Novel positive bias auxiliary photo-Fenton technology

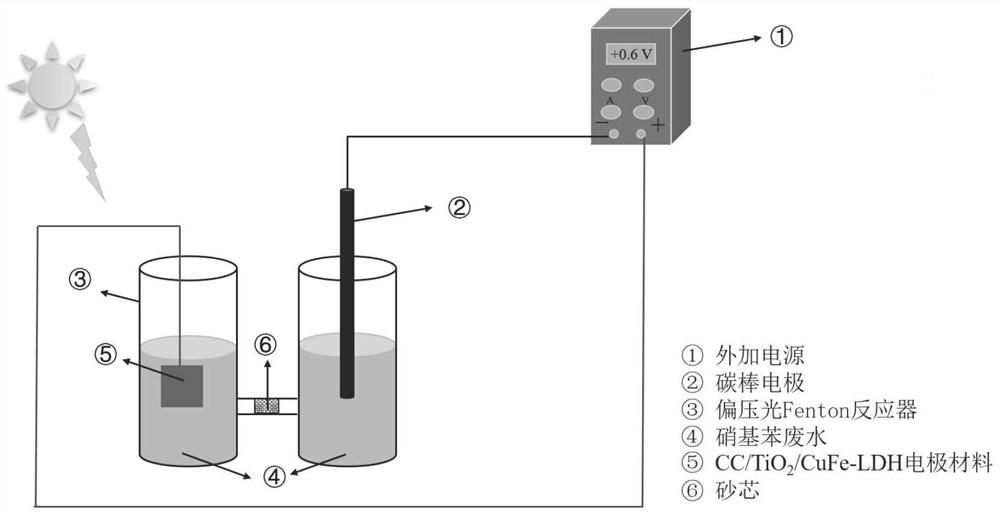

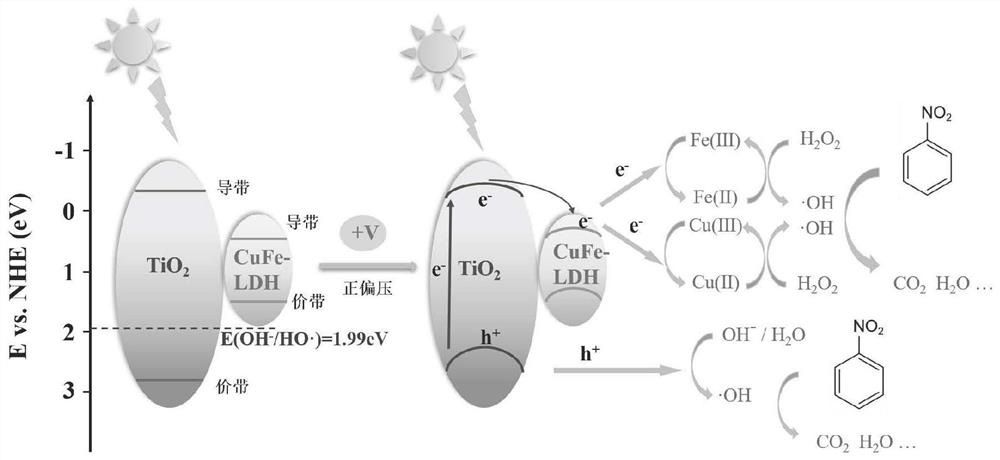

A technology of auxiliary light and positive bias, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of high energy consumption and low utilization rate of electrons, and achieve the purpose of prolonging the life of electrons, Improve the utilization rate and promote the effect of photogenerated electron-hole separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

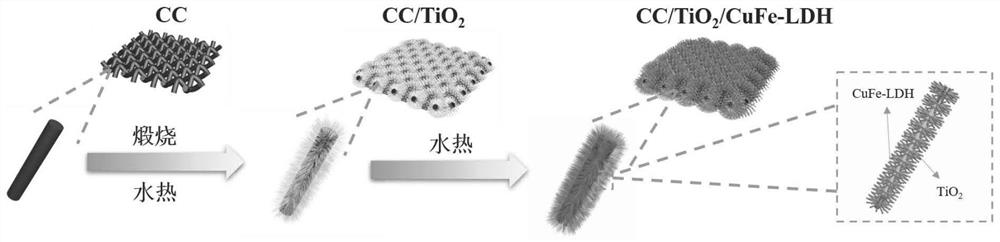

[0047] (1) CC / TiO 2 / Preparation of CuFe-LDH material

[0048] At room temperature, ultrasonically clean the carbon cloth with acetone, ethanol, and deionized water, each time for 10 minutes, and then dry at 60°C for 30 minutes; soak the clean carbon cloth in 0.075M tetrabutyl titanate solution , and then dried at 60°C for 20min, repeated three times; then the sample was heated in a muffle furnace at 500°C for 1h; 0.66mL tetrabutyl titanate was added to 30mL of hydrochloric acid, and stirred continuously for 6h; the solution was transferred to the reaction Put carbon cloth in the kettle, heat at 150°C for 12h; wash the carbon cloth with deionized water, then dry at 60°C, repeat twice; put the carbon cloth in the muffle furnace, heat at 550°C for 2h, and get CC / TiO 2 Material.

[0049] Weigh 0.1389g ferric nitrate nonahydrate, 0.1664g copper nitrate pentahydrate, 0.7507g urea, 0.185g ammonium fluoride, dissolve in 50mL ultrapure water, stir for 30min, transfer to the reacti...

Embodiment 2

[0059] Keep the operating steps and other degradation conditions in Example 1 unchanged, compare the degradation situation of nitrobenzene under light conditions, degrade for 60min, and record the degradation rate and degradation kinetics of nitrobenzene under different conditions as follows: Figure 8 As shown, the degradation kinetic parameters are shown in Table 2:

[0060] Depend on Figure 8 It can be seen that the degradation rate of nitrobenzene is slow and the removal rate is low when there is no light and only bias is applied. When light and positive bias are applied, the degradation kinetic constant is changed from 0.009min -1 Increase to 0.075min -1 , the degradation rate of nitrobenzene was greatly improved.

[0061] Table 2 Degradation Kinetic Parameters

[0062] No light +0.6V bias Light +0.6V bias k(min -1 )

Embodiment 3

[0064] Keeping the operation steps and other degradation conditions in Example 1 unchanged, the degradation experiments were carried out under the conditions of applying bias voltages of 0V, +0.3V, +0.6V, +0.9V, and +1.2V, and the degradation was 60min. The degradation rate and degradation kinetics of nitrobenzene under bias voltage are as follows: Figure 9 , and the degradation kinetic parameters are listed in Table 3:

[0065] Depend on Figure 9 It can be seen that the degradation kinetic constant of nitrobenzene is the largest and the degradation rate is the fastest when the applied bias voltage is 0.6V.

[0066] Table 3 Degradation Kinetic Parameters

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com