Method and module for detecting gas in excimer laser discharge chamber

An excimer laser and detection module technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as inability to connect equipment to a discharge cavity, high laser operating pressure, equipment damage, etc., to improve efficiency and operating effects, reduce Time and energy wastage, the effect of improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

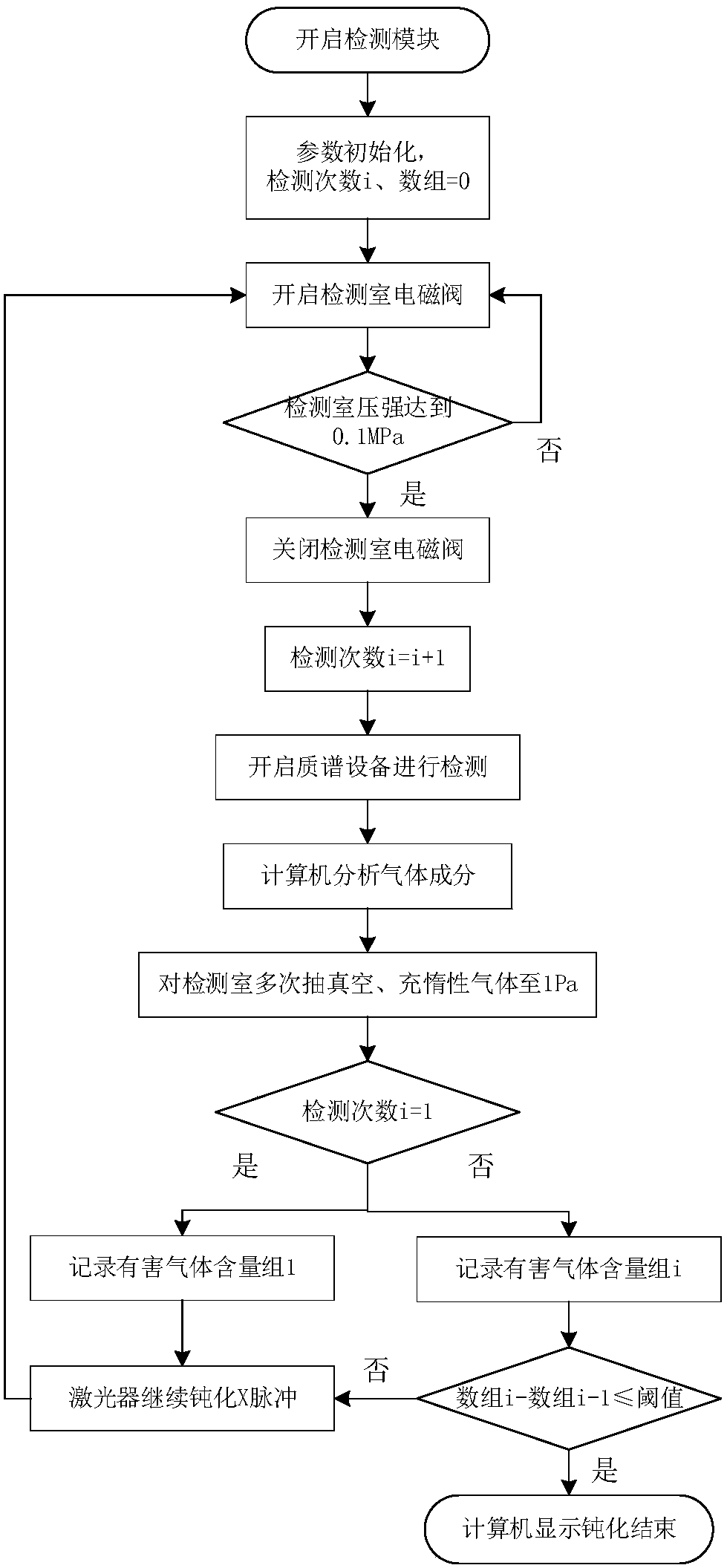

[0061] Taking the ArF excimer laser as an example, the discharge cavity mainly includes typical copper alloy electrodes, aluminum alloy cavity walls and impellers, and alumina ceramic auxiliary parts.

[0062] The gas in the passivation process of the discharge cavity of the excimer laser of the present invention is used to detect the gas in the passivation of the discharge cavity of the ArF excimer laser, and the results are as follows:

[0063] The following table (table 1) shows the gas content value (in ppm, ie 10 -6 ).

[0064]

O 2 content

CO 2 content

HF content

SiF 4 content

CF 4 content

N 2 content

i=1

0.5

0.7

12.4

5.4

10.8

i=2

0.7

0.9

16.9

9.4

14.2

0.2

…

…

…

…

…

…

…

i=n-2

1.1

1.4

23.3

18.2

18.6

0.4

i=n-1

1.2

1.4

25.9

19.6

19.9

0.4

i=n

1.2

1.5

26.4

20.4

21.2

0.5

[0065] Among them, D.L. refers to the detection limit of the device, and n is the number of detections at the end of the detection.

[0066] In this embodiment O 2 , CO 2 , HF, SiF 4 The gas difference threshold is ...

Embodiment 2

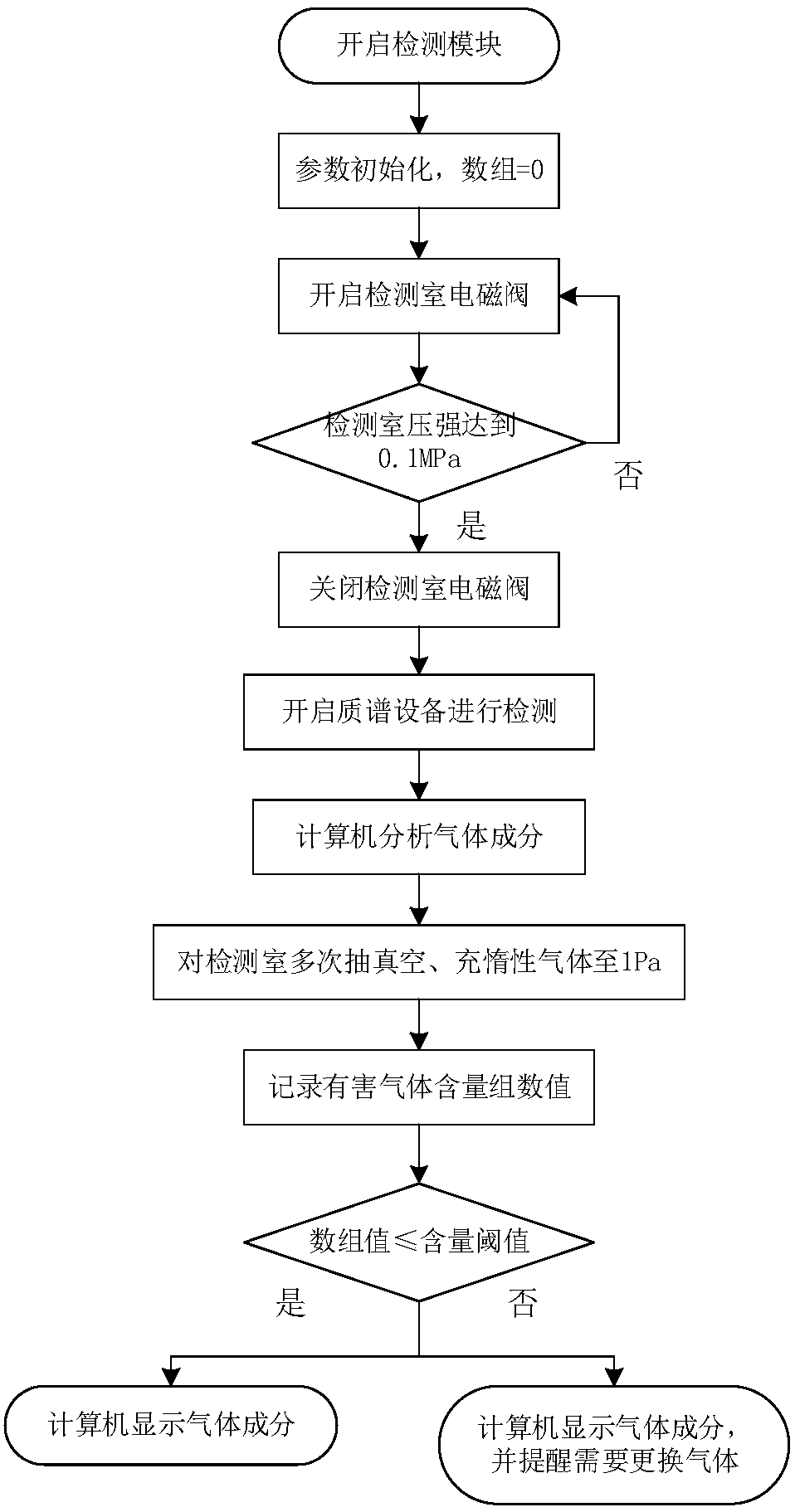

[0068] Taking the ArF excimer laser as an example, the discharge cavity mainly includes typical copper alloy electrodes, aluminum alloy cavity walls and impellers, and alumina ceramic auxiliary parts.

[0069] Using the method for detecting discharge cavity gas before / during the operation of the excimer laser of the present invention, the gas in the discharge cavity before / during the operation of the ArF excimer laser is detected, and the results are as follows:

[0070] The following table (table 2) shows the gas content value (in ppm, ie 10 -6 ).

[0071]

O 2 content

CO 2 content

HF content

SiF 4 content

CF 4 content

N 2 content

i=1

0.6

7.0

0.3

i=2

3.5

0.8

10.2

3.8

2.1

…

…

…

…

…

…

…

i=n-2

11.1

0.7

16.2

8.3

7.8

0.2

i=n-1

12.3

0.7

19.8

9.4

9.4

0.2

i=n

12.7

0.8

21.4

10.1

9.7

0.4

[0072] Among them, D.L. refers to the detection limit of the device, and n is the number of detections at the end of the detection.

[0073] In this embodiment O 2 , CO 2 , HF, SiF 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com