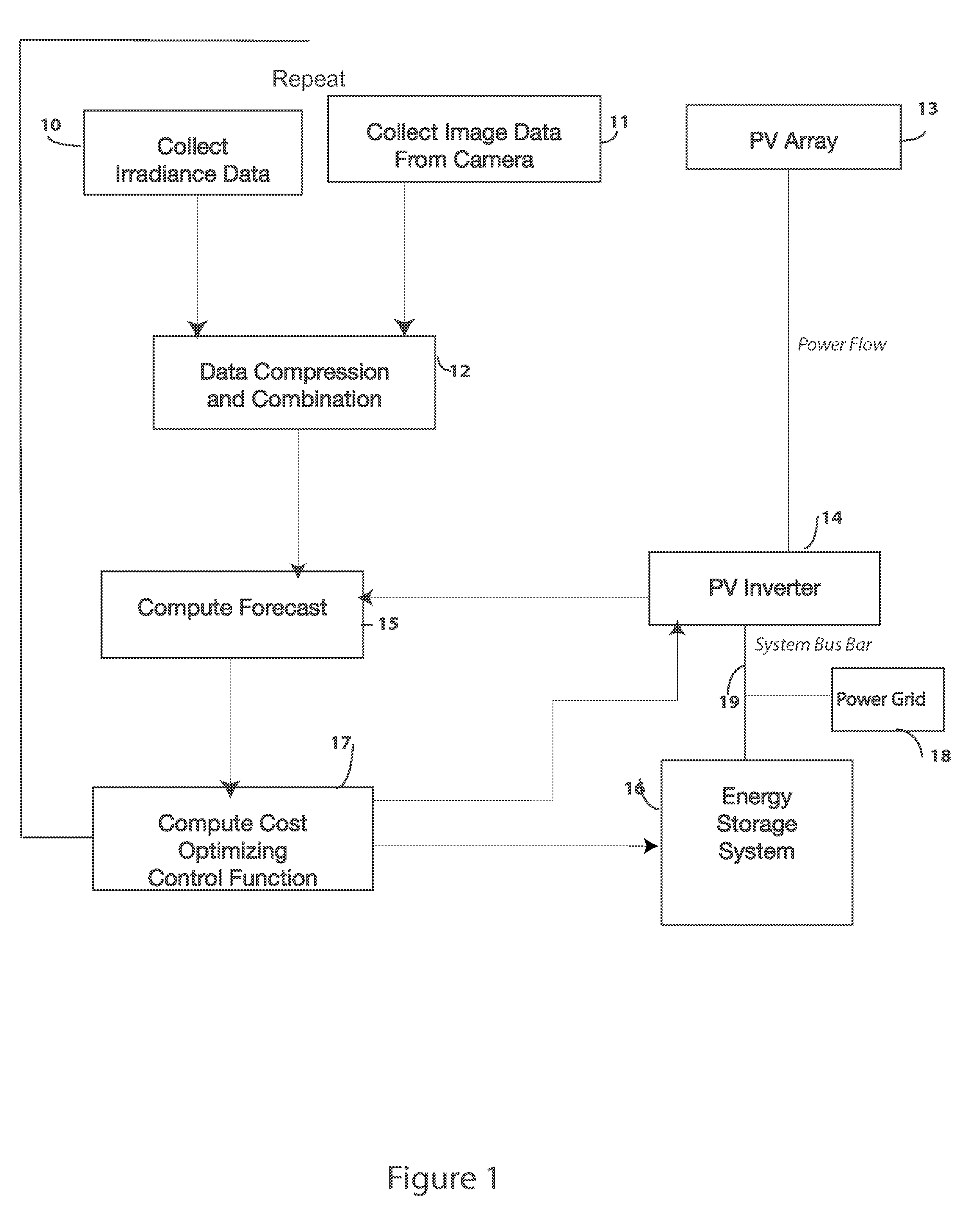

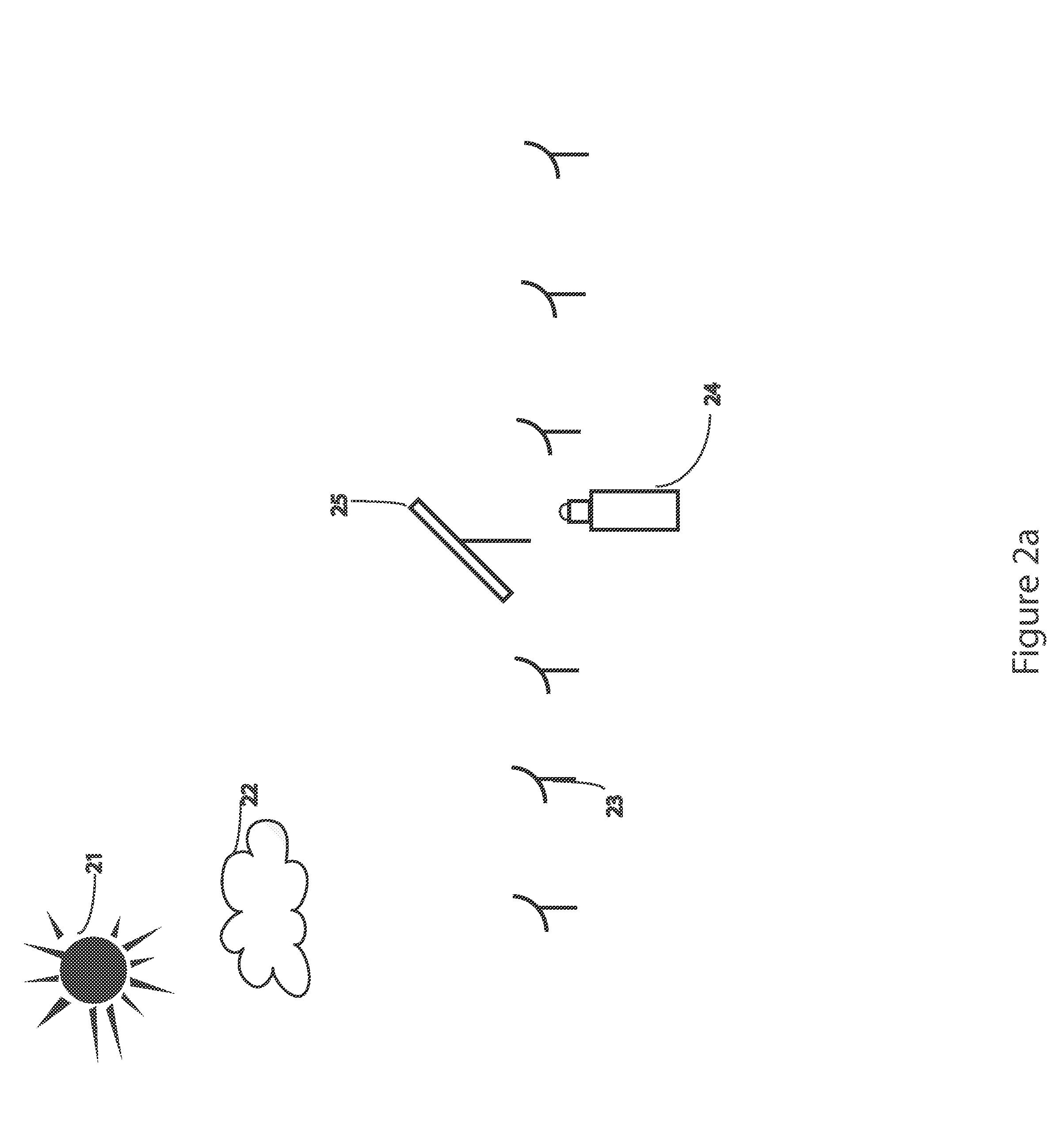

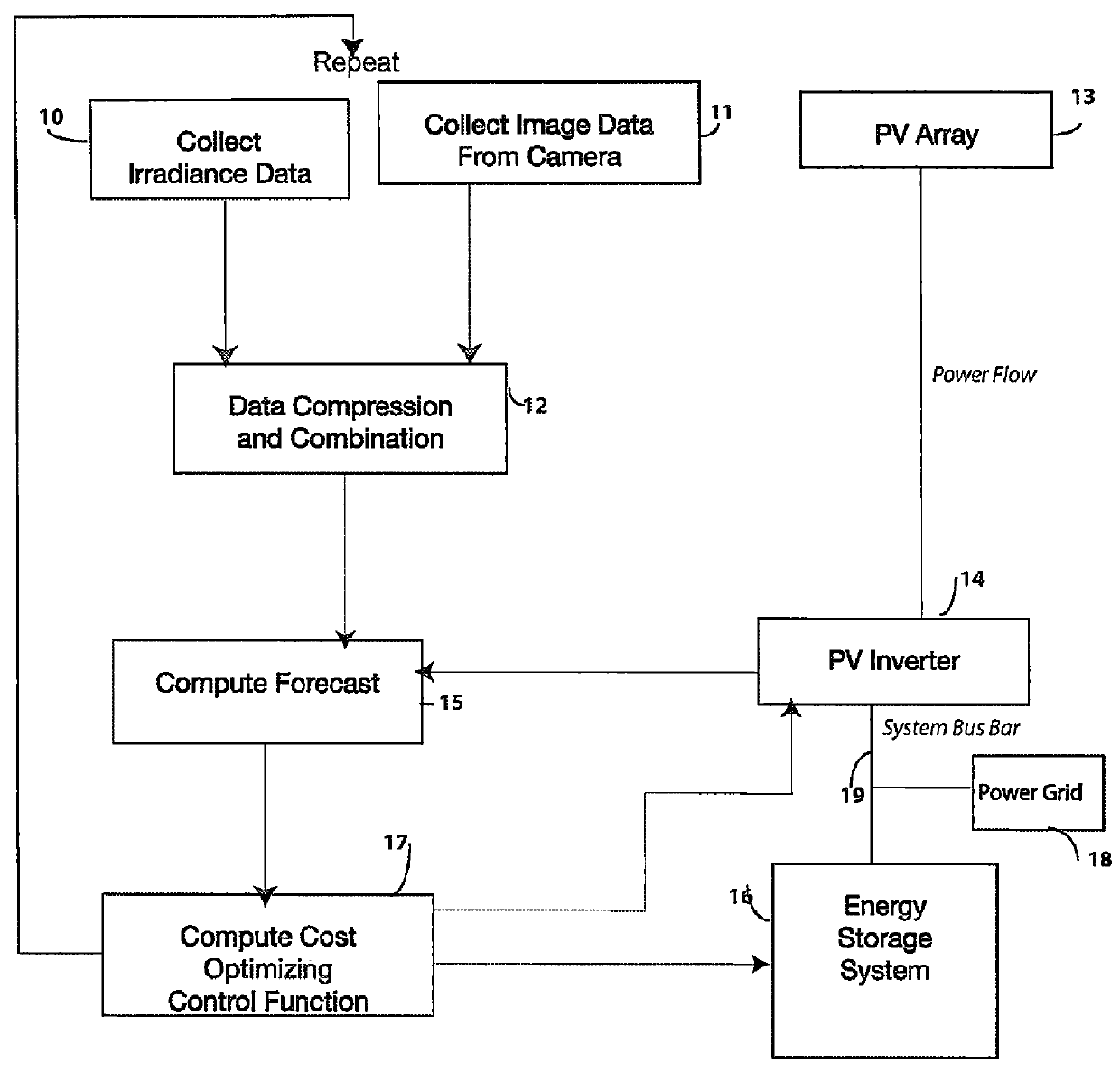

Device for Smoothing Fluctuations in Renewable Energy Power Production Cause by Dynamic Environmental Conditions

InactiveUS20150019034A1Reduce decreaseLoss of revenueSolar heating energySolar heat simulation/predictionPower modulationPower grid

A renewable energy generator imposes costs on a power grid from rapid fluctuations in output. A device is disclosed that collects data on renewable power production, meteorological and other information, forecasts short timescale renewable power production then mitigates costs incurred by power fluctuations by modulating the power output, while maximizing power production revenue. Mitigation may be effected by an AC / DC inverter, an energy storage system, demand response or a FACTS device. The magnitude and costs for modulating response required from energy storage, FACTS or other power modulation equipment is thereby reduced.

Owner:GONATAS CONSTANTINE

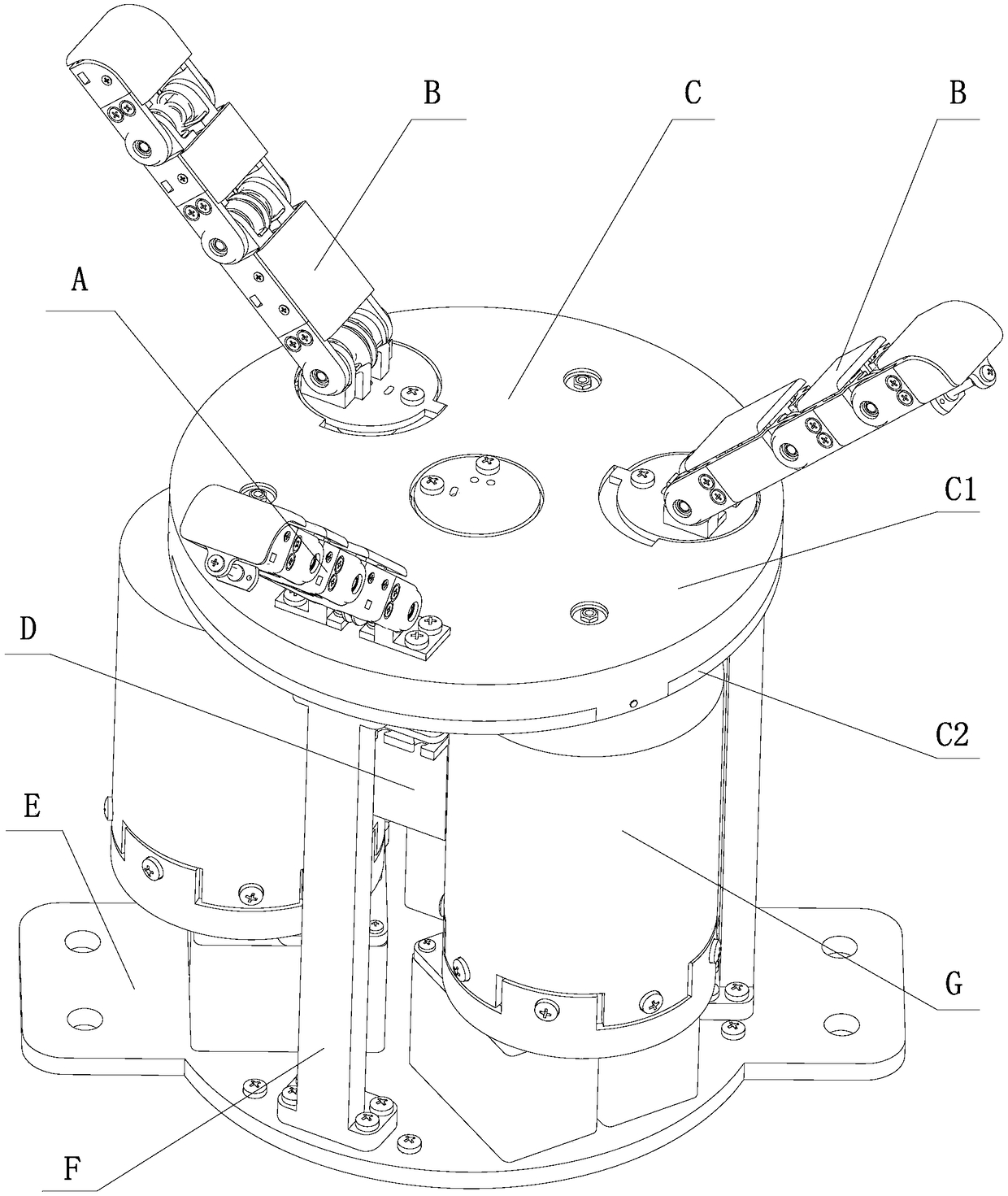

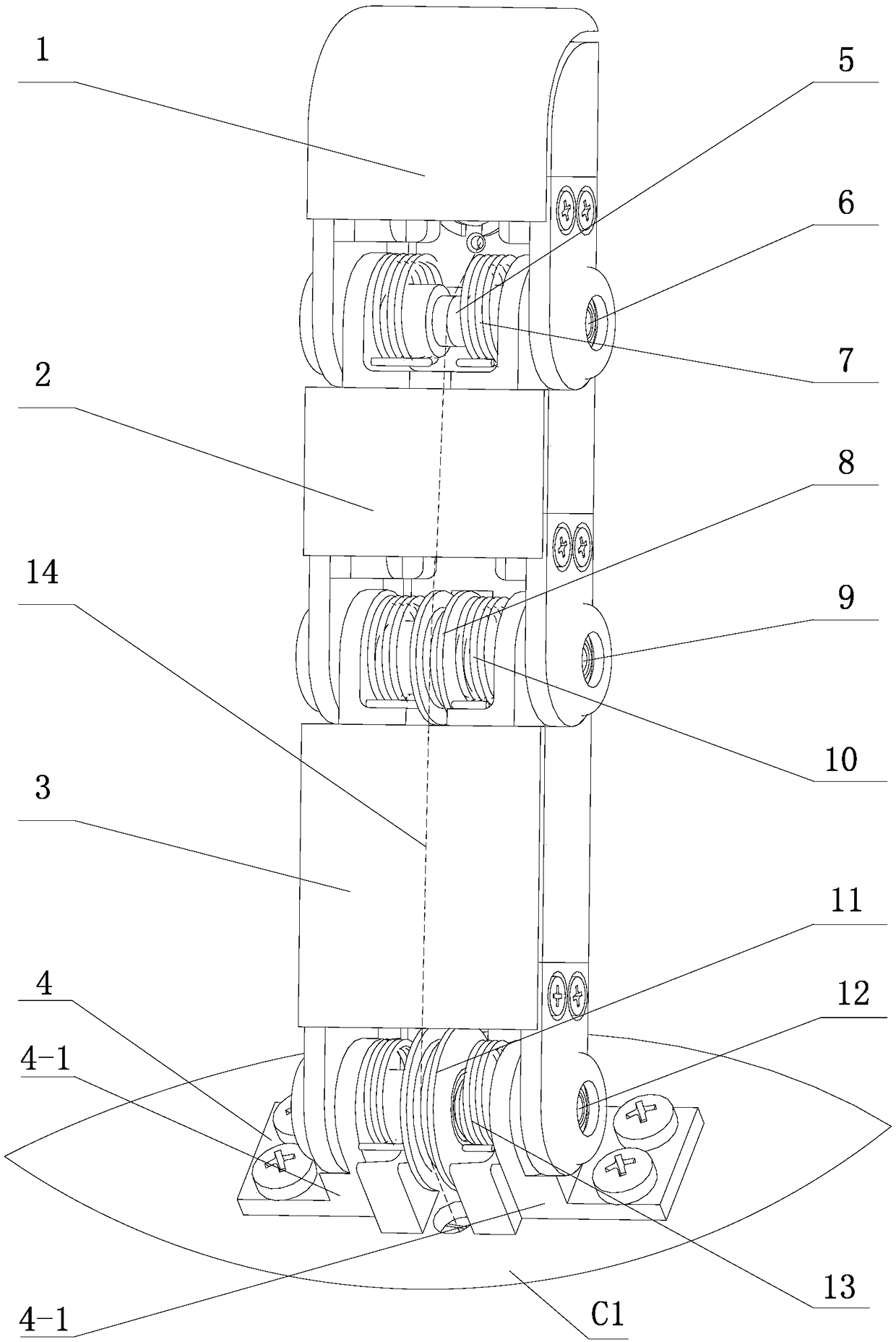

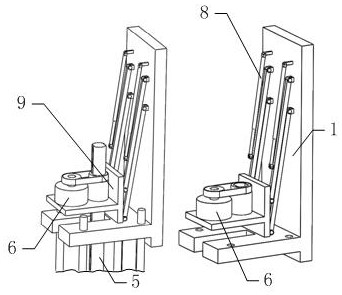

Underactuated variable-stiffness manipulator based on variable-stiffness elastic joints

PendingCN108748254AImprove gripImprove response speedJointsGripping headsVariable stiffnessSacroiliac joint

The invention provides an underactuated variable-stiffness manipulator based on variable-stiffness elastic joints, relates to a variable-stiffness manipulator, and aims to solve the problem about application limitations of a stiff manipulator and a flexible manipulator in the prior art. The underactuated variable-stiffness manipulator comprises the three variable-stiffness elastic joints, and further comprises a palm, a motor, a base, supporting columns and three fingers, wherein the three fingers comprise one flexion-extension finger and two coupling rotary flexion-extension fingers; the palmis arranged above the base; the palm and the base are connected through the supporting columns; the vertically-arranged motor and the three variable-stiffness elastic joints are mounted on the base;the flexion-extension finger and the two coupling rotary flexion-extension fingers are arranged on the palm along the circumferential direction of the palm; through a steel wire rope, the two couplingrotary flexion-extension fingers are driven by an output shaft of the motor to perform rotary motion; output shafts of the three variable-stiffness elastic joints are arranged in a one-to-one correspondence manner; and the flexion-extension motion of the flexion-extension finger and that of the two coupling rotary flexion-extension fingers are driven through the steel wire rope. The underactuatedvariable-stiffness manipulator provided by the invention belongs to the field of robots.

Owner:HARBIN INST OF TECH

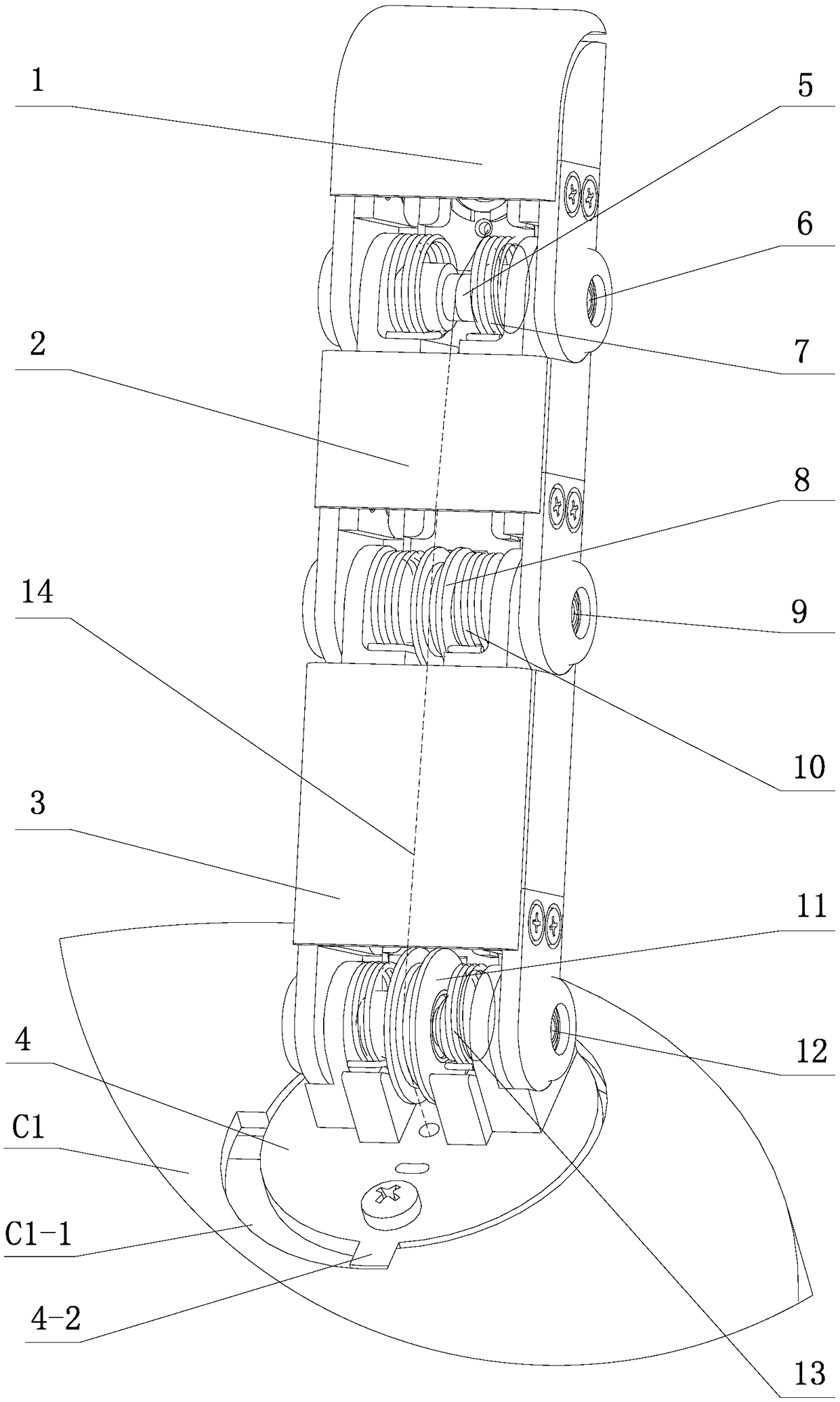

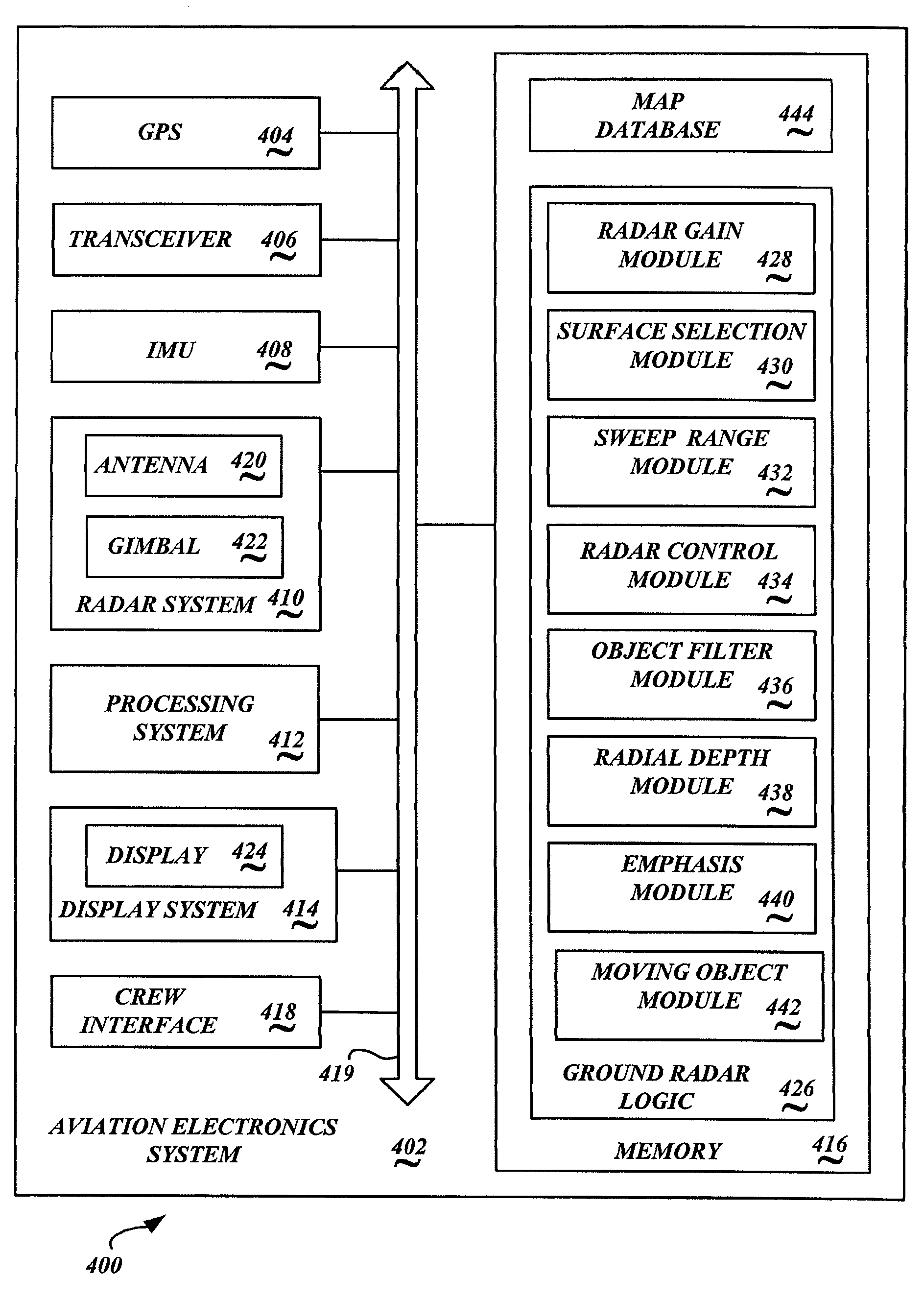

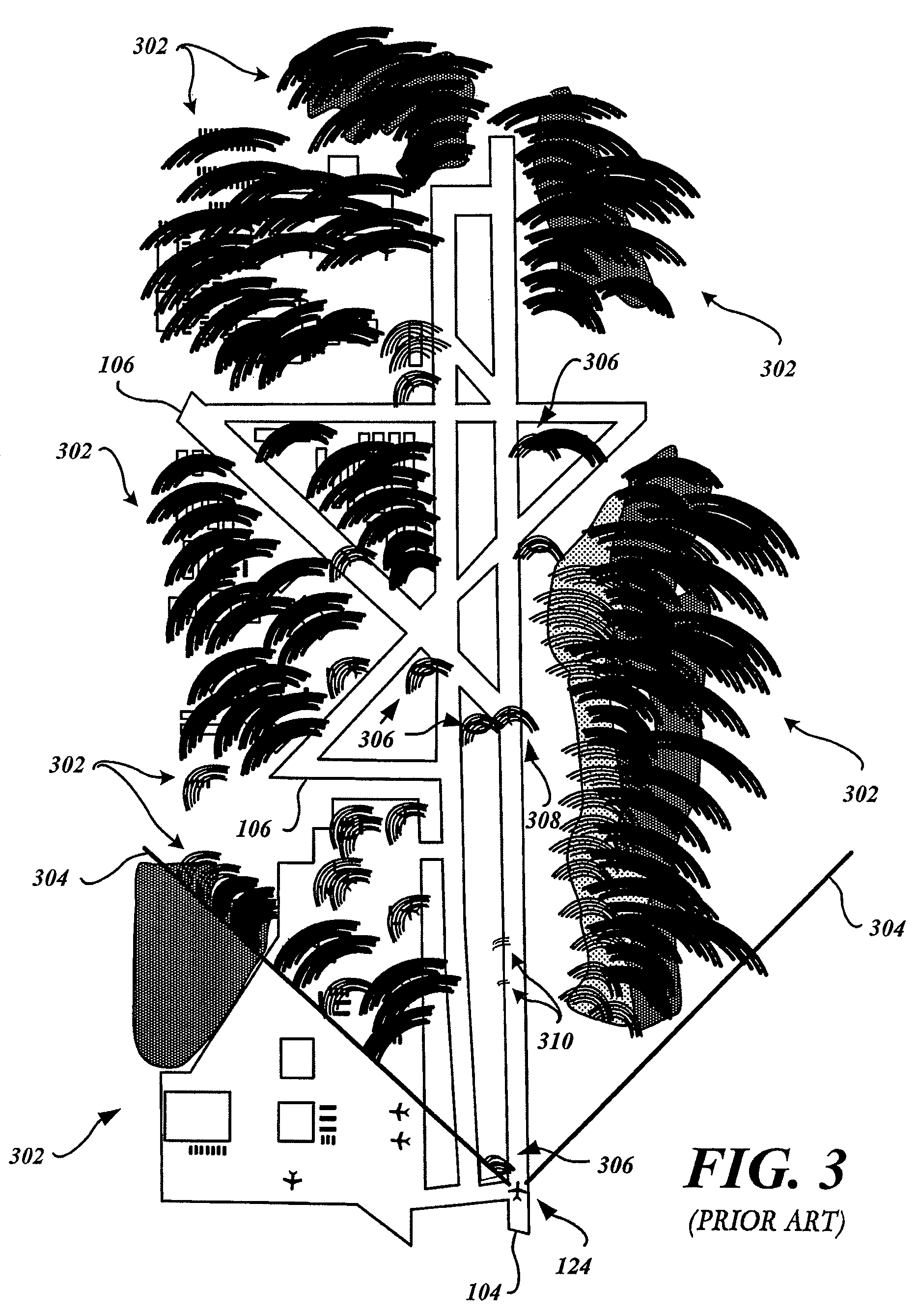

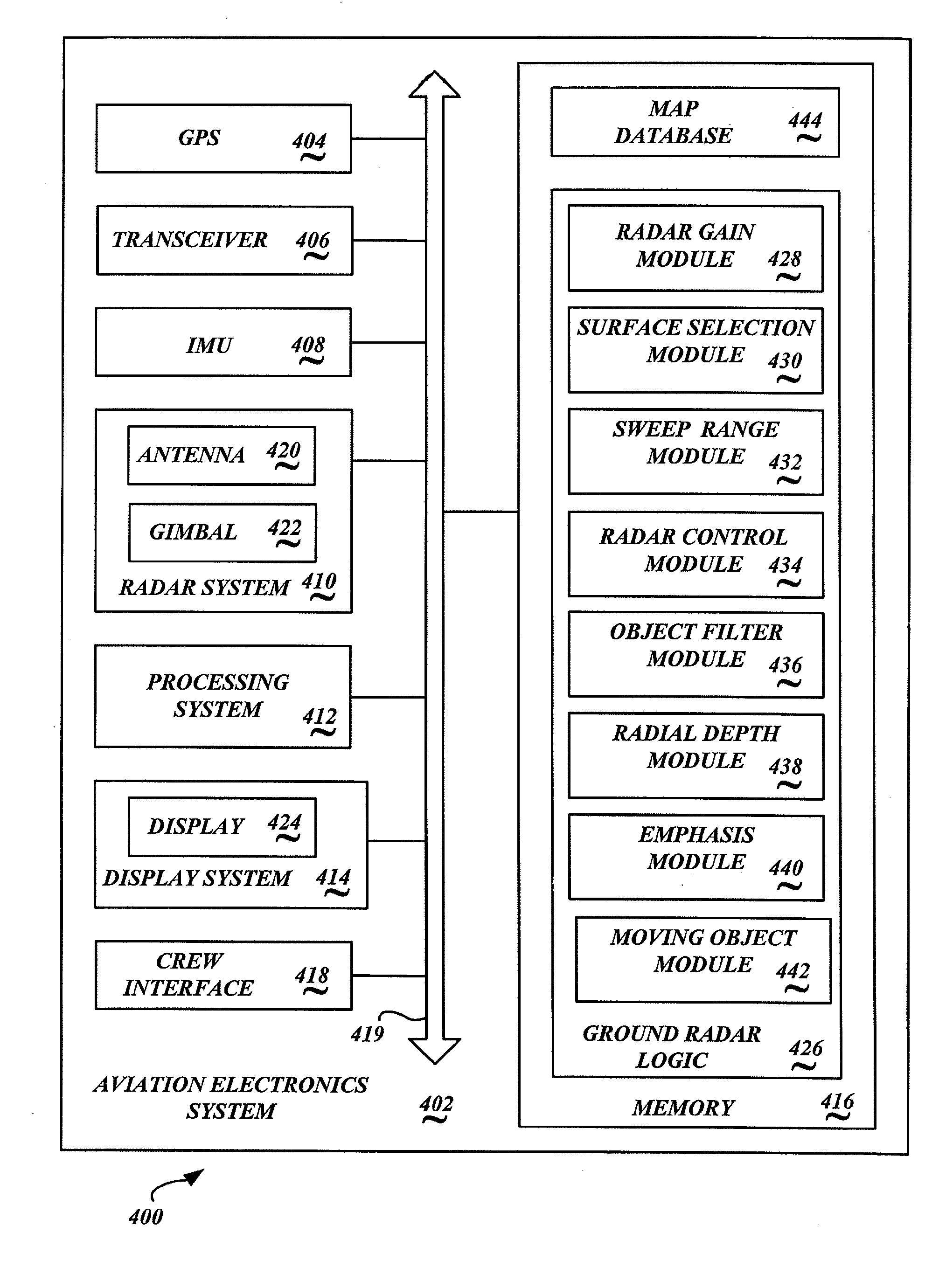

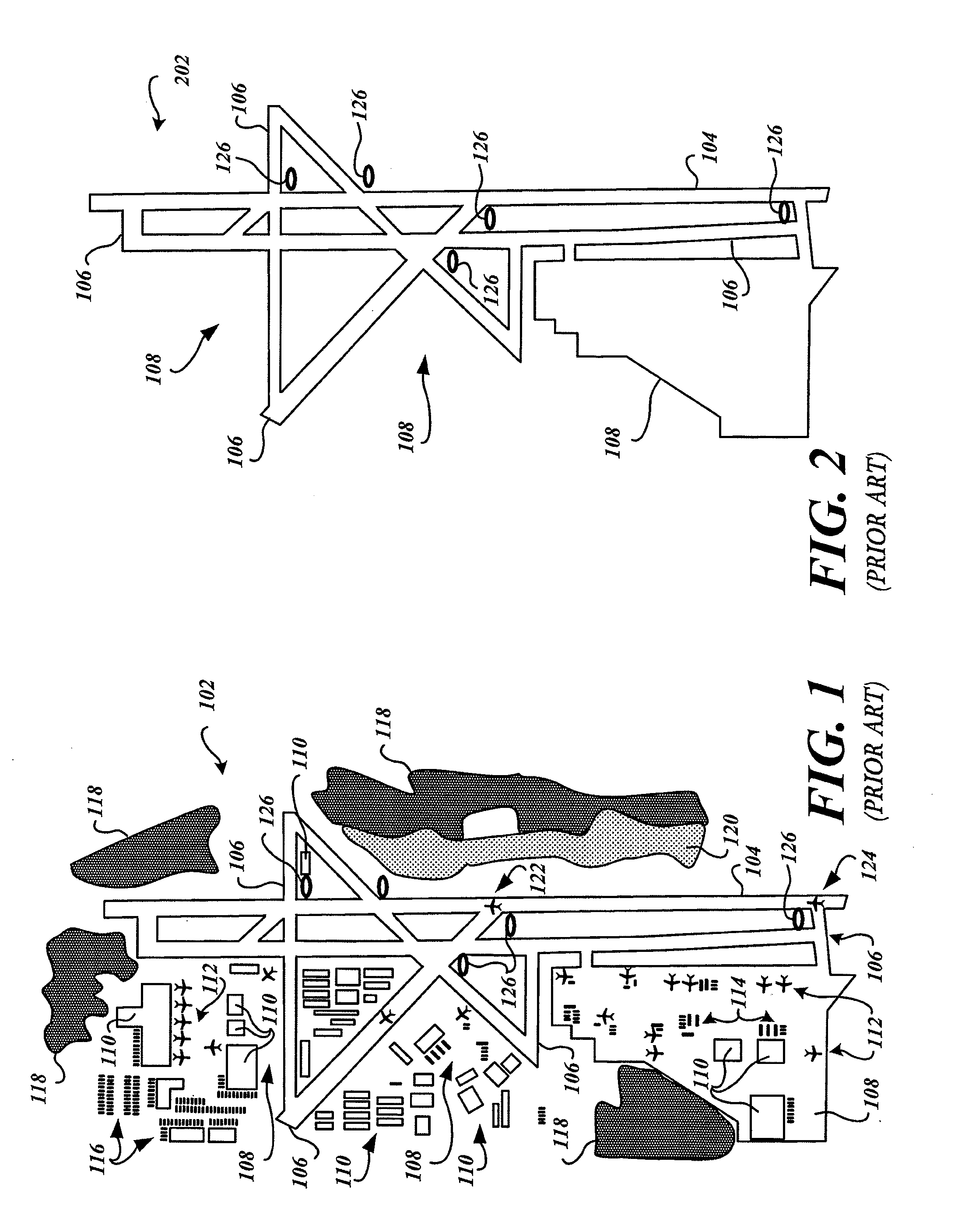

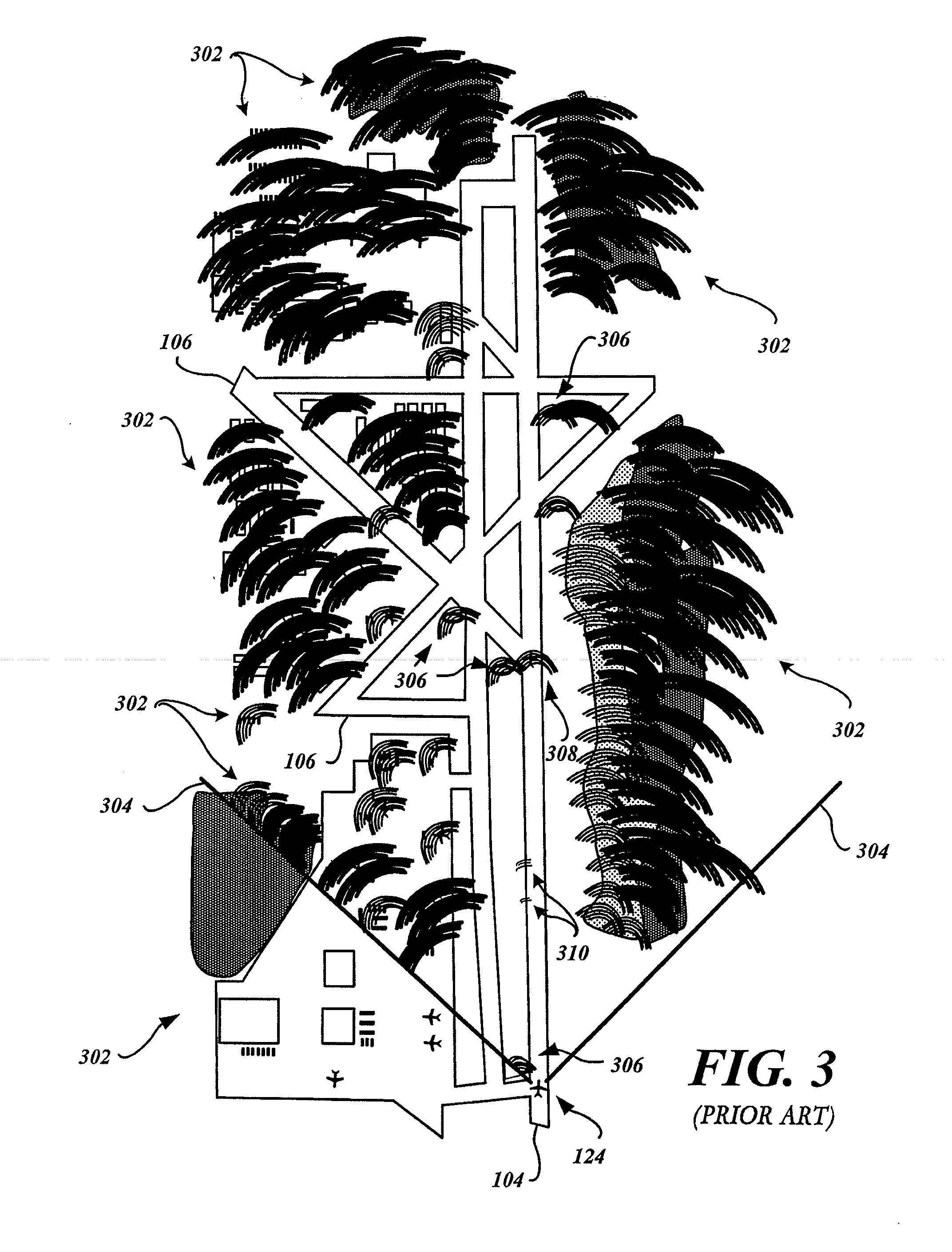

Ground collision instrument for aircraft and marine vehicles

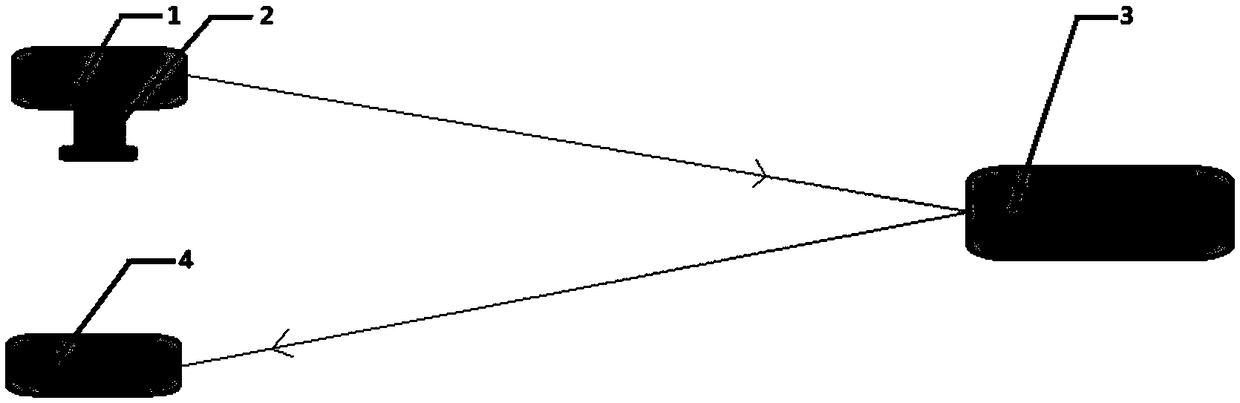

ActiveUS8077081B2Reduce output energyNarrow down the scan rangeAnti-collision systemsPosition fixationRadarHandling system

Radar return processing systems and methods are operable to process radar information when an installation vehicle is operating in proximity to a surface area of interest. An exemplary embodiment reduces energy of an output pulse emitted from a radar system; receives a plurality of radar returns from a plurality of objects that reflect the reduced energy output pulses emitted from the radar system; determines a surface area of interest based upon at least a current location of the installation vehicle; and filters the radar returns generated by objects that are located outside of the surface area of interest. Optionally, some systems and methods may reduce a sweep range of an antenna from which the reduced energy output pulses are emitted.

Owner:HONEYWELL INT INC

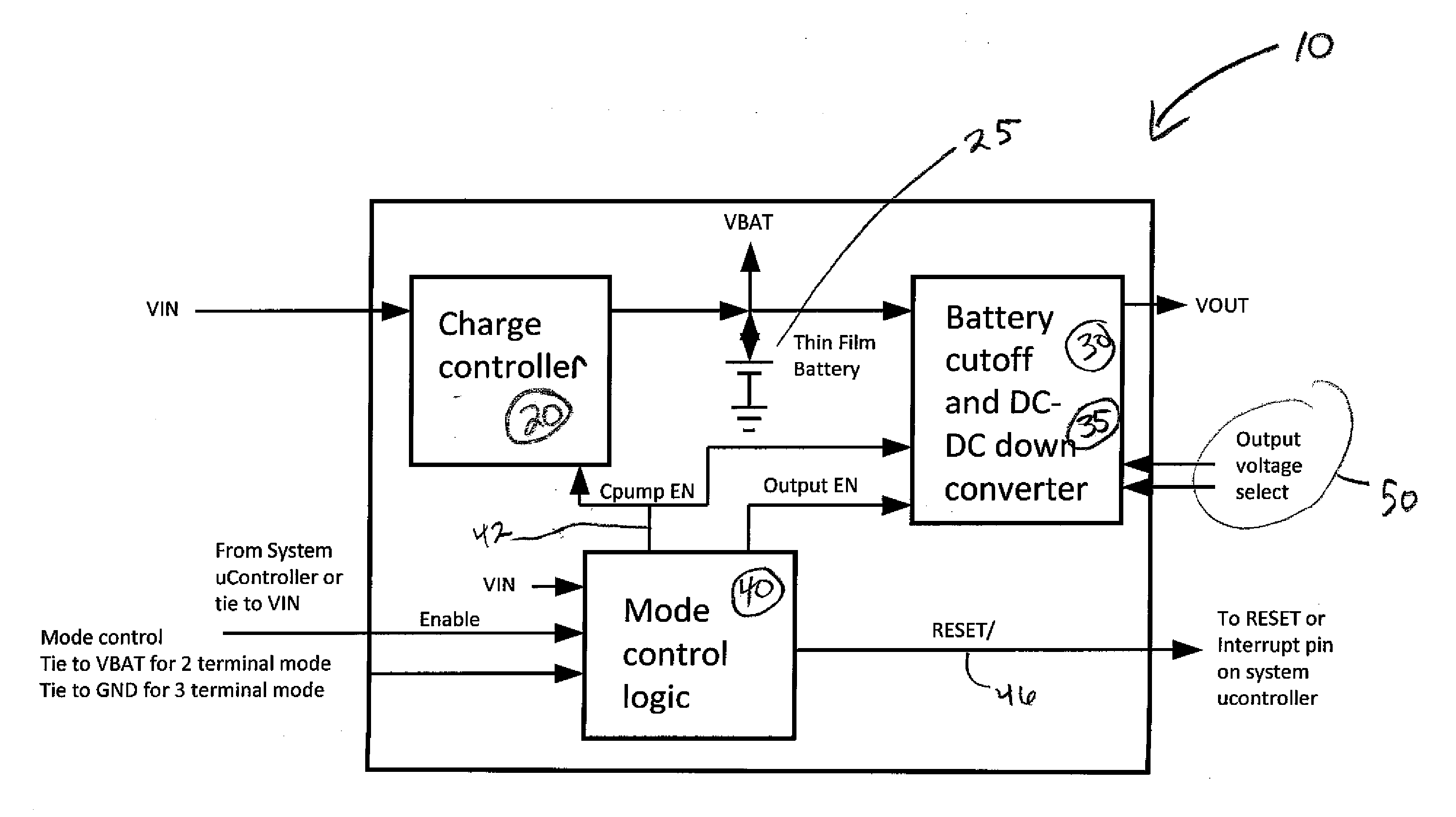

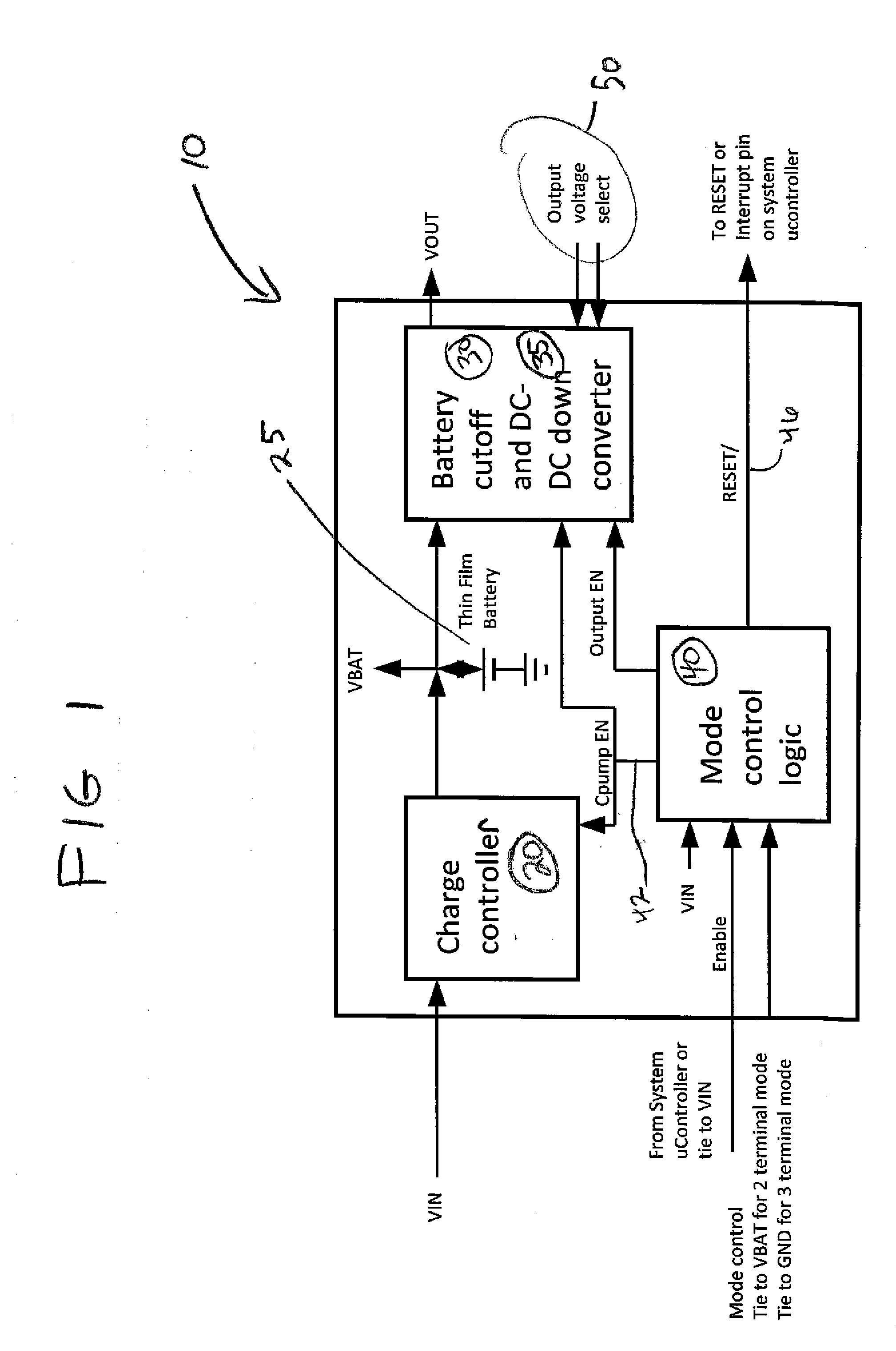

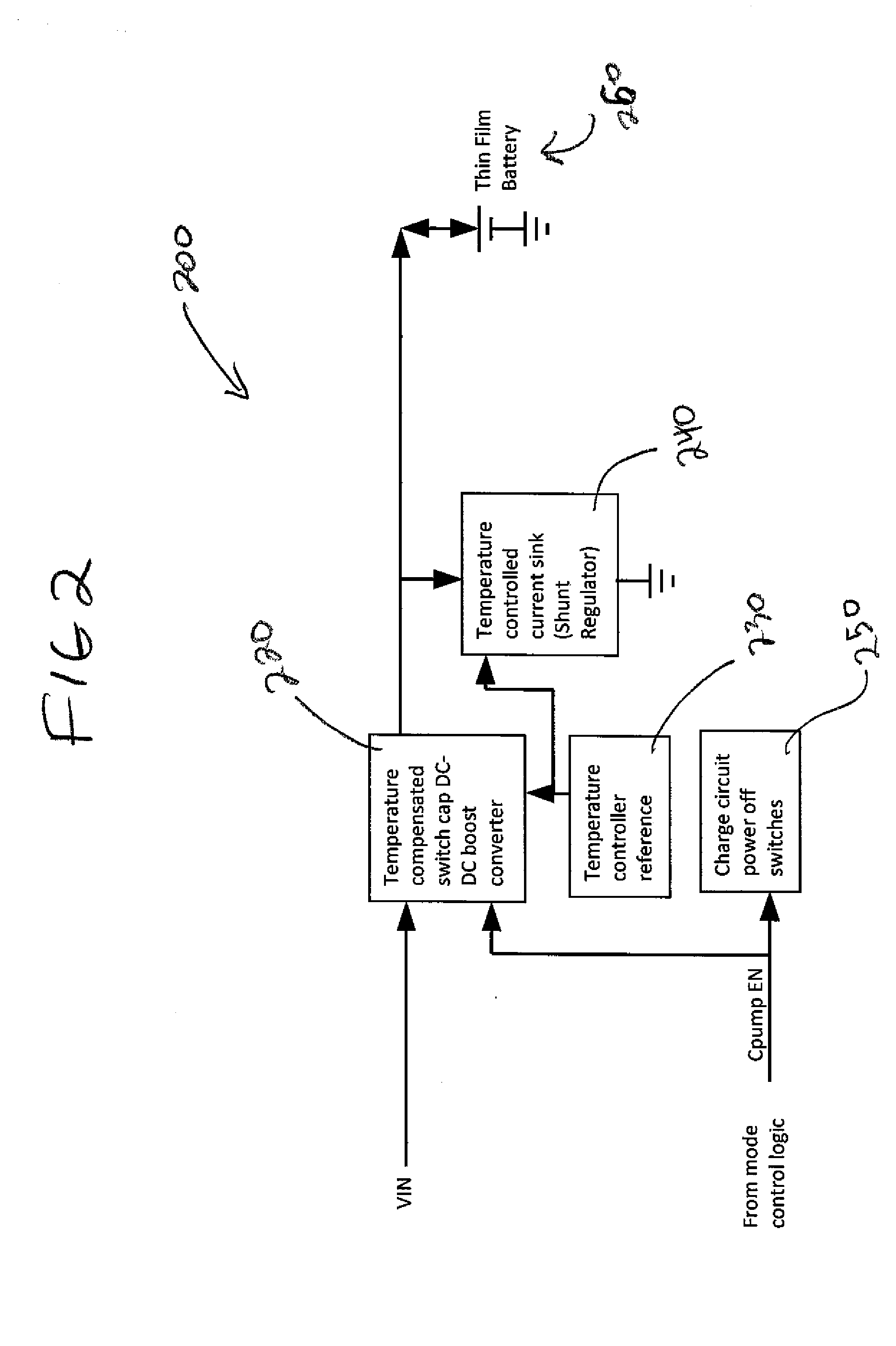

Thin film microbattery charge and output control

ActiveUS20140145680A1Extend battery lifeHigh impedanceElectric powerCharging/discharging current/voltage regulationCapacitanceMode control

A control system for charge and output control of a rechargeable thin film microbattery cell comprises a charge control logic component configured to control the level of charge of a thin film microbattery cell, a battery cut-off logic component to cease current draw on the thin battery thin film microbattery cell under predetermined conditions, a mode control logic component operably coupled to the charge control logic component and the battery cut-off logic component to enable operation of the charge control logic component and the battery cut-off logic component under predetermined conditions, and a Switch Capacitor DC-DC Downconverter Component for delivery of voltage external to the system configured to reduce battery output voltage potential by a factor of at least 2:1. Systems operably connected to a rechargeable thin film microbattery cell and powered devices comprising the system and the microbattery cell are also described.

Owner:CYMBET CORP

Ground collision instrument for aircraft and marine vehicles

ActiveUS20090219189A1Reduce output energyNarrow down the scan rangeRadio wave reradiation/reflectionICT adaptationRadarHandling system

Radar return processing systems and methods are operable to process radar information when an installation vehicle is operating in proximity to a surface area of interest. An exemplary embodiment reduces energy of an output pulse emitted from a radar system; receives a plurality of radar returns from a plurality of objects that reflect the reduced energy output pulses emitted from the radar system; determines a surface area of interest based upon at least a current location of the installation vehicle; and filters the radar returns generated by objects that are located outside of the surface area of interest. Optionally, some systems and methods may reduce a sweep range of an antenna from which the reduced energy output pulses are emitted.

Owner:HONEYWELL INT INC

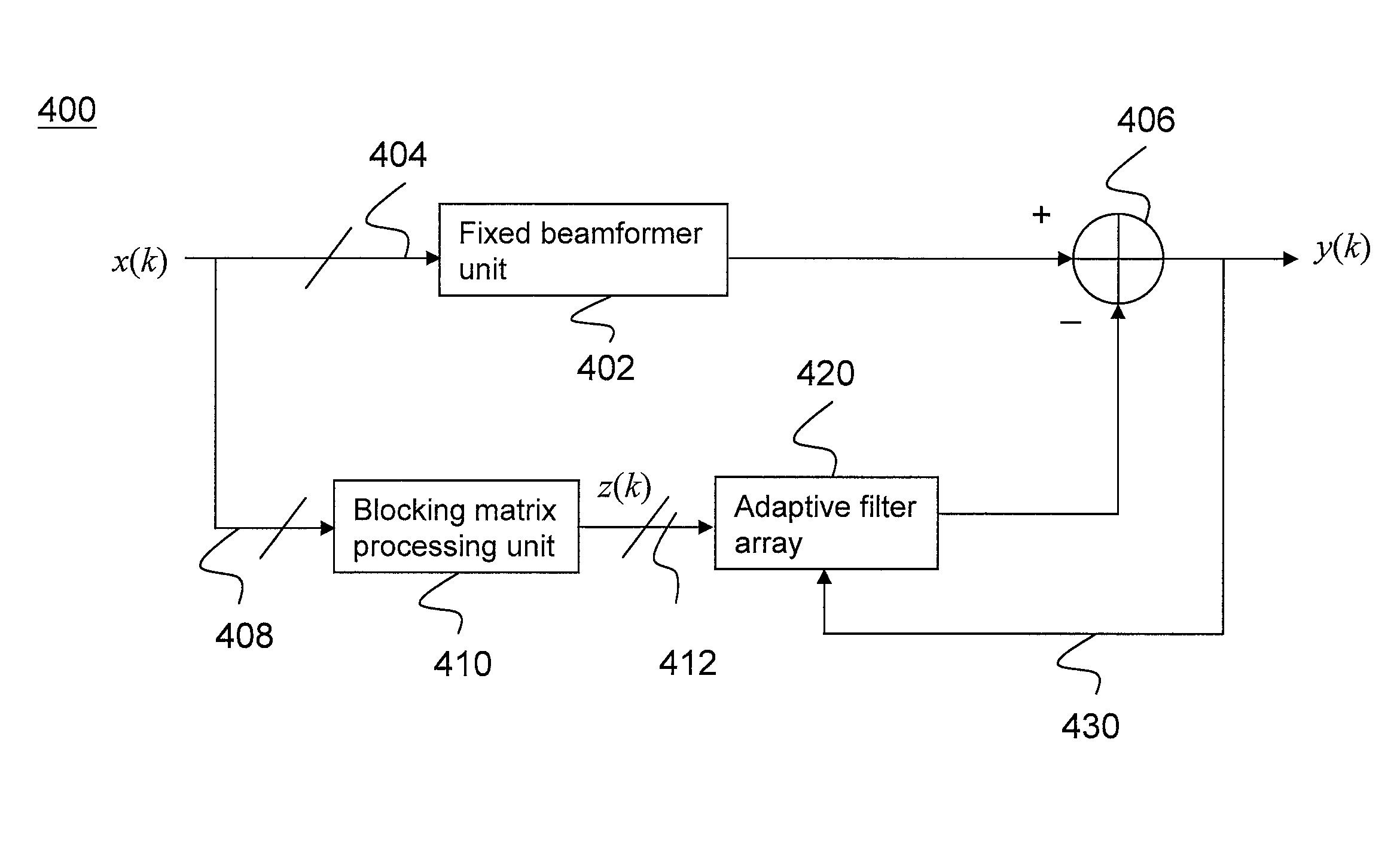

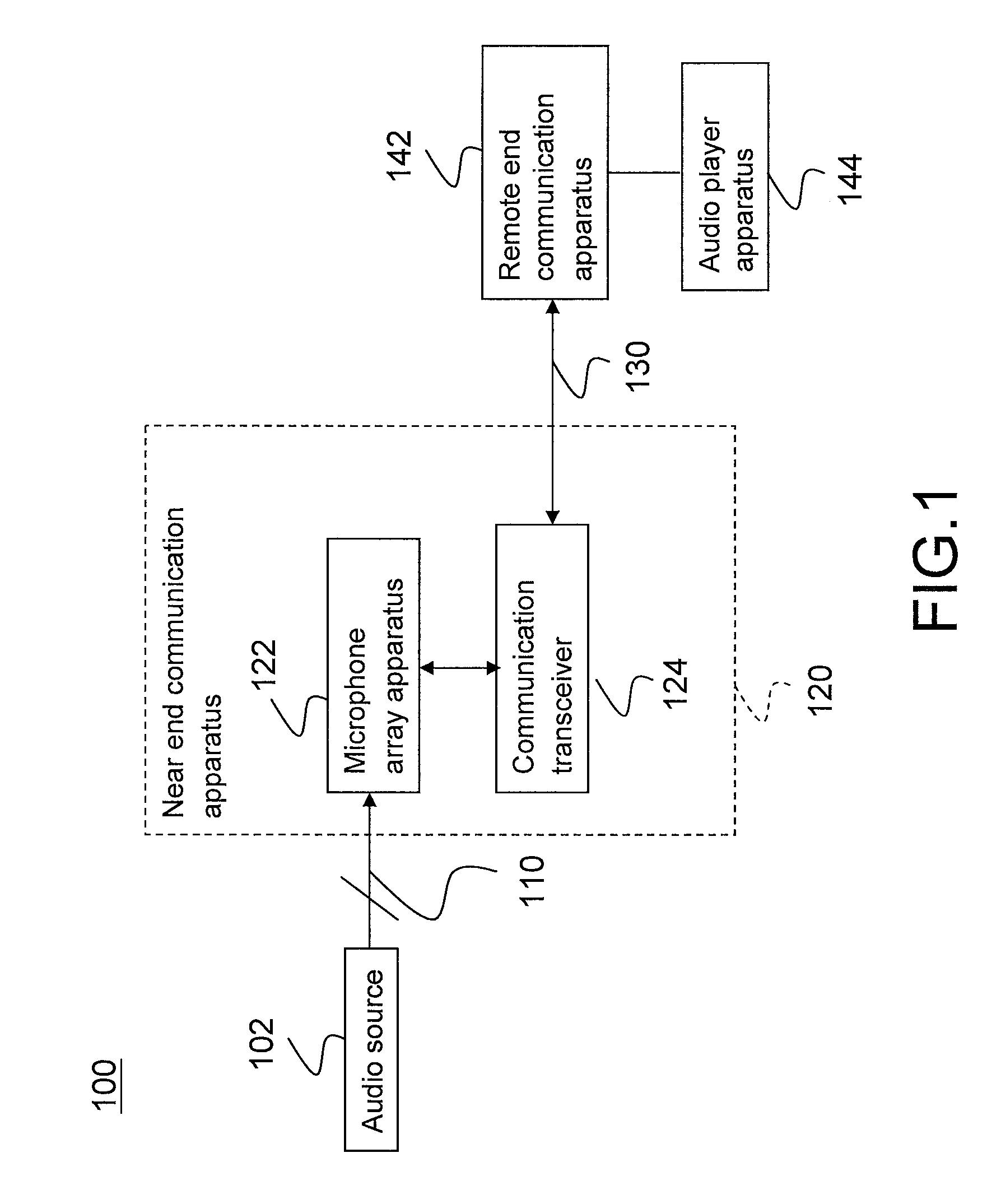

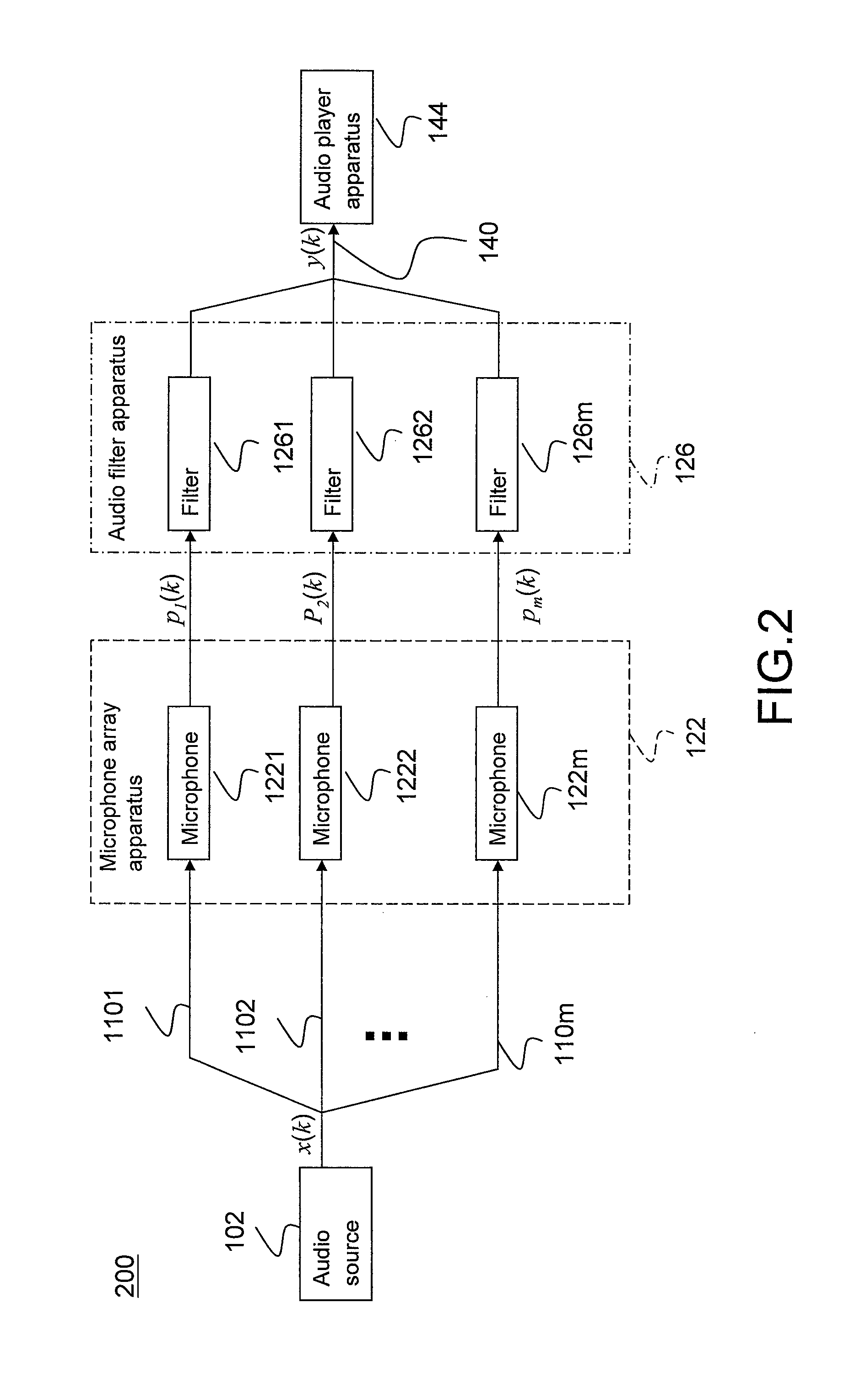

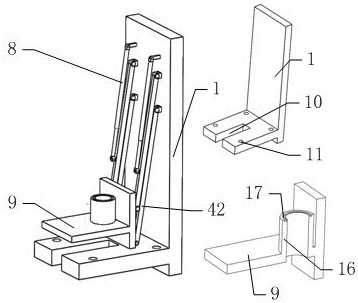

Dereverberation and noise reduction method for microphone array and apparatus using the same

ActiveUS8351618B2Reduce output energyReduce signalingTransmission noise suppressionLine-transmissionAdaptive filterNoise reduction

A dereverberation and noise reduction method adapted for a microphone array and an apparatus using the same are proposed. The microphone array receives a plurality of audio signals from an audio source. The dereverberation and noise reduction method includes the following steps. The received audio signals are processed by a beamforming processing, and a first audio signal is generated. Besides, the received audio signals are processed by a suppression processing, and a suppression audio vector is generated. Further, suppression audio vector is processed by an adaptive filtering processing, and a second audio signal is generated. In addition, the second audio signal is subtracted from the first audio signal to acquire an audio output signal, where parameters of the adaptive filtering processing are adjusted according to a feedback of the audio output signal.

Owner:U MEDIA COMM

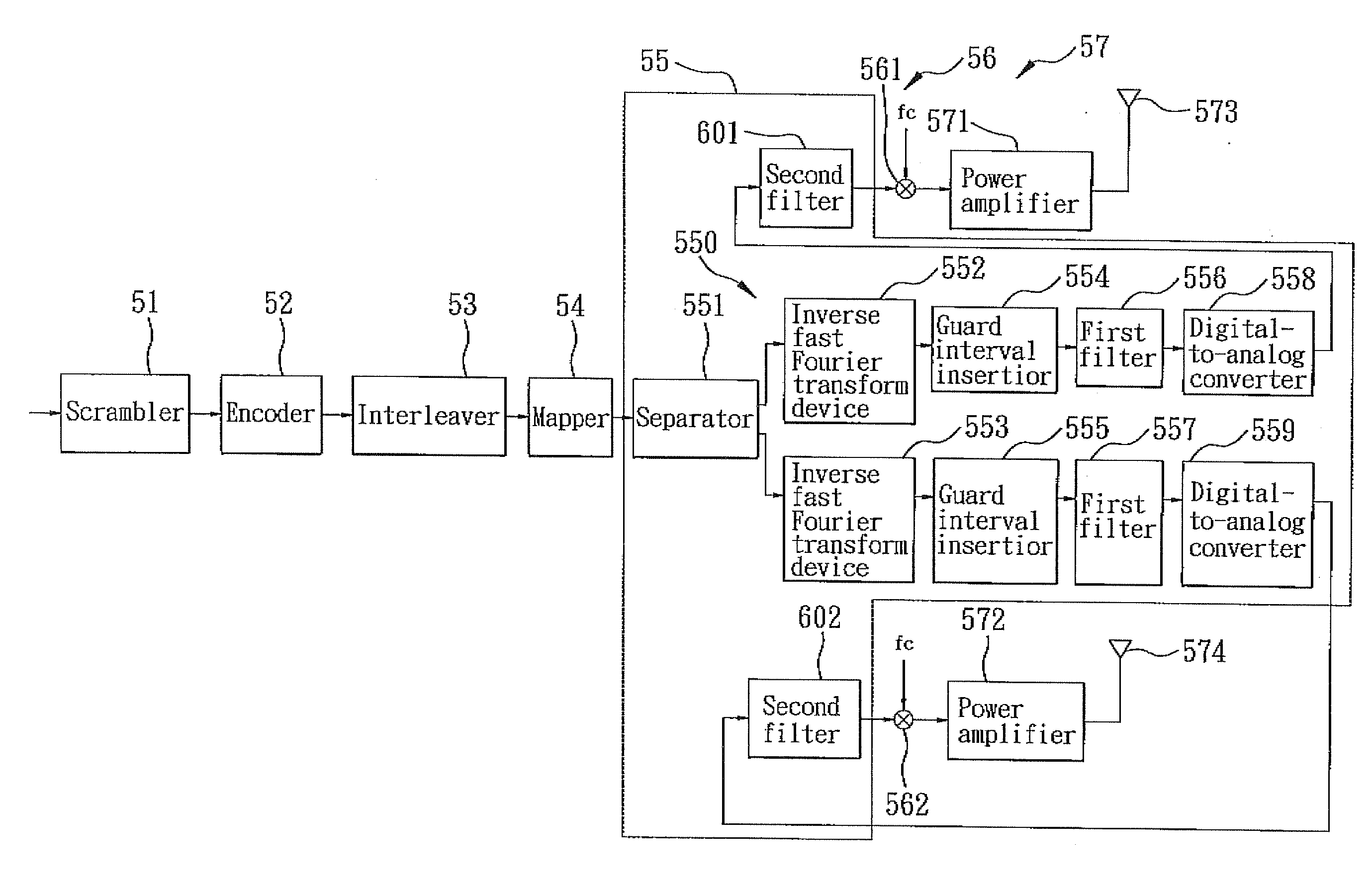

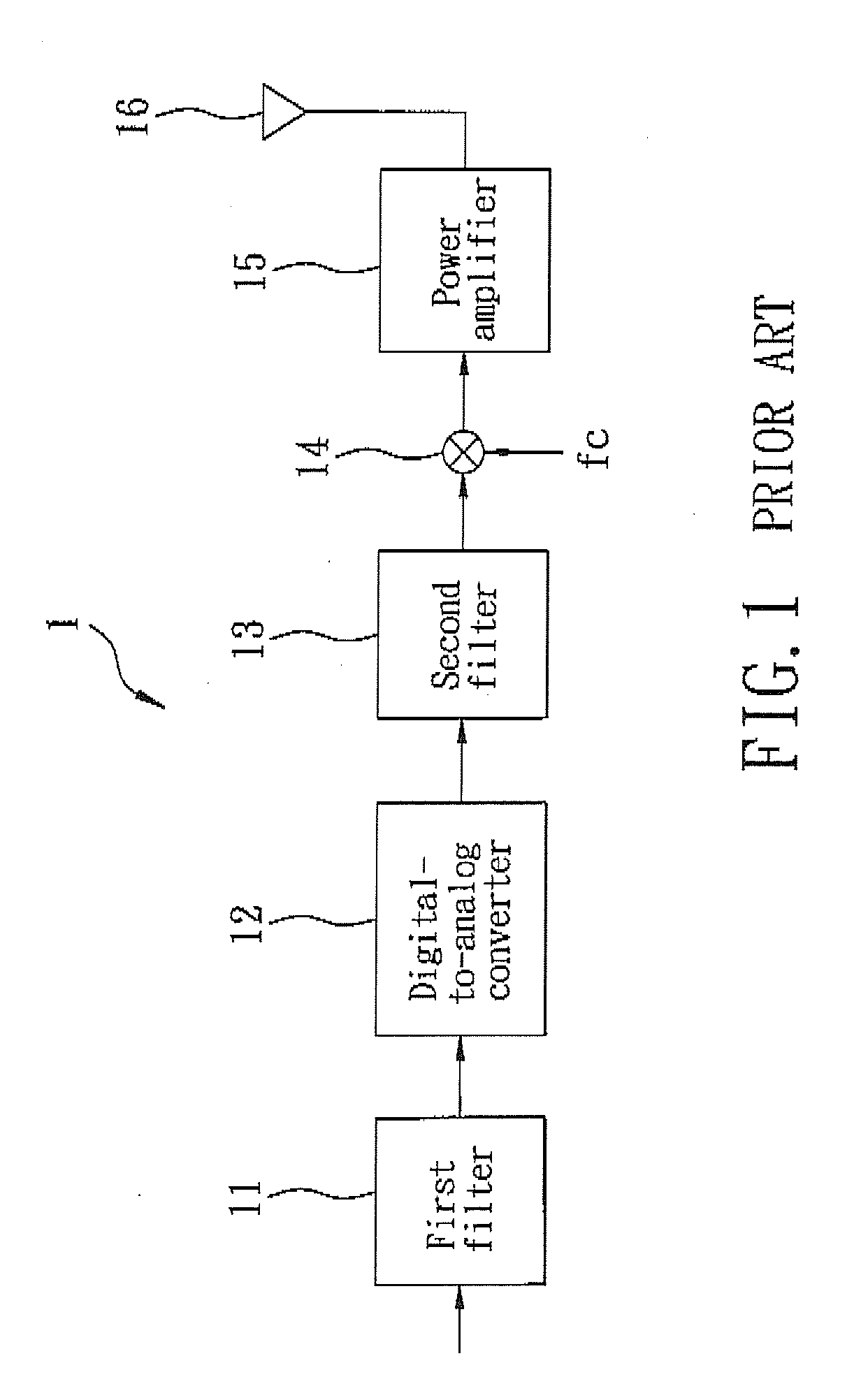

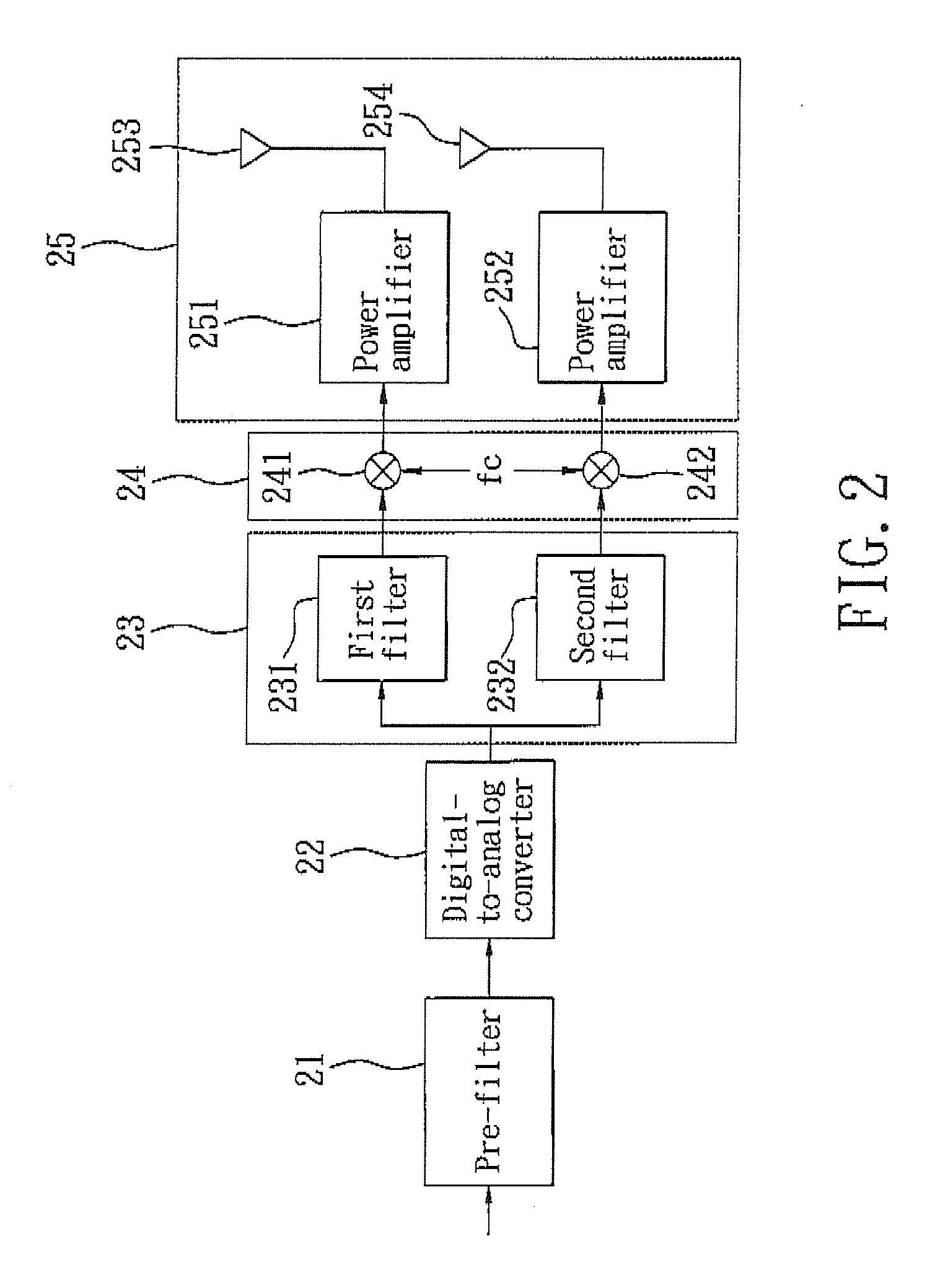

Transmitter and Transmission Method Thereof

ActiveUS20090054012A1Reduce output energyWeaken energyResonant long antennasModulated-carrier systemsTransmitter

A signal transmission method includes: converting an input signal to generate a first converted signal having a first bandwidth, and a second converted signal having a second bandwidth; mixing the first converted signal with an oscillation signal to generate a first mixed signal, and mixing the second converted signal with the oscillation signal to generate a second mixed signal; and transmitting the first and second mixed signals by different antennas; wherein the input signal has a predetermined bandwidth, the first bandwidth is smaller than the predetermined bandwidth; and the second bandwidth is smaller than the predetermined bandwidth.

Owner:REALTEK SEMICON CORP

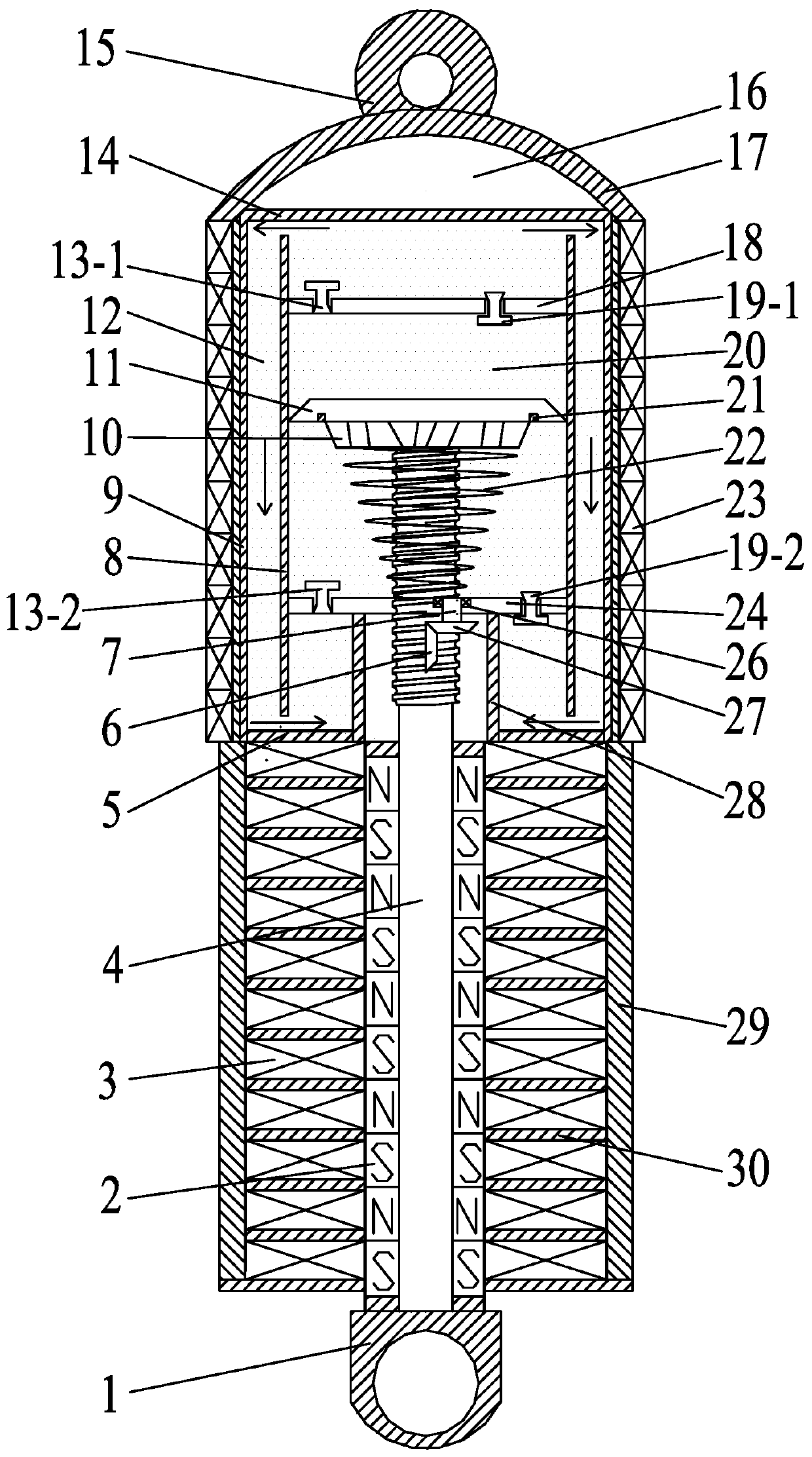

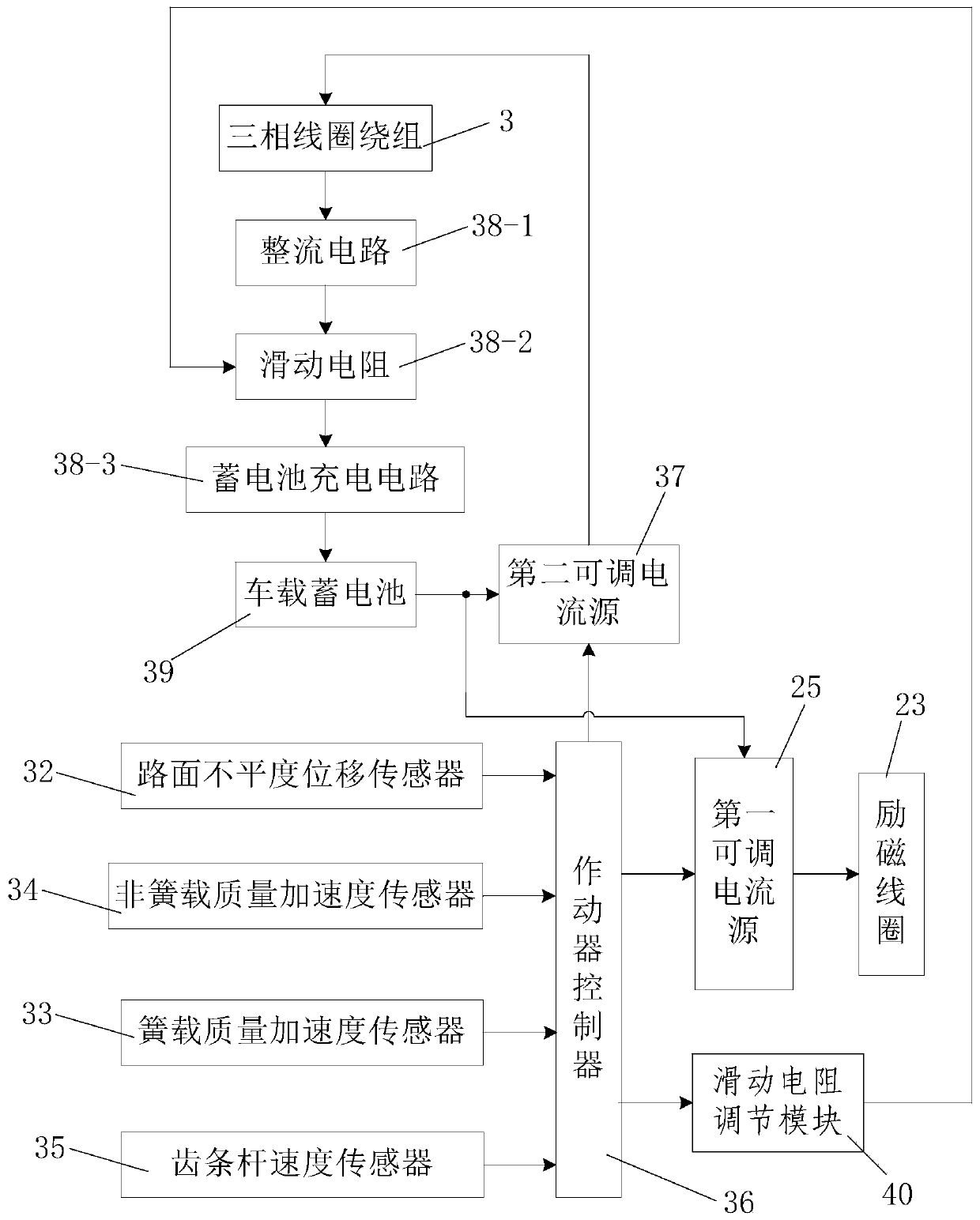

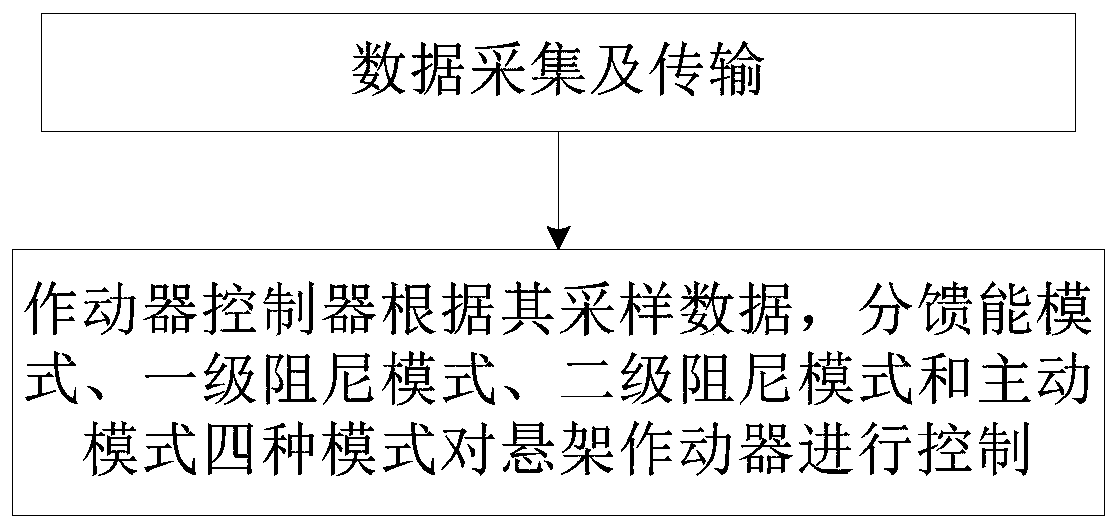

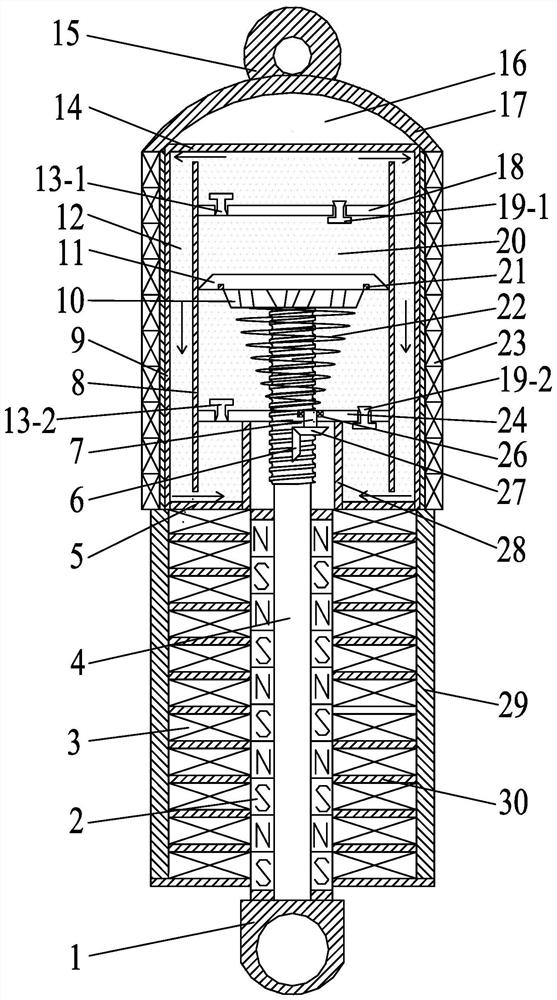

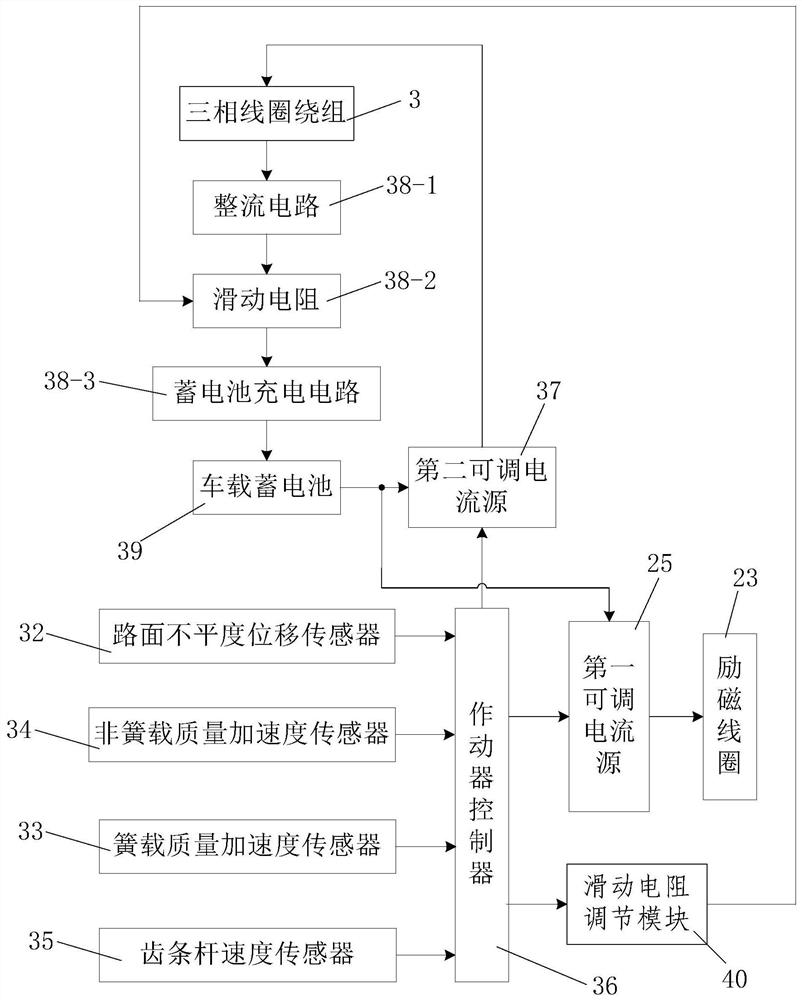

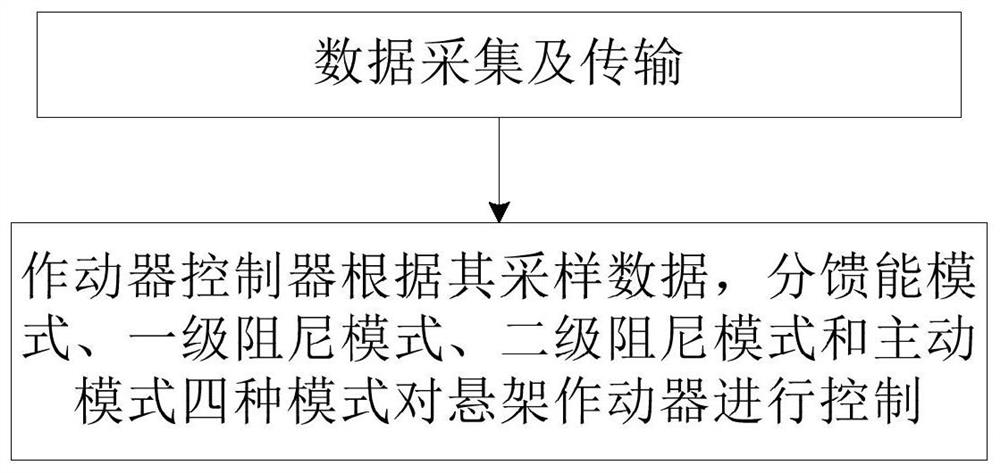

Electromagnetic integrated type energy feedback suspension actuator of electric vehicle and control method of electromagnetic integrated type energy reclaiming suspension actuator of electric vehicle

ActiveCN109808437AReasonable designSimple structureResilient suspensionsElectric machineData acquisition

The invention discloses an electromagnetic integrated type energy feedback suspension actuator of an electric vehicle and a control method of the electromagnetic integrated type energy feedback suspension actuator of the electric vehicle. The suspension actuator comprises a magnetorheological damper, a linear motor and an actuator monitoring device, wherein the magnetorheological damper comprisesa cylinder, a magnetorheological fluid, an inner chamber upper partition board and an inner chamber lower partition board, wherein the linear motor comprises a linear motor shell, a secondary part anda primary part; the actuator monitoring device comprises an actuator controller. The control method of the suspension actuator comprises the following steps: 1, data acquisition and transmission; 2,control of the suspension actuator by the actuator controller in an energy feedback mode, a primary damping mode, a secondary damping mode and an active mode according to sample data. The suspension actuator is reasonable in design, multi-mode switching of a suspension system can be realized according to different road conditions of vehicle traveling, energy waste of the electric vehicle is reduced, driving mileage of the electric vehicle can be increased, and the promotion and application values are high.

Owner:XIAN UNIV OF SCI & TECH

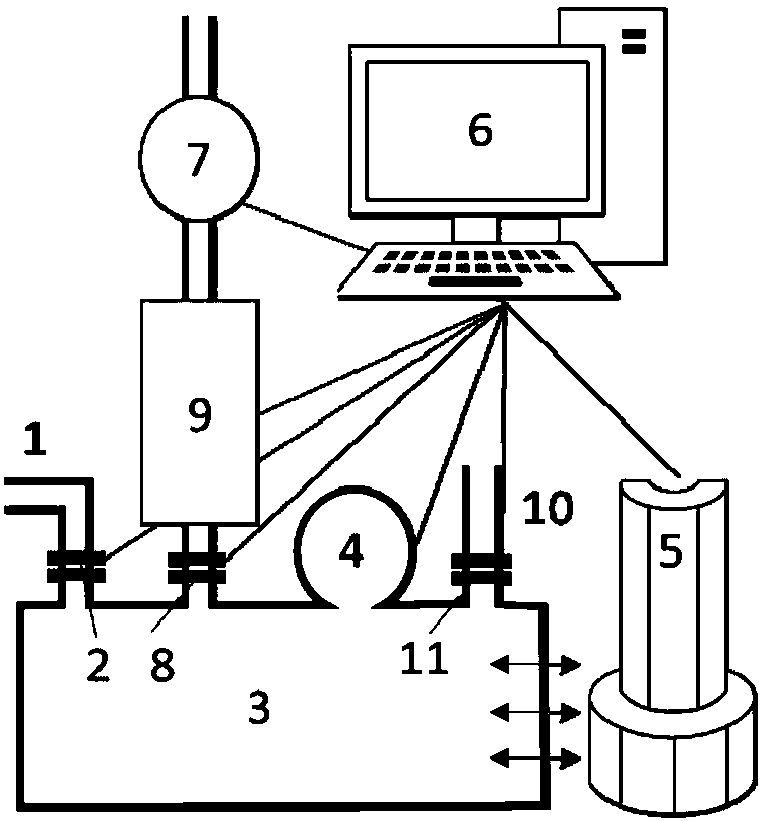

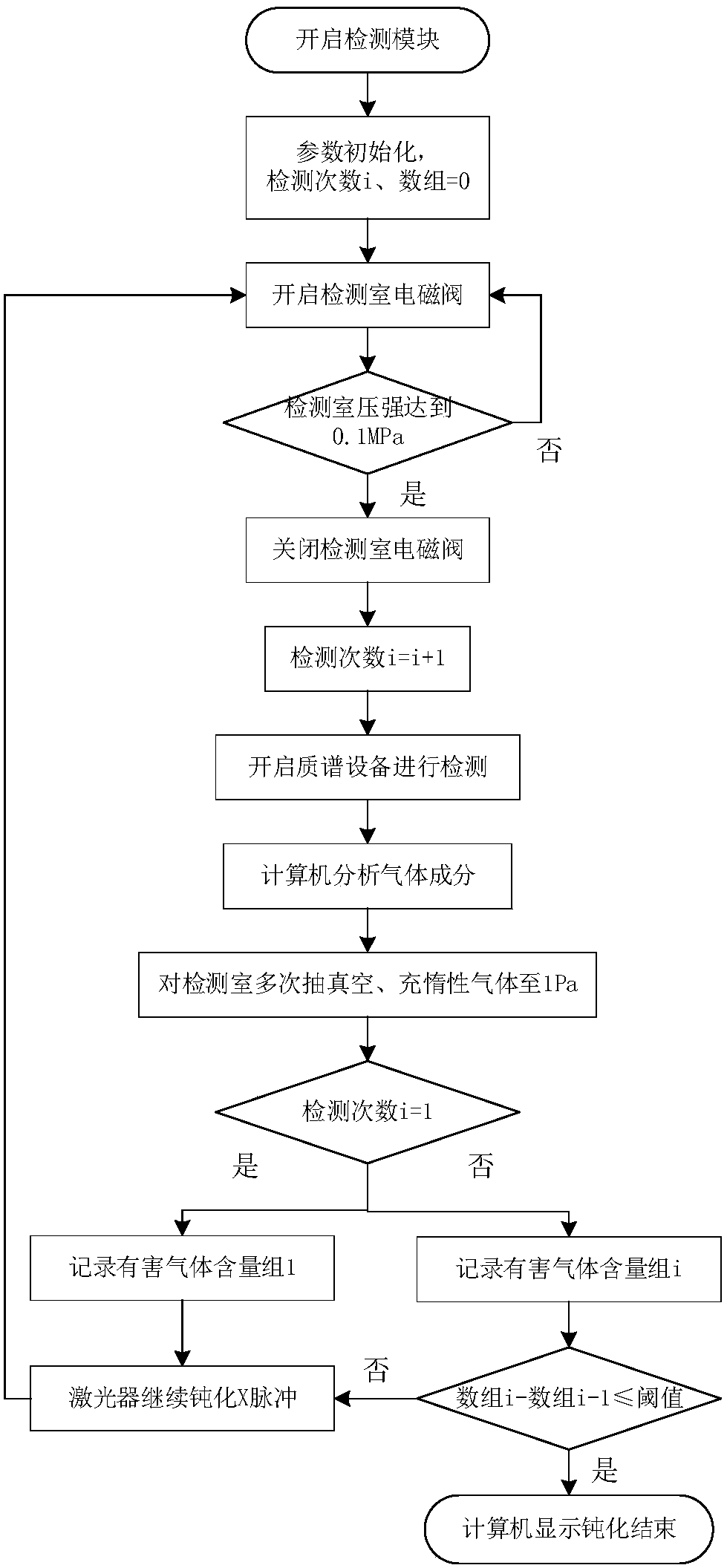

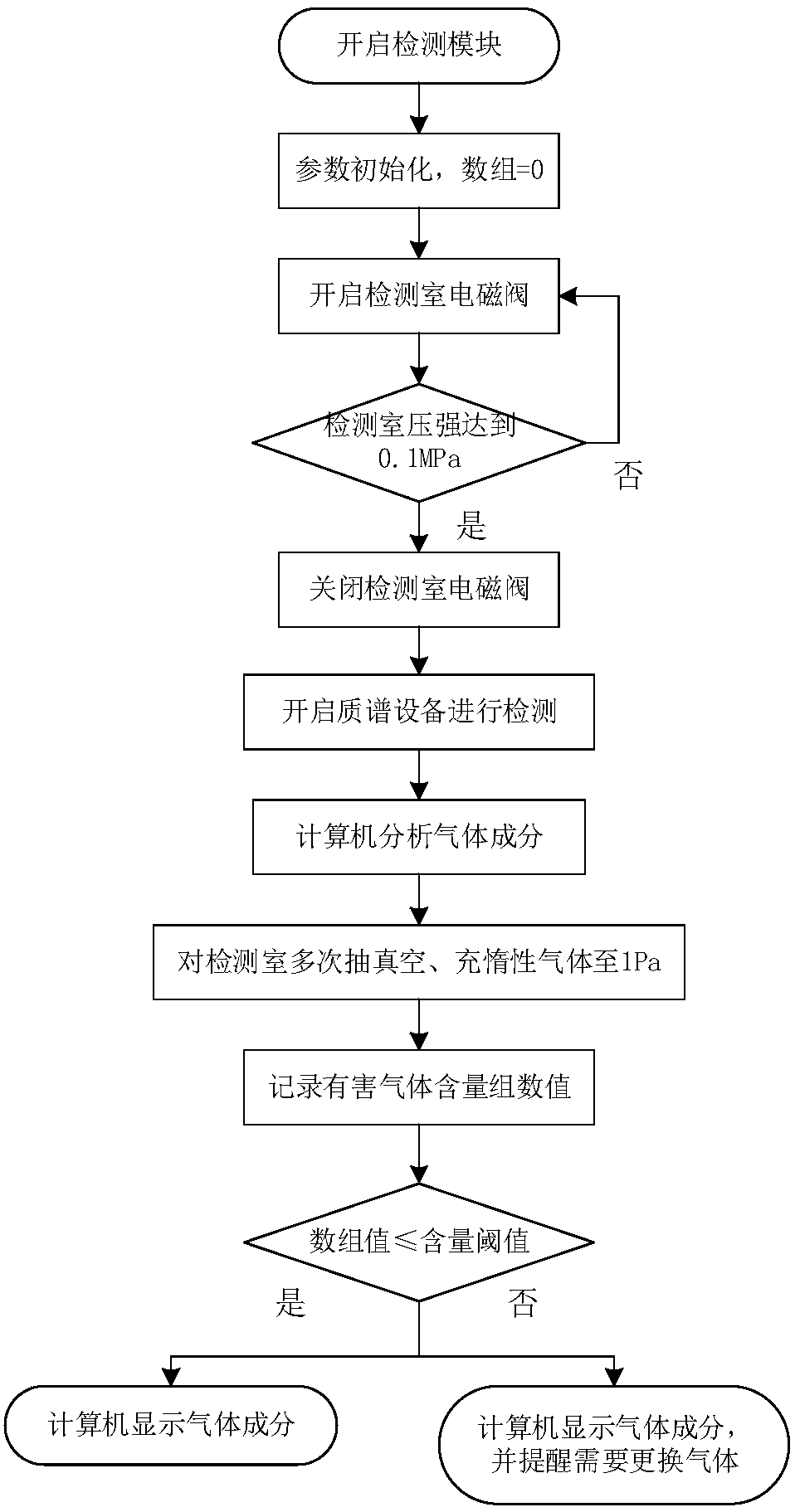

Method and module for detecting gas in excimer laser discharge chamber

PendingCN108414612AReduce time and energy wasteImprove efficiency and operational effectivenessMaterial analysis by electric/magnetic meansHalogenGas processor

The invention relates to a method and module for detecting a gas in an excimer laser discharge chamber. The detection module comprises a gas inlet tube, a gas inlet solenoid valve, a gas chamber, a pressure detector, a mass spectrometer, a computer, a vacuum pump, a vacuum pipeline solenoid valve, a halogen gas processor, an inert gas pipeline and an inert gas solenoid valve. The detection of thegas in the excimer laser discharge chamber in the passivation process or the passivation / operation process is realized by the detection module. T The detection method and the module reduce unnecessarytime and energy wastes in the passivation / operation process, and improve the passivation efficiency and the operation effect.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Predictive analytics device for integrating energy storage with solar generation coupled to electrical loads

InactiveUS20180097126A1Reduce decreaseLoss of revenueSolar heating energySolar heat simulation/predictionSolar powerShort terms

A device is disclosed that uses short term solar energy forecasting to enhance the use of energy storage coupled to an electrical load. By predicting momentary fluctuations in solar energy output, the energy storage is controlled to avoid short term drops in energy production resulting in higher apparent electrical load and potentially higher demand charges. By enhancing the use of the energy storage, less storage is required to mitigate demand charges, thereby reducing capital costs.

Owner:GONATAS CONSTANTINE

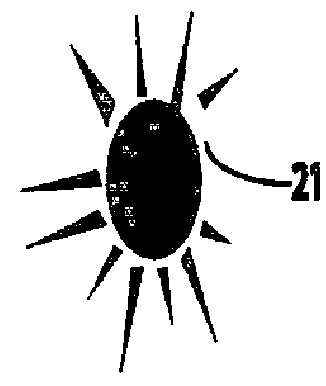

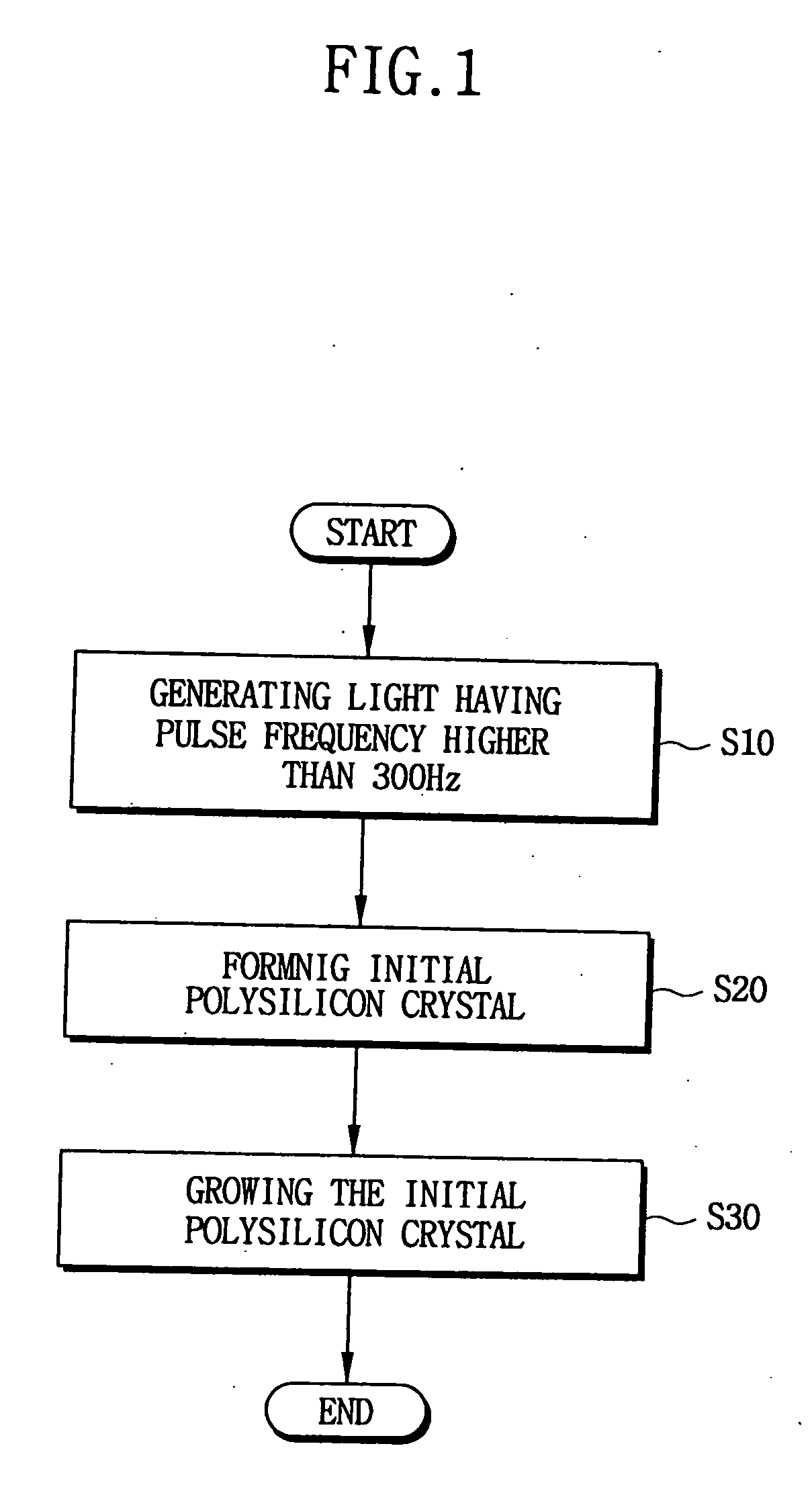

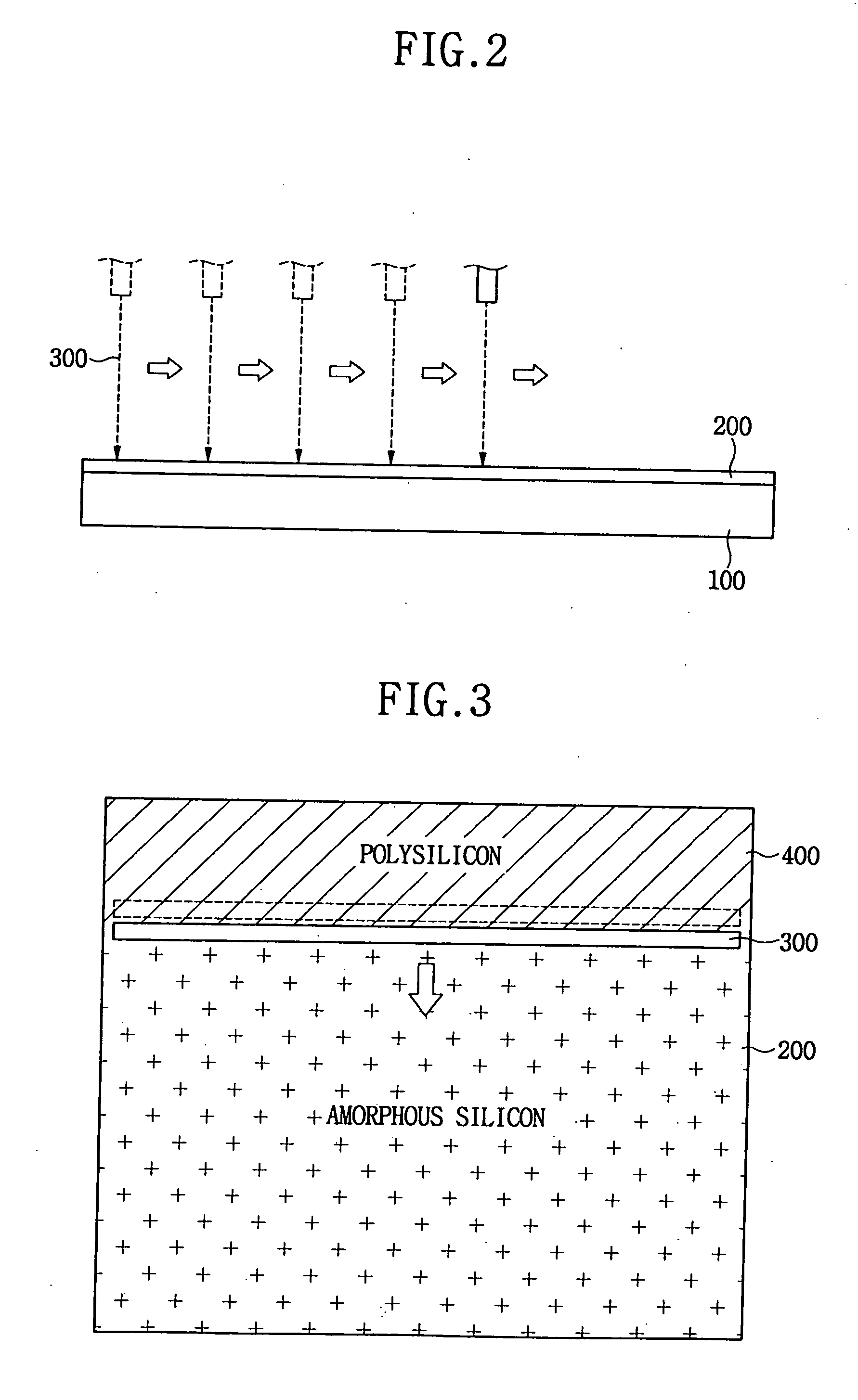

Method and apparatus for crystallizing silicon, method of forming a thin film transistor, a thin film transistor and a display apparatus using same

InactiveUS20060240608A1Reduce output energyReduce loadTransistorAfter-treatment apparatusAmorphous siliconLaser beams

A light having a pulse frequency higher than about 300 Hz is generated. The light is irradiated on an amorphous silicon thin film for a predetermined time period to form an initial polysilicon crystal. The light is transported in a predetermined direction to grow the initial polysilicon crystal. A laser beam having a decreased output energy is irradiated on the amorphous silicon thin film to crystallize the amorphous silicon thin film to a polysilicon thin film so that the load of an apparatus for generating the laser beam is decreased, and the lifetime of the apparatus for generating the laser beam increases.

Owner:SAMSUNG ELECTRONICS CO LTD

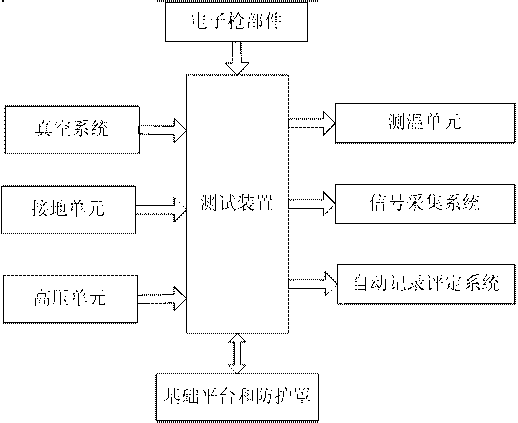

Electronic gun tester for high voltage electron accelerator

The invention discloses an electronic gun tester for a high voltage electron accelerator. The electronic gun tester for the high voltage electron accelerator is characterized by comprising mutually connected electronic gun components of a testing device. The testing device is further connected with a signal acquisition unit, an automatic recording and evaluating unit, a high voltage unit and a grounding unit. The electronic gun tester for the high voltage electron accelerator solves the problem that an electronic gun in the prior art is tedious in operating process, has high requirements for technological level of participants, is long in operating period, and needs to be provided with a perfect beam collection system. The electronic gun tester adopts a small power beam to test the electronic gun, greatly reduces output energy and X-ray dose, does not need to build a specified cooling system for beam collection, increases a temperature measurement system, enables a user to read temperature of a lamp filament directly when the electronic gun is operated, can observe testing data in real time through the signal acquisition unit, utilizes a computer to complete automatic recording and evaluating of testing parameters, simplifies ratio of operating staff, improves production efficiency, and correspondingly reduces cost of an electronic gun assembly.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

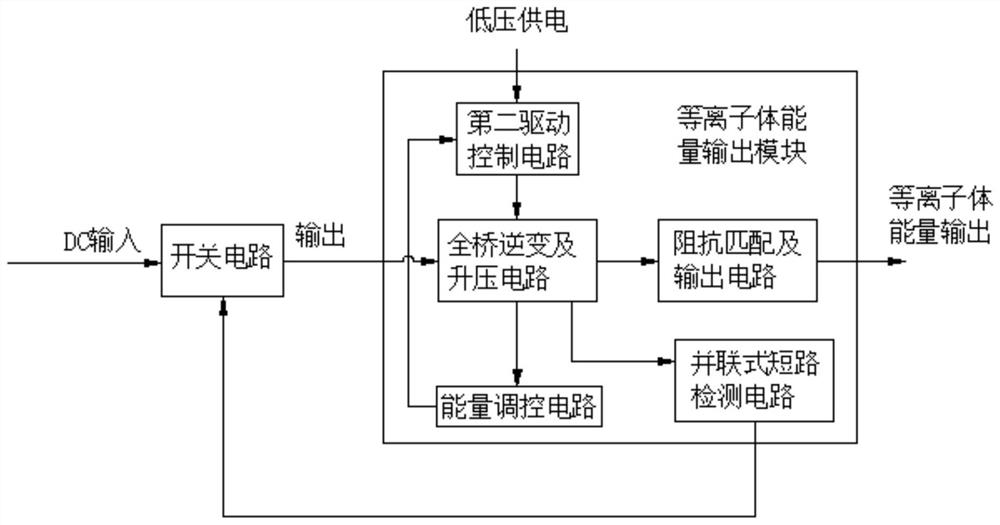

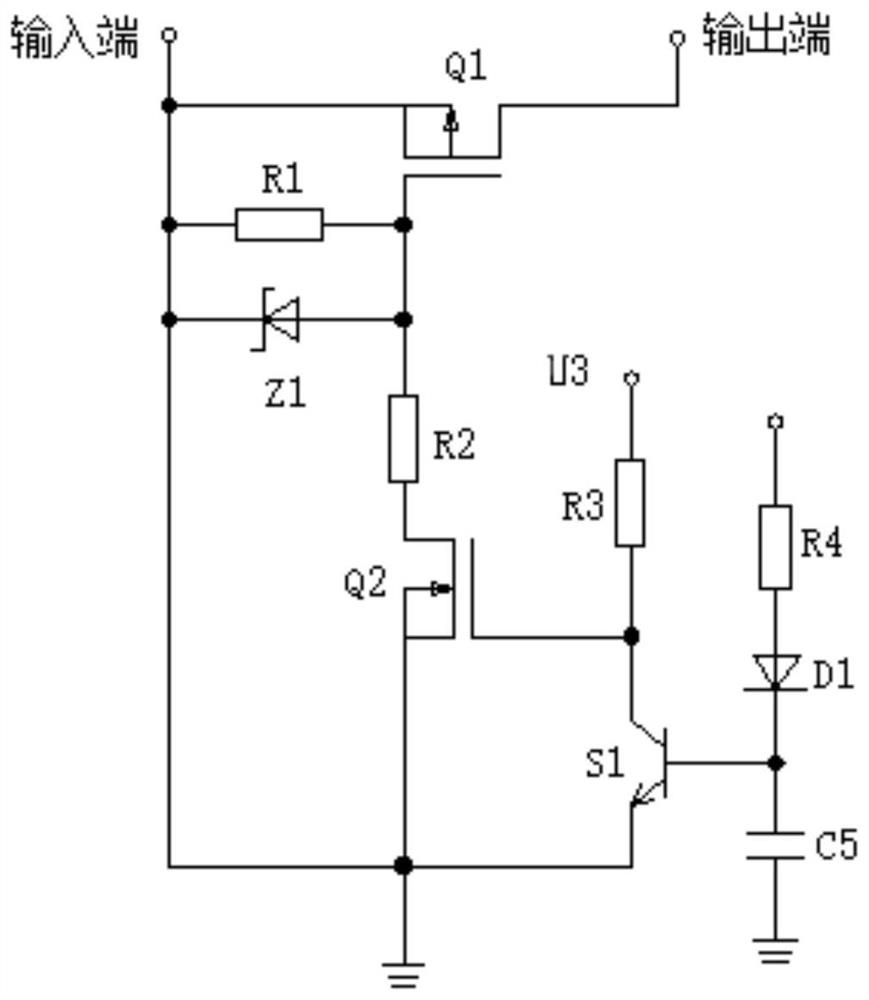

Plasma precise energy control protection system

PendingCN112701935AAvoid Equipment DamageRapid responseProgramme controlAc-dc conversion without reversalPhysicsEnergy regulation

The invention discloses a plasma precise energy control protection system. The system comprises an AD / DC module, a DC control module and a plasma energy output module; the system further comprises a switching circuit connected in series between the DC control module and the plasma energy output module. In the plasma energy output module, an energy regulation and control circuit is used for dynamically sampling current to detect an impedance value and directly feeding back the impedance value to a second driving control circuit; when the detected impedance value is lower than the excitation impedance value of the plasma, energy regulation and control are carried out, so that the output energy of an impedance matching and output circuit is reduced; and a parallel short-circuit detection circuit is used for carrying out parallel short-circuit detection and then sending an obtained short-circuit detection signal to the switching circuit to carry out short-circuit judgment so as to realize on-off of the switching circuit. According to the plasma precise energy control protection system of the invention, a direct feedback mechanism and parallel voltage sampling are adopted to detect a short-circuit signal, and therefore, the response is fast, the system energy output is stable, and the safety is good.

Owner:成都美创卓尔医疗科技有限公司

An electric vehicle electromagnetic integrated energy-feeding suspension actuator and its control method

ActiveCN109808437BReasonable designSimple structureResilient suspensionsMagnetorheological fluidData acquisition

Owner:XIAN UNIV OF SCI & TECH

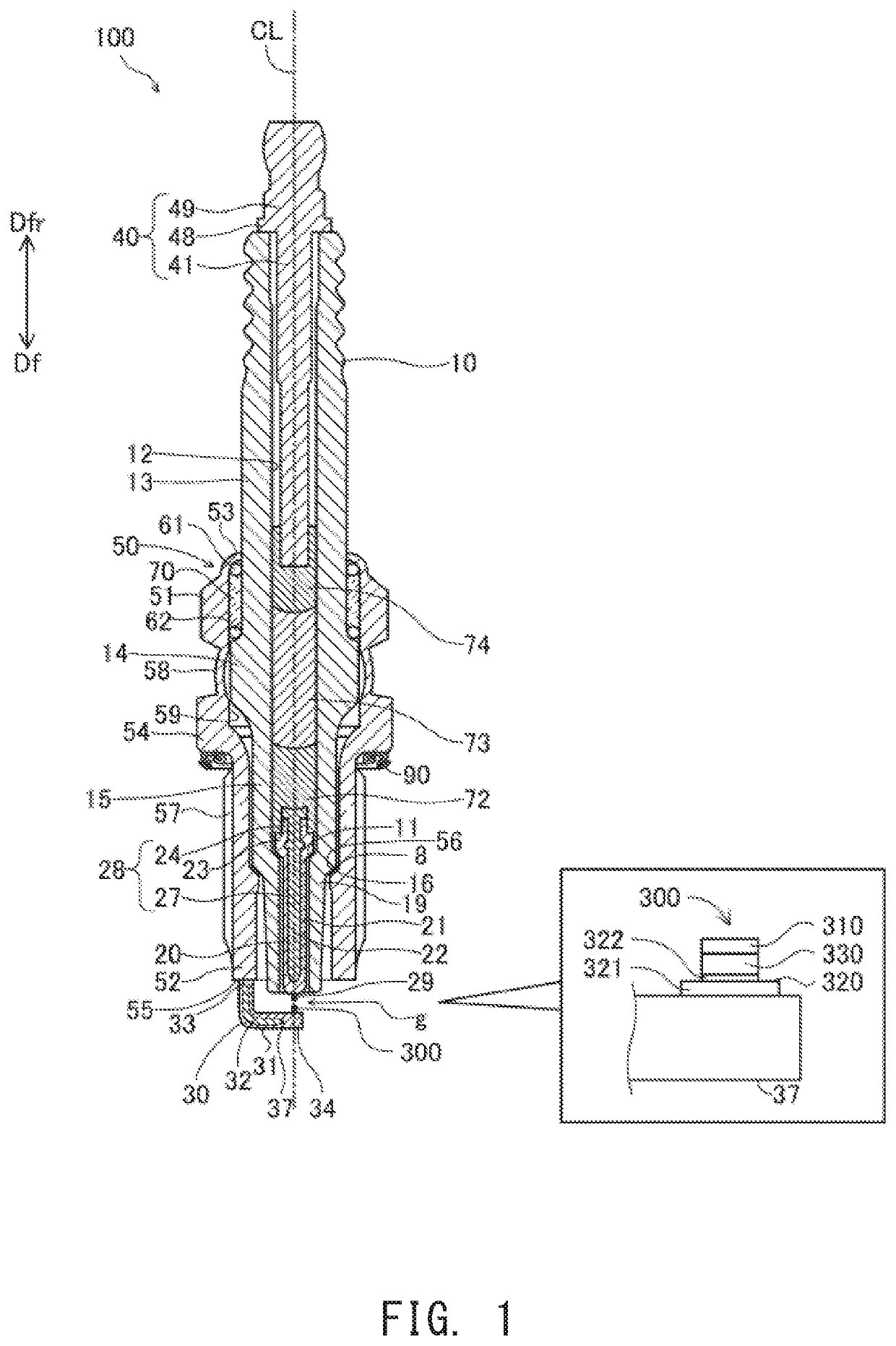

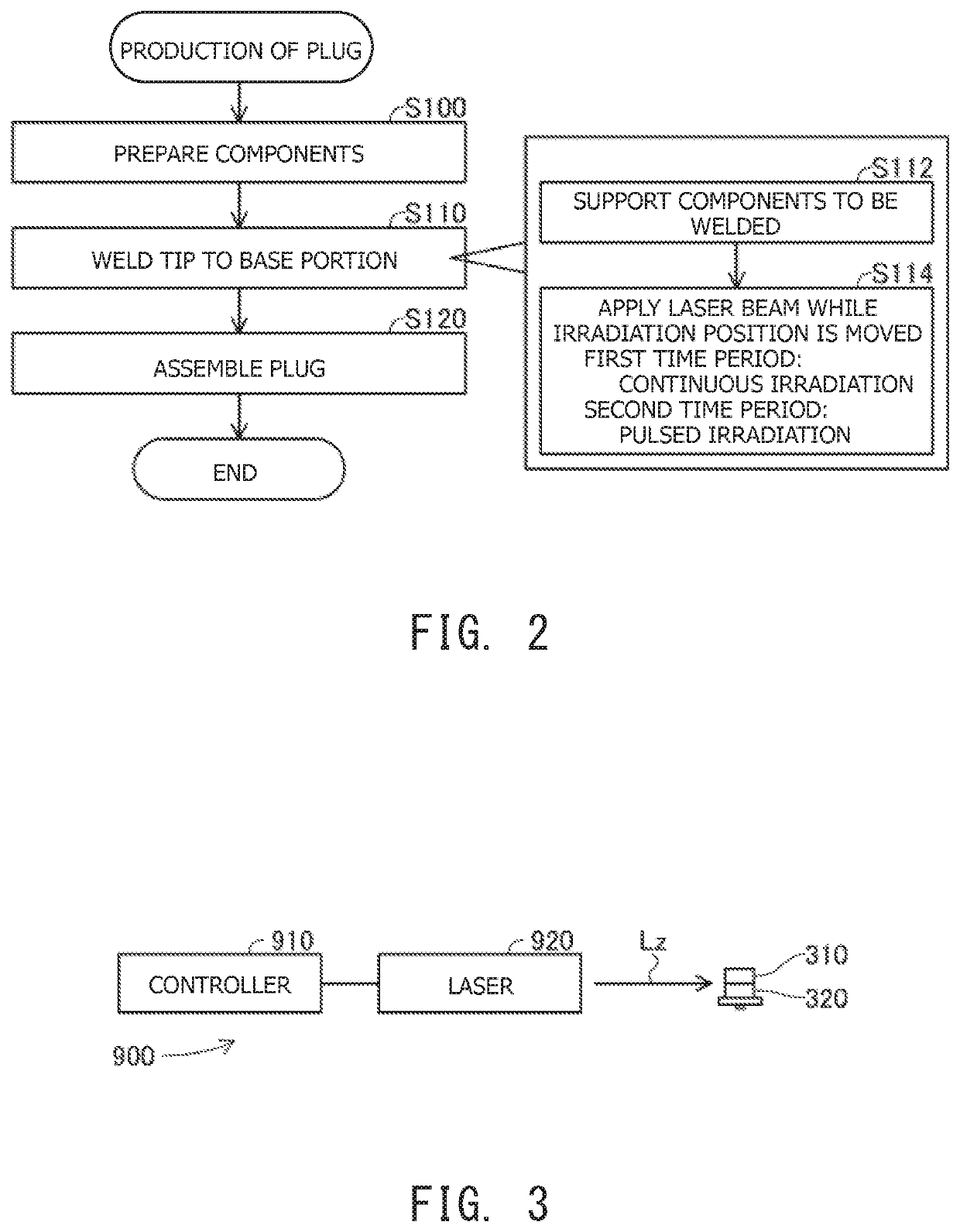

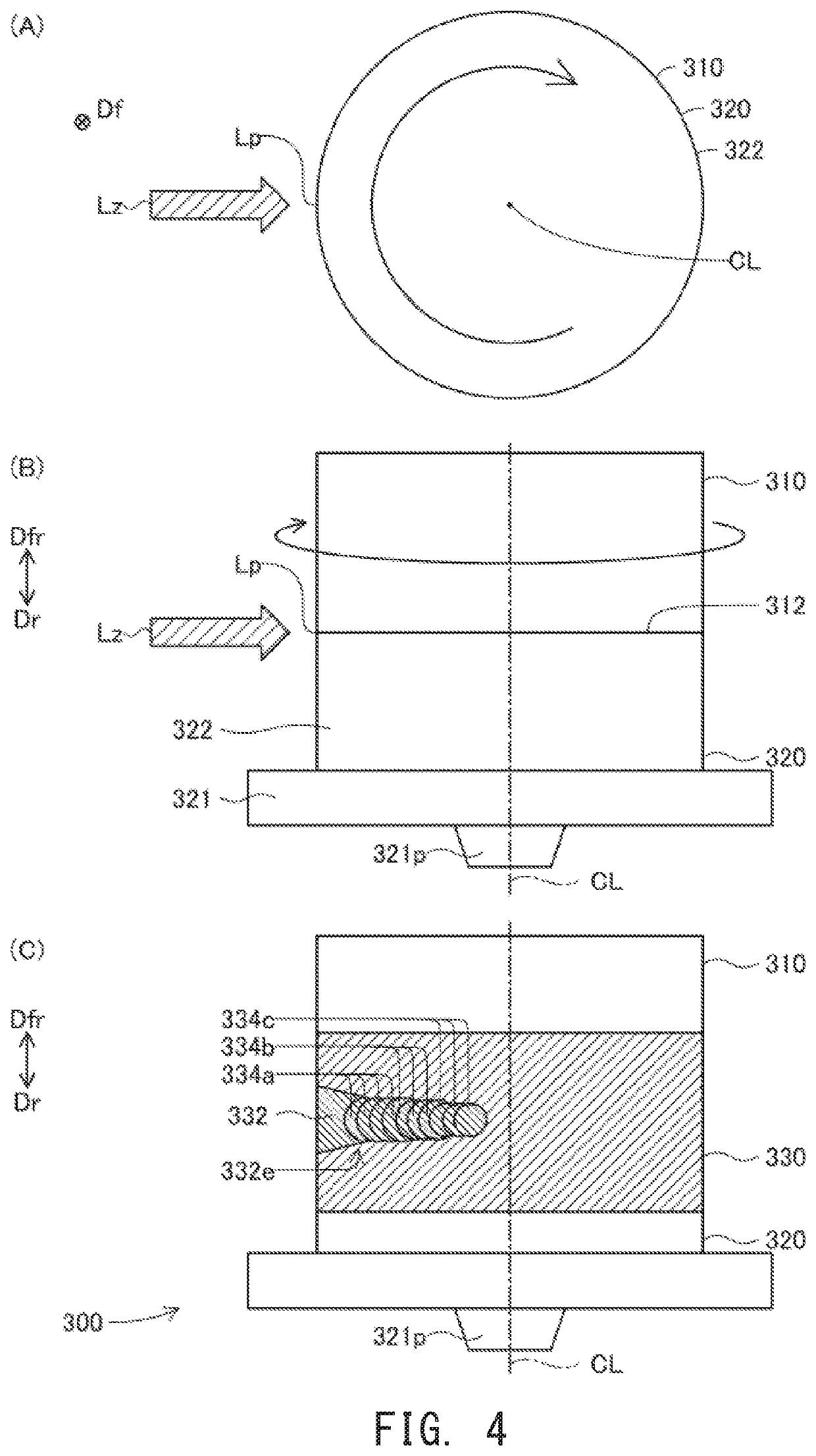

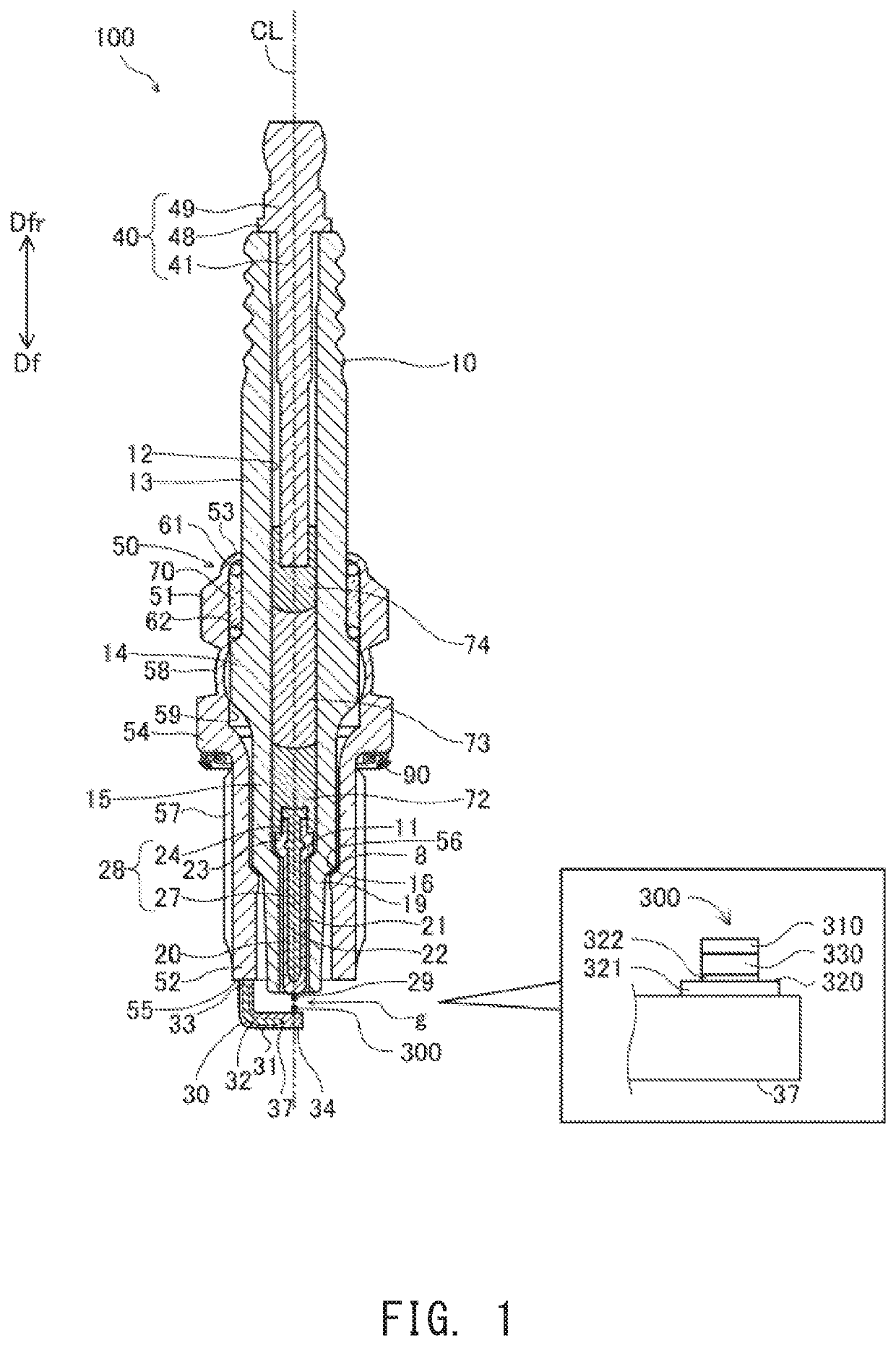

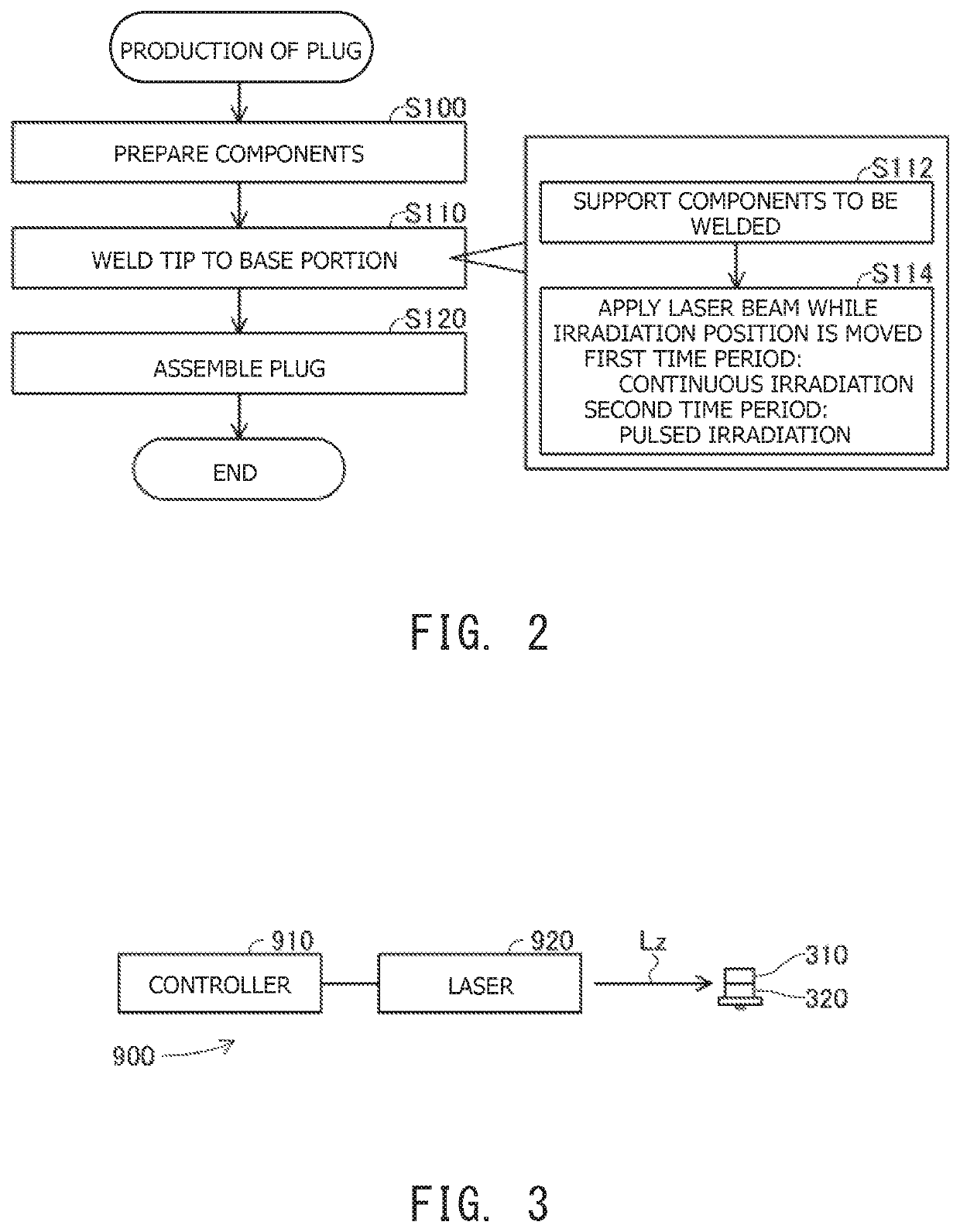

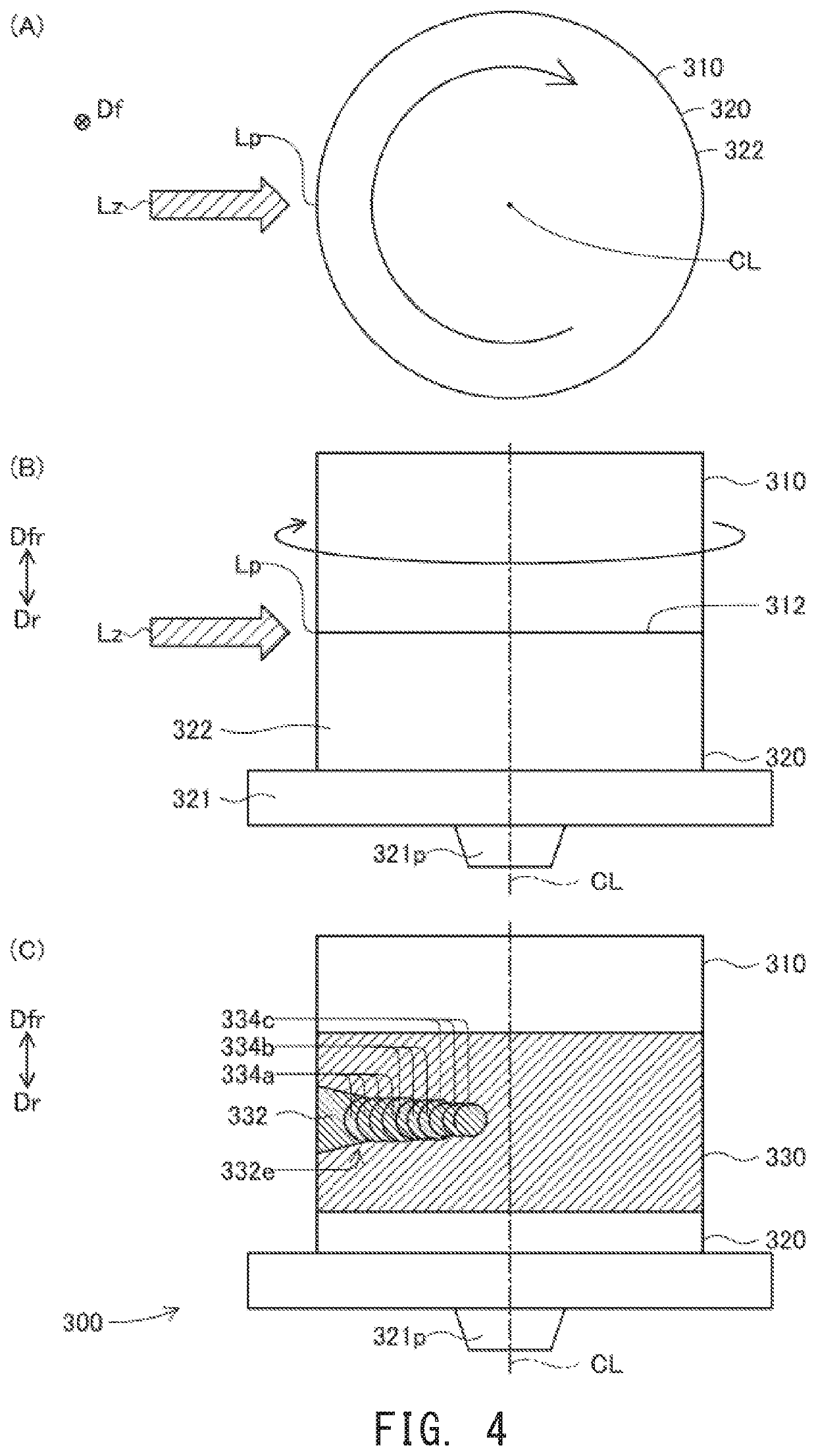

Spark plug production method

ActiveUS20190393683A1Extension of timeReduce distanceSparking plugs manufactureMetal working apparatusEngineeringIrradiation

A tip is welded appropriately using an energy beam. The tip is welded to a base portion by irradiating the interface between the base portion and the tip with the energy beam. The welding the tip to the base portion includes: applying the energy beam continuously, while moving the irradiation position of the energy beam, in a first period of time; and applying the energy beam a plurality of times according to a pulsed output pattern, while moving the irradiation position of the energy beam, in a second period of time subsequent to the first period of time.

Owner:NGK SPARK PLUG CO LTD

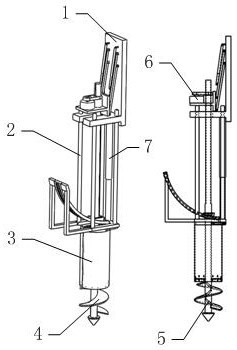

Plantation equipment

InactiveCN112997632APhase ratio increaseReduce resistancePlantingFurrow making/coveringClassical mechanicsElectric machinery

The invention belongs to the technical field of plantation, and particularly relates to plantation equipment. The plantation equipment comprises an installation element, collection barrels, a spiral sheet, an installation rotary shaft, a motor, a first hydraulic rod, second hydraulic rods, a swinging element, an installation plate, an arc-shaped guide rail, third hydraulic rods, installation rings, baffle plates and fourth hydraulic rods. In the plantation equipment, through two groups of designed parallelogram structures formed by four swinging rods, the installation element and the swinging element, on one hand, output energy generated when the second hydraulic rods upwards drive the installation element can be reduced, resistance generated for driving the installation element to upwards swing is relatively small, on the other hand, through the designed parallelogram structures, height generated after the installation rotary shaft and the spiral sheet on the lower side are raised can be increased, meanwhile, the lateral movement distance of the installation rotary shaft and the spiral sheet on the lower side can be increased, so that the installation rotary shaft and the spiral sheet on the lower side are far away from the lower side area of the installation element; and after the installation rotary shaft and the spiral sheet on the lower side are raised, the lower side area of the installation element can contain saplings, and height for sapling plantation can be improved.

Owner:都美娟

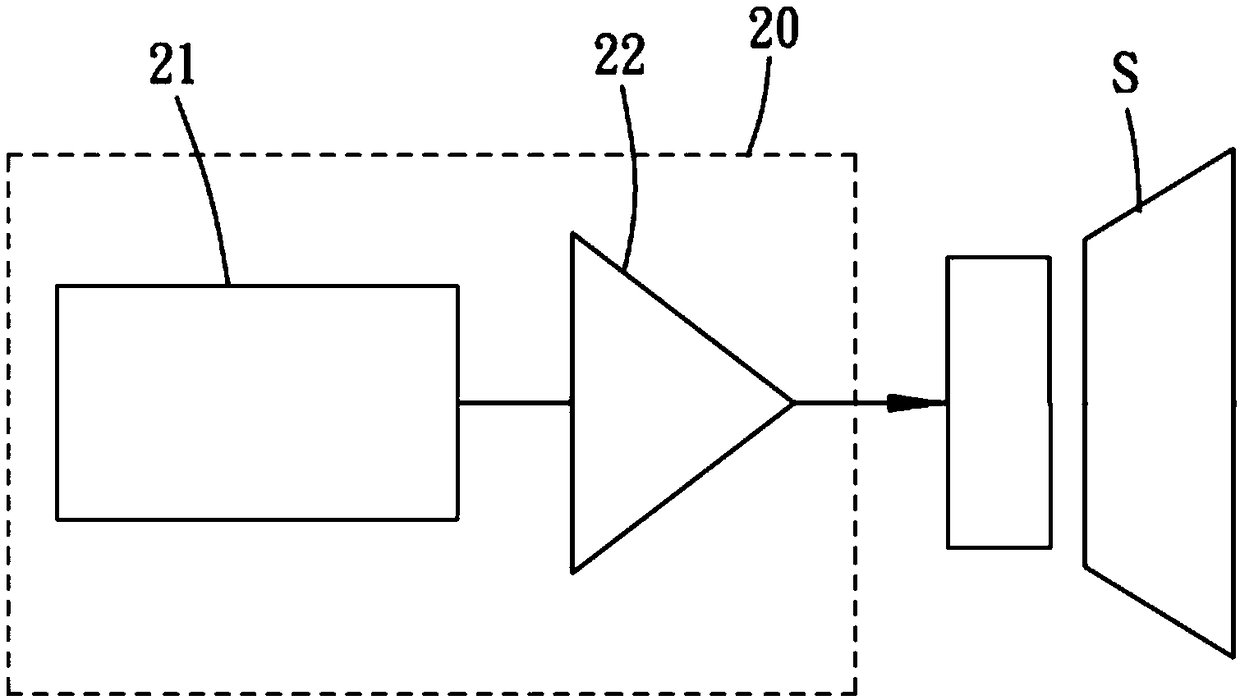

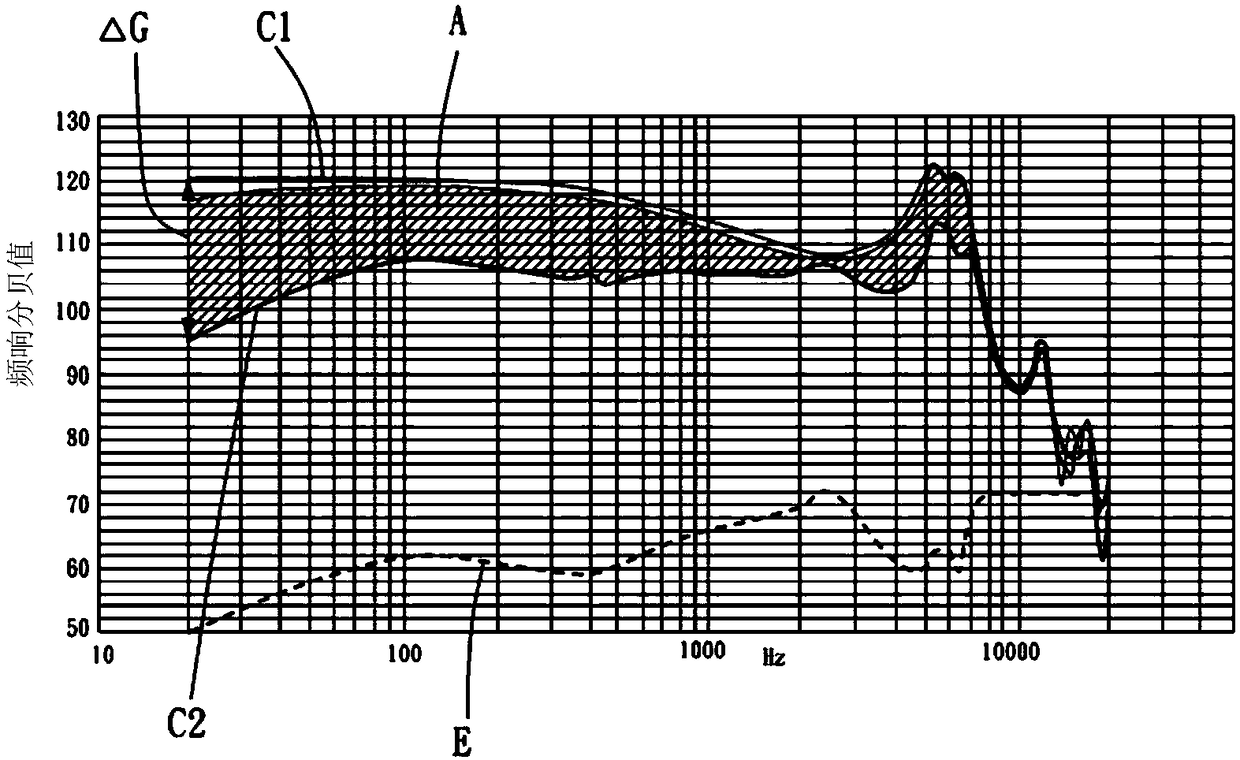

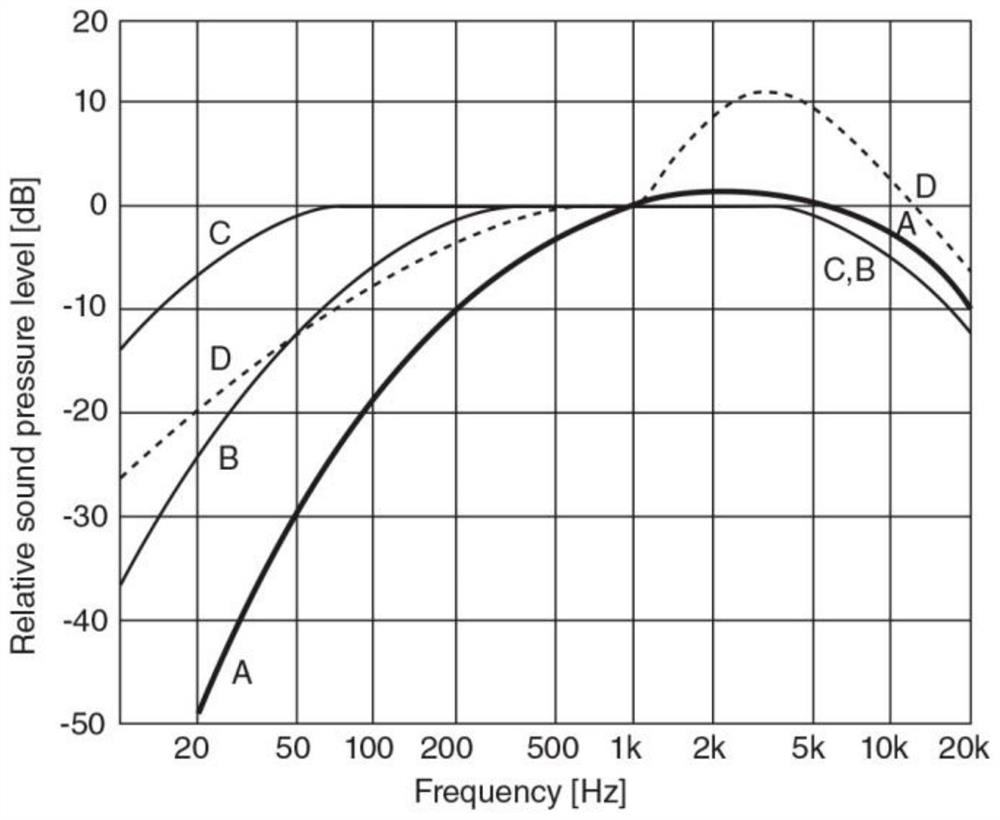

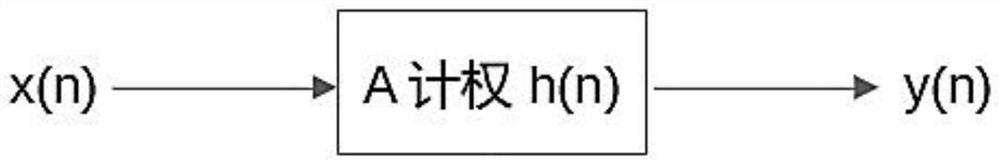

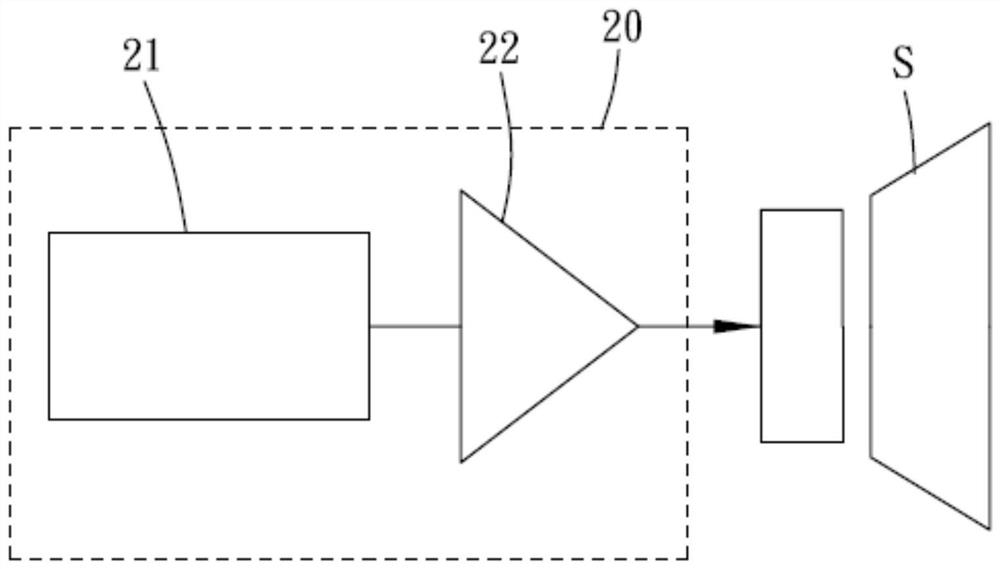

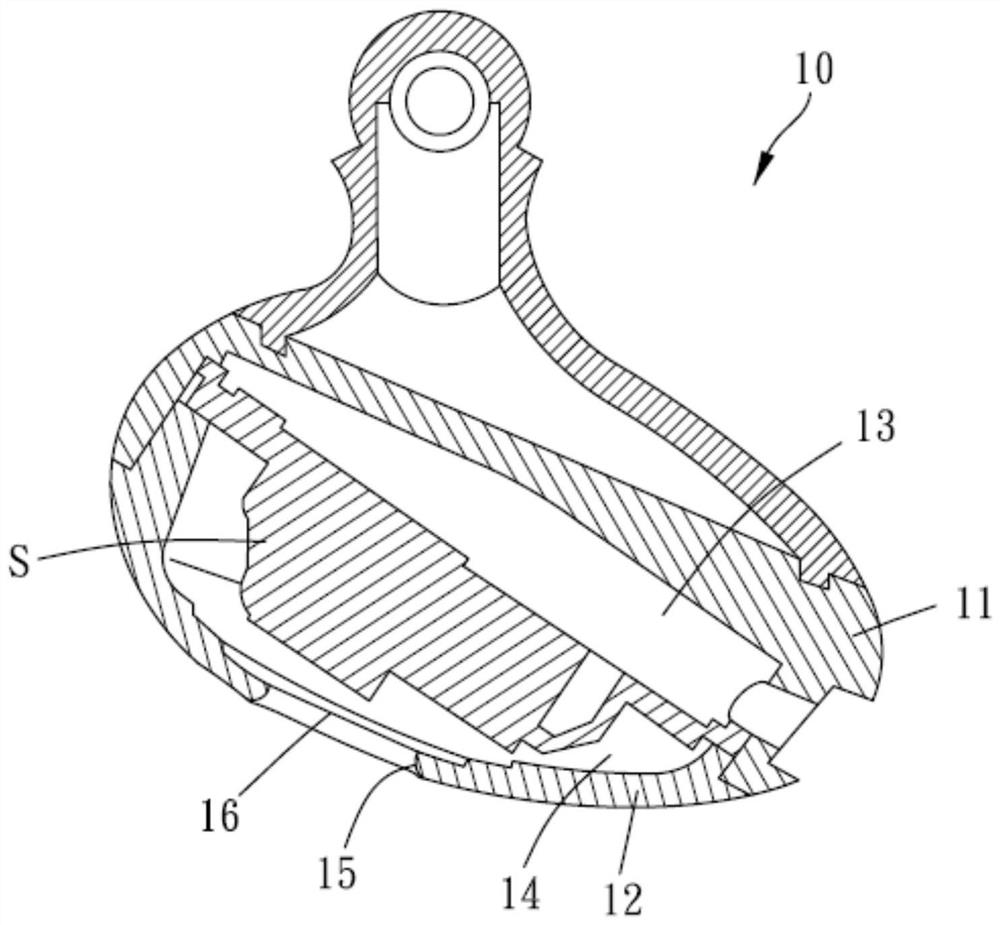

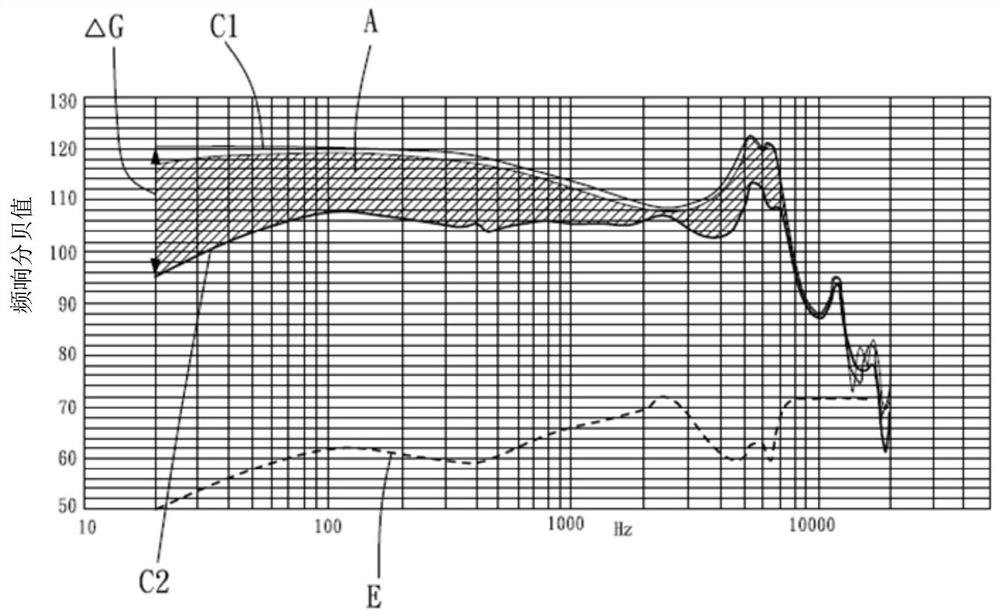

Earphone

ActiveCN109246523ADoes not affect sound qualityLarge frequency response decibel valueMicrophonesLoudspeakersAcoustic energyEngineering

An earphone has a housing with a signal process unit to output sound. The housing has a chamber and a speaker mounted inside the chamber. The chamber is defined as a front volume and a rear volume bythe speaker, and the rear volume having a port. Wherein the speaker in the volume outputting a chamber frequency response curve is at least a portion higher than the earphone's ideal frequency response curve at the bandwidth ranging from 20 Hz to 1000 Hz, where creates a gain difference between the chamber frequency response curve and the ideal frequency response curve to be decreased the (superfluous) positive value by a signal process unit at the bandwidth ranging from 20 Hz to 1000 Hz. Therefore, the total acoustic energy is maintained, the earphone acoustic quality is preserved, and the earphone volume may output even higher power to be deduced by the signal process unit for lowering down the circuit power consumption.

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

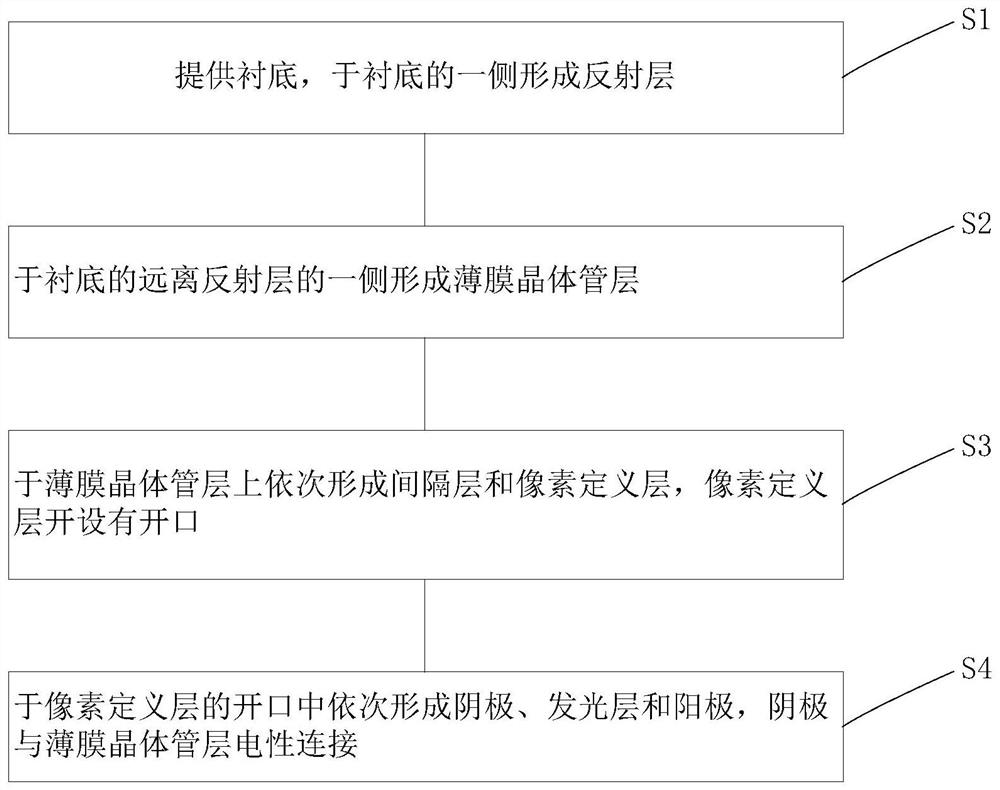

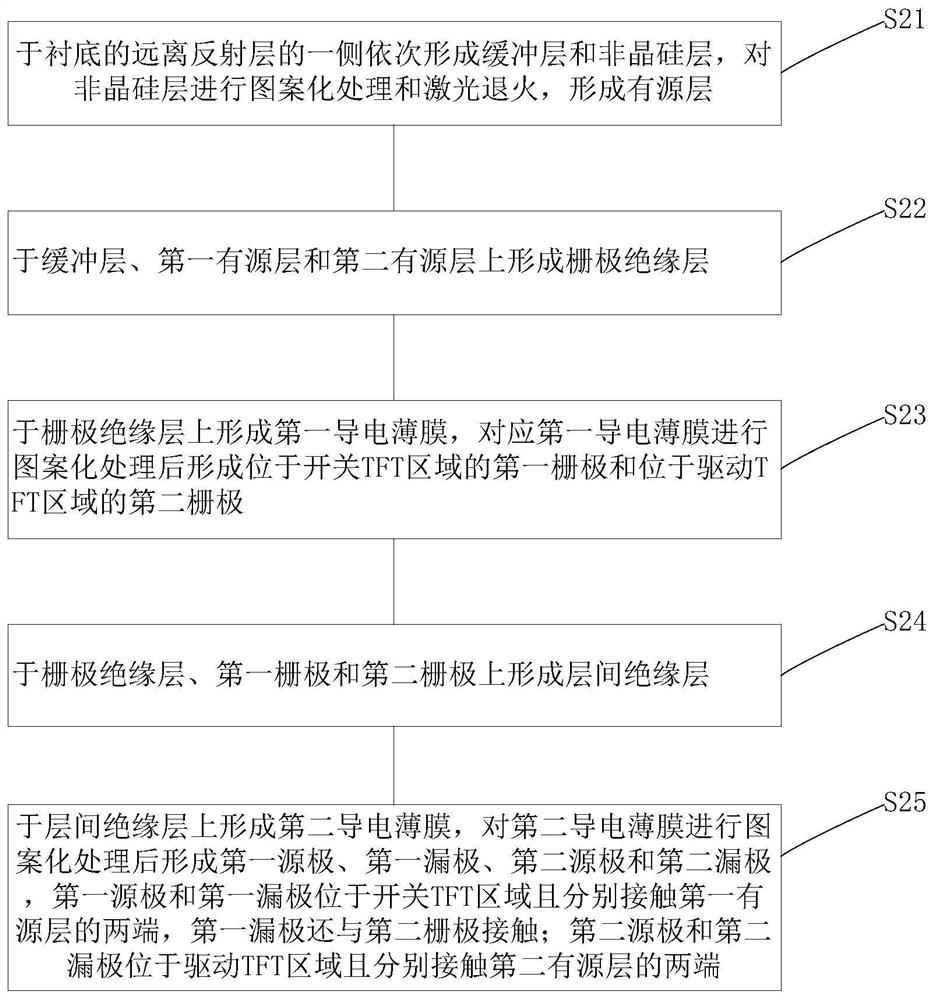

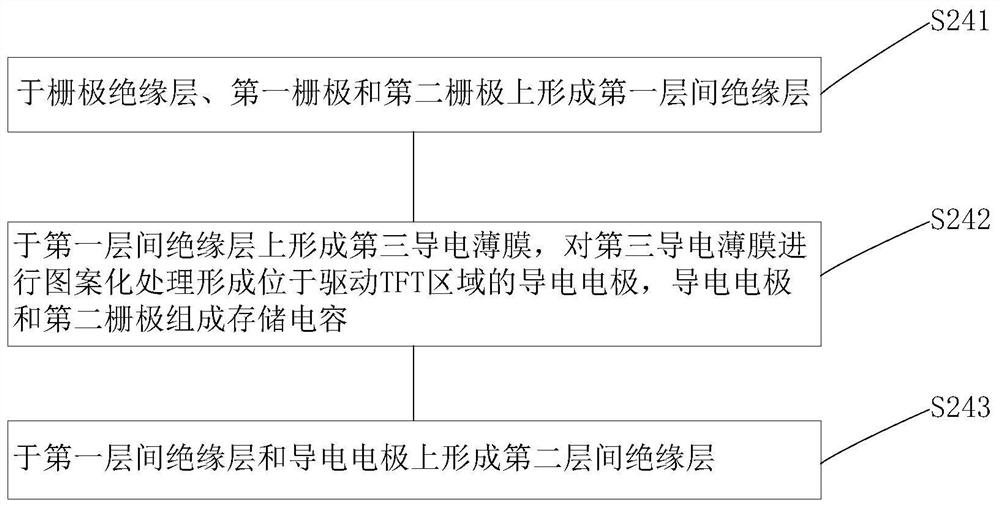

Display panel and manufacturing method thereof

PendingCN112768479AReduce manufacturing costIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconReflective layer

The invention is suitable for the technical field of display, and provides a display panel and a manufacturing method thereof. The manufacturing method of the display panel comprises the following steps: forming a reflecting layer on one side of a substrate; and sequentially forming a buffer layer and an amorphous silicon layer on one side, far away from the reflecting layer, of the substrate, and performing patterning treatment and laser annealing on the amorphous silicon layer to form an active layer. When laser penetrates through the amorphous silicon layer, the buffer layer and the substrate and then irradiates the reflecting layer, the reflecting layer can reflect the laser back to the amorphous silicon layer, and the utilization rate of the laser is greatly improved, so that even if the output energy of an ELA machine table is reduced, it can be guaranteed that the amorphous silicon layer is converted into polycrystalline silicon and forms an active layer, meanwhile, the production time can be shortened, the production efficiency can be improved, and the manufacturing cost of the display panel is reduced.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD +1

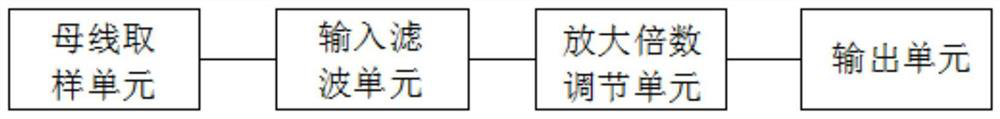

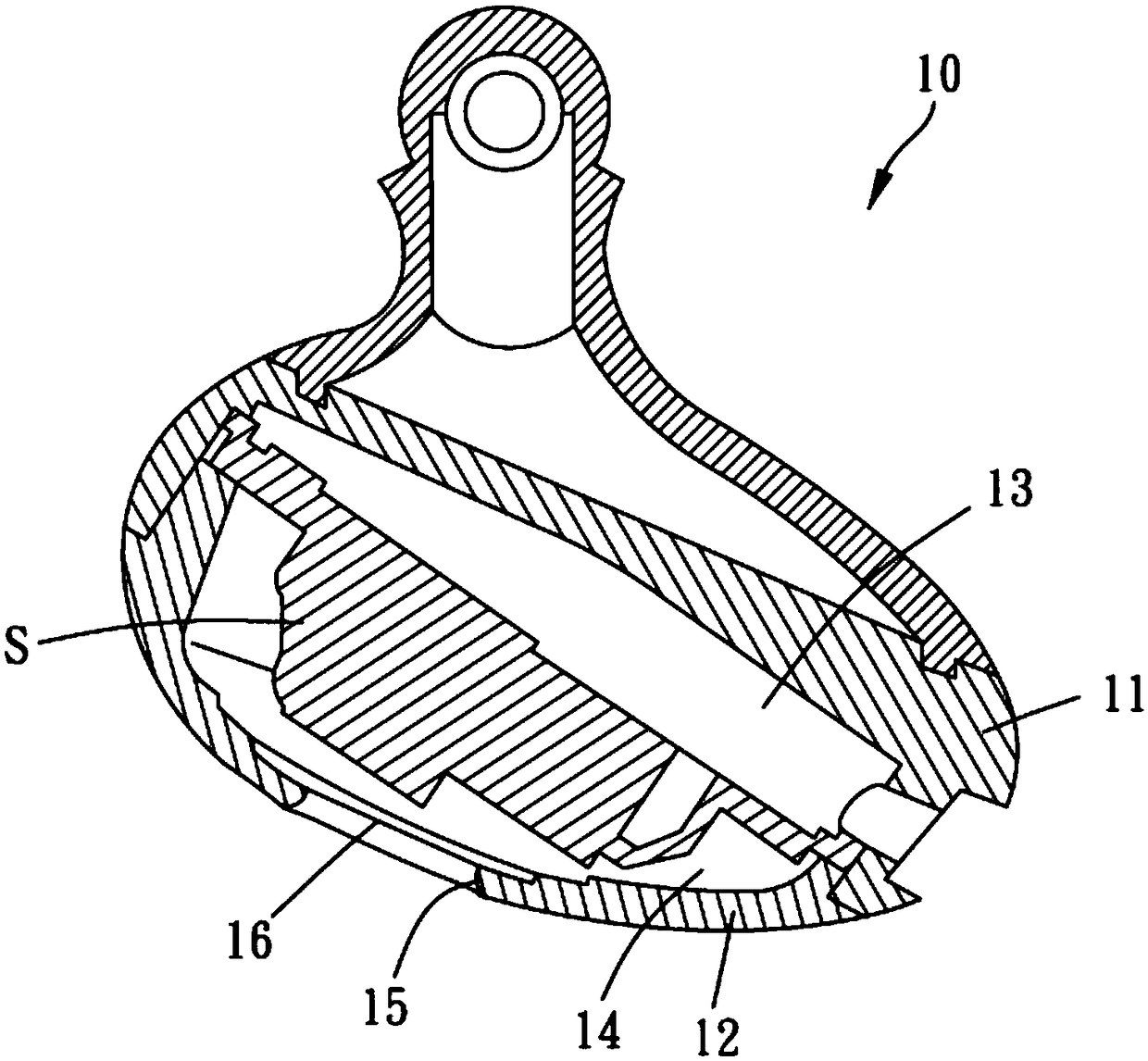

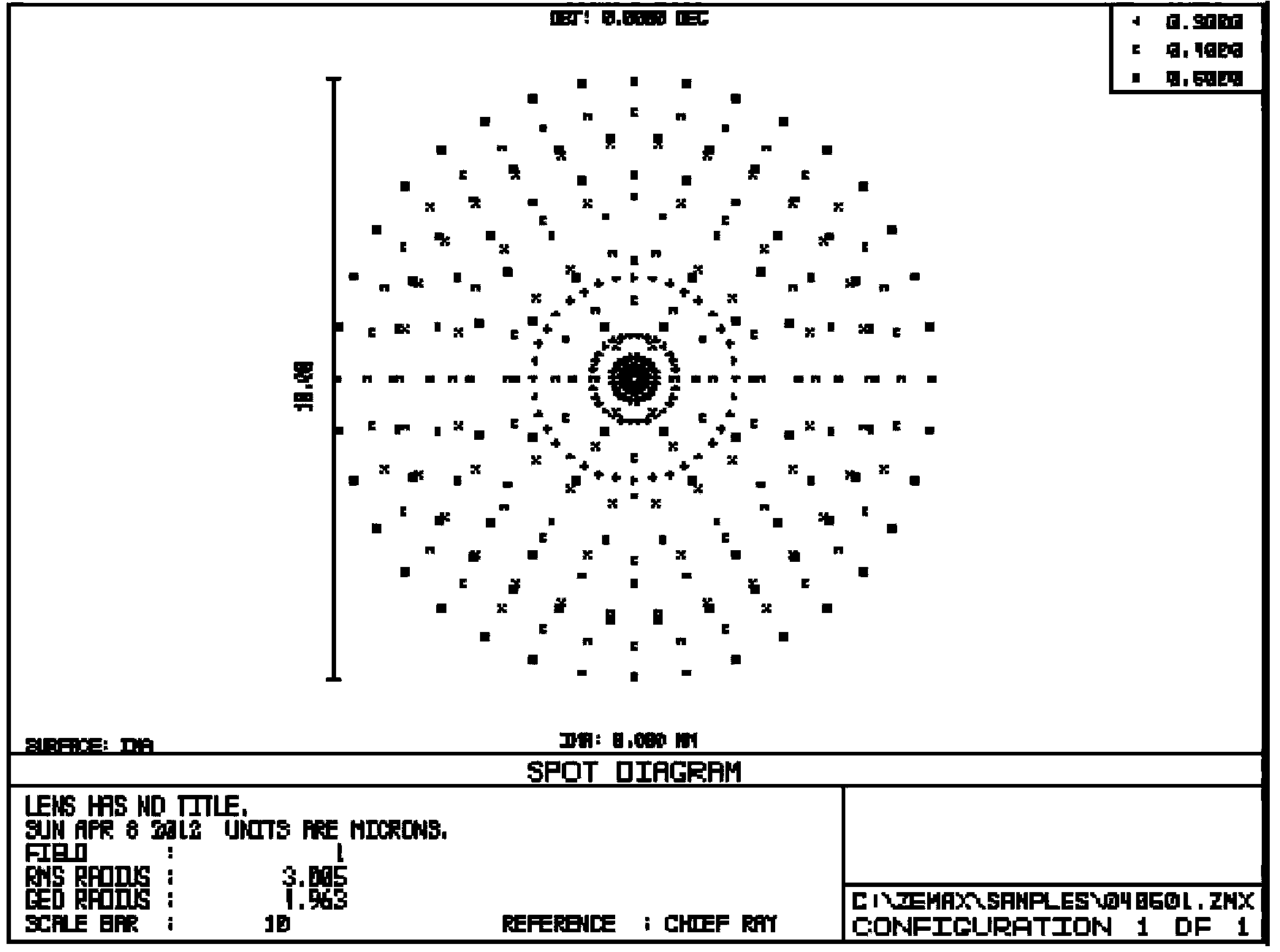

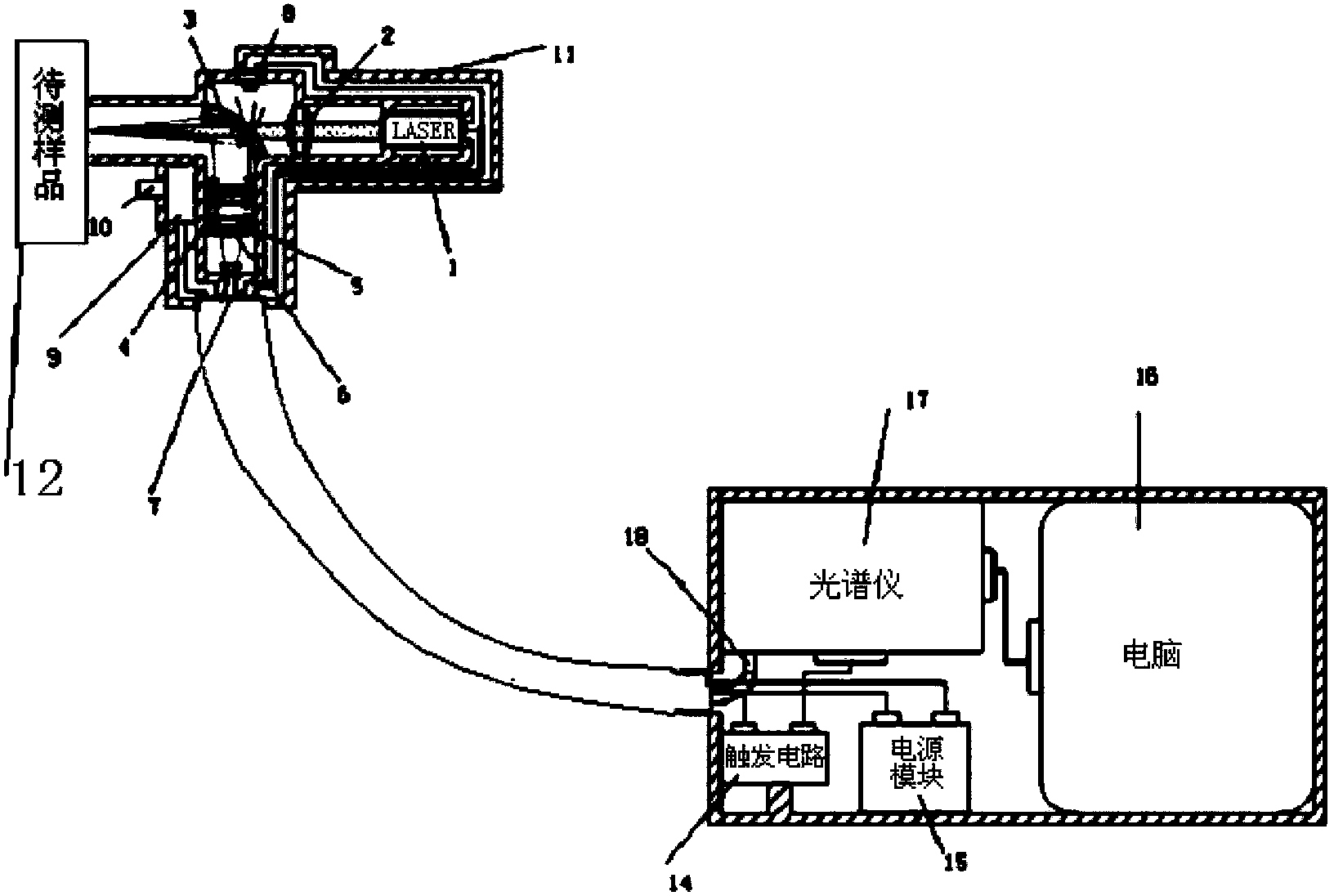

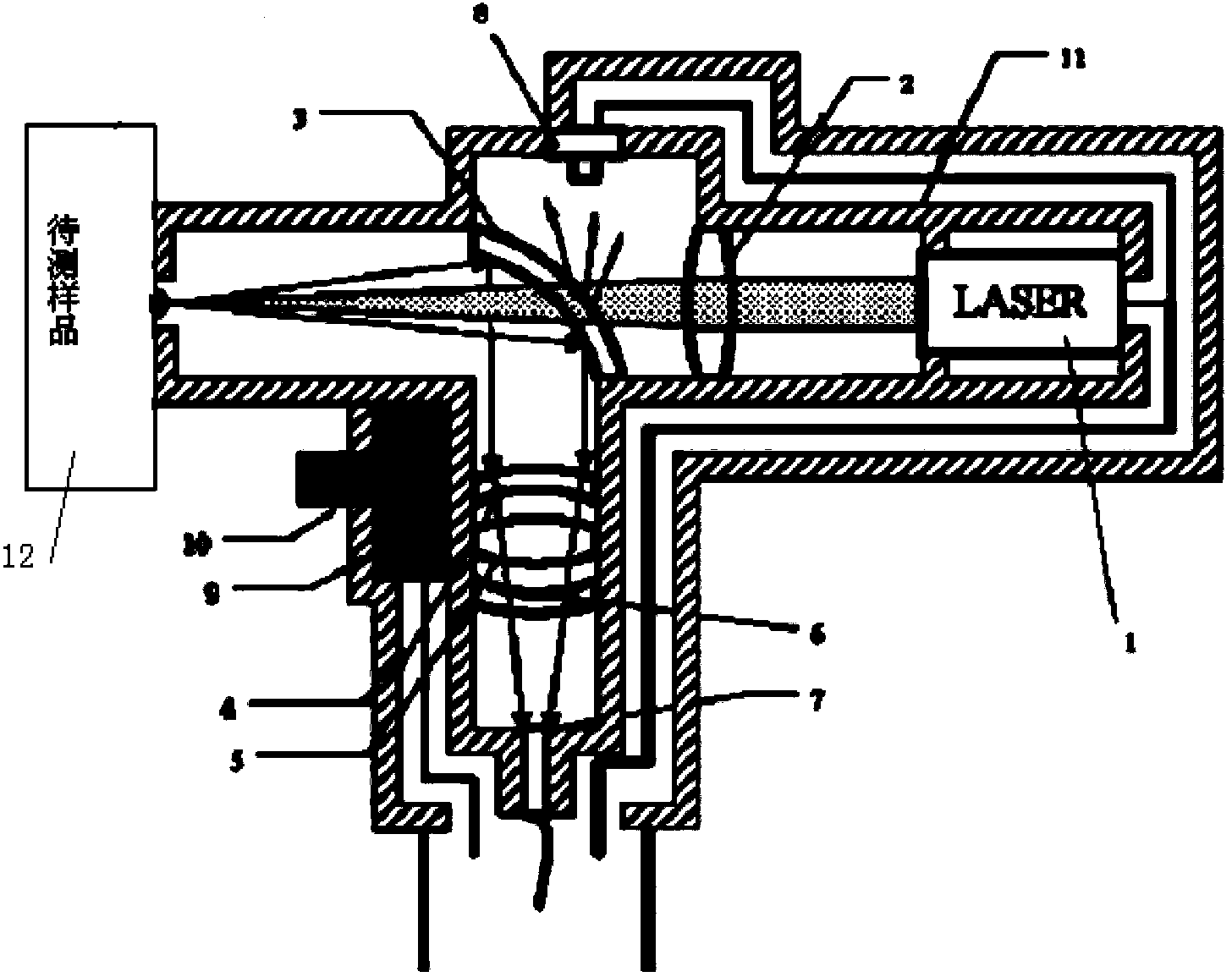

Portable handheld soil heavy metal detection device based on laser-induced breakdown spectroscopy

ActiveCN102901717BNo color differenceImprove acceptance efficiencyAnalysis by material excitationSpectrographHand held

The invention discloses a laser-induced breakdown spectroscopy-based portable handheld soil heavy mental detection device. The laser-induced breakdown spectroscopy-based portable handheld soil heavy mental detection device comprises an optical probe part and a signal acquisition and control part. The optical probe part is characterized in that a laser emission head in a housing emits laser; and the emitted laser passes through a series of lenses, then is coupled to optical fibers and then is input into a spectrograph of the signal acquisition and control part. An optical signal is transformed into an electrical signal and then is input into a computer. The computer stores and processes the input electrical signal. The laser-induced breakdown spectroscopy-based portable handheld soil heavy mental detection device adopts an off-axial aspherical mirror so that height calibration and turning of a light beam emitted by plasma are carried out simultaneously without a color difference so that coupling of follow-up light beams to optical fibers is guaranteed. The laser-induced breakdown spectroscopy-based portable handheld soil heavy mental detection device adopts the lenses to realize laser beam conversion so that output energy of the laser emission head is reduced and thus the damage on a sample in detection is reduced. The laser-induced breakdown spectroscopy-based portable handheld soil heavy mental detection device has a high system integration level, a small volume, light weight and a low cost, is convenient for carrying and operation, and can be realized easily.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for producing a spark plug including an electrode having a base portion and a tip fixed to the base portion

ActiveUS10680416B2CrackingReduce output energySparking plugs manufactureWelding/soldering/cutting articlesEngineeringAtomic physics

A tip is welded appropriately using an energy beam. The tip is welded to a base portion by irradiating the interface between the base portion and the tip with the energy beam. The welding the tip to the base portion includes: applying the energy beam continuously, while moving the irradiation position of the energy beam, in a first period of time; and applying the energy beam a plurality of times according to a pulsed output pattern, while moving the irradiation position of the energy beam, in a second period of time subsequent to the first period of time.

Owner:NGK SPARK PLUG CO LTD

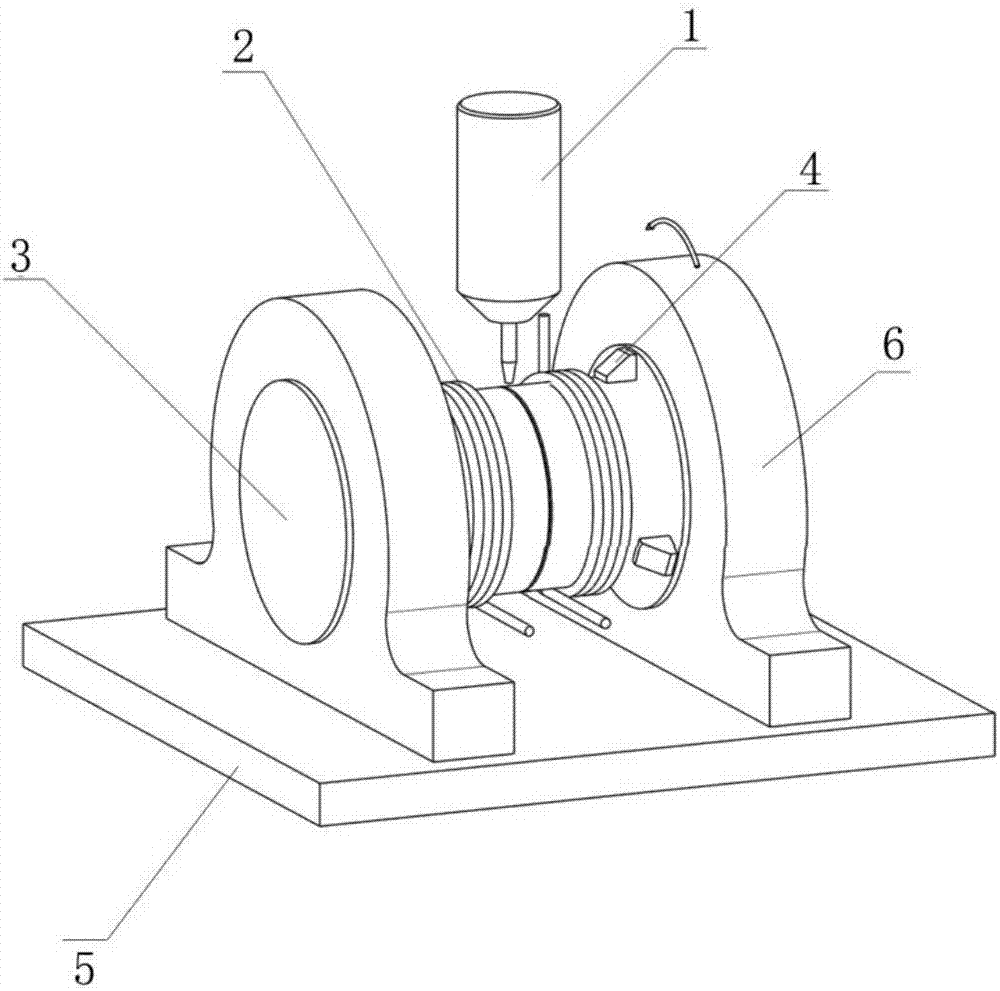

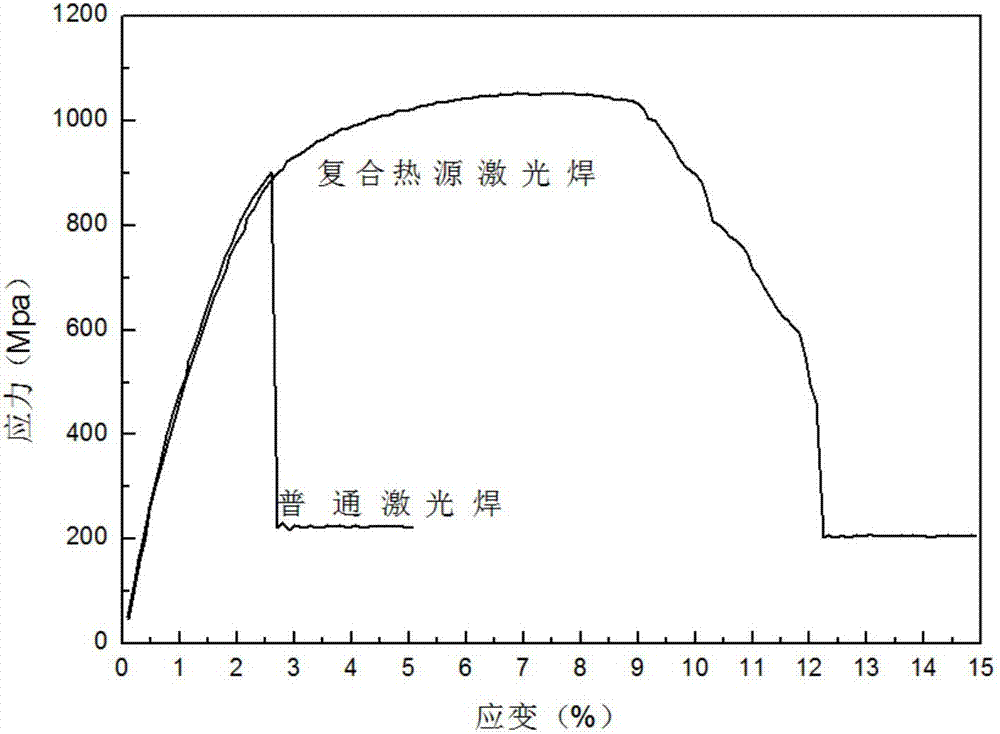

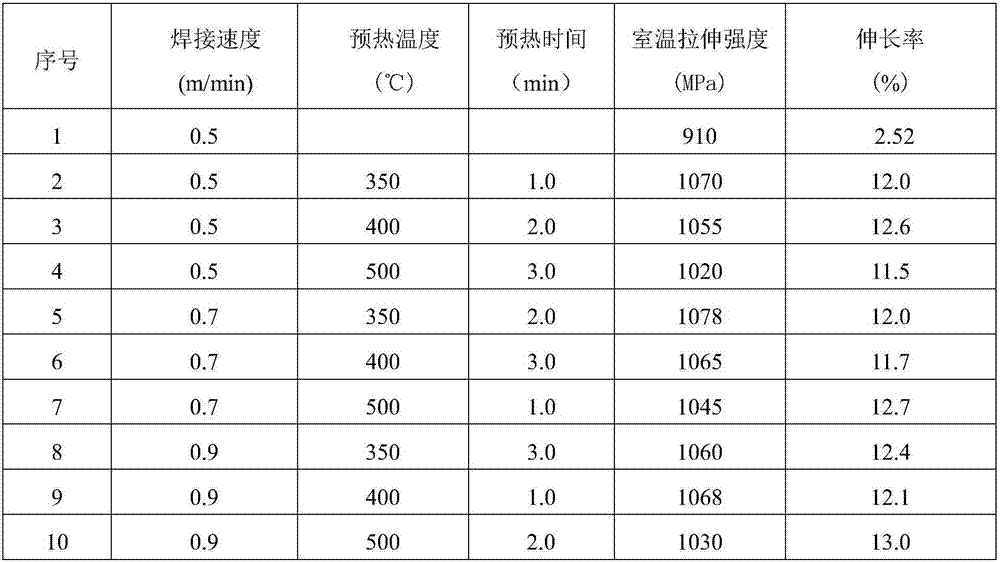

Laser welding connecting device and technology of forged steel piston

InactiveCN106944753AIncrease in sizeReduce generationPistonsMetal working apparatusIntermediate frequencyMegasonic cleaning

The invention relates to a laser welding connecting device and technology of a forged steel piston. The device mainly comprises a laser, an intermediate frequency induction heating device, adjustable variable speed rotating devices, piston clamping devices, a base and supporting components. The technology comprises the steps of 1, surface pretreatment: after treating the surface of the piston through a mechanical method, placing the treated piston into an acetone solution to be subjected to ultrasonic cleaning; 2, assembly: after accurate locating, starting the piston clamping devices to fix the piston at the clamping range (phi) of 100 mm to 150 mm; 3, preheating: energizing the intermediate frequency induction heating device to preheat the piston at the temperature of 350 DEG C to 500 DEG C for 1 min to 3 min; 4, welding: turning off the intermediate frequency induction heating device, starting the adjustable variable speed rotating devices to rotate the piston at the speed of 0.5 m / min to 0.9 m / min, and starting the laser of which power is 3 kw to 5 kw to weld the piston; and 5, slow furnace cooling: putting the piston into a constant-temperature heat-insulated furnace at the temperature of 350 DEG C to 400 DEG C, turning off the power, and carrying out furnace cooling on the piston. According to the laser welding connecting device and the laser welding connecting technology, the problem that joints crack after welding can be solved, and welding quality of the laser welding joints of the forged steel piston is guaranteed.

Owner:JILIN UNIV

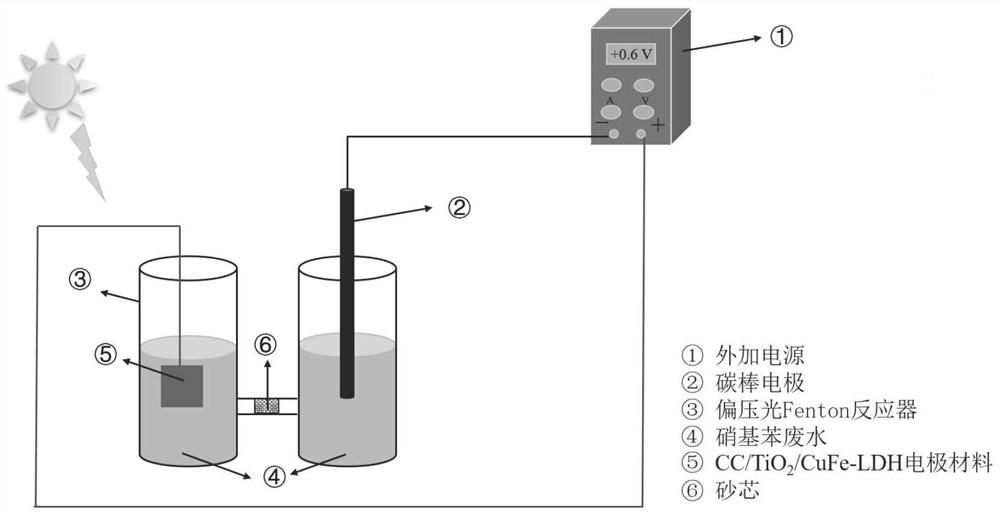

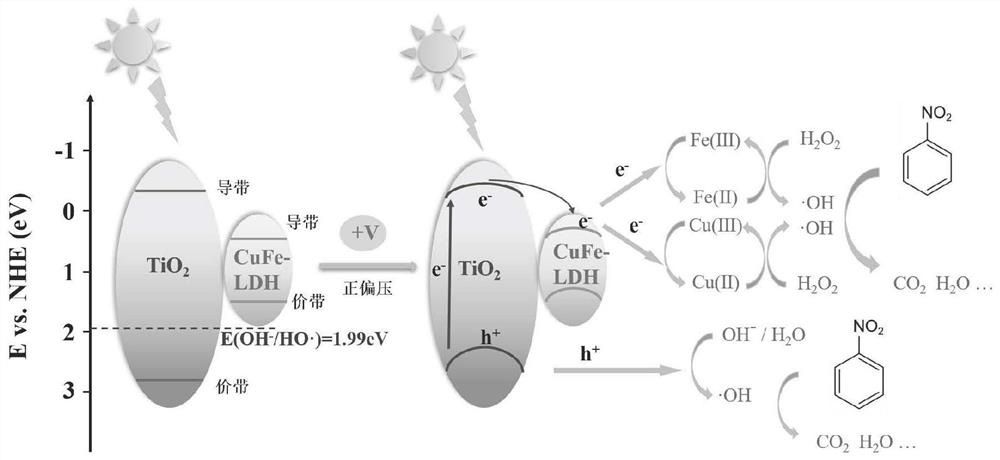

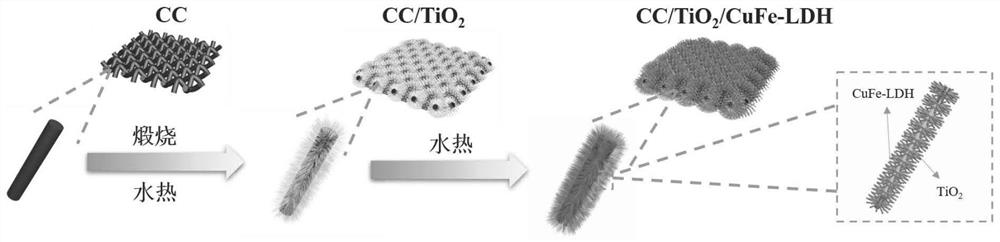

Novel positive bias auxiliary photo-Fenton technology

PendingCN113896297AFacilitate hole separationExtend your lifeWater/sewage treatment by irradiationWater treatment compoundsElectron holeSemiconductor materials

The invention belongs to the technical field of water treatment, and particularly relates to a novel positive bias auxiliary photo-Fenton technology which comprises the following steps: step 1, preparing a material, namely preparing a CC / TiO2 / CuFe-LDH material; and step 2, carrying out bias voltage-assisted Fenton photo-reaction to degrade nitrobenzene. The technology is reasonable in design, and under the action of positive bias voltage, the energy band of the semiconductor material is bent upwards, the band gap is narrowed, photo-induced electron-hole separation is promoted, and the service life of current carriers can be prolonged; under the action of positive bias voltage, photo-induced electrons excited by TiO2 illumination move towards CuFe-LDH, and the photo-induced electrons promote circulation of Cu<3+> / Cu<2+> and Fe<3+> / Fe<2+>; and .OH generated by holes is used for degrading pollutants, and can effectively separate photo-induced electron holes and improve the utilization rate of the photo-induced electron holes.

Owner:JILIN UNIV

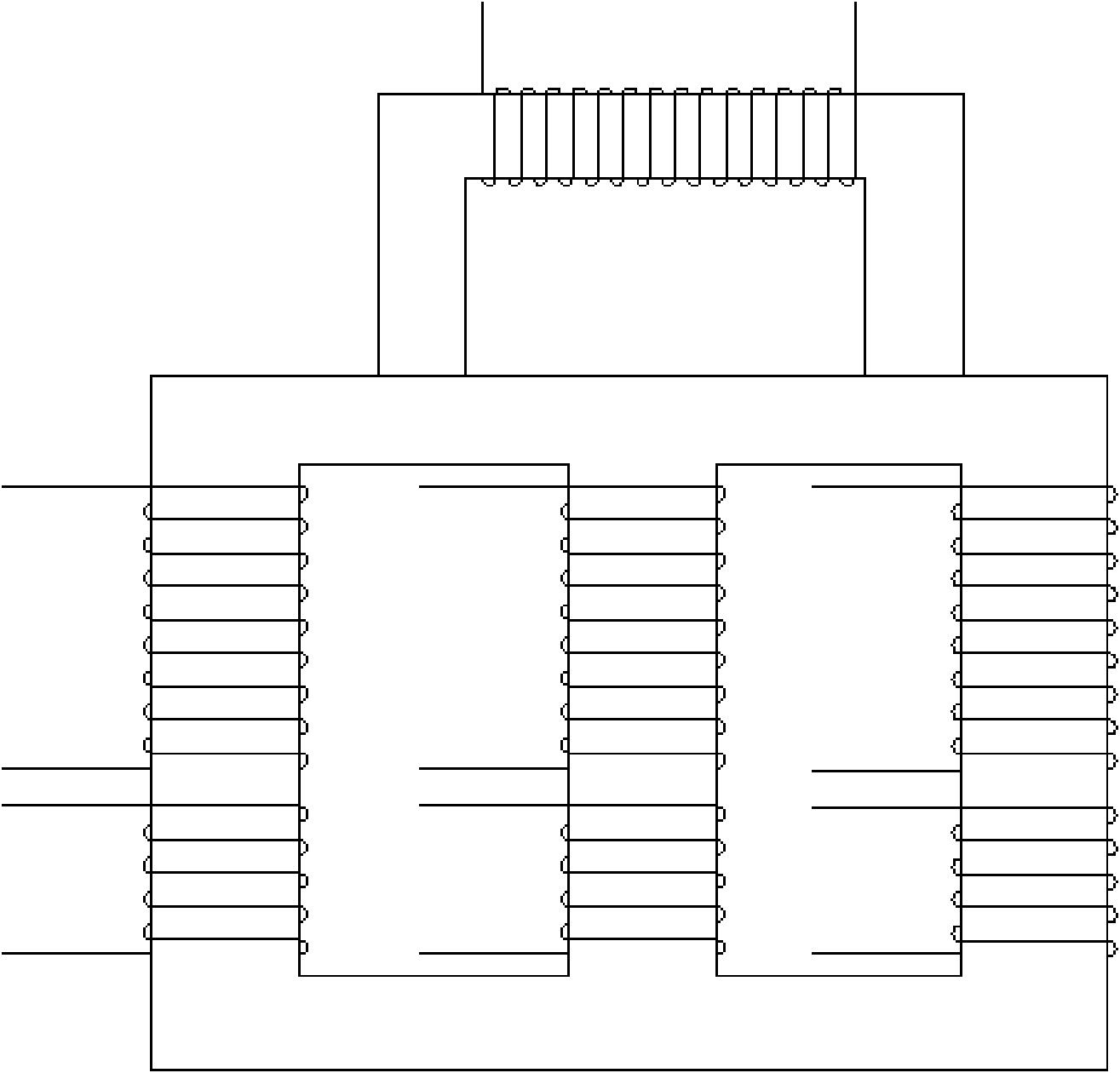

Gas shielded welding machine power supply

InactiveCN101653854AReduce output energySignificant power transfer capabilityArc welding apparatusTransformerPower grid

The invention discloses a gas shielded welding machine power supply, comprising a main transformer for power network isolation and energy conversion and an inductor in series connection in an main power rectification loop. The inductor is installed in a range in which the magnetic lines generated when the inductor is power-on and the magnetic lines generated when the coils of the main transformerare power-on are crossed. Compared with the present product, the invention has the beneficial effects of fast arc ignition in welding, no splashing and enhanced fusion depth.

Owner:JIANGMEN BOSJOB

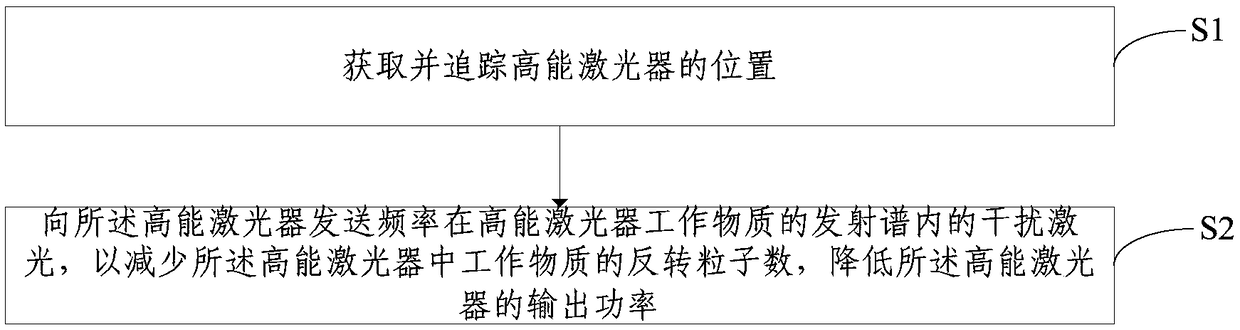

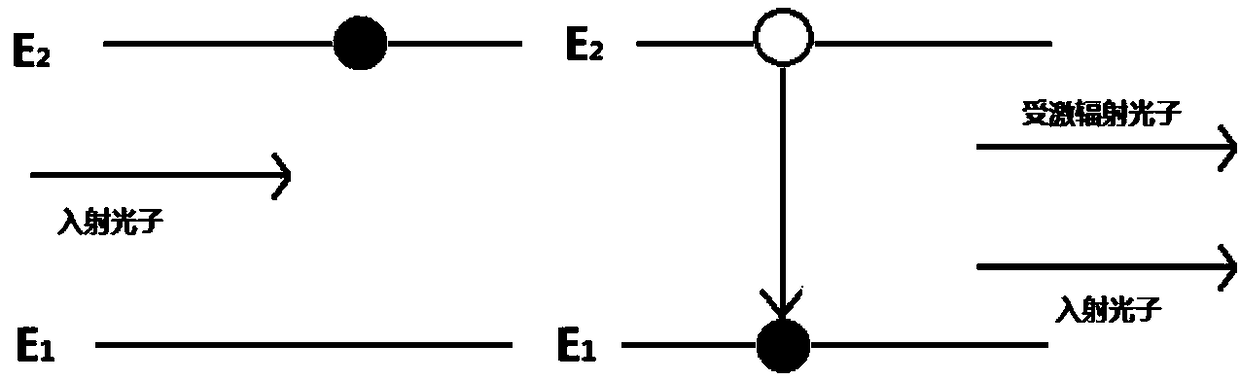

Method and device for suppressing and jamming high-energy laser device

ActiveCN109405636AReduce output energyReduce gainTraining adaptationOptoelectronicsHigh energy laser

The embodiment of the invention provides a method and device for suppressing and jamming a high-energy laser device. The method comprises the steps that the position of the high-energy laser device isobtained and tracked, jamming laser with the frequency within an emission spectrum of a working substance of the high-energy laser device is sent to the high-energy laser device so as to decrease thenumber of inverted particles of the working substance in the high-energy laser device, and thus the output power of the high-energy laser device is lowered. The high-energy laser device is irradiatedthrough a laser source, the laser enters the working substance of the high-energy laser device to consume the cumulative number of upper energy level particles in the working substance and decrease the number delta n of the inverted particles, thus the gain of the high-energy laser device during working is greatly decreased, the output power of the high-energy laser device is lowered, and the purpose of effectively and quickly suppressing and jamming the high-energy laser device at the lowest cost is achieved.

Owner:BEIJING UNIV OF TECH

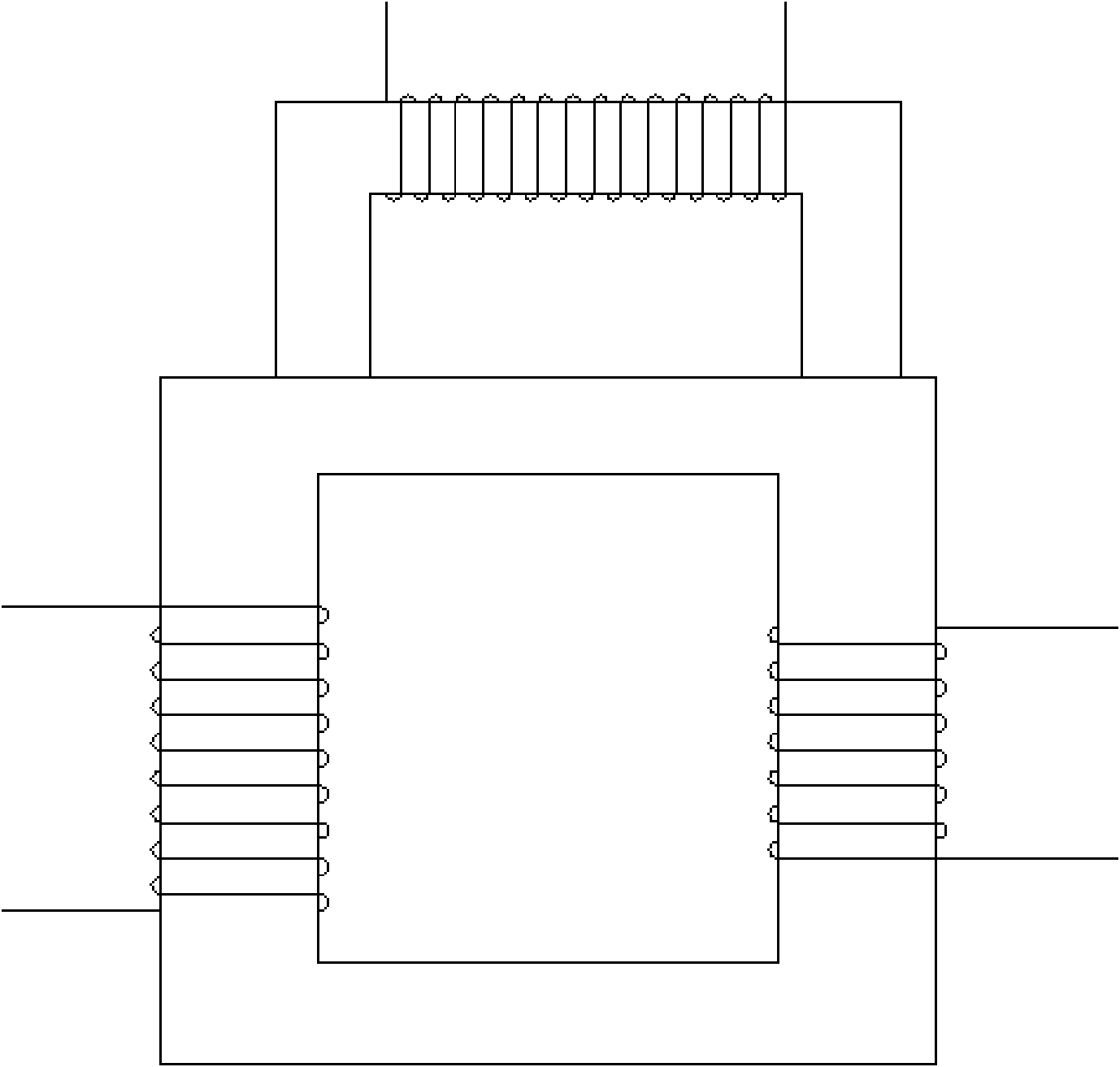

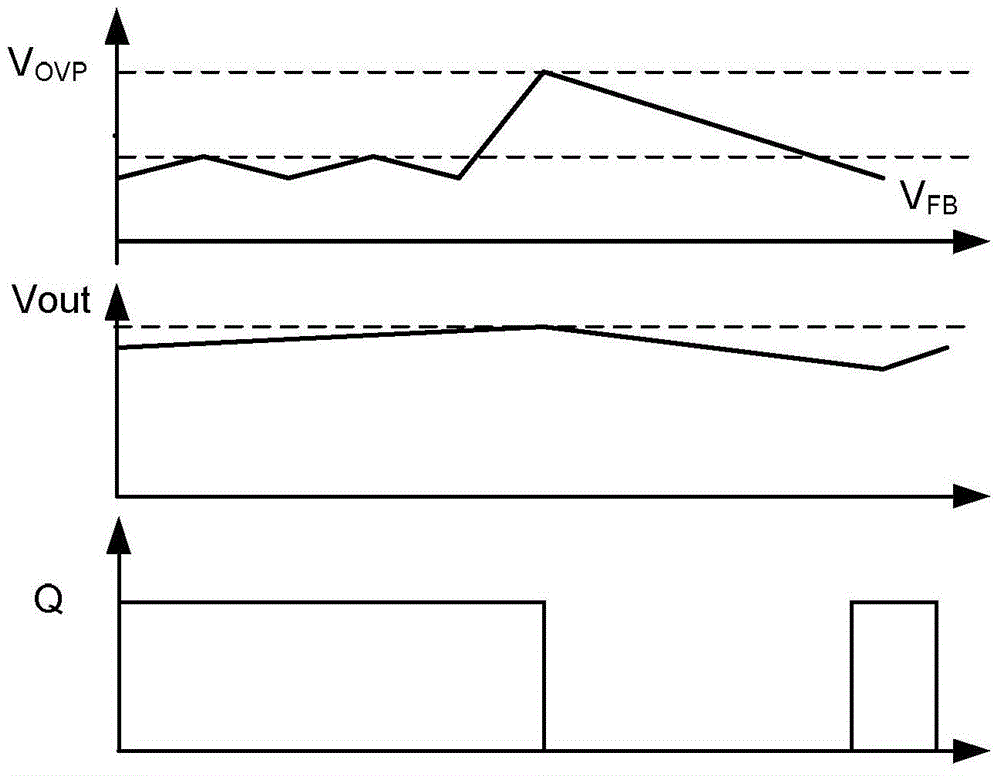

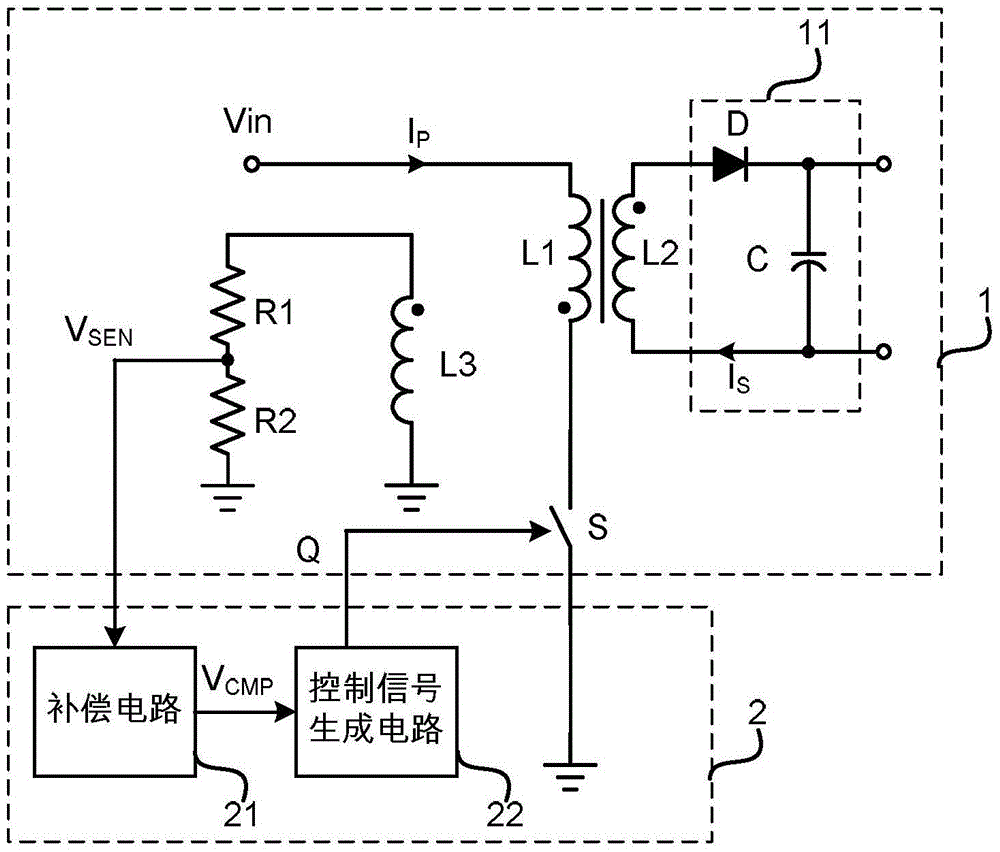

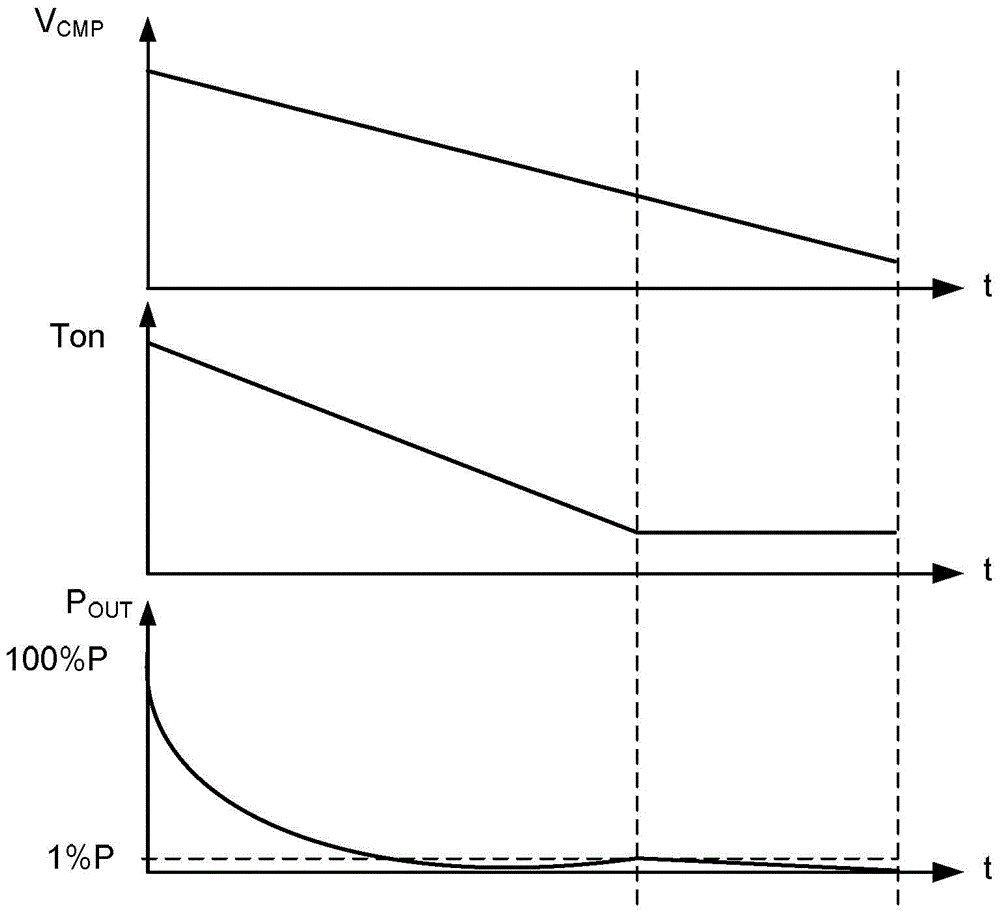

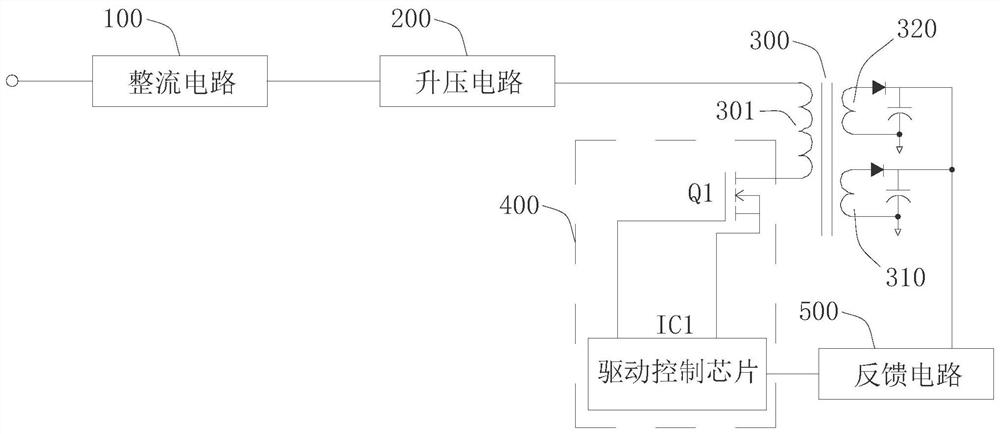

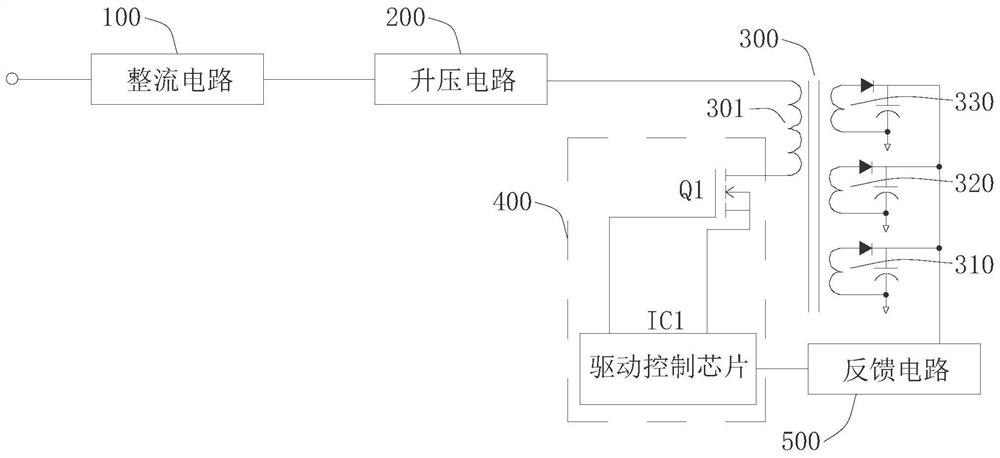

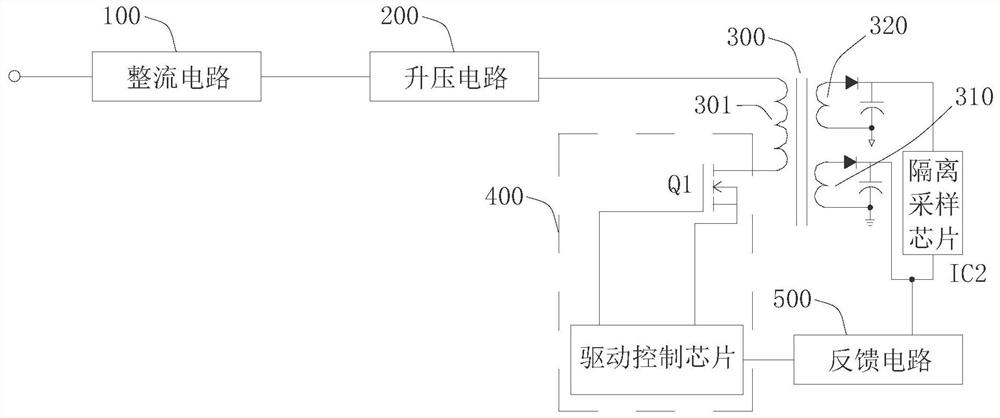

Control circuit, control method and flyback converter using same

ActiveCN104779799BImprove light load efficiencyReduce output energyEfficient power electronics conversionDc-dc conversionTransformerEngineering

Disclosed are a control circuit, a control method and a flyback converter using the same. The present invention alternately adopts the pulse width modulation mode (that is, the constant switching frequency mode) and the constant on-time mode to control the power stage circuit according to the voltage compensation signal at light load, so that the output energy can be quickly and gently reduced without stopping the control circuit. , while improving the light-load efficiency of the flyback converter, the output voltage ripple is reduced.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

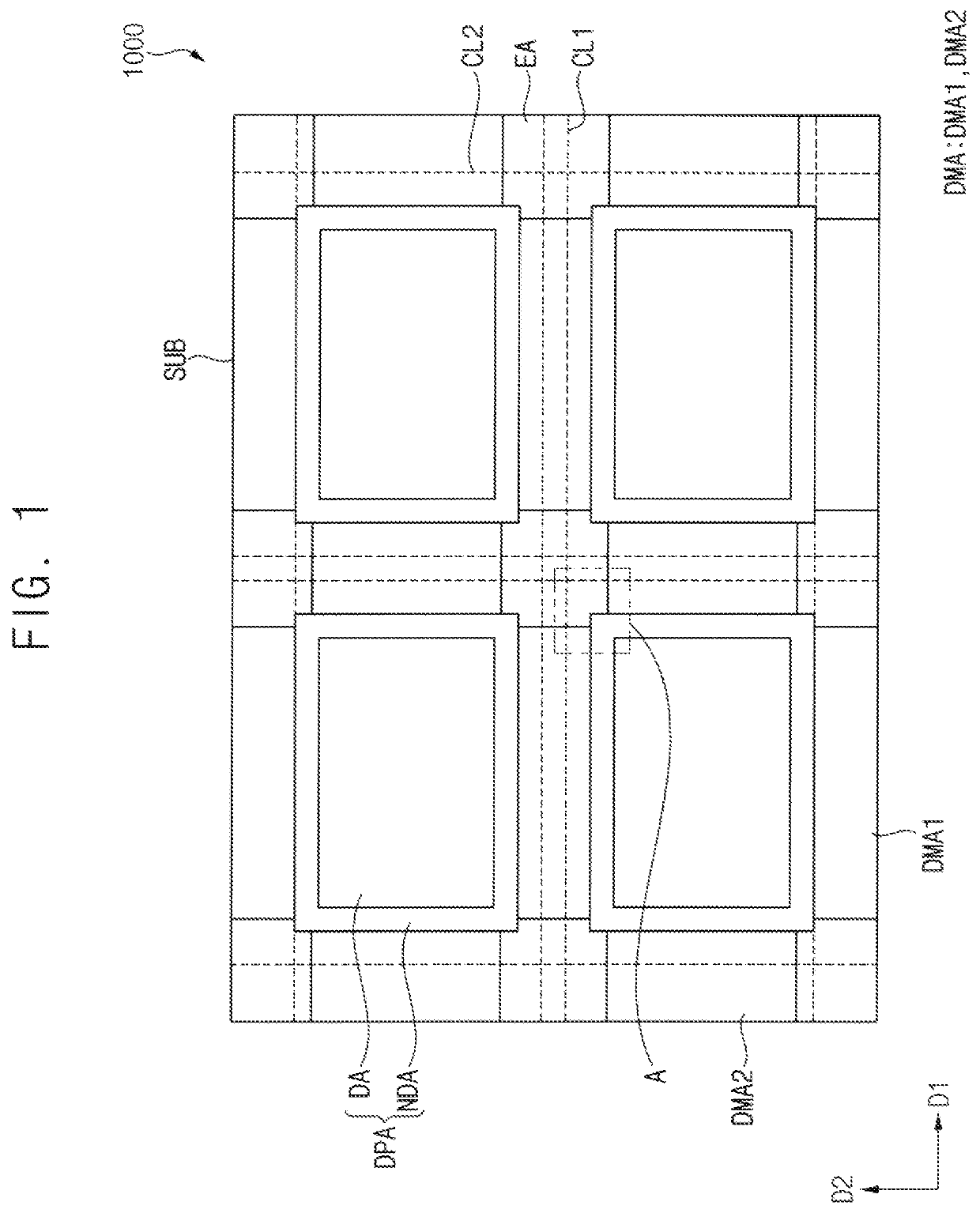

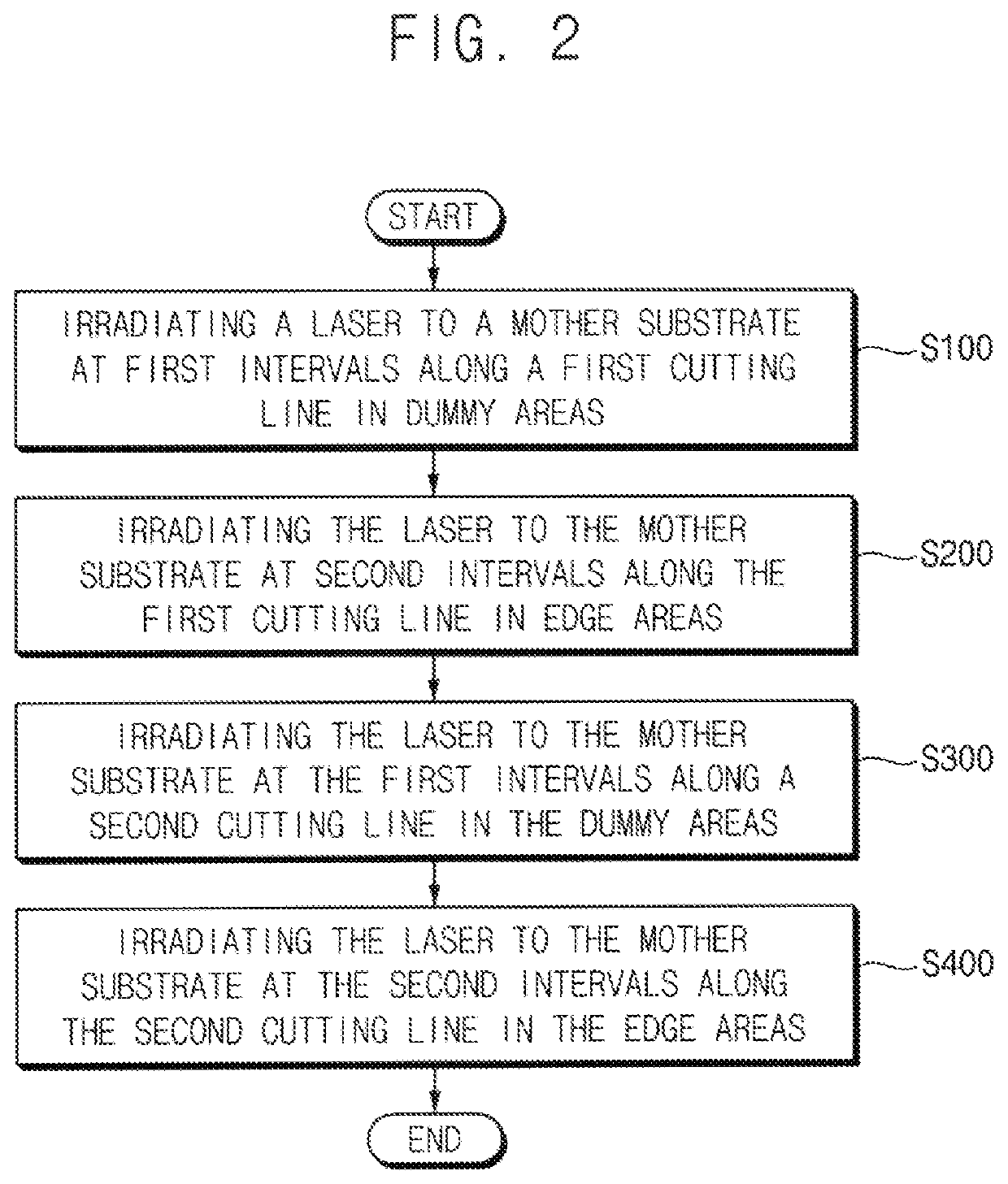

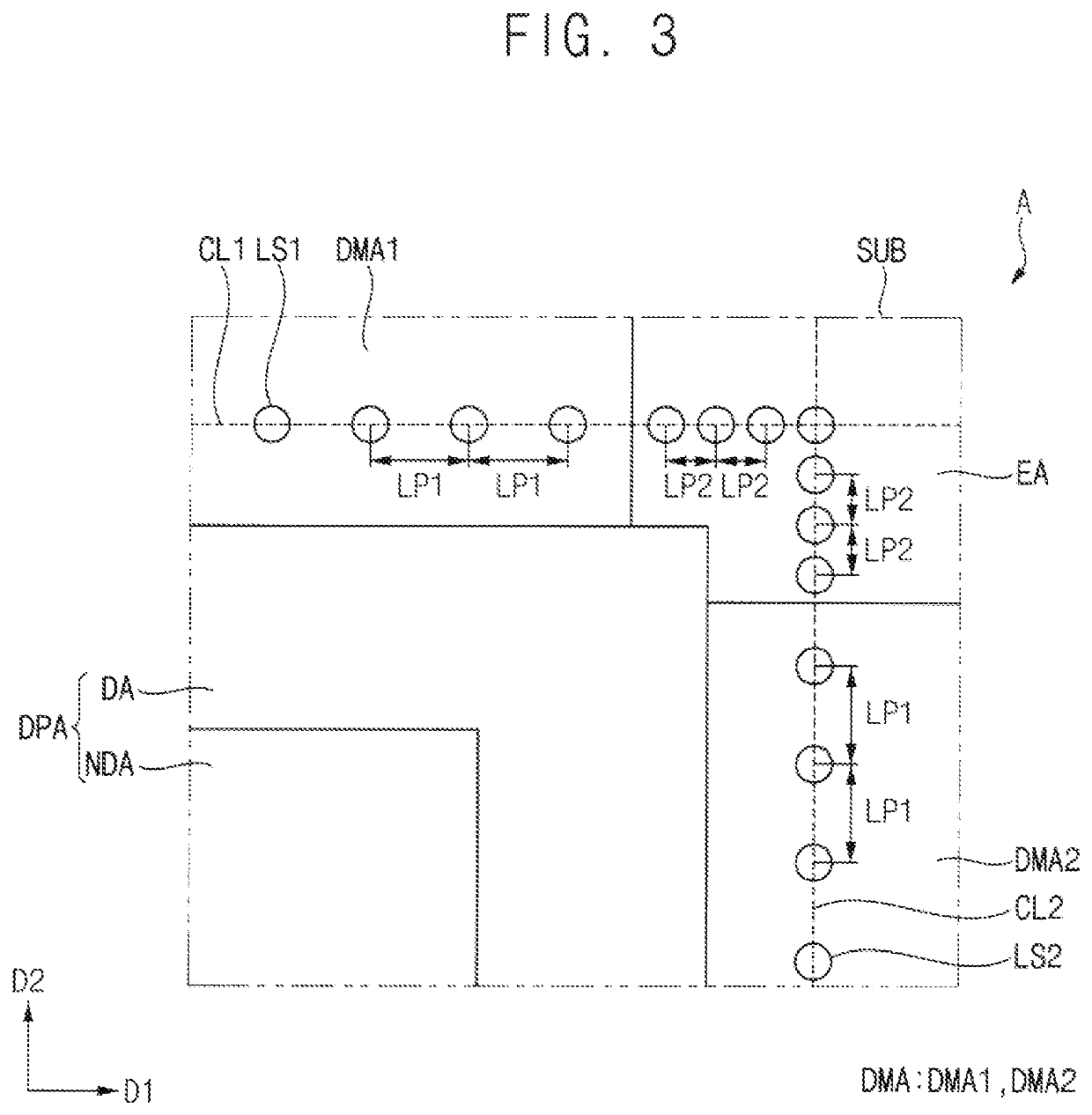

Cutting method of mother substrate for display panel using a laser

PendingUS20220324059A1Small sizeReduce output energySemiconductor/solid-state device manufacturingGlass severing apparatusEngineeringLaser cutting

A cutting method of a mother substrate includes: irradiating a laser to the mother substrate at first intervals along a first cutting line overlapping dummy areas positioned adjacent to sides of each of display panel areas on the mother substrate; and irradiating the laser to the mother substrate at second intervals different from the first intervals along the first cutting line overlapping edge areas positioned adjacent to corner portions of each of the display panel areas.

Owner:SAMSUNG DISPLAY CO LTD

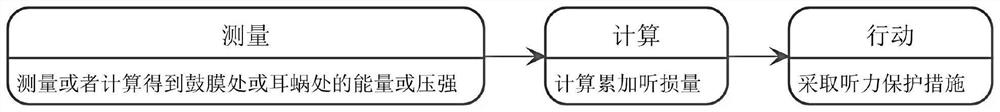

Audio device output energy control method capable of protecting hearing

ActiveCN114025276AReal-time monitoring of sound pressure levelDoes not affect user experienceSignal processingEarplugsEnergy controlElectrophonic hearing

The invention discloses an audio device output energy control method capable of protecting hearing, and the method comprises the following steps: S1, obtaining energy or pressure intensity at a loudspeaker or at any point in a sound field from the loudspeaker to a tympanic membrane through a calculation or measurement mode, and compensating or calculating the energy or pressure intensity as energy or pressure intensity at the tympanic membrane or cochlea of a user; S2, calculating an accumulated hearing loss value according to the energy or pressure intensity of the tympanic membrane or cochlea of the user, or calculating the accumulated energy of the position according to the energy or pressure intensity of any point in the sound field from the loudspeaker to the tympanic membrane, and then equivalently calculating the accumulated hearing loss value of the tympanic membrane or cochlea of the user; S3, comparing the accumulated hearing loss value with a preset hearing loss threshold value, and if the accumulated hearing loss value reaches the hearing loss threshold value, executing the step S4; S4, reducing the volume of the audio device. According to the invention, energy at the tympanic membrane or cochlea of a user can be monitored in real time and output energy of the audio device can be adjusted in time, thereby realizing hearing protection.

Owner:深圳市大十未来科技有限公司

Switching power supply circuit and household electrical appliance

PendingCN113300610AReduce voltageReduce output energyDc-dc conversionElectric variable regulationTransformerControl engineering

The invention discloses a switching power supply circuit and a household electrical appliance. The circuit comprises a rectification module, a boost circuit, a transformer, an input control circuit and a feedback circuit, wherein the boost circuit is connected with the output end of the rectification module; the transformer comprises a primary winding, a first secondary winding and a second secondary winding, and the primary winding is connected with the output end of the booster circuit; the input control circuit comprises a first switch tube connected with the primary winding and a driving control chip connected with the first switch tube; the input end of the feedback circuit is connected with the first secondary winding and the second secondary winding to detect the output voltage, and the output end of the feedback circuit is connected to the driving control chip. The output voltage of the first secondary winding and the output voltage of the second secondary winding are collected at the same time, that is, the feedback voltage is jointly acted by the output voltage of the multiple input windings, the wider cross adjustment rate is achieved, and the stability of the output voltage of the multiple windings can be improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRONICS TECH CO LTD +1

earphone

ActiveCN109246523BDoes not affect sound qualityLarge frequency response decibel valueMicrophonesLoudspeakersAcoustic energyEngineering

An earphone has a housing with a signal process unit to output sound. The housing has a chamber and a speaker mounted inside the chamber. The chamber is defined as a front volume and a rear volume bythe speaker, and the rear volume having a port. Wherein the speaker in the volume outputting a chamber frequency response curve is at least a portion higher than the earphone's ideal frequency response curve at the bandwidth ranging from 20 Hz to 1000 Hz, where creates a gain difference between the chamber frequency response curve and the ideal frequency response curve to be decreased the (superfluous) positive value by a signal process unit at the bandwidth ranging from 20 Hz to 1000 Hz. Therefore, the total acoustic energy is maintained, the earphone acoustic quality is preserved, and the earphone volume may output even higher power to be deduced by the signal process unit for lowering down the circuit power consumption.

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

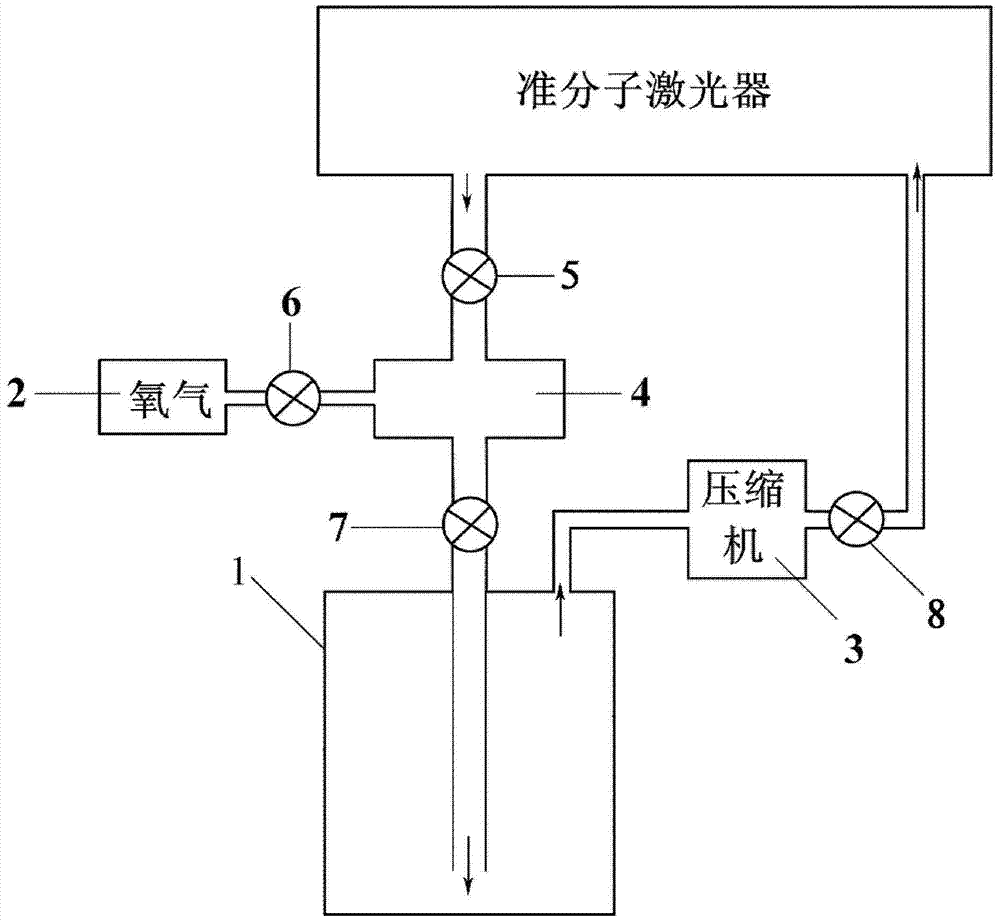

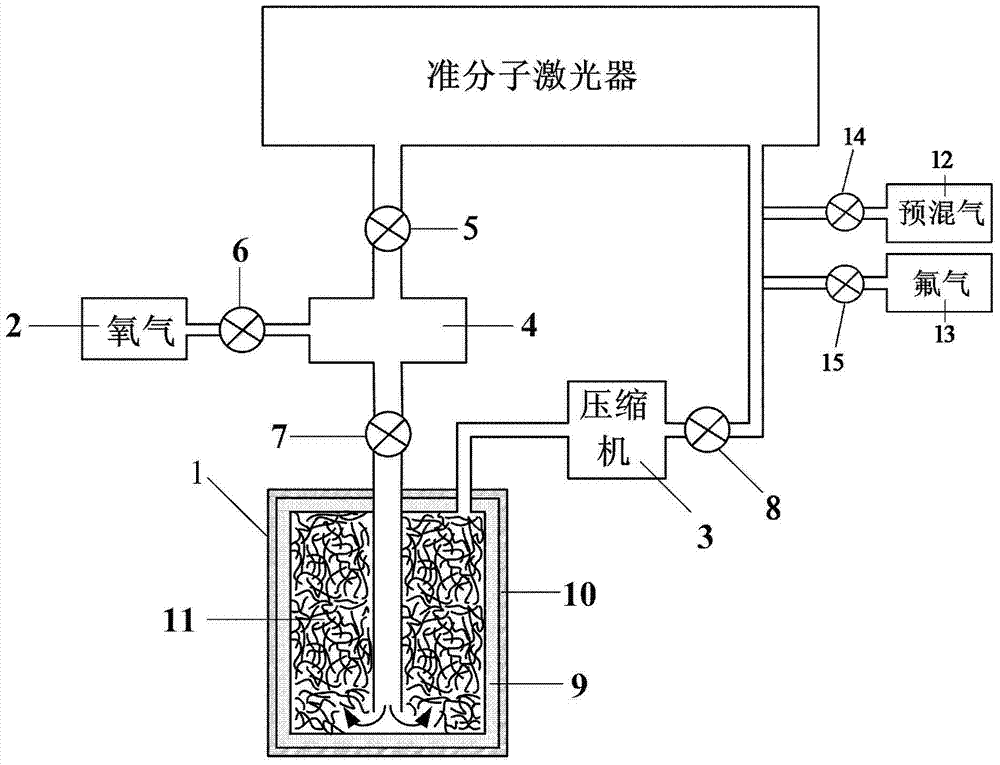

A gas circulation system for excimer laser

Owner:RAINBOW SOURCE LASER RSLASER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com