A gas circulation system for excimer laser

An excimer laser and gas circulation technology, applied in the field of ArF and KrF excimer lasers, can solve the problems of limited scope of application, inability to reduce costs, inability to remove impurities in working gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

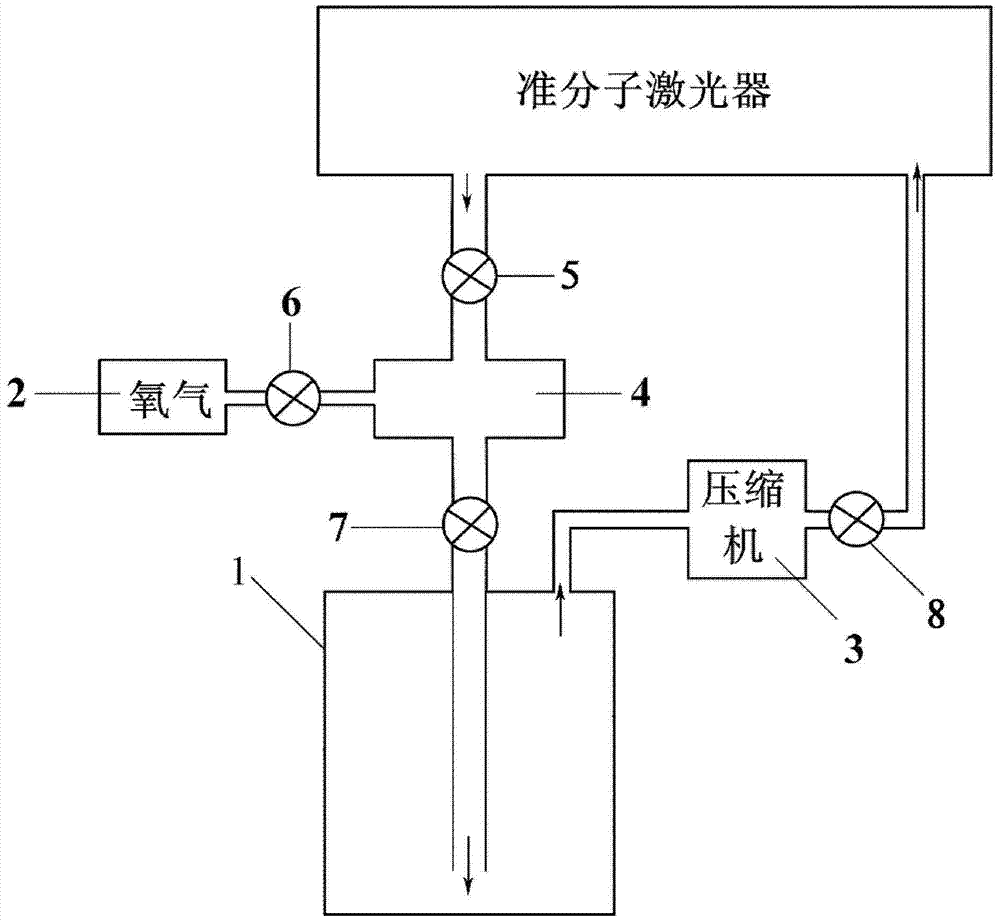

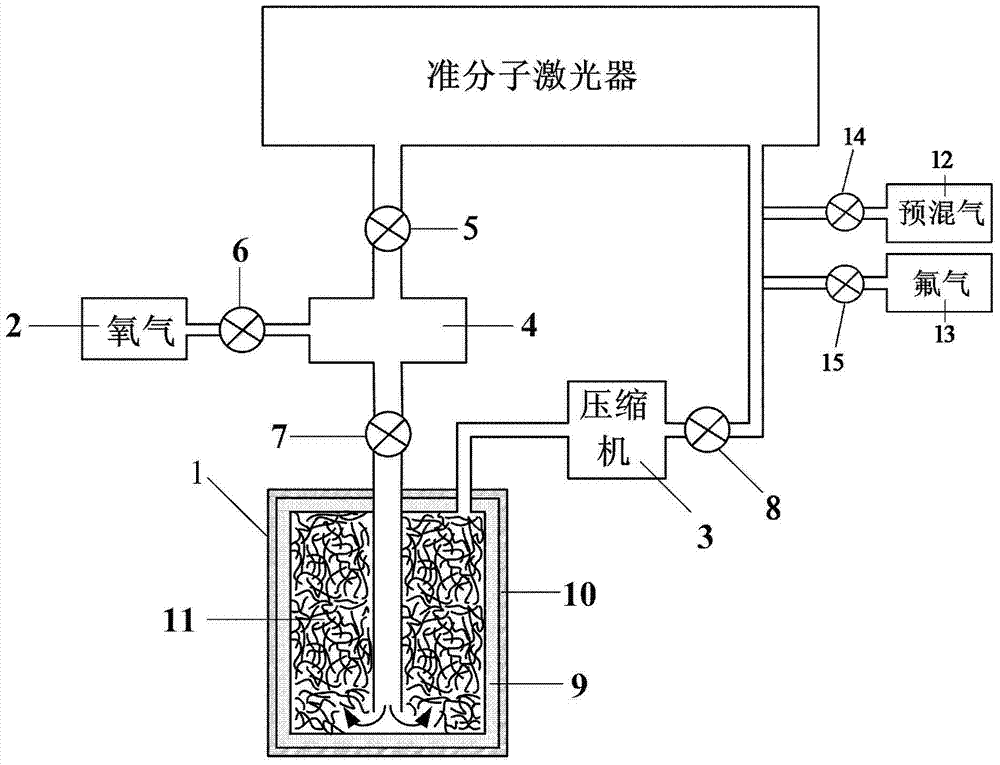

[0019] The invention obtains a gas circulation system, which improves the working life of excimer laser gas by supplementing halogen gas and removing impurities. The system of the present invention first prolongs the working time of the laser by intermittently replenishing the halogen gas. When the intermittently replenishing the halogen gas cannot effectively restore the output energy of the laser, it uses a part of the gas that has been worked for a long time to react with oxygen outside the cavity and then use a cold trap Remove impurities, and finally fill the purified gas back into the chamber for reuse. In this way, the output energy is recovered, the service life of the working gas is improved, and the cost is saved. The amount of oxygen charged is analyzed by a mass spectrometer to ensure that the impurities are fully reacted and at the same time there is no oxygen remaining, which not only effectively removes the impurities, but also does not cause a significant drop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com