Laser welding connecting device and technology of forged steel piston

A laser welding and piston technology, applied in laser welding equipment, pistons, welding equipment, etc., can solve problems such as joint cracking, difficulty in realization, engine damage, etc., to reduce the tendency of joint cracks, reduce equipment investment, and reduce output energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of the present invention is further specifically described by the examples given below.

[0025] A forged steel piston laser welding connection device and process, comprising the following steps:

[0026] a. Pretreat the surface of the forged steel piston;

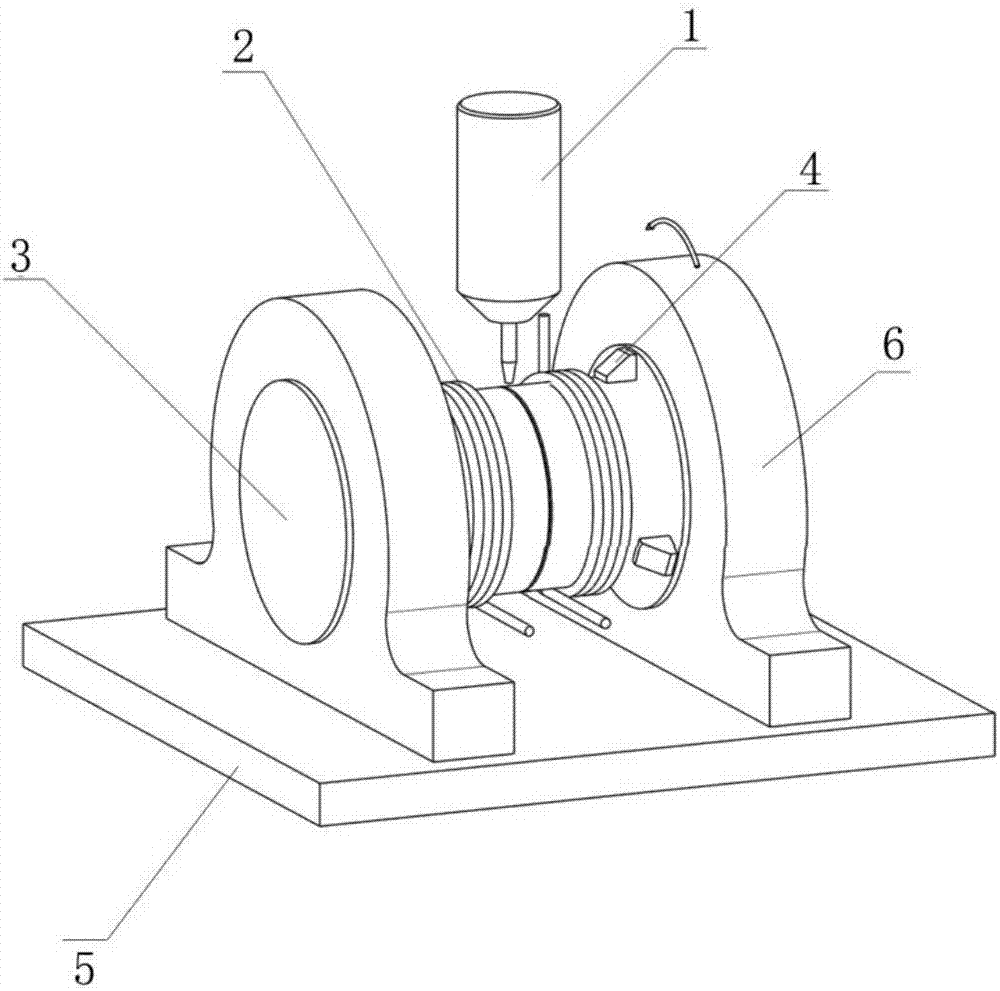

[0027] b. After the forged steel piston is accurately positioned, start the piston clamping device to fix the piston 4, and the clamping range (Φ) of the device is 100-150mm;

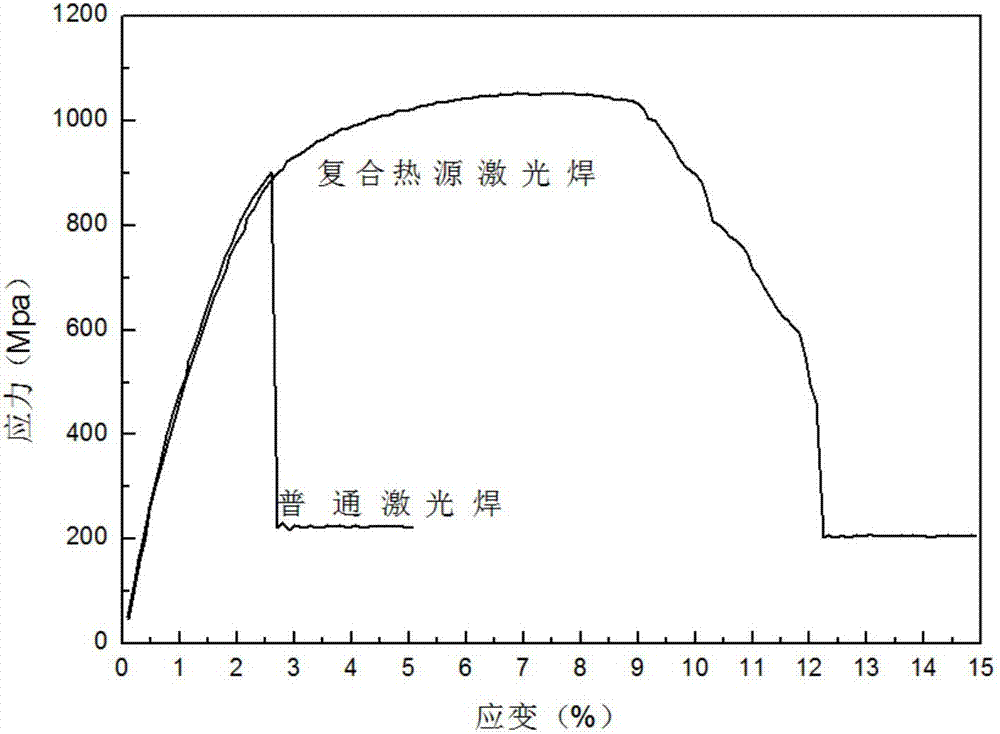

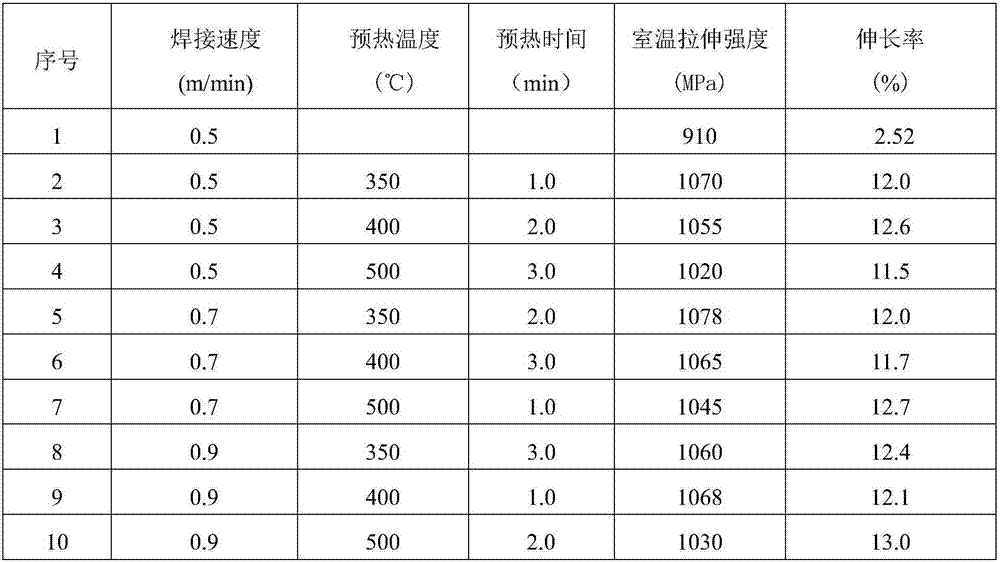

[0028] c. Turn on the power of the intermediate frequency induction heating device 2, and preheat the forged steel piston. The intermediate frequency induction heating device can be heated at a constant temperature. The preheating temperature is 350-500°C and the preheating time is 1-3min. If the preheating temperature is too high, the base metal of the forged steel piston will soften; if the preheating temperature is too low, crack defects will easily appear in the joint after welding. If the preheating time is too long, the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com